High-pressure bursting test system for pressure vessels

A blasting test, pressure vessel technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problem of not being able to reflect the elastic deformation of the container to plastic deformation, not recording, and not being able to give pressure in real time - Problems such as the change of the liquid inlet curve, to achieve the effect of simple structure, comprehensive data and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

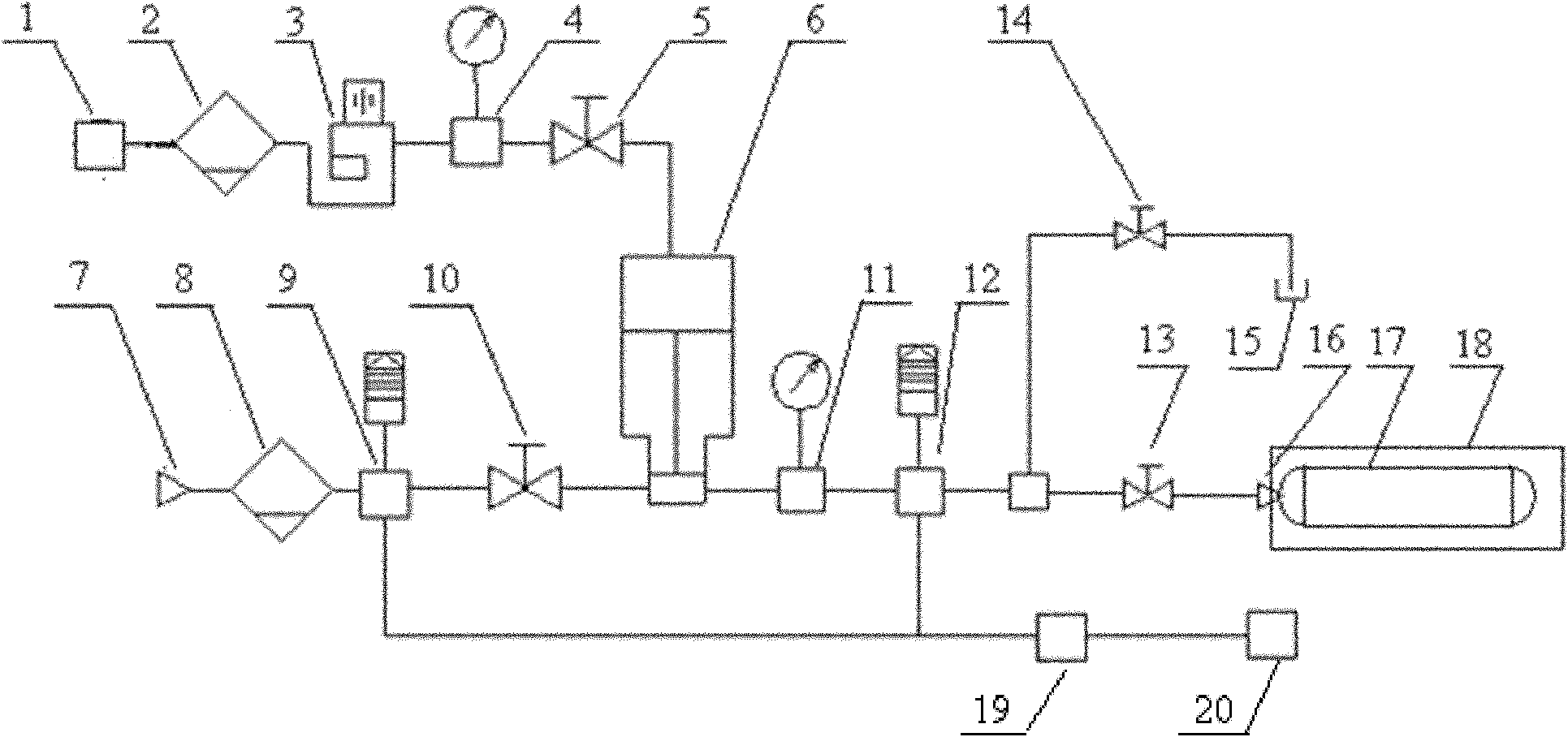

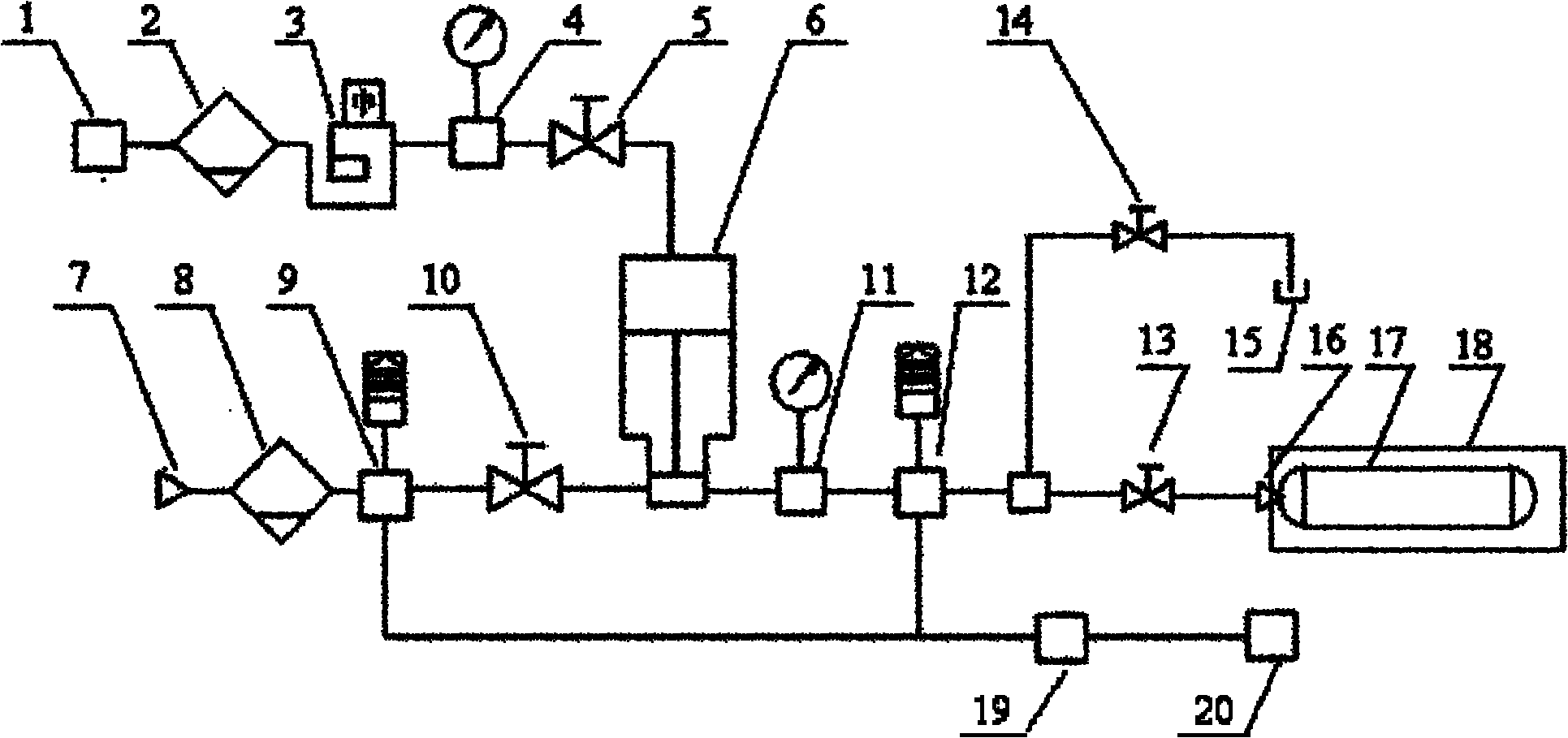

[0026] Such as figure 1 Shown is a structural block diagram of the pressure vessel high-pressure burst test system of the present invention. The system includes: a high-pressure blasting sample container, a high-pressure power source module, a container installation and sealing protection device module, a pressure relief device module, a pressure / flow signal measurement and display module; the high-pressure power source module is installed and sealed through the container The device module is sealed and connected to the high-pressure blasting sample container, the pressure / flow signal measurement and display module is set on the air flow path / liquid flow path of the high-pressure power source module, and the pressure relief device module is connected to the high-pressure power source module Between the high pressure blasting sample container.

[0027] Wherein, the airflow path of the high-pressure power source module includes an air compressor 1 and a pneumatic liquid booster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com