Pressure-yielding anchor device

A technology of yielding anchors and anchor bars, applied in the field of anchors, can solve the problems of reducing the service life of anchor cables, prone to corrosion, etc., and achieve the effect of reliable effect and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

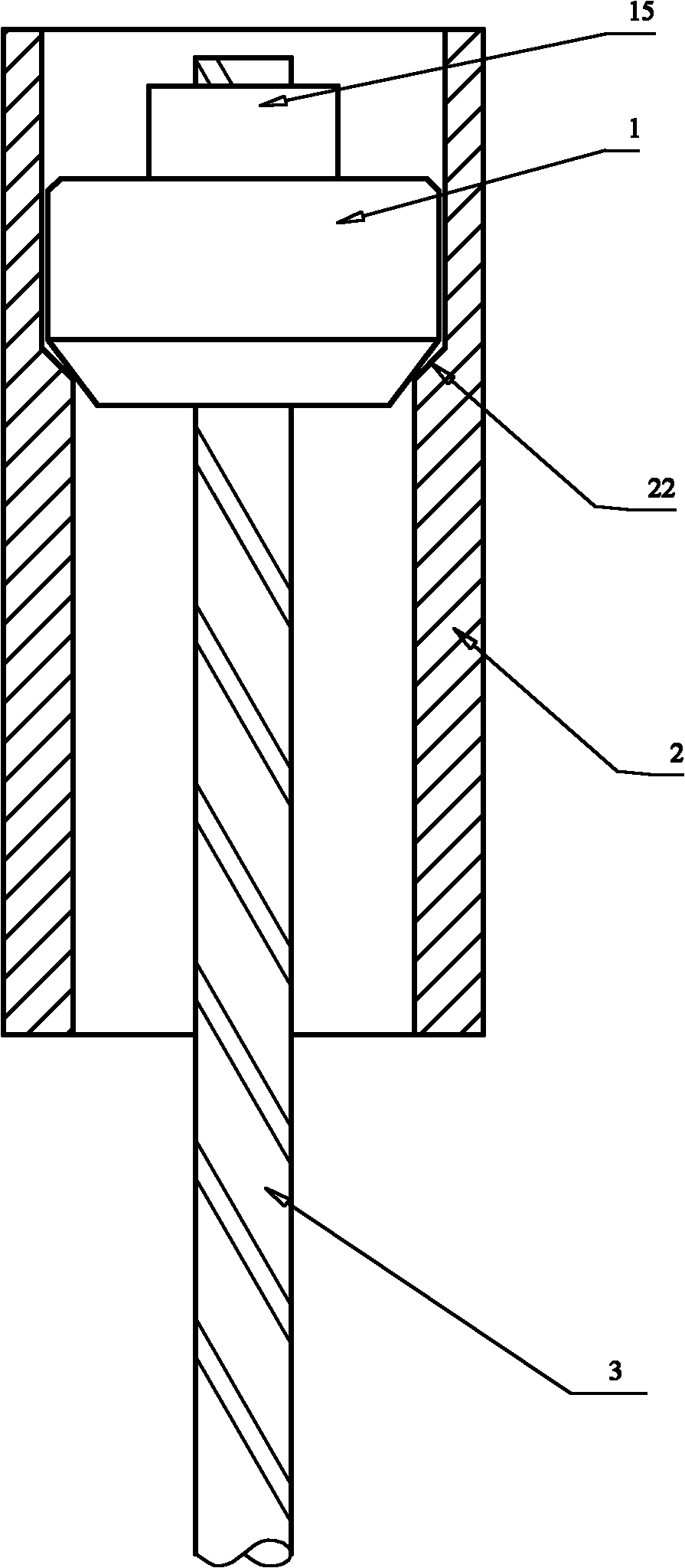

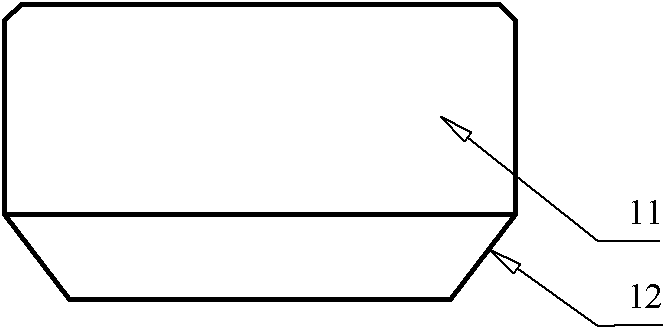

[0031] Such as figure 1 , figure 2 As shown, a pressure-yielding anchor device includes an extrusion head 1 and a pressure-yielding sleeve 2. The extrusion head 1 is a cylinder 11 with a tapered surface 12 on the lower part. The anchor bar 3 passes through the extrusion head 1 and passes through the The fixing part 15 is integrated with the extrusion head 1 ; the extrusion head 1 is placed in the pressure relief sleeve 2 , and the inner wall of the pressure relief sleeve 2 is provided with a protruding surface 22 matching the tapered surface 12 of the extrusion head 1 .

[0032] The cone surface 12 of the extrusion head 1 is a straight cone surface or a curved cone surface, which is continuous in a ring shape.

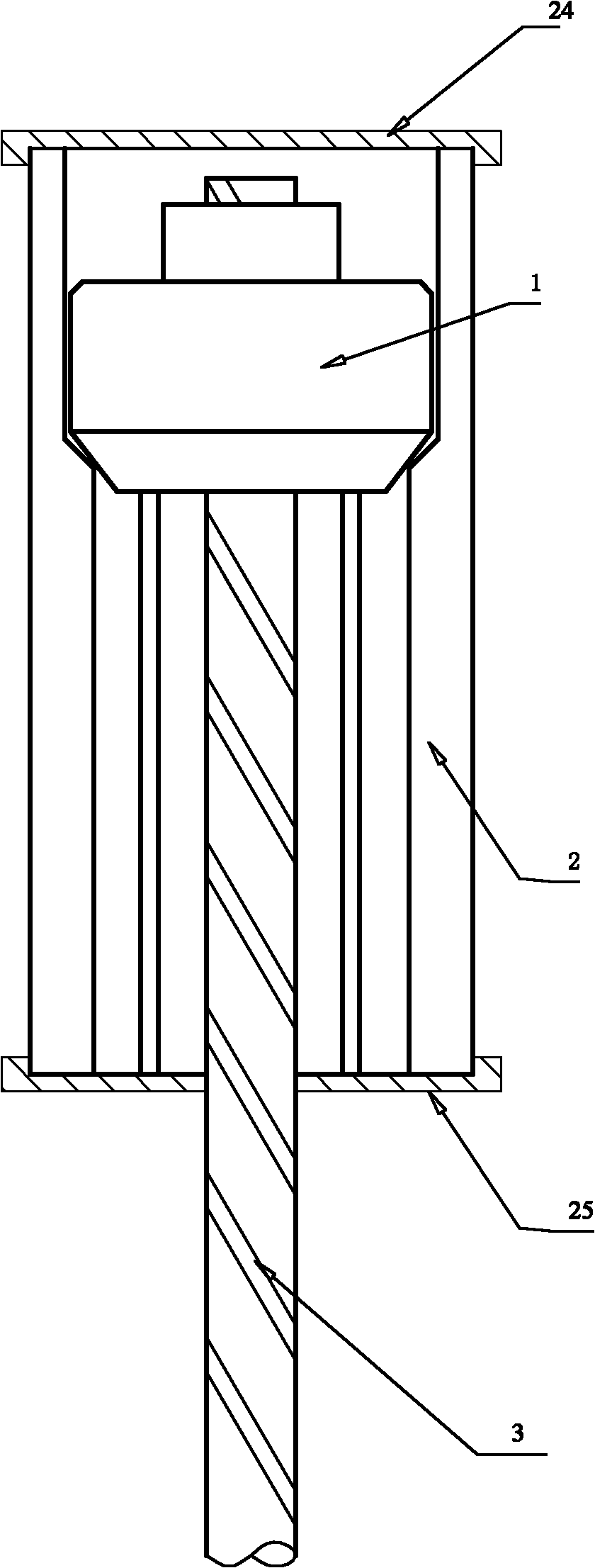

[0033] Such as image 3 , Figure 4 , Figure 5 As shown, the pressure relief sleeve 2 has a plurality of evenly distributed straight ribs 21 on the inner wall, and the end of the straight ribs 21 is a protruding surface 22 that matches the tapered surface 12 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com