Spacer fabric, spacer fabric section and heatable cladding element

A technology of knitted fabrics and segments, which is applied in the direction of knitting, warp knitting, electric heating fuel, etc., and can solve the problems that cannot be realized, consume preparation quality, and produce peculiar smell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

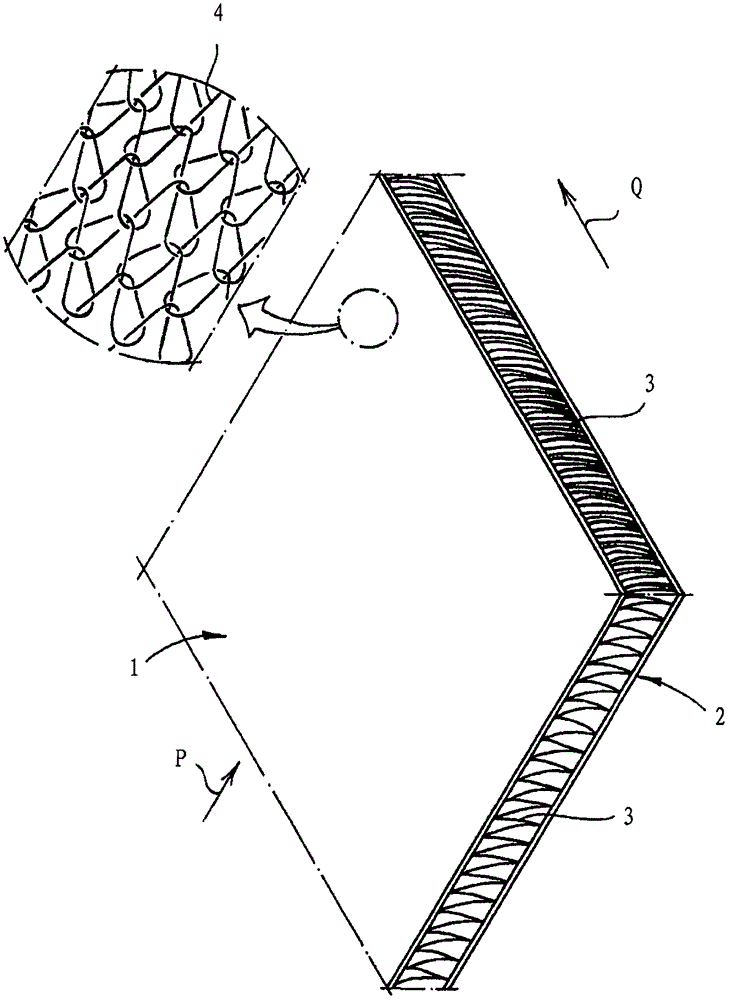

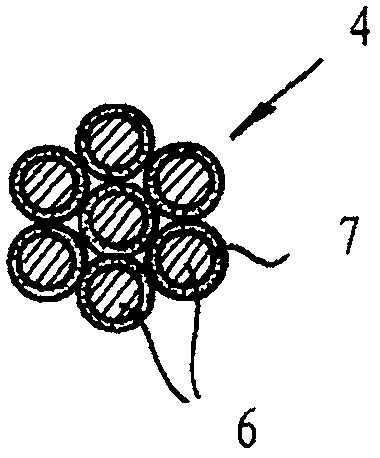

[0060] figure 1 The basic structure of a spacer knitted fabric according to the invention is shown with a first areal knitted fabric layer 1 , a second areal knitted fabric layer 2 and a spacer yarn 3 connecting the knitted fabric layers 1 , 2 . The first knitted fabric layer 1 has conductive yarns 4 which are bonded underneath image 3 Further explanation.

[0061] according to figure 1 As shown, the entire first knitted fabric layer 1 is composed of conductive yarns 4, according to figure 1 As shown in the detailed diagram of , the conductive yarn 4 is arranged in the warp knitting lap yarn (Trikot-Legung), so that the conductive yarn 4 in the first knitted fabric layer 1 forms loops on two stitches. By forming the loops so that Adjacent conductive yarns 4 are tightly interwoven with each other and are electrically connected to each other on the surface of conductive yarns 4 through direct electrical contact.

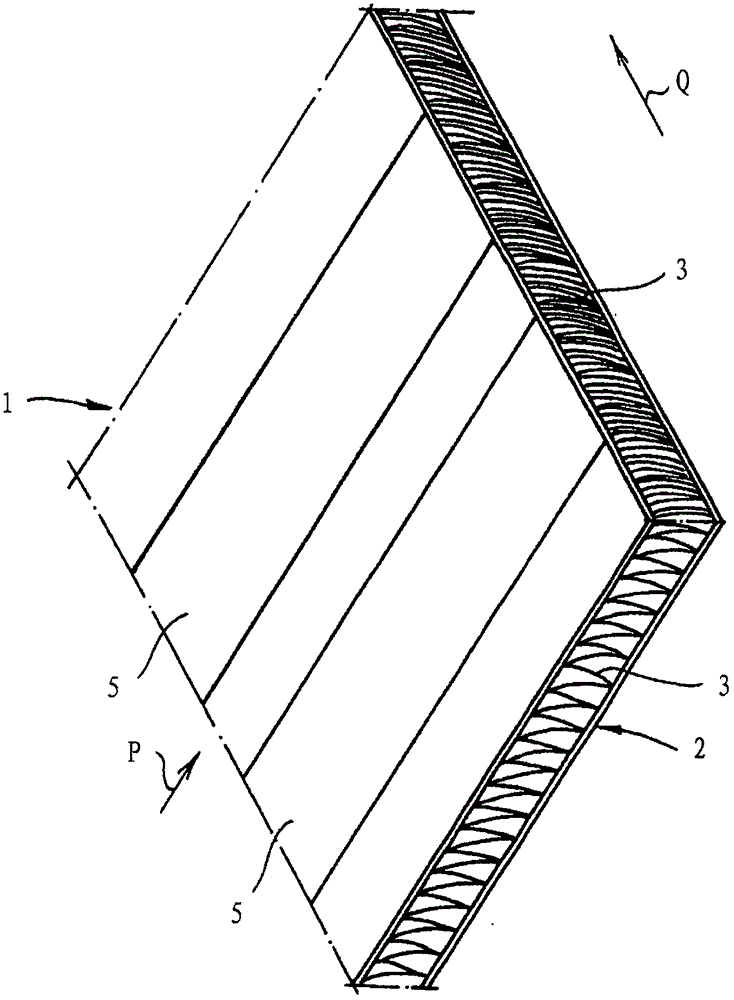

[0062] figure 1 and figure 2 The spacer knits shown diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com