Construction method of walling and filling combined gob-side entry retaining wall body

An empty entry retaining and combined technology, which is applied in the fields of backfill, earthwork drilling, safety devices, etc., can solve the problems of inability to effectively control and timely cut off the direct roof, difficult to support the roof effectively in time, and poor adaptability to changes in the mining height of the formwork. , to achieve the effect of avoiding spontaneous combustion of leftover coal, wide practicability and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

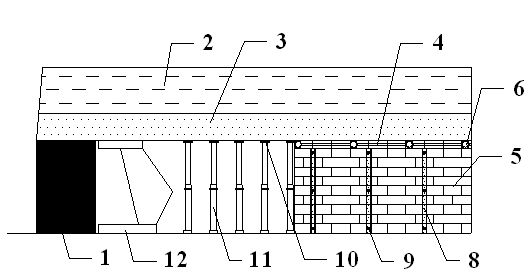

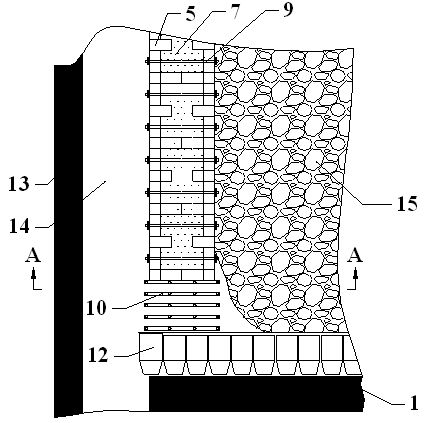

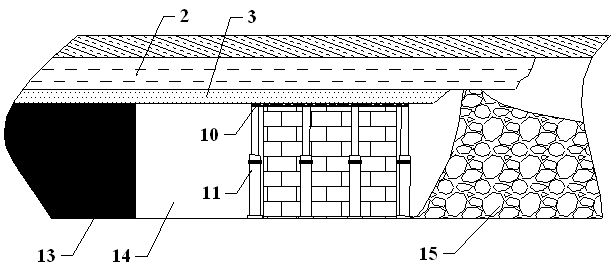

[0031] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0032] The construction method of the masonry filling combined type gob-side retaining wall of the present invention: firstly prefabricate concrete piers of standard size on the ground, transport the cured concrete piers to the underground construction site for standby; In the rear part, immediately behind the hydraulic support 12 of the mining face, dense pillars 10 with a row spacing of 800×300mm are erected to support the upper coal seam direct roof 3 and coal seam old roof 2, and under the common support of the adjacent coal body 13, the working 14 spaces are reserved in the mining roadway at the rear of the face. The dense pillars 10 are composed of a beam and four individual pillars 11 arranged on the beam; under the cover of the dense pillars 10, inside the two rows of individual pillars 11 close to the two sides of the dense pillars 10, concrete pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com