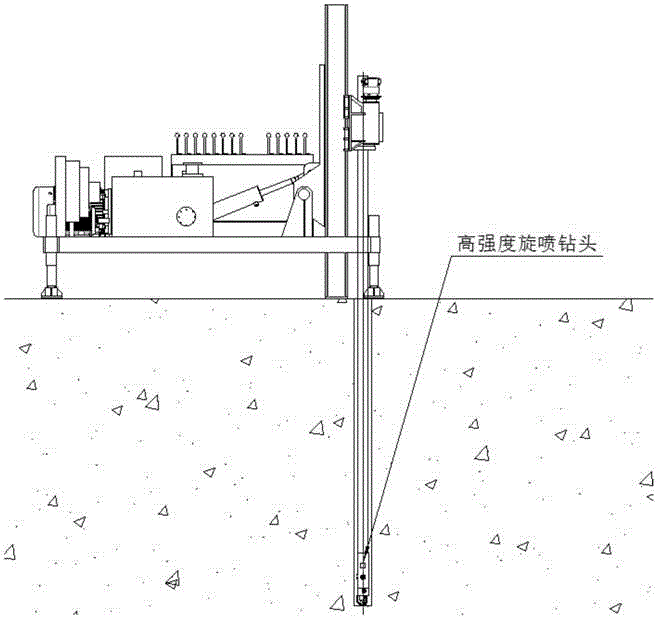

High-performance rotary jet drill

A high-performance, drill-bit technology, used in construction, sheet pile walls, infrastructure engineering, etc., can solve problems such as inability to meet spray distance, complex working conditions, and inability to guarantee construction quality, and achieve improved construction quality. The effect of improving the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

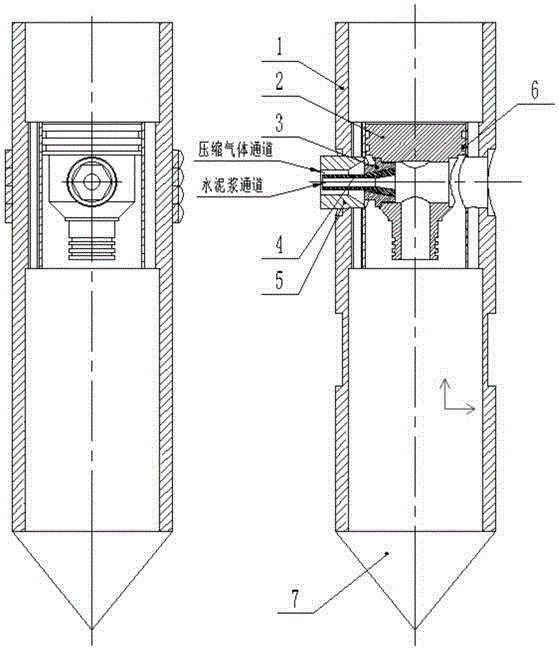

[0026] The method of adopting a kind of high-performance rotary jet drill bit of the present invention, comprises the following steps:

[0027] Step 1) Level the site to achieve "three links and one leveling";

[0028] Step 2) Measure and locate;

[0029] Step 3) Build the construction platform and equipment;

[0030] Step 4) The high-performance jet-jet drill bit is connected with the drilling rig by threads;

[0031] Step 5) The drill bit is rotated and inserted into the soil to reach the design depth;

[0032] Step 6) Cement slurry and compressed gas are ejected from the cement slurry channel and compressed gas channel respectively;

[0033] Step 7) The rotary spraying is lifted to the top of the designed pile to stop lifting;

[0034] Step 8) Pull out the drill pipe from the rotary jet drilling machine and move to the next hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com