Full-automatic polypropylene (PP) ribbon automatic compression packer

A fully automatic and automatic technology, applied in the field of balers, can solve the problems of unfavorable packing, large volume, deformation of the discharge port, etc., and achieve the effect of increasing the reinforcement range, increasing the reinforcement range, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

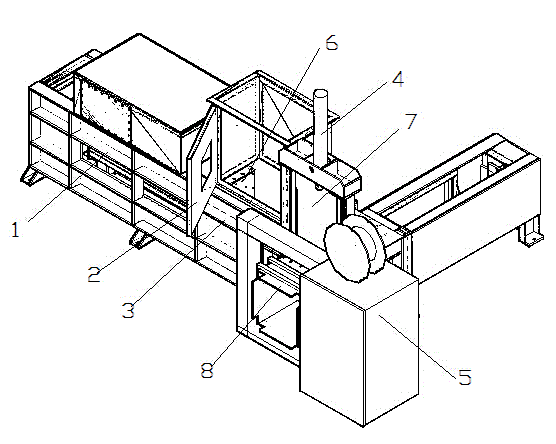

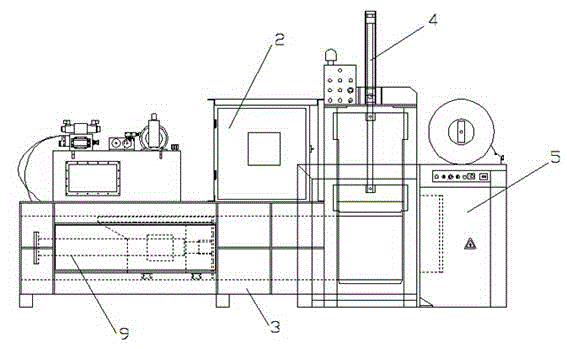

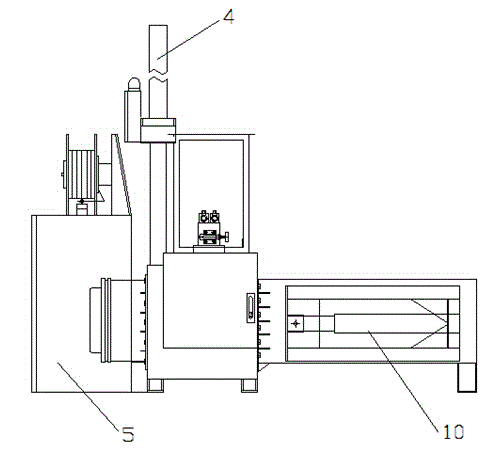

[0026] Such as Figure 1 to Figure 4 As can be seen from the schematic diagram shown, the fully automatic PP belt automatic compression packing machine of the present invention includes a frame 1, a feeding mechanism, a pressing mechanism, a discharging mechanism, a pushing mechanism and a packing mechanism.

[0027] The pressing mechanism, the feeding mechanism, the pushing mechanism and the discharging mechanism are sequentially distributed on the frame 1, wherein the pressing mechanism and the feeding mechanism are located on the same plane, the pushing mechanism and the discharging mechanism are located on the same plane, and the above two planes They are perpendicular to each other, and the packing mechanism is set on the side of the discharging mechanism.

[0028] The pressing mechanism includes a master cylinder 9 and a pressure plate 6, the master cylinder 9 is fixed inside the frame 1, the front end of the piston rod of the master cylinder 9 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com