Suspension Device of Electromagnetic Track Brake for Light Rail Vehicles

A technology of rail brakes and suspension devices, which is applied in the directions of brakes where braking elements interact with rails, railway braking systems, transportation and packaging, etc. Aluminium paste service life and other issues, to achieve the effect of reducing equipment maintenance workload, avoiding safety accidents, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

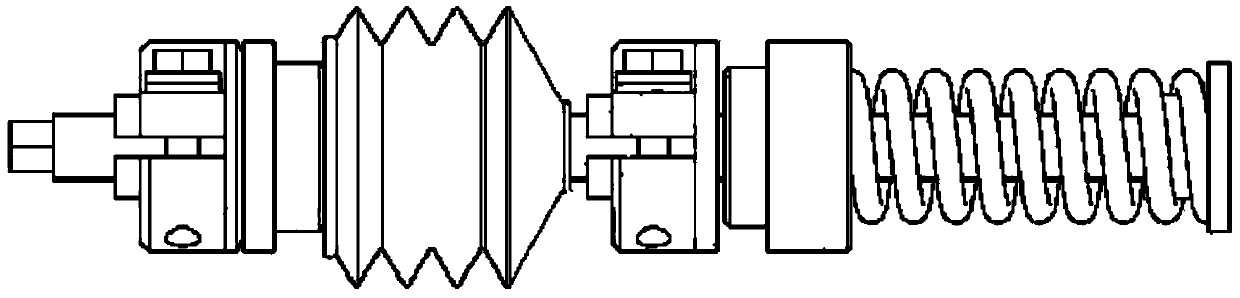

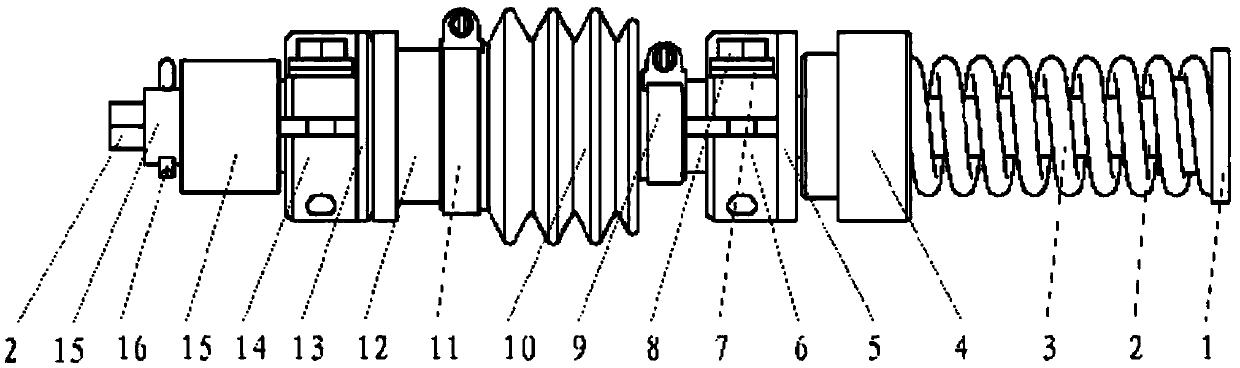

[0013] See figure 2 The suspension device of the light rail vehicle electromagnetic track brake of the present embodiment comprises an end cover 1, an adjusting screw mandrel 2, a suspension spring 3, a spring tray 4, a flat washer 5, an upper elastic nut 6, a dish washer 7, a bolt 8, Upper clamp 9, dust cover 10, lower clamp 11, suspension tray 12, spherical gasket 13, lower elastic nut 14, locking sleeve 15 and cotter pin 16.

[0014] The end cap 1 is an integral piece made of steel. The end cap 1 is a hollow structure integrally formed by two sections of cylinders with different outer diameters, wherein the upper cylinder has a relatively larger outer diameter and a relatively shorter length. The central hole of the end cap 1 is an internally threaded cylindrical through hole.

[0015] The adjusting screw rod 2 is a strip-shaped high-strength rolled stainless steel stud, and the thread diameter of the adjusting screw rod 2 matches the threaded through hole of the end cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com