Novel internal winding machine

An inner winding machine, a new type of technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of the winding effect to be improved, the winding running speed is slow, the vibration noise is large, etc., and the winding shape can be maintained. , The equipment has a compact structure and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

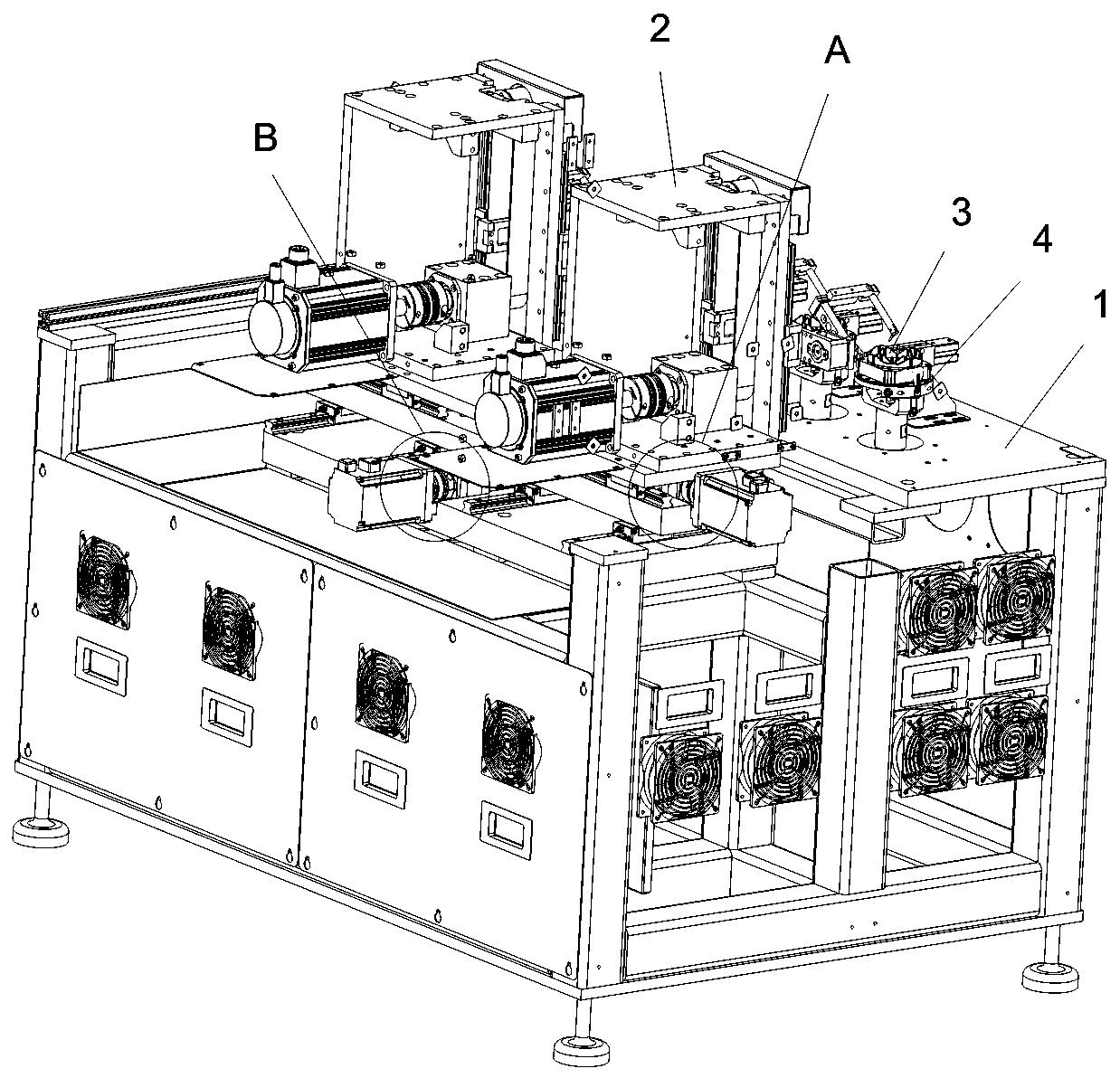

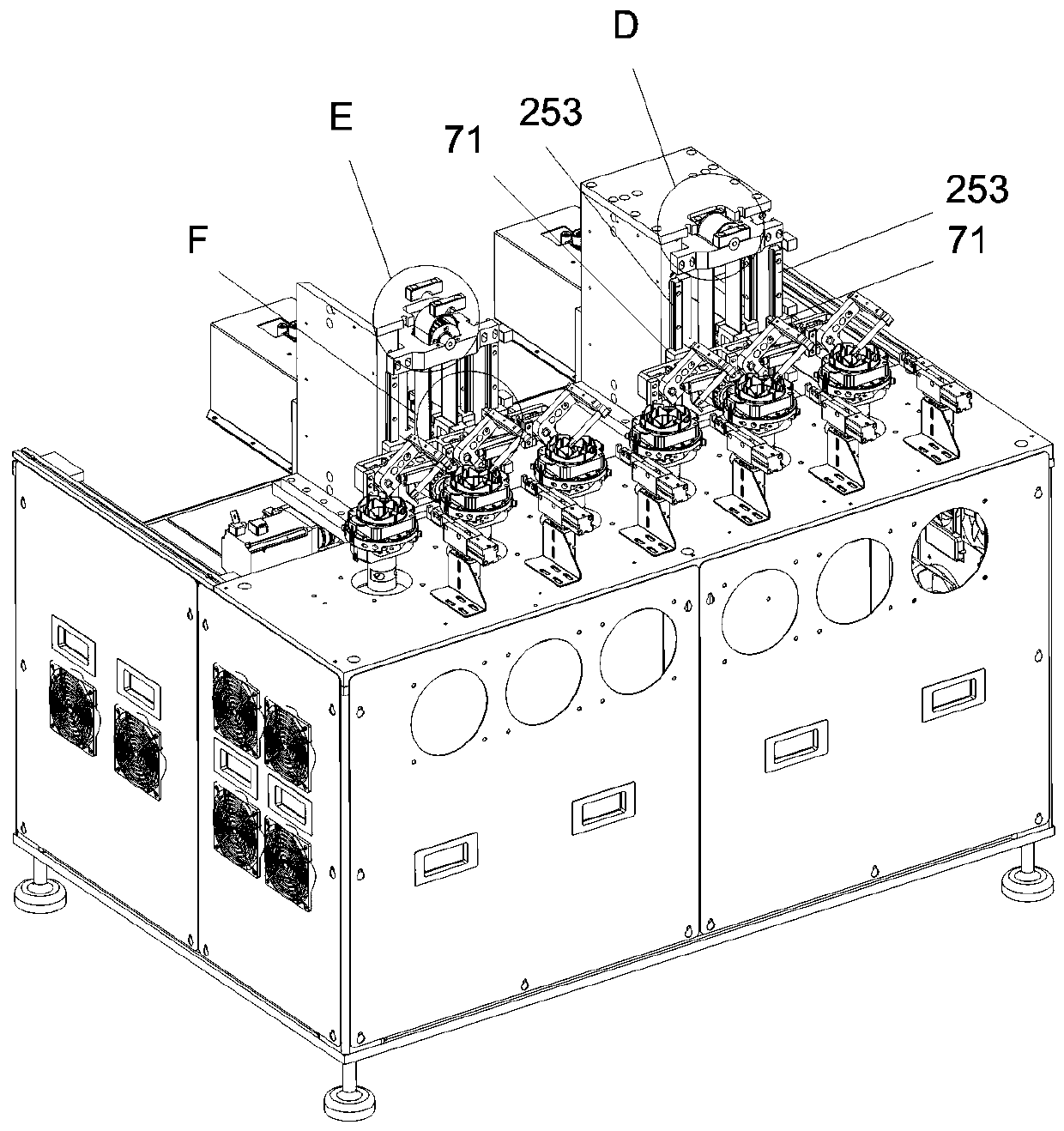

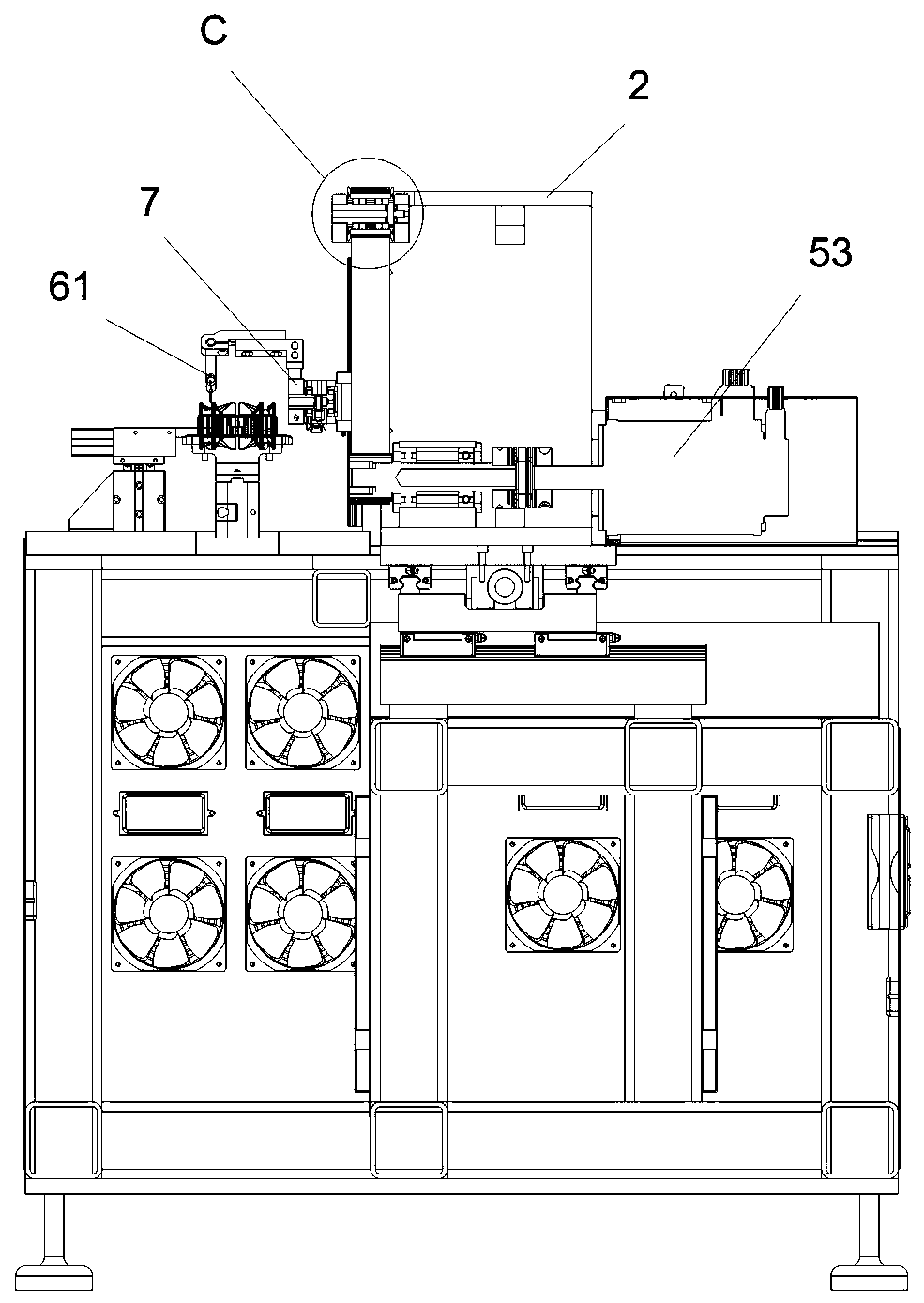

[0039] see Figure 1-Figure 13 , the new inner winding machine includes a main table 1, a drive base 2 and a winding seat 4 for placing the stator 3, the bottom of the drive base 2 is provided with a first base plate 21, and the first base plate 21 is provided with a The first drive motor 51 that makes the drive base 2 move horizontally on the track of the first base plate 21 in the left and right directions, the first base plate 21 is provided with a first groove 211 corresponding to the first drive motor 51, and the first base plate 21 The bottom of the second base plate 22 is provided with a second base plate 22, and the second base plate 22 is provided with a second driving motor 52 for making the first base plate 21 move horizontally forward and backward on the track of the second base plate 22. The second base plate 22 is provided with The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com