Full-section closed-type deep-shallow coupling yielding anchoring and grouting support method for broken soft rock roadway

A full-section, closed technology, used in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of high cost, neglecting the control of deep fissure expansion in the surrounding rock, complicated procedures, etc. The ability to resist deformation of surrounding rock and the effect of wide damage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

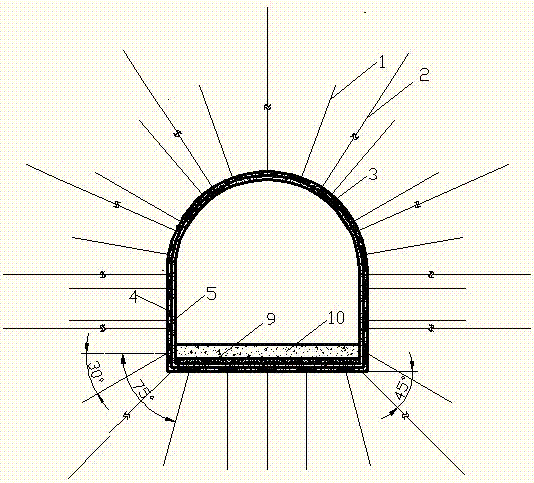

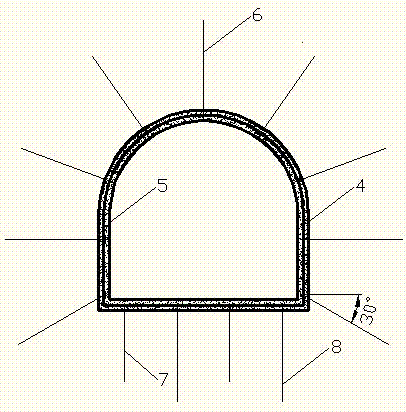

[0051] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and taking a certain mine as an example.

[0052] The full-section closed-type deep-shallow coupling yielding anchoring and grouting support method of broken soft rock roadway, the specific steps are as follows:

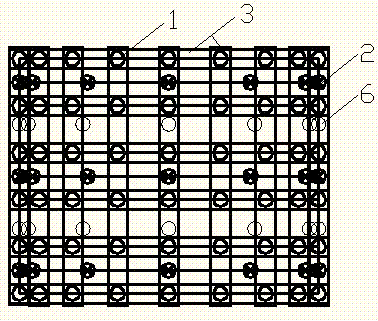

[0053] Step 1): After the roadway is excavated, bolt holes are drilled on the full section of the roadway, and high-strength prestressed anchor bolts 1 are installed. The metal mesh is laid out in a right-angled way to cross the reinforcement ladder 3. The metal mesh is welded by steel bars with a diameter of 6mm, the specification is 2000×1000mm, and the mesh size is 100×100mm. Welding process; install the anchor pallet, the pallet passes through the anchor rod to press the steel ladder 3, and makes its pre-tightening force reach 80kN.

[0054] Step 2): After the installation of the full-section high-strength prestressed anchor rod 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Preload force | aaaaa | aaaaa |

| Preload force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com