Patents

Literature

122results about How to "Compressible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

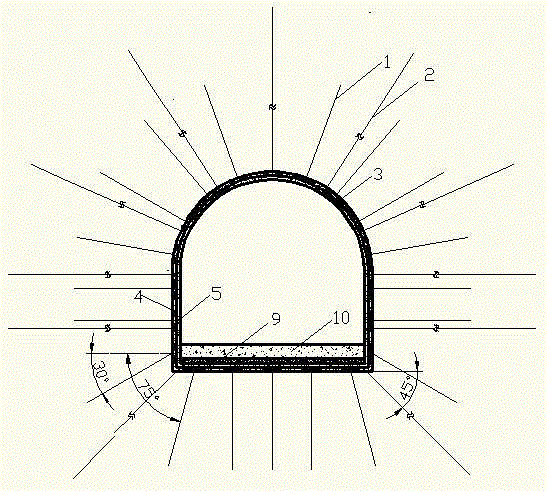

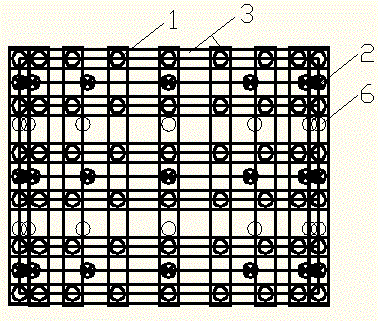

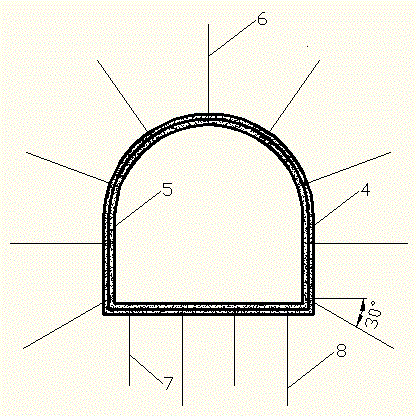

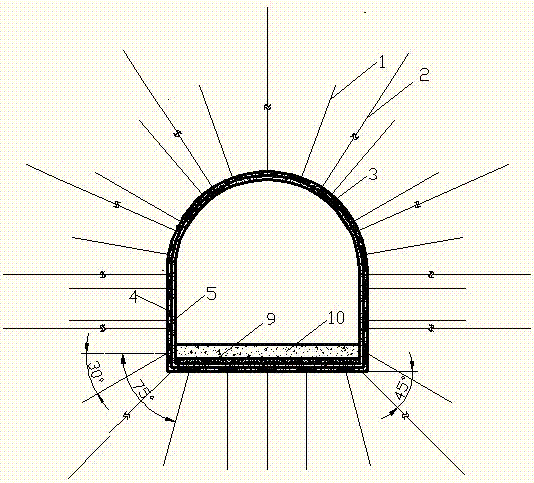

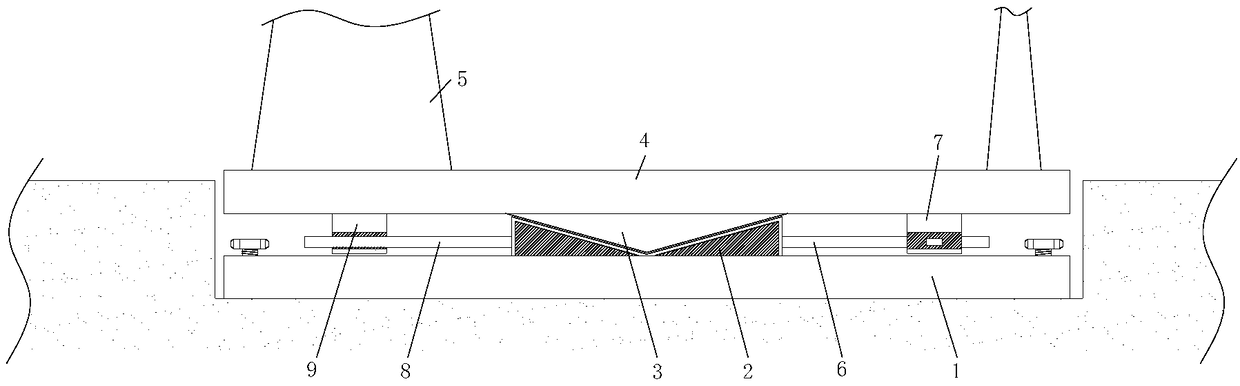

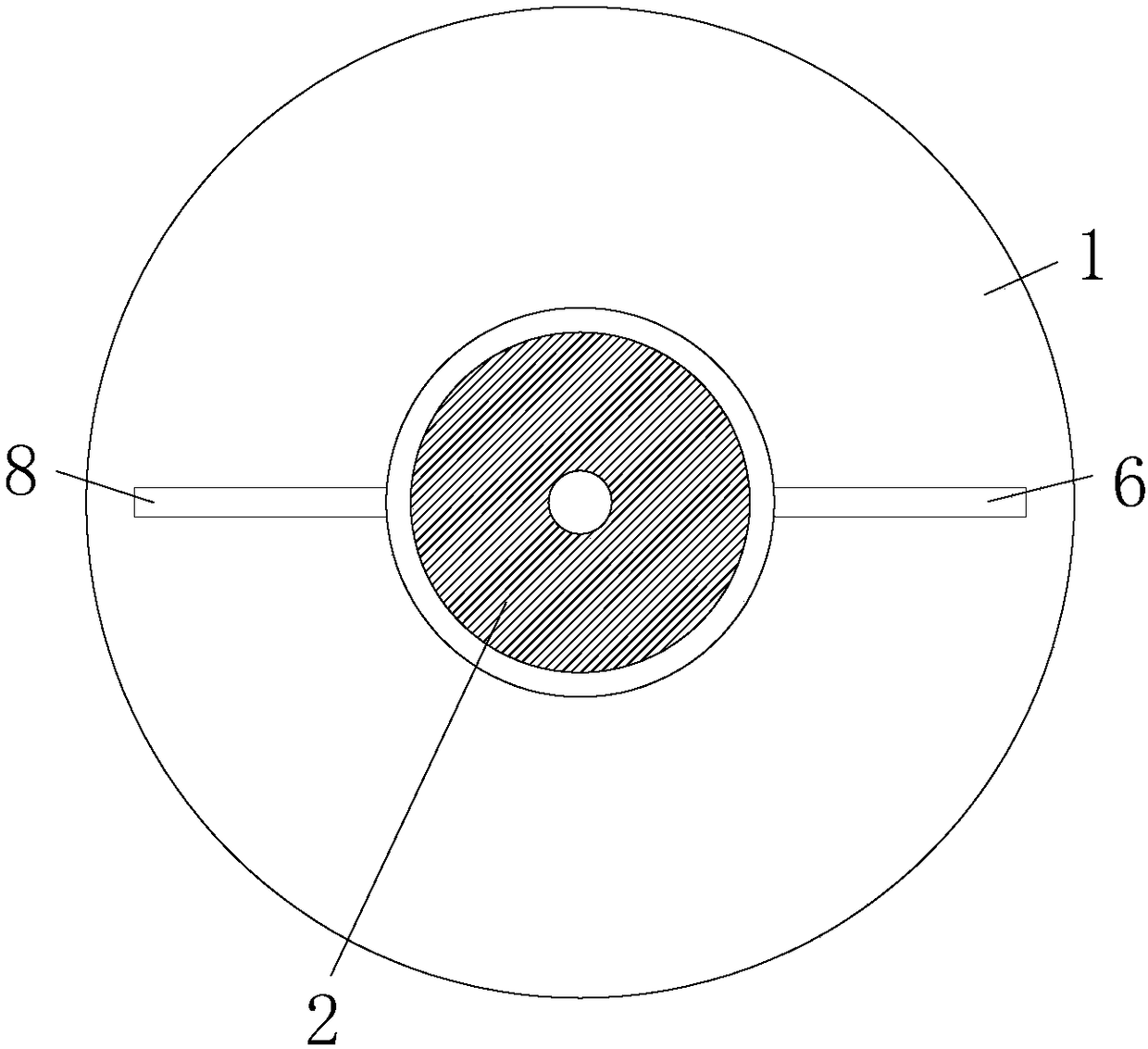

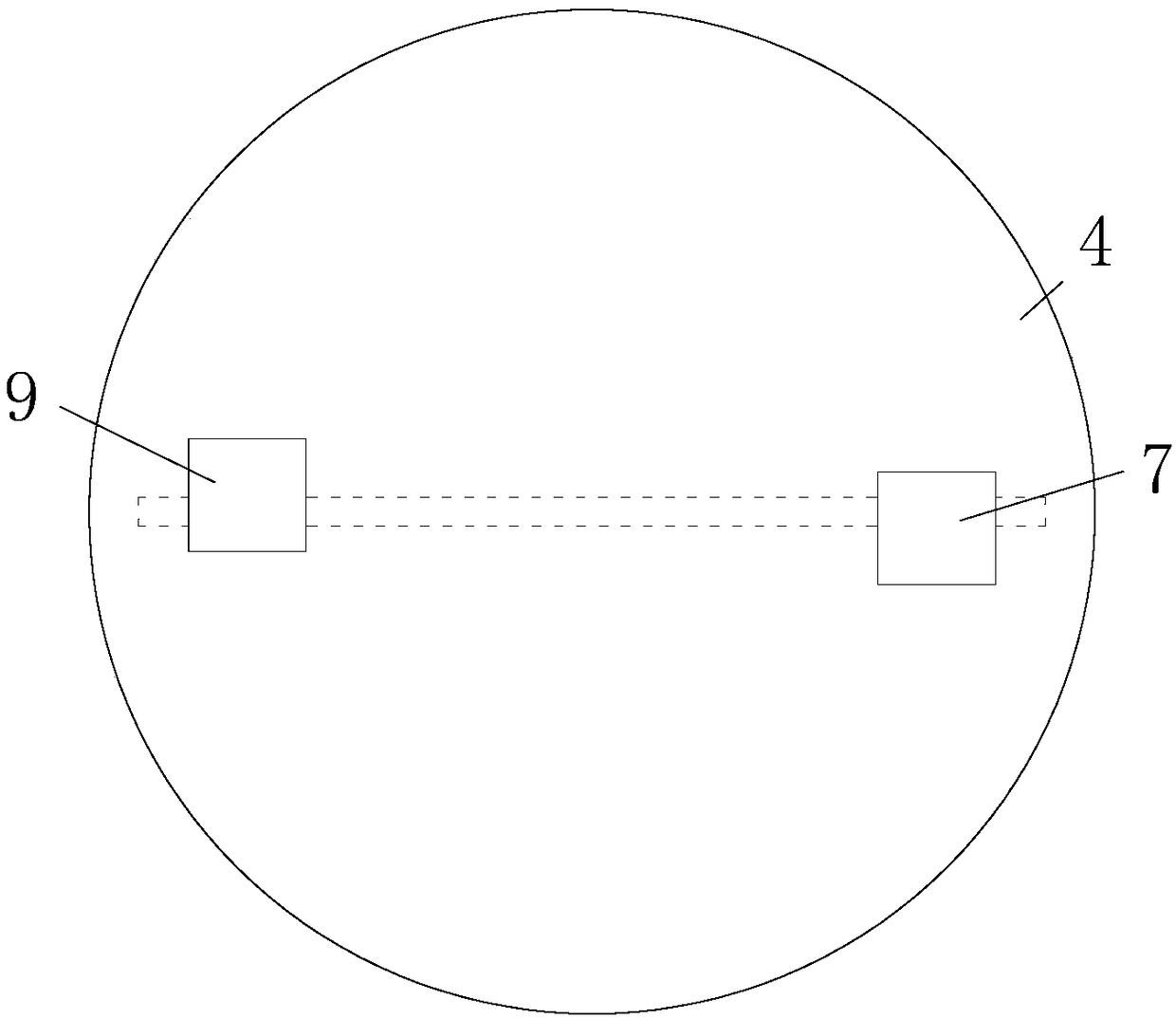

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

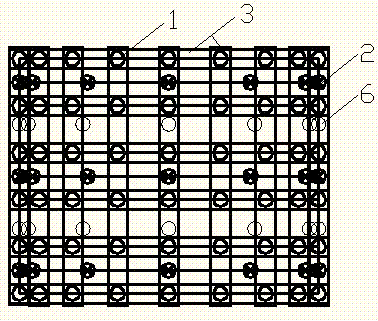

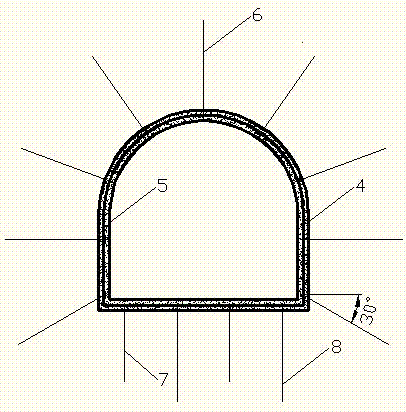

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

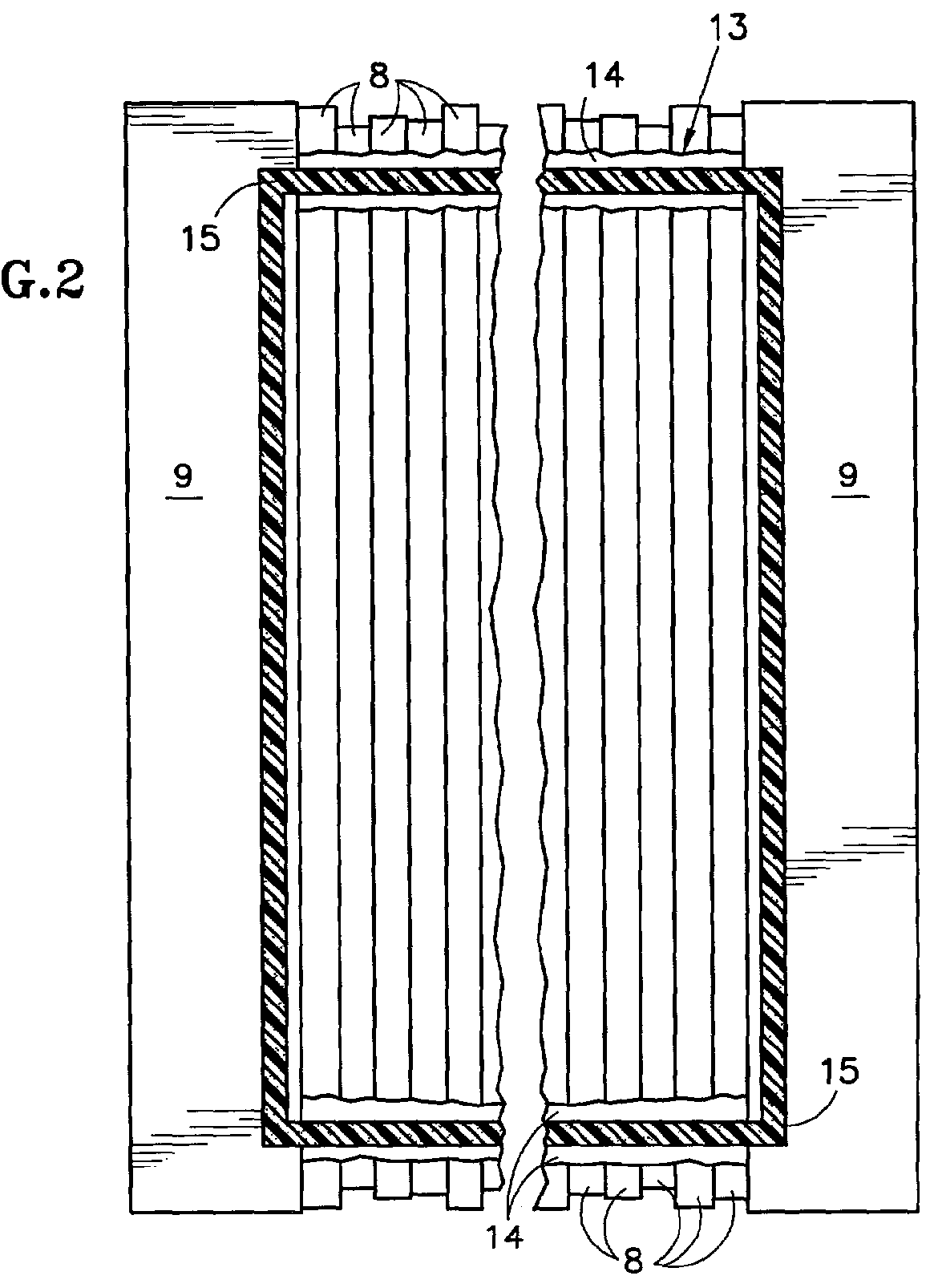

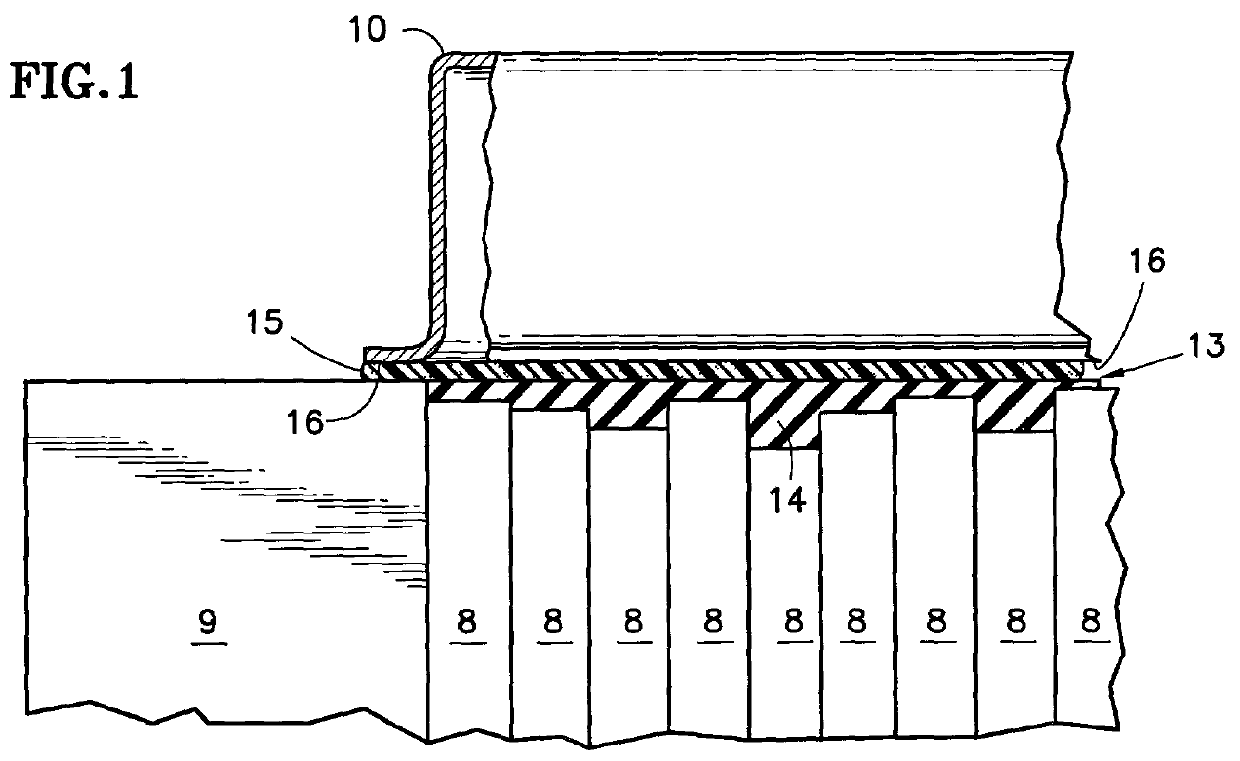

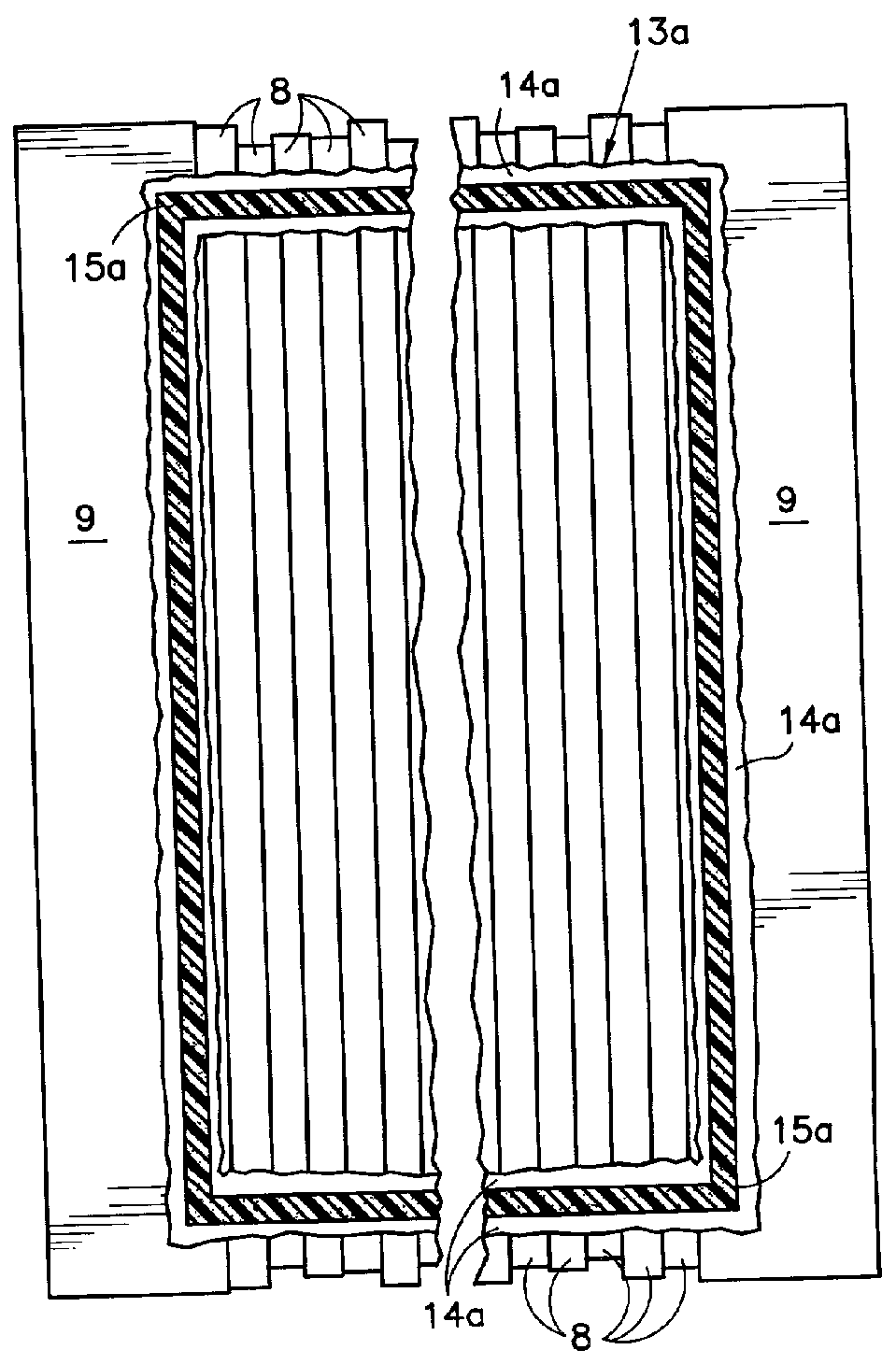

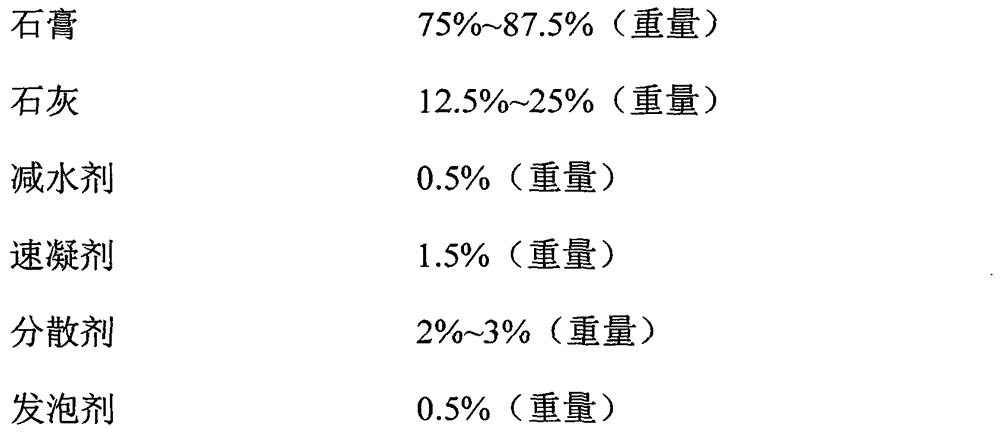

Proton exchange membrane fuel cell external manifold seal

InactiveUS20010055708A1Low creepCompressibleSolid electrolytesFuel cells groupingLow temperature curingEngineering

A sealant system 13 for a manifold 10 of a proton exchange membrane fuel cell includes low temperature cured or heat cured silicone rubber bridges 14, 14a, 14c between the end plates 9 to compensate for the uneven edges of various fuel cell component layers, and a layer 15 of silicone rubber foam or sponge, or a molded silicone rubber gasket 15a, extending across the bridges and along the end plates, around the entire contact perimeter surfaces of the manifold, to seal the manifold to the fuel cell. The cured silicone rubber may extend along the end plates between the bridges. A rubber strip 20 may be adhered to the silicone rubber bridges and end plates. The bridges may comprise a first layer 22 of low shrinkage self-leveling RTV liquid rubber with viscosity in the range of 10,000-20,000 cps and a second layer 14 of RTV liquid rubber.

Owner:AUDI AG

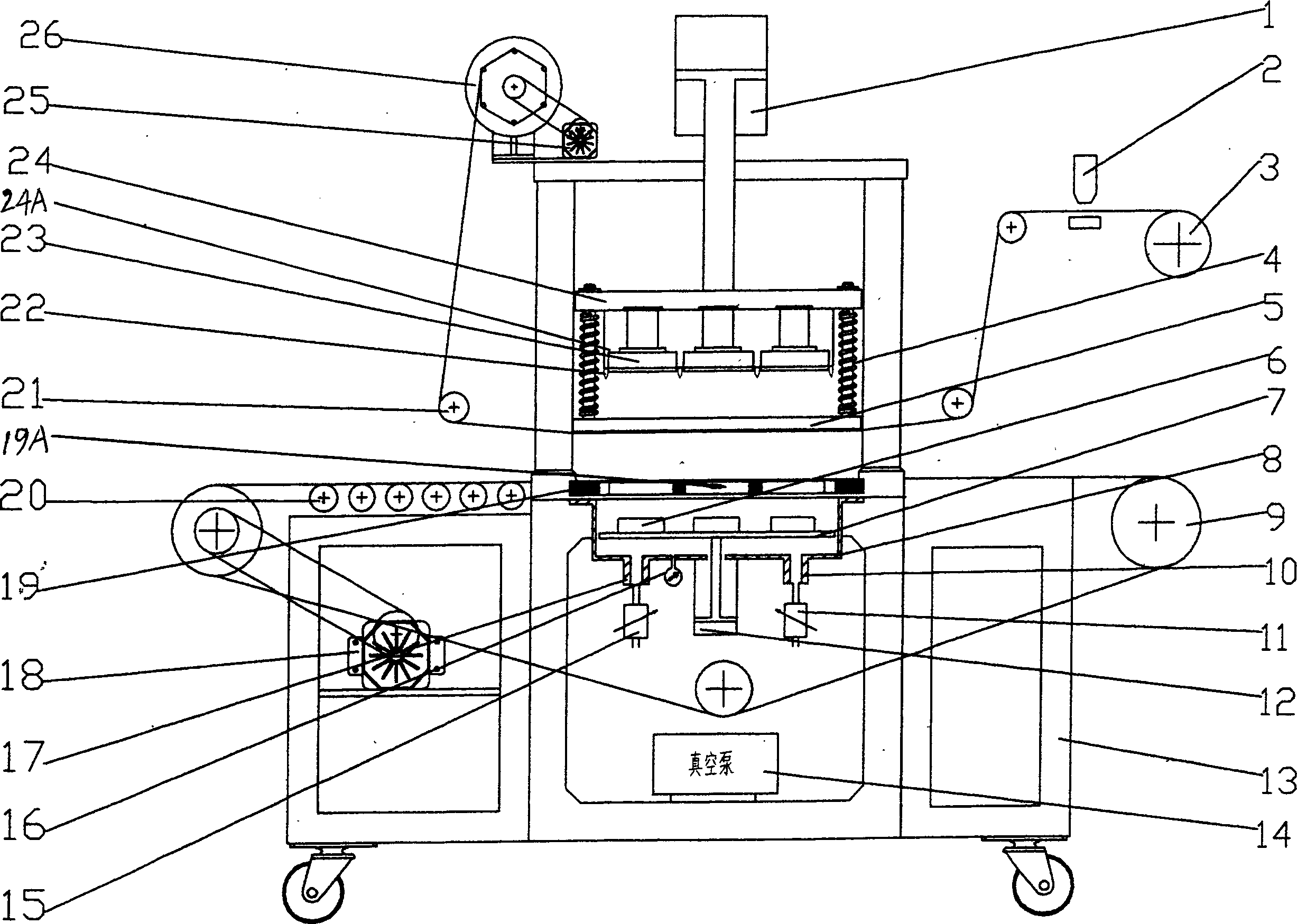

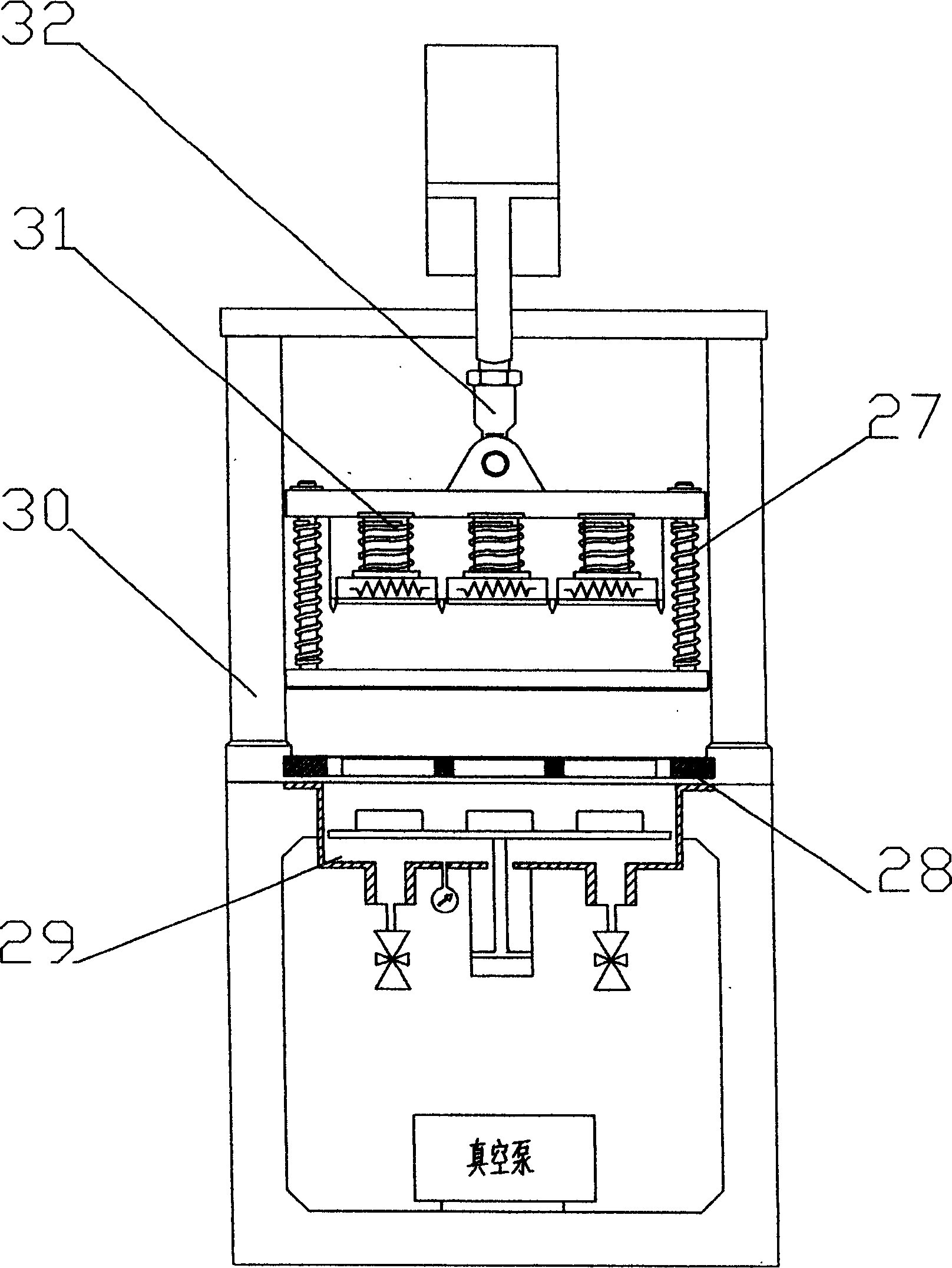

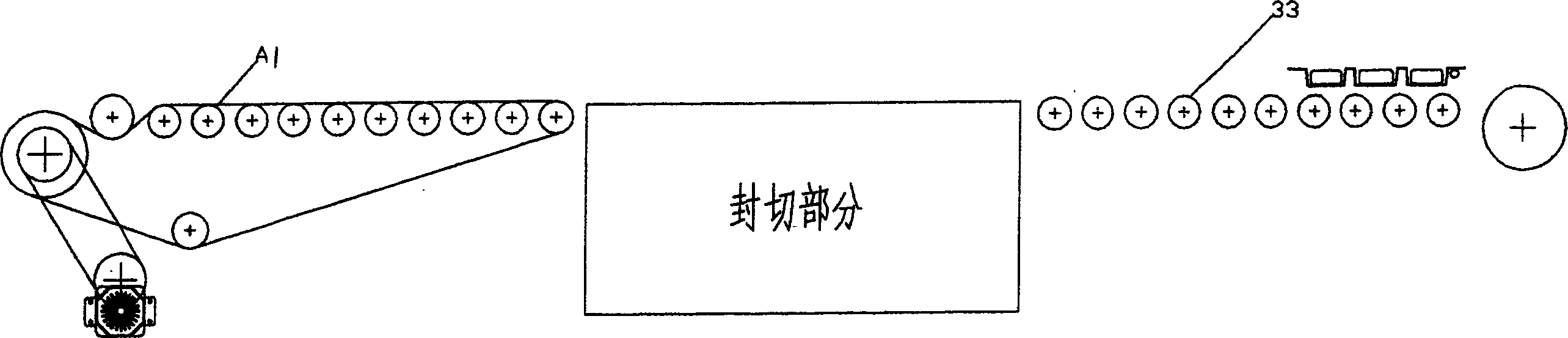

Continuous casing cake and food air conditioned preserving packers

InactiveCN1644458AAccurate identificationMake sure you are in a safe placePackaging under special atmospheric conditionsThin membraneEngineering

A continuous packing machine with gas antistaling function for the cake food box is composed of machine frame, pressure-variable sealing-cutting unit, conveyer, heating-sealing unit, cutting unit, vacuumizing-inflating unit, film winding unit, and controller. Said heating-sealing unit has upper and lower sealing dies.

Owner:苏明智

Peony seed oil microcapsule and preparation method of peony seed oil microcapsule

InactiveCN105028706AGood water solubility and stabilityUniform particle sizeEdible oils/fatsEmulsionChemistry

The invention discloses a peony seed oil microcapsule and a preparation method of the peony seed oil microcapsule, and belongs to the technical field of food engineering. The peony seed oil microcapsule comprises a core material phase and a wall material phase. Through being metered by weight parts, the core material phase consists of 10 to 60 parts of peony seed oil and 0.5 to 5 parts of oil soluble emulsifiers; the wall material phase consists of 20 to 75 parts of wall materials, 5 to 50 parts of wall material connecting auxiliary agents, 20 to 150 parts of water, 1 to 8 parts of water-soluble emulsifiers and 0.5 to 5 parts of stabilizers. The pressure emulsification homogenizing is used, so that the particle diameter of an emulsion reaches the nanometer level, so that the particle size of an obtained product is uniform; the reconstitution capacity is good; the solubleness is good; the peony seed oil microcapsule can be dissolved in cold water; no precipitate and no floating object exist in a solution; no floating oil exists after the still standing for 48 hours; the solution can be compounded with other emulsions such as milk; the application range of the peony seed oil is expanded. The peony seed oil microcapsule and the preparation method have the advantages that the process is simple; the production cost is low; the product stability is greatly improved; and the nutrition activity of the peony seed oil is maintained.

Owner:刘进

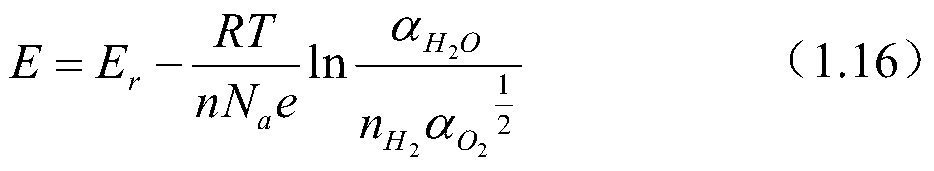

Proton exchange membrane fuel cell modeling method, storage medium and computer equipment

ActiveCN109902435APredicted state variablesImprove analysis accuracyFuel cells groupingSpecial data processing applicationsElectrochemical responseHydrogen

The invention provides a proton exchange membrane fuel cell modeling method, a storage medium and computer equipment. The proton exchange membrane fuel cell modeling method comprises the following steps: constructing a fuel cell stack model by utilizing an electrochemical reaction equation; Constructing a cathode side model by considering the thermodynamics and flow state change process of reactants; wherein the cathode side model comprises an air compressor model, a heat exchanger model, an air outlet valve model and a cathode side inlet and outlet gas flow relation model; Constructing an anode side model by considering thermodynamic parameters of hydrogen in a flowing process and changes of a flowing state; The anode side model comprises a hydrogen control valve model, an ejector model and an anode side inlet and outlet flow relation model.

Owner:SHANDONG UNIV

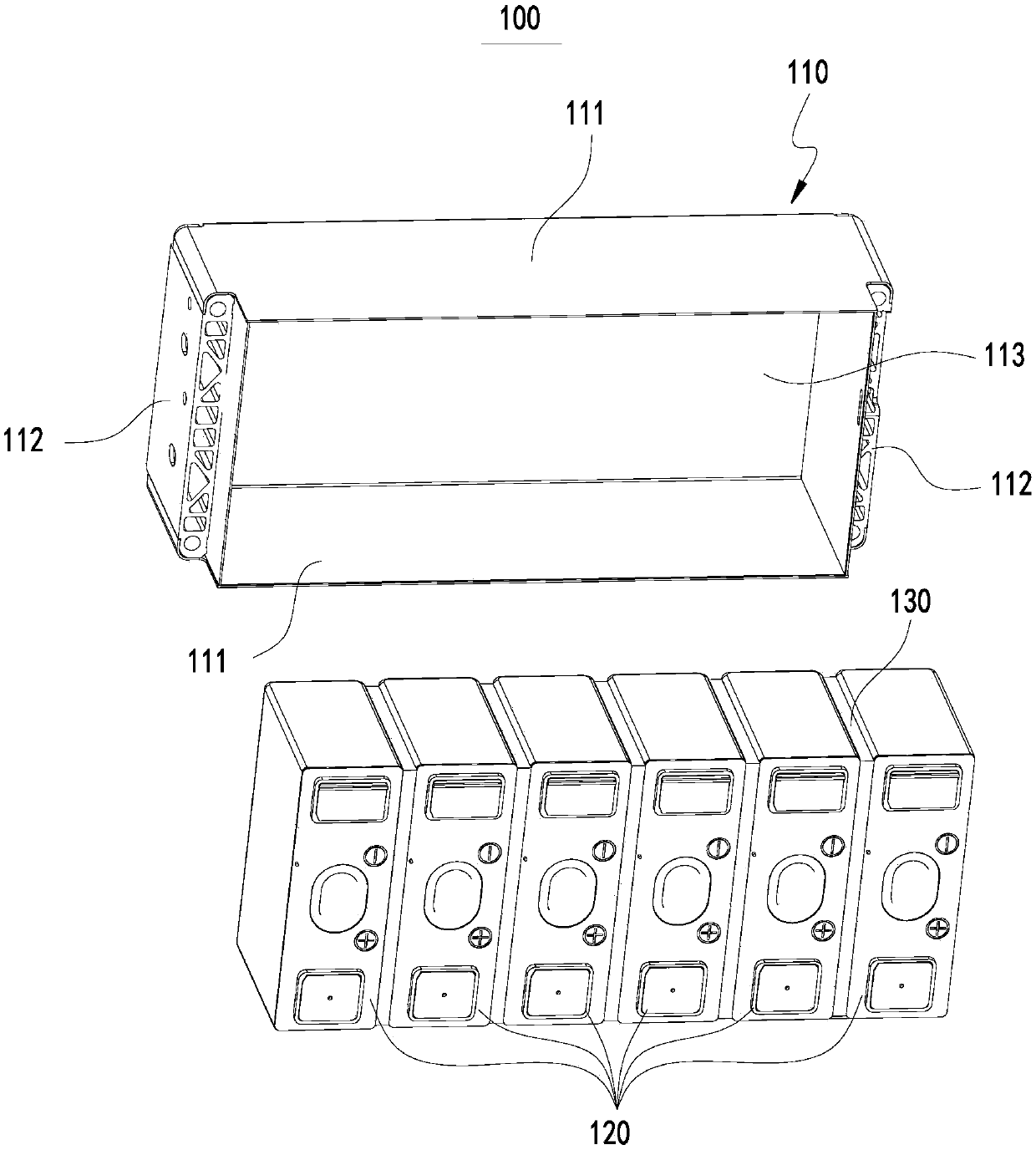

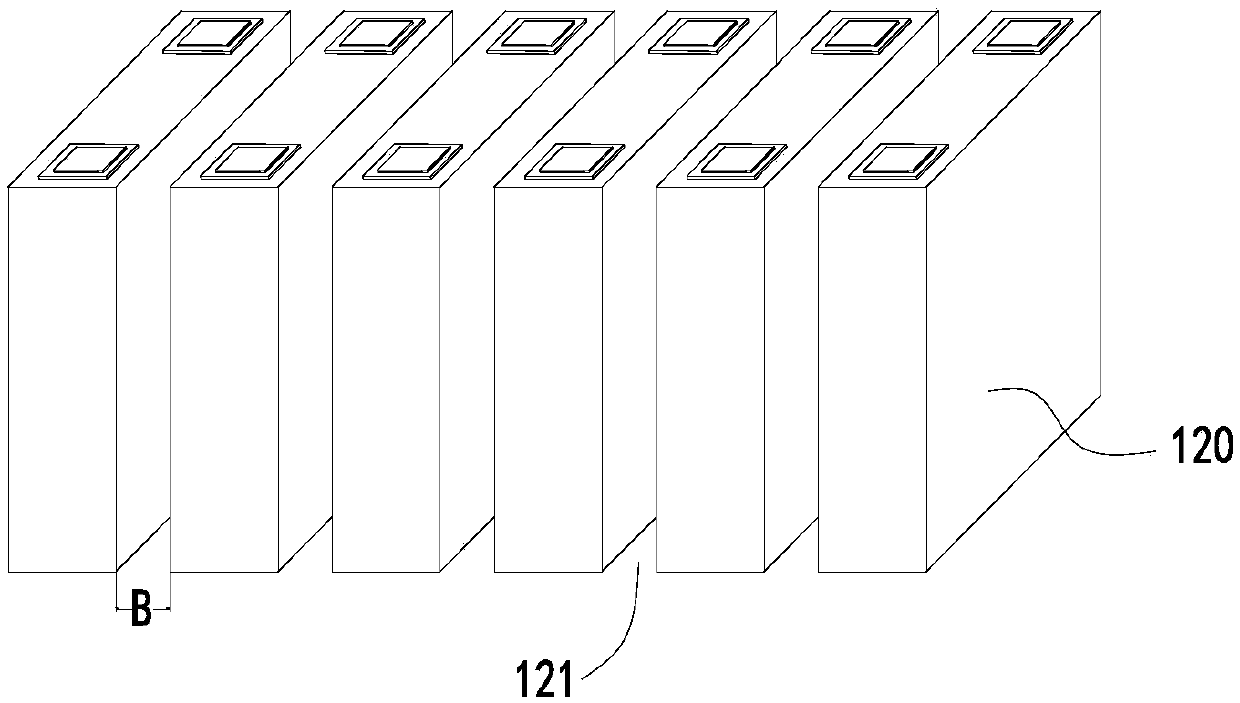

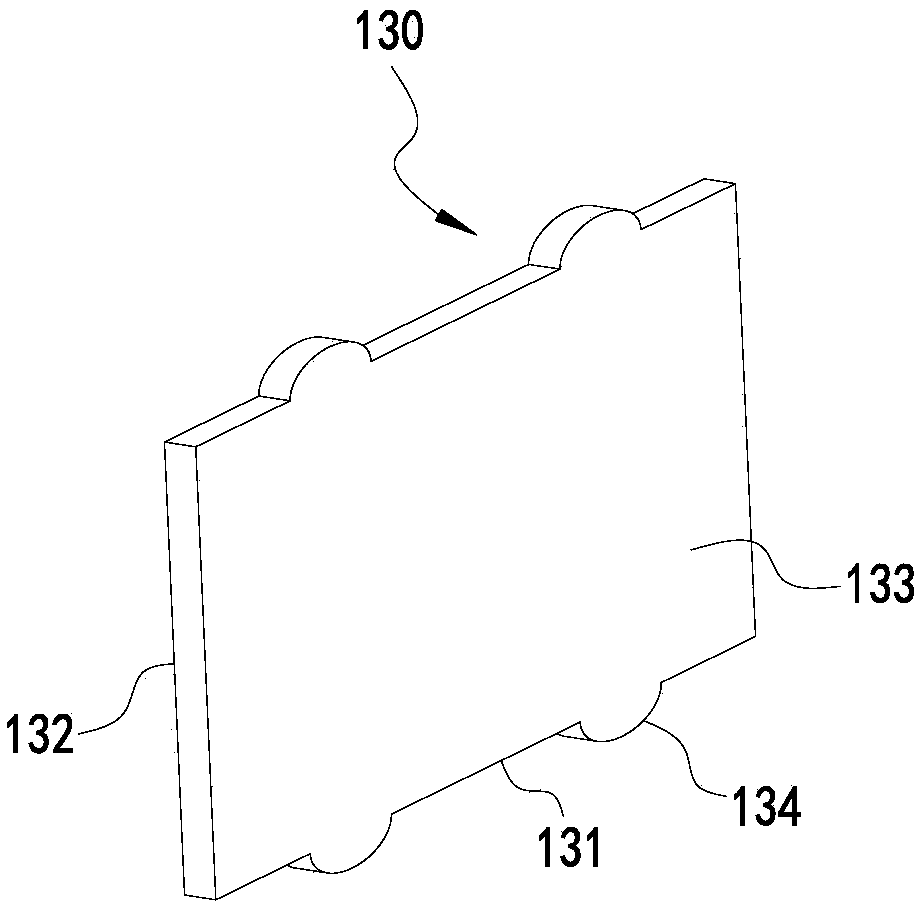

Battery module

ActiveCN110265591APromote circulationCompressibleFinal product manufactureSecondary cellsEngineeringCompressibility

The invention discloses a battery module and belongs to the technical field of energy storage. The battery module includes: a frame having a receiving space; a plurality of battery units which are successively arranged in the receiving space of the frame along the thickness direction of the battery units, wherein separating plates are disposed between adjacent battery units and have compressibility, and a compression ratio [delta]1 of the separating plates at a pressure less than or equal to 2MPa satisfies a condition of C0*[delta]1 <= A0*0.2, wherein C0 is the initial thickness of the separating plates, and A0 is the initial thickness of the battery units. The battery module provided by the invention has excellent cycle performance.

Owner:CONTEMPORARY AMPEREX TECH CO

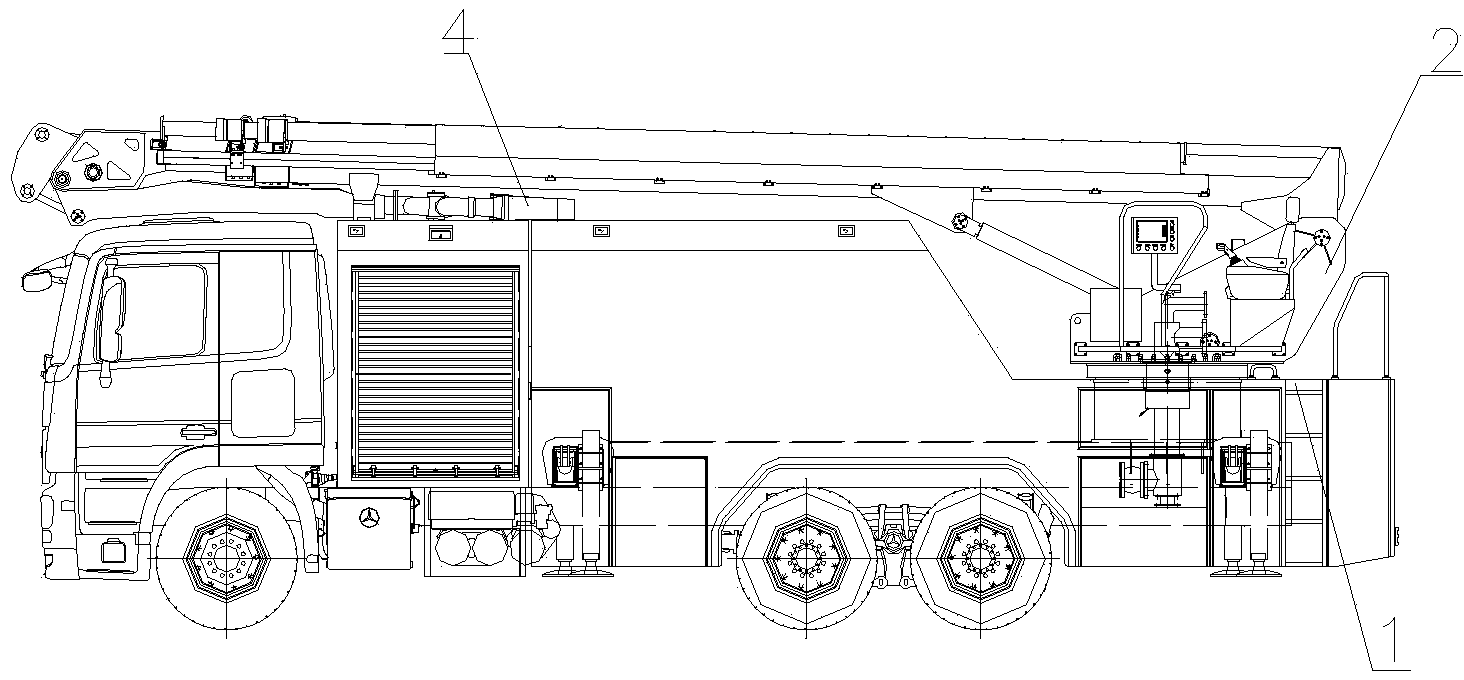

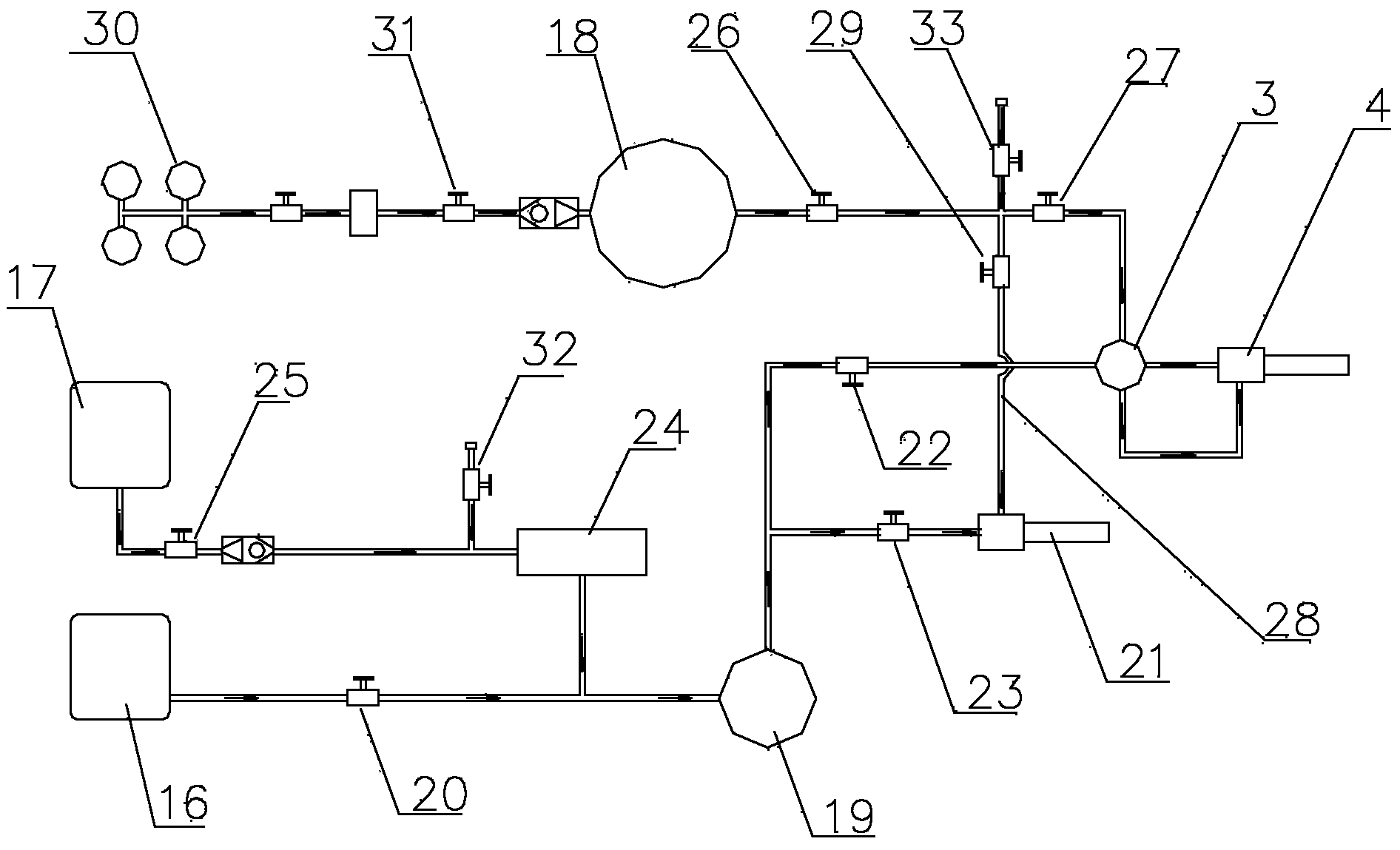

Vehicle-mounted high-spray multi-agent combination jet fire extinguishing device

ActiveCN103751937AReduce dosageChange fire extinguishing functionFire rescueAgent CombinationEngineering

The invention discloses a vehicle-mounted high-spray multi-agent combination jet fire extinguishing device which is characterized in that a rotary table rack is fixedly arranged by using a fire truck as a carrier, a rotary table is rotationally arranged on the rotary table rack, and a spray gun is arranged at the front end of a lifting arm support of a revolving body; an outer output pipe and an inner output pipe which are arranged in parallel are arranged at the rotating part of a central revolving body, and the outer output pipe and the inner output pipe are respectively communicated with the spray gun by pipelines on respective arm supports; an outer input pipe and an inner input pipe which are arranged in parallel are arranged at the fixed part of the central revolving body; various fire extinguishing agent storage tanks are arranged in the fire truck, and are communicated with the outer input pipe and the inner input pipe through multiple conveying pipelines to convey fire extinguishing agents, and multiple control valves are arranged in the multiple conveying pipelines to control the opening or closing of the pipelines. The device disclosed by the invention achieves the purpose that one fire extinguishing agent can be sprayed solely, and two or more fire extinguishing agent combination can be sprayed simultaneously, thereby meeting the demands for different types of extinguishment tactics.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

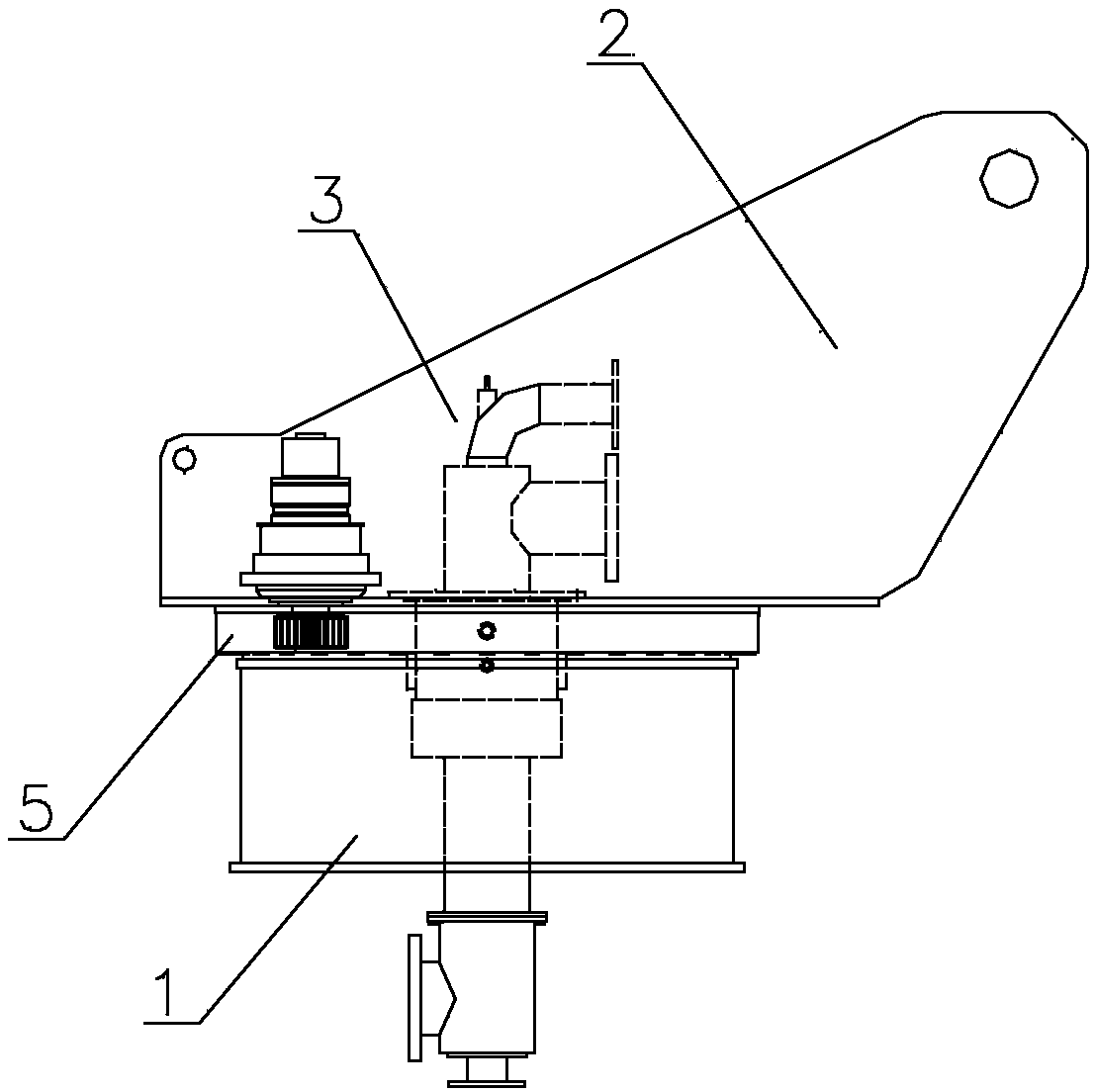

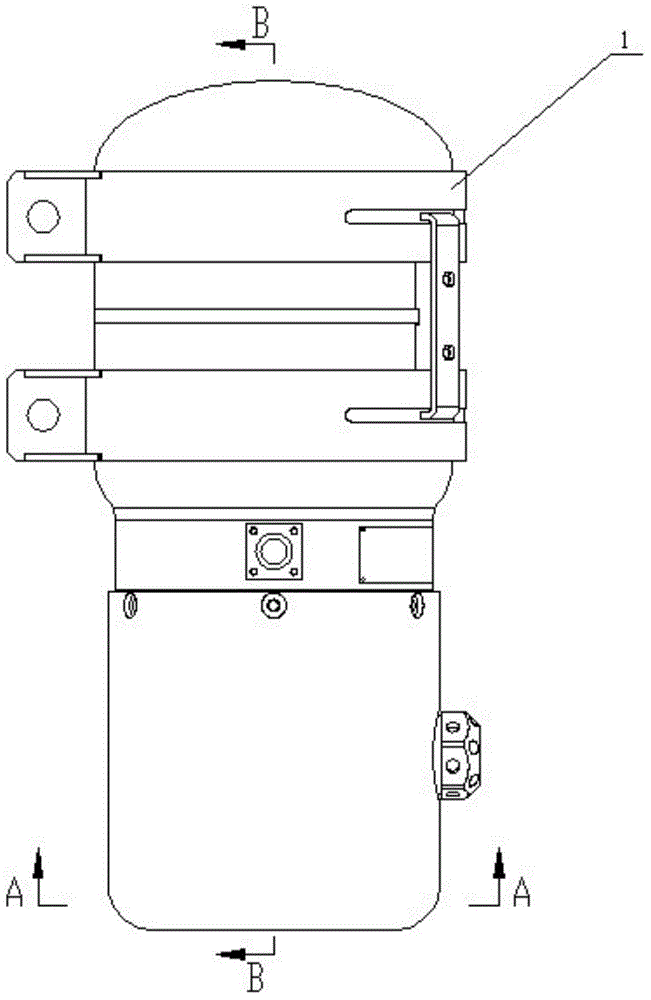

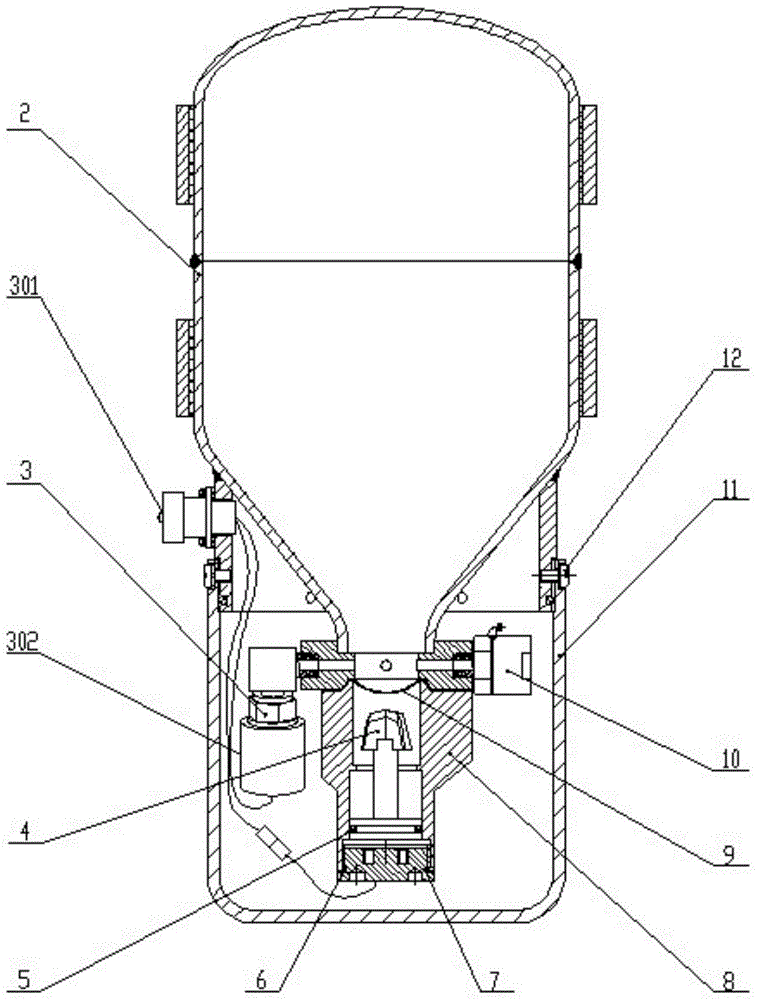

Automatic explosion suppression and fire extinguishing device

The invention relates to the technical field of fire protection and discloses an automatic explosion suppression and fire extinguishing device. The fire extinguishing device comprises a nozzle, a bottle body which is internally provided with a superfine dry powder cool air sol fire extinguishing agent, a pressure switch and a filling valve which are arranged on the bottle body, a sealing membrane sealing an opening of the bottle body, a bottle head pressing cover with a cavity at the center, and a protective cover covering the bottle body, wherein the filling valve is in sealed connection with the bottle body by a thread; the pressure switch is connected with the bottle body by a thread; the bottle head pressing cover is fixed on the opening at the upper end of the bottle body; the bottle head pressing cover is internally provided with an electric explosion box; the electric explosion box is provided with a puncturing needle; the protective cover is connected with the bottle body by screws; the bottle head pressing cover is in sealed connection by the nozzle by a thread.

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

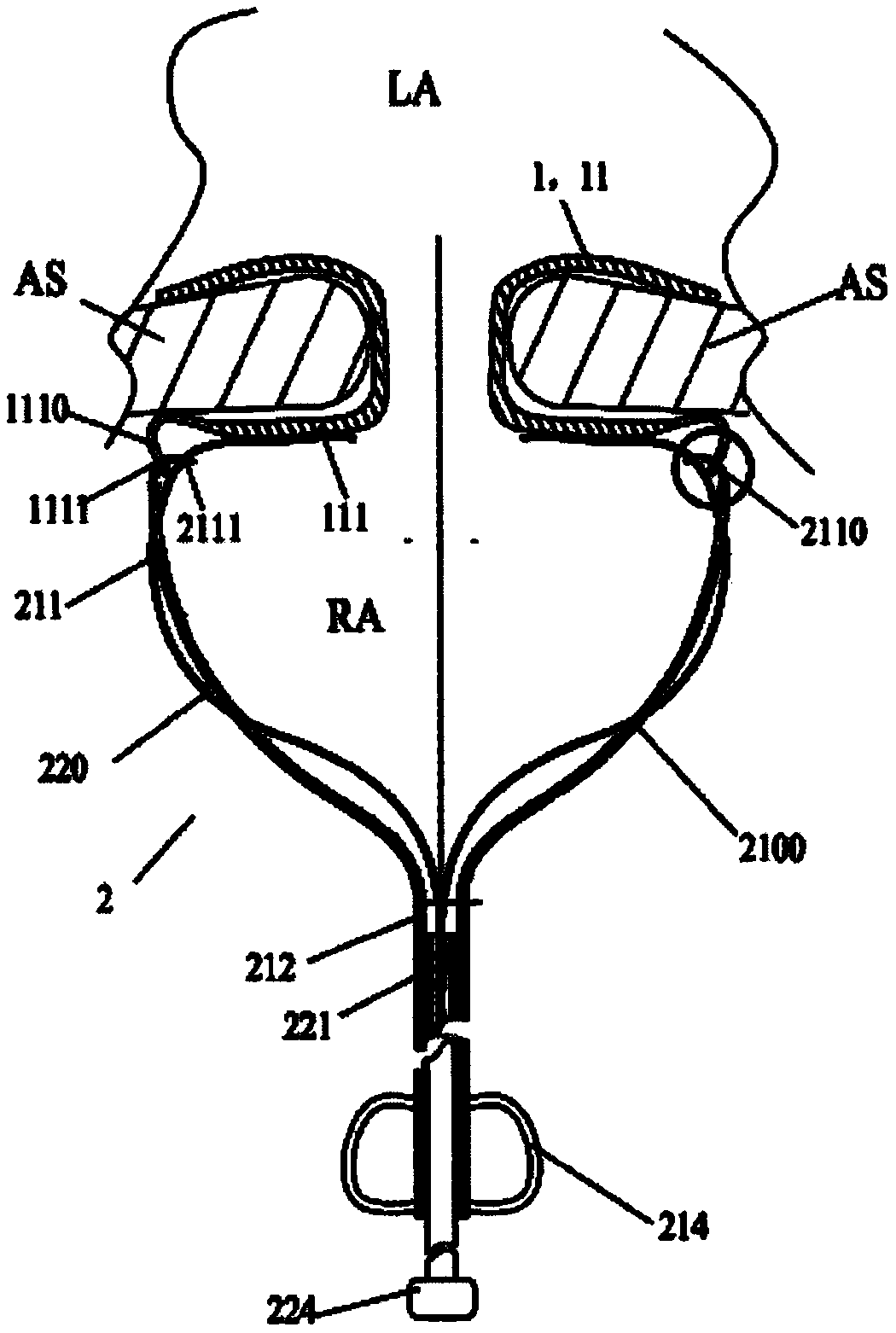

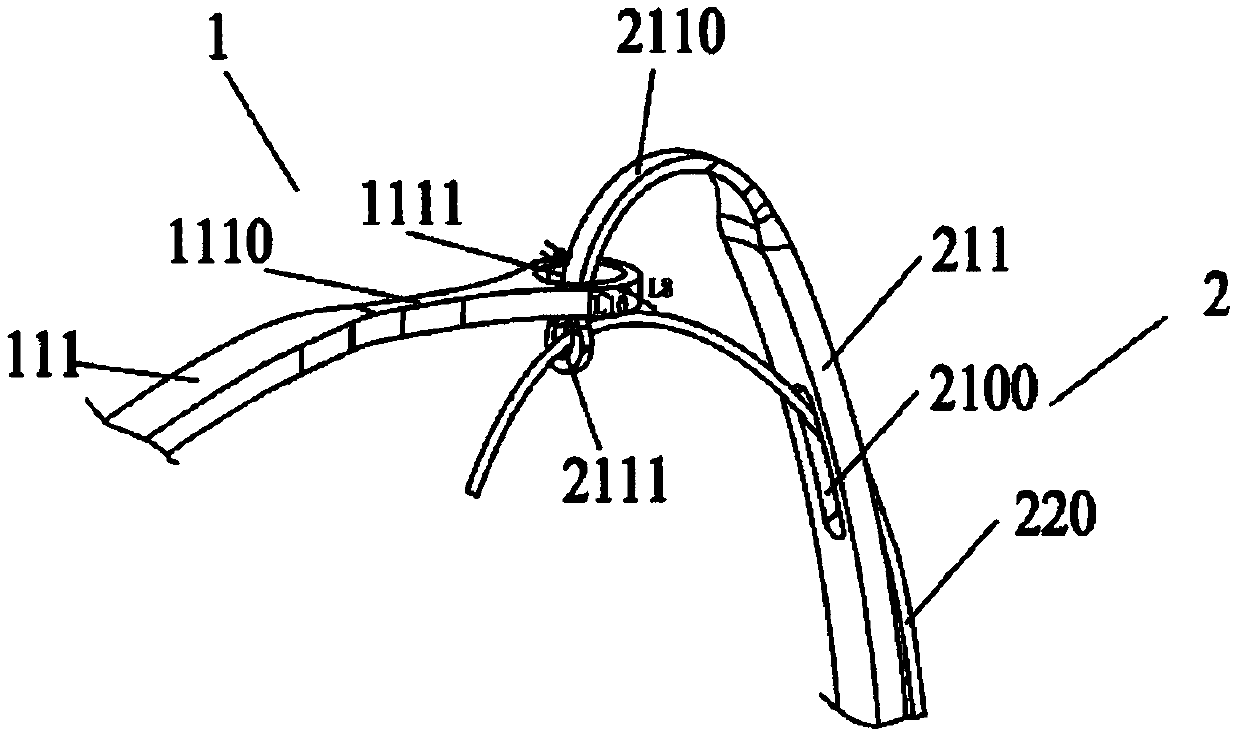

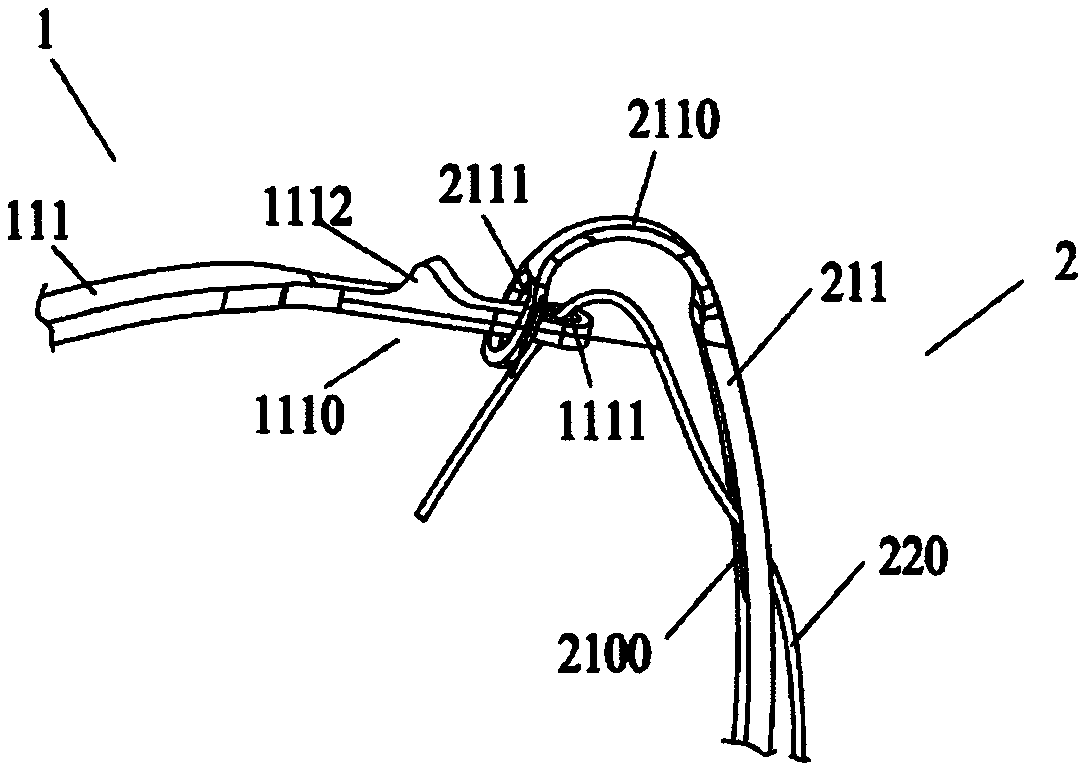

Controllable release system

The application relates to a controllable release system comprising an implantation instrument and a conveying system. A plurality of first holes are formed in the near-end area of the implantation instrument. The conveying system includes a plurality of traction rods and a plurality of release wires; the plurality of release wires, the plurality of traction rods and the plurality of first holes are in one-to-one correspondence in number and position; each traction rod is provided with a second hole and a constraint part; the second holes are formed in the far ends of the traction rods; the release wires penetrate the constraint parts and the first holes or the second holes to realize connection between the implantation instrument and the conveying system. During the conveying process, theconstraint parts can limit movement of the release wires; and when the implantation instrument is released, the release wires can move relative to the traction rods. According to the system, the implantation instrument is convenient to repeatedly recover timely before dismounting of the implantation instrument; and during the releasing process, the implantation instrument can slowly stretch to anoptimal form from a sheath tube, detachable connection can be realized by withdrawing the release wires to realize the controllable release function. The system is simple in overall structure, convenient to operate, safe and reliable.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

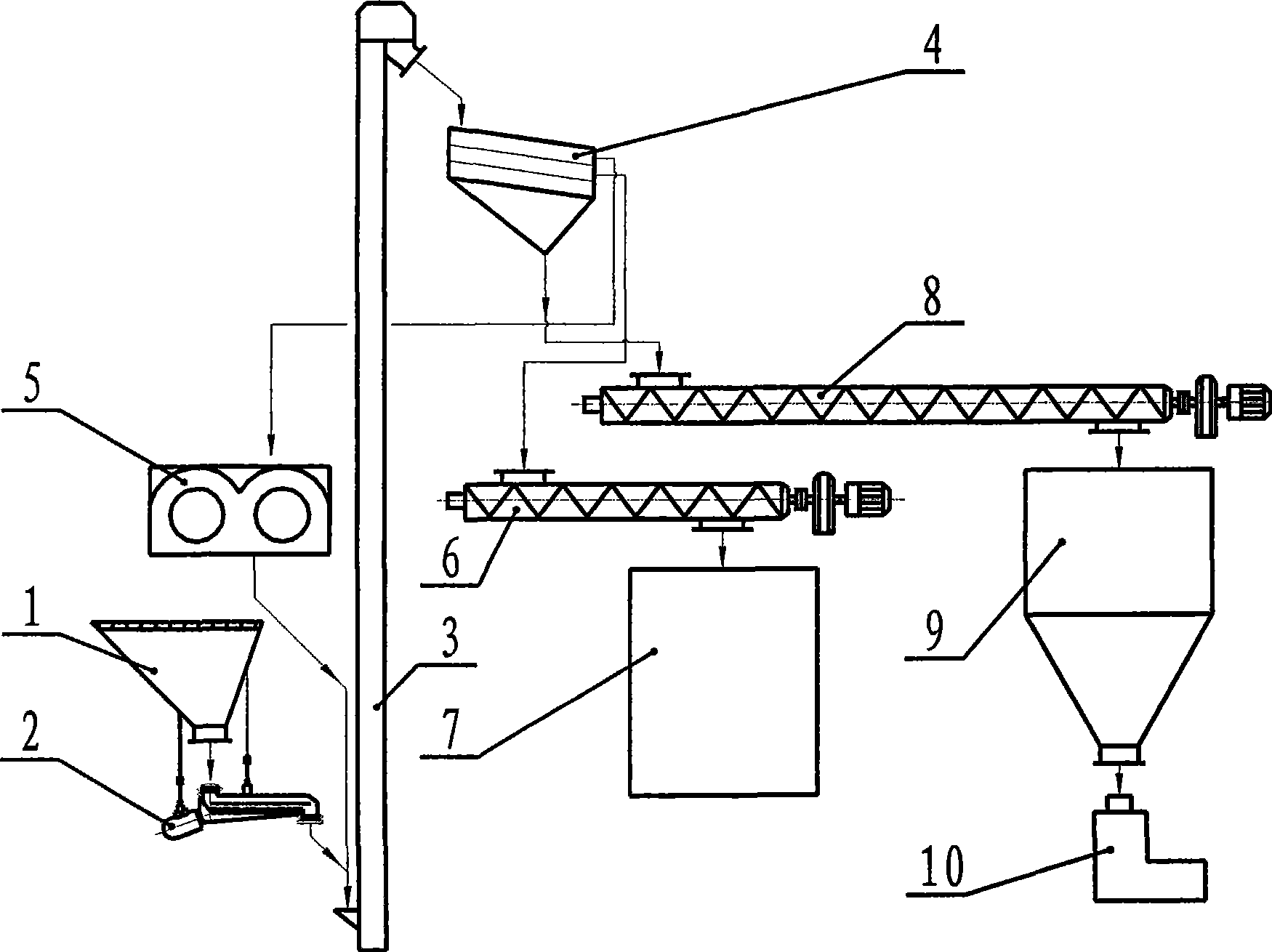

Calcining filler processing method and system

The invention discloses a packing material for baking and particularly relates to a processing method and a processing system for the packing material for baking applicable to producing anodes, cathodes and electrodes for aluminum. The processing method for the packing material for baking comprises the following steps: sending metallurgical coke to sieving equipment for sieving; sending the metallurgical coke with qualified sieve size into a finished product screw conveyer; sending the metallurgical coke with unqualified sieve size to the processing equipment for processing; and sending the metallurgical coke which is sent to the metallurgical coke to a finished product silo. The invention adopts processing technology of the packing material for baking to process the metallurgical coke through crushing and sieving into a finished packing material product with optimum matching which has a size fraction of between 0.5 and 6 millimeters and has compressibility, adsorptivity and gas permeability, improves the volume density and the mechanical strength of a baked product and reduces the contraction rate of a green body. The method improves production operation environment. The method effectively solves technical problems that raw materials of the packing material have small selectivity and high cost, and the packing material can cause serious environmental pollution and raw material loss during the transportation.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

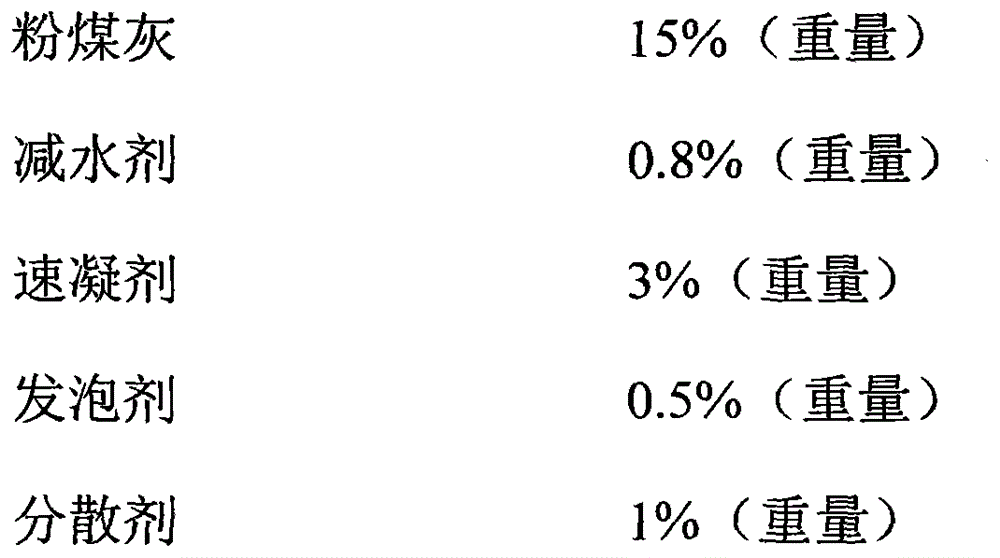

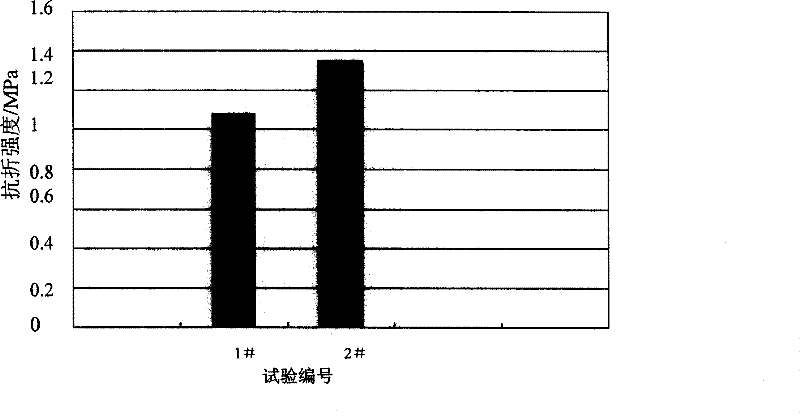

Lightweight quick setting top-caving area filling material

The invention discloses a lightweight quick setting top-caving area filling material. The lightweight quick setting top-caving area filling material is mixed by primary materials B and primary materials B, wherein the primary materials consist of sulfate aluminum cement, coal ash, a water reducer, a setting accelerator, a foaming agent and a dispersing agent; the primary materials B consist of gypsum, lime, a water reducer, a setting accelerator, a dispersing agent and a foaming agent. The lightweight quick setting top-caving area filling material has the lightweight quick setting characteristic; after entering and filling into a top-caving area, the foamed slurry can quickly lose mobility and is solidified within 5 minutes to form a lightweight filling body, wherein the density of the filling body is about 1.4t / m<3>, the 2h uniaxial compressive strength can reach 4 MPa, certain compression performances are provided, the performances of the filling body are stable, the cracking deformation is avoided, and the filling needs of the top-caving area can be met very well.

Owner:HENAN COLLEGE OF IND & INFORMATION TECH

Filter sealing system

ActiveCN1911487AMutual sealing is effectiveGood compressibilityDispersed particle filtrationMembrane filtersStream flowEngineering

Owner:MANN HUMMEL GMBH

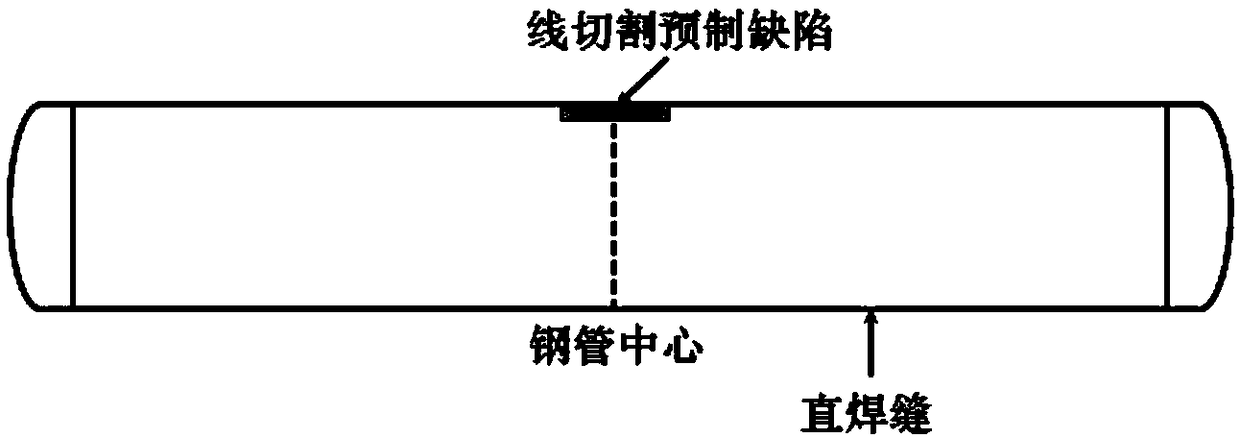

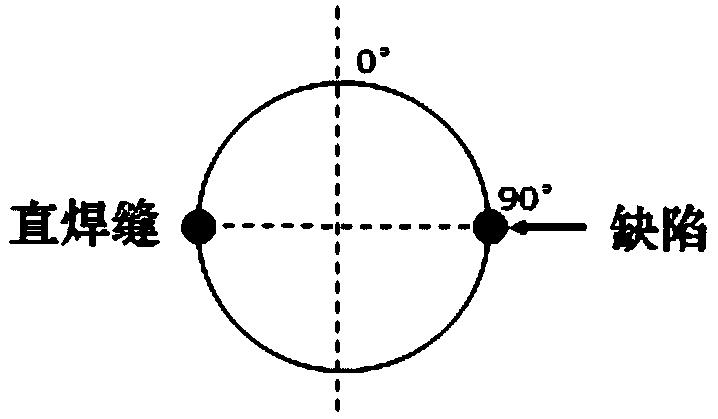

Full-scale testing method for pressure bearing capacity and ductile-brittle transition behaviors of gas transmission steel pipe at low temperature

ActiveCN109163978ALarge heat capacityCompressibleMaterial strength using tensile/compressive forcesInvestigating phase/state changeCrack mouthRebar

The invention discloses a full-scale testing method for pressure bearing capacity and ductile-brittle transition behaviors of a gas transmission steel pipe at low temperature. The method comprises thefollowing steps: a defect is preformed in the surface of a test steel pipe, plugs are welded at two ends of the steel pipe, and the pressure bearing capacity of the defective steel pipe at low temperature is tested; the steel pipe is placed in a pipe trench, and the plugs at two ends of the steel pipe are anchored by reinforced concrete for constructing a test pipeline; measuring devices such asa strain gauge, a clip gauge and a surface temperature sensor are mounted on the steel pipe; low temperature control of the whole test steel pipe is realized by filling the body of the test steel pipewith liquid nitrogen and an alcohol cooling liquid; after the test steel pipe is filled with the low-temperature liquid, bursting pressure is reached by injecting nitrogen, and a fracture resistancecurve and ductile-brittle transition temperature of the steel pipe are analyzed and determined by acquiring information of pipe internal pressure, pipe body wall temperature, pipe body strain, openingamount of crack mouth at a preformed crack and video data. The method is economical, simple, easy to operate and safer, and can realize precise temperature control.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

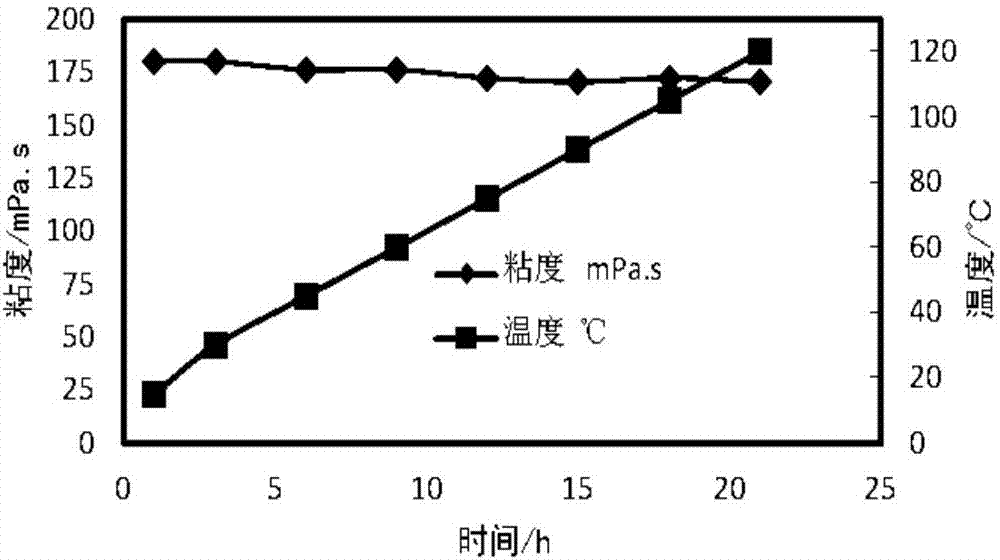

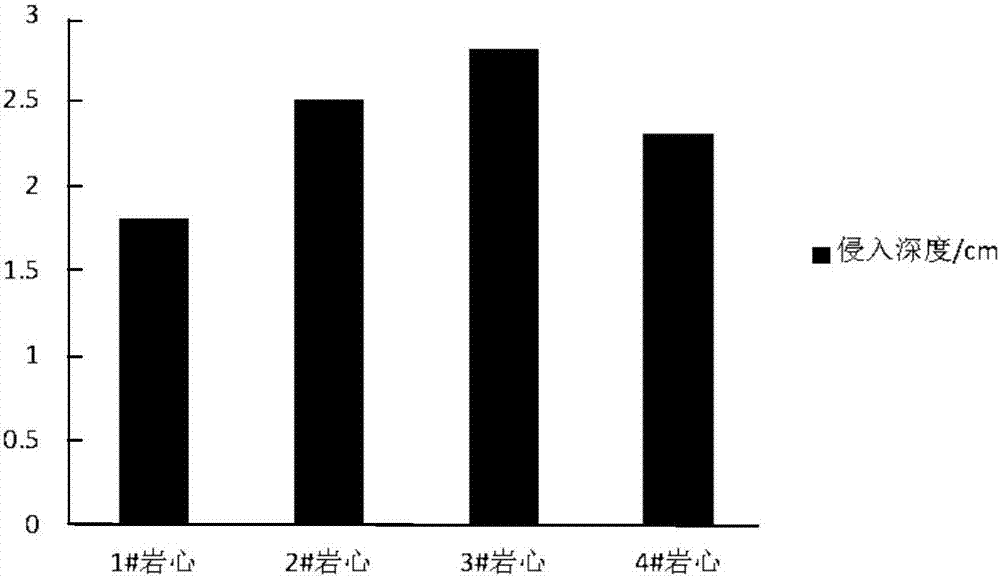

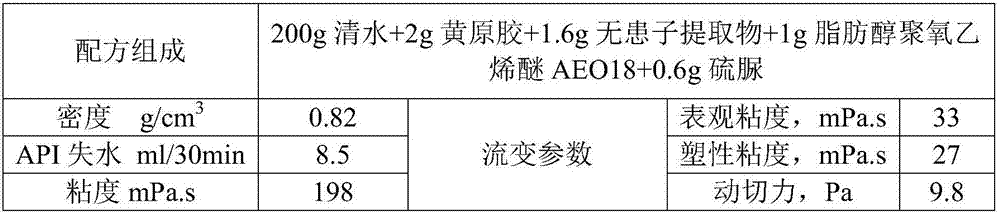

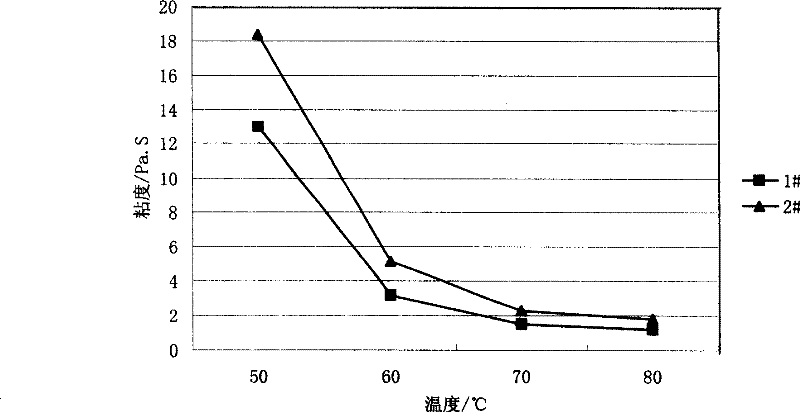

Microbubble workover fluid and preparation method thereof

The invention relates to a microbubble workover fluid and a preparation method thereof and belongs to the field of workover treatment of petroleum and gas. The microbubble workover fluid provided by the invention is composed of the following components in parts by mass: 90-200 parts of water, 0.2-1.6 parts of soapberry extract, 0.1-1 part of fatty alcohol-polyoxyethylene ether AEO, 0.5-2 parts of xanthan gum and 0.3-0.8 part of thiourea. The microbubble workover fluid provided by the invention is high in viscosity, good in foam stability, high in oil resistance, high in capacity of resisting degree of mineralization and suitable for gas condensate-containing natural gas wells with high degree of mineralization and low pressure. The microbubble workover fluid provided by the invention is non-toxic and easy to degrade, and does not pollute the environment.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

Cutting device for automobile window glass

ActiveCN106927668AAchieve fixationPrevent floatingGlass severing apparatusMagnetic polesConveyor belt

The invention belongs to the technical field of automobile part machining, and discloses a cutting device for automobile window glass. The cutting device comprises a rack. A workbench is arranged at the bottom of the rack. A cutter is in sliding connection with the top of the rack. Two parallel conveyor belts at different conveying speeds are arranged on the workbench. The conveyor belts are arranged side by side and make contact with each other. Shaping frames are arranged at the portions, on the two sides of the conveyor belts, of the workbench. Air bags are arranged inside the shaping frames. Inflation pipes are connected to the air bags. The inflation pipes penetrate through the shaping frames. The air bags are the same as the shaping frames in height, the shaping frames are 2-3 cm lower than the conveyor belts, magnets are arranged on the upper surfaces of the air bags, the thickness of the magnets is 2-3 cm, electromagnets are arranged above the air bags, a power source is connected to the electromagnets, and the direction of a magnetic field of the electromagnets is opposite to the magnetic pole direction on the upper surfaces of the magnets. The problems that in the prior art, only glass of the same thickness can be cut, and the glass is fragile during cutting are solved.

Owner:CHONGQING TIANYUN AUTO PARTS

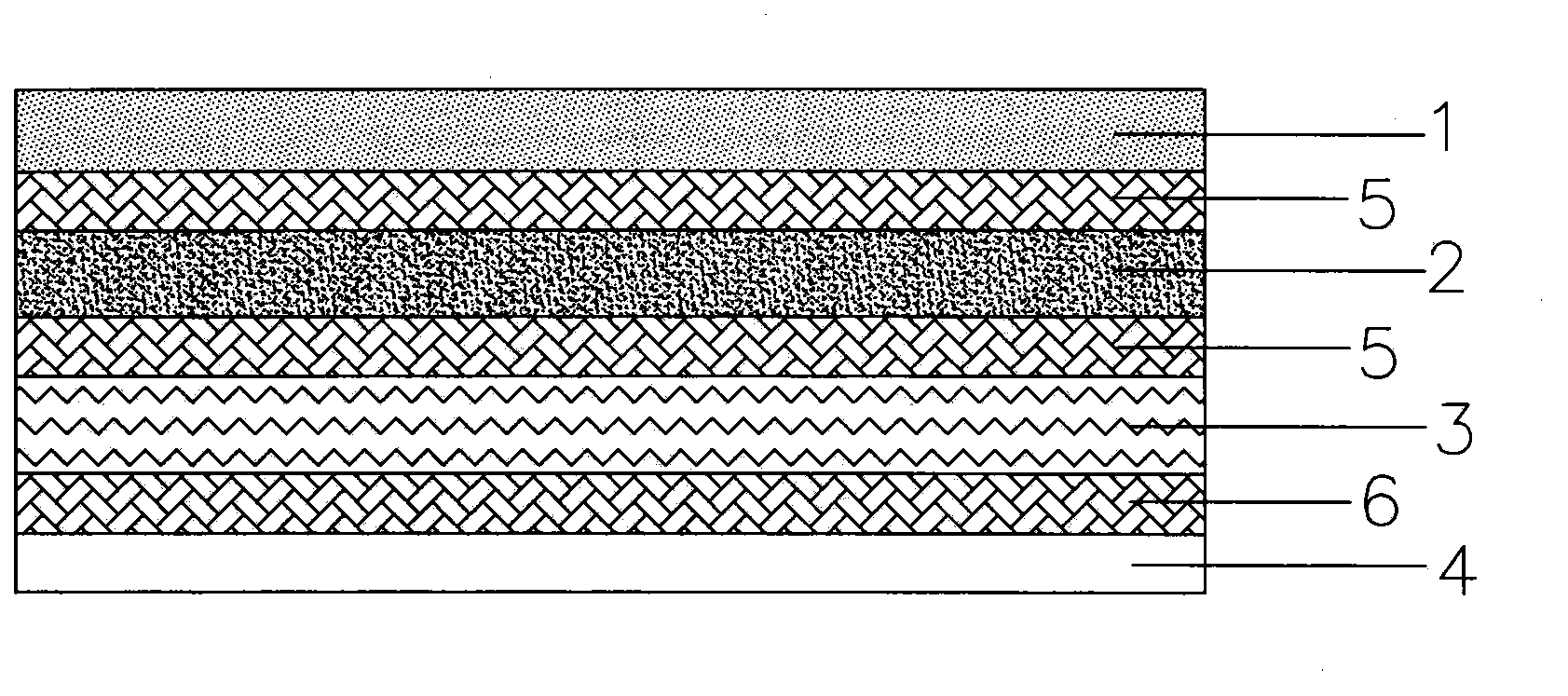

Graphite aluminum foil heat-conducting material

InactiveCN103781329AImprove cooling effectWith high and low temperature resistanceCooling/ventilation/heating modificationsMetal layered productsHeat conductingGraphite

The invention discloses a graphite aluminum foil heat-conducting material which is successively composed of a black matt base material layer, a graphite base material layer, an aluminum foil base material layer, and a PET release film. One surface of the black matt base material layer is bonded with one surface of the graphite base material layer by using an adhesive material layer. The other surface of the graphite base material layer is bonded with one surface of the aluminum foil base material layer by using an adhesive material layer. The other surface of the aluminum foil base material layer is bonded with one surface of the PET release film by using an insulating adhesive layer. The black matt base material layer, the graphite base material layer, the aluminum foil base material layer, and the PET release film are successively and mutually bonded together to form the graphite aluminum foil composite diaphragm material. According to characteristics of the black matt base material layer, the graphite base material layer, the aluminum foil base material layer, and the PET release film and effects obtained in a plurality of experiments, the graphite aluminum foil heat-conducting material has the advantages of light weight, a good heat-dissipating effect, and excellent performance such as high and low temperature resistance, corrosion resistance, non-ageing performance, self-lubricating performance, compressibility, rebound resilience and sealing performance.

Owner:QIHUA OPTRONICSKUNSHAN CO LTD

Hydraulic pipeline cleaning method

InactiveCN107639085AReduce string washing timeReduce cleaning costsHollow article cleaningEngineeringCleaning methods

The invention relates to a hydraulic pipeline cleaning method. The method mainly comprises the following steps of shooting sponge bullets, wherein a cleaning blower gun shoots the sponge bullets intoa hydraulic pipeline with the help of high-pressure blast at high speed; intermingling and cleaning, wherein oil the same as the oiliness of oil at work is selected, and the oil is poured into the hydraulic pipeline to be intermingled and cleaned; testing pressure, wherein a safety threshold valve of a system is adjusted to a selected pressure testing value to supply oil to the system, when pressure is tested, grading pressure test is normally adopted, when a grade is added, inspection is carried out once, and a prescribed pressure testing value is achieved by grading step by step; flushing, wherein a flushing loop is determined, and a recycle flushing method is adopted to flush the hydraulic pipeline continuously. The hydraulic pipeline cleaning method has the advantages that the hydraulic pipeline shoots the sponge bullets in a workshop to replace workshop intermingling and cleaning work, part of pipeline inner wall dirt is removed in advance, therefore, the pipeline intermingling and cleaning time is shortened, the overall efficiency is improved, the intermingling and cleaning period is shortened, and the cleaning cost of the hydraulic pipeline workshop is effectively reduced.

Owner:NVISION ELECTRICAL APPLIANCE

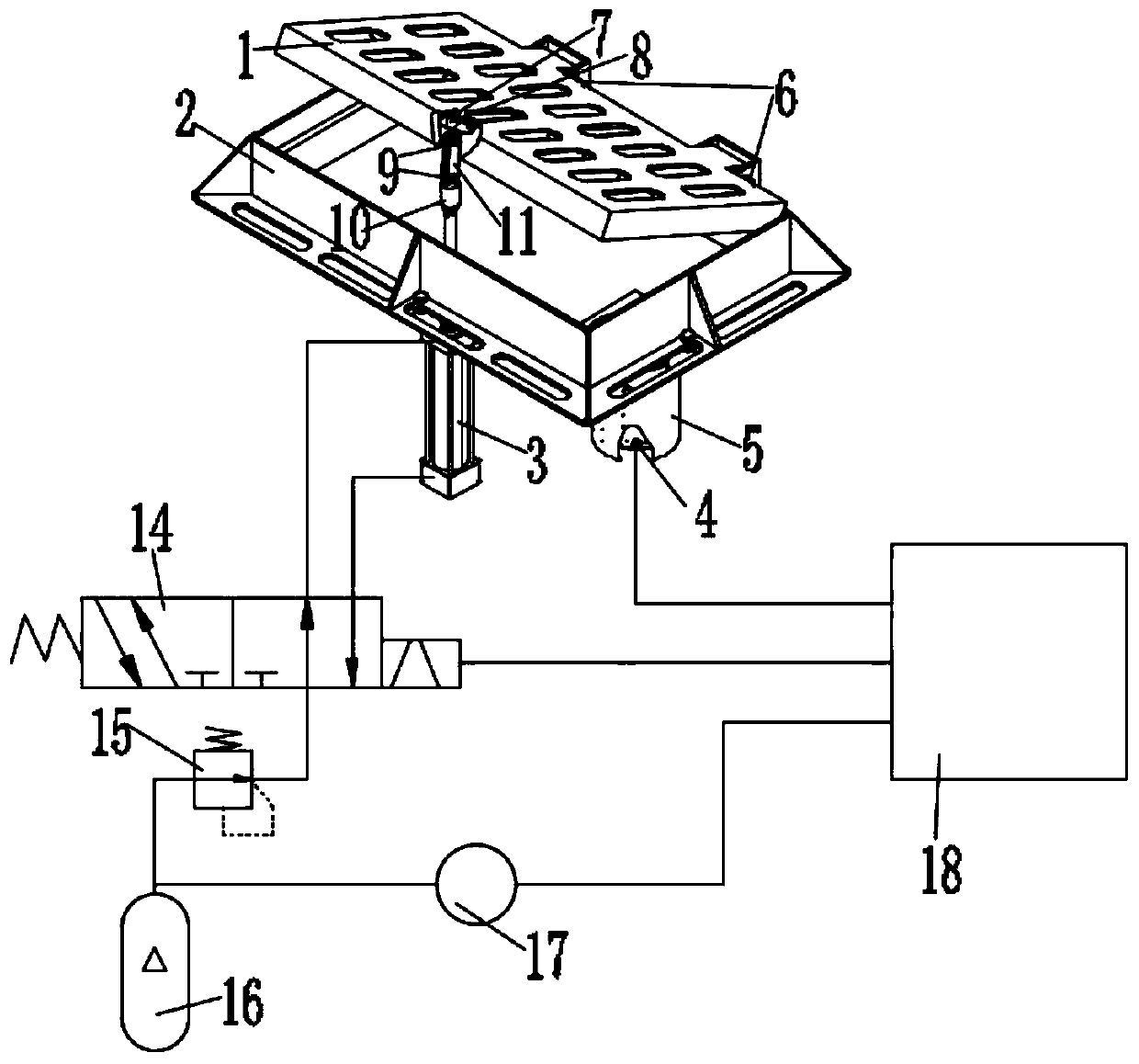

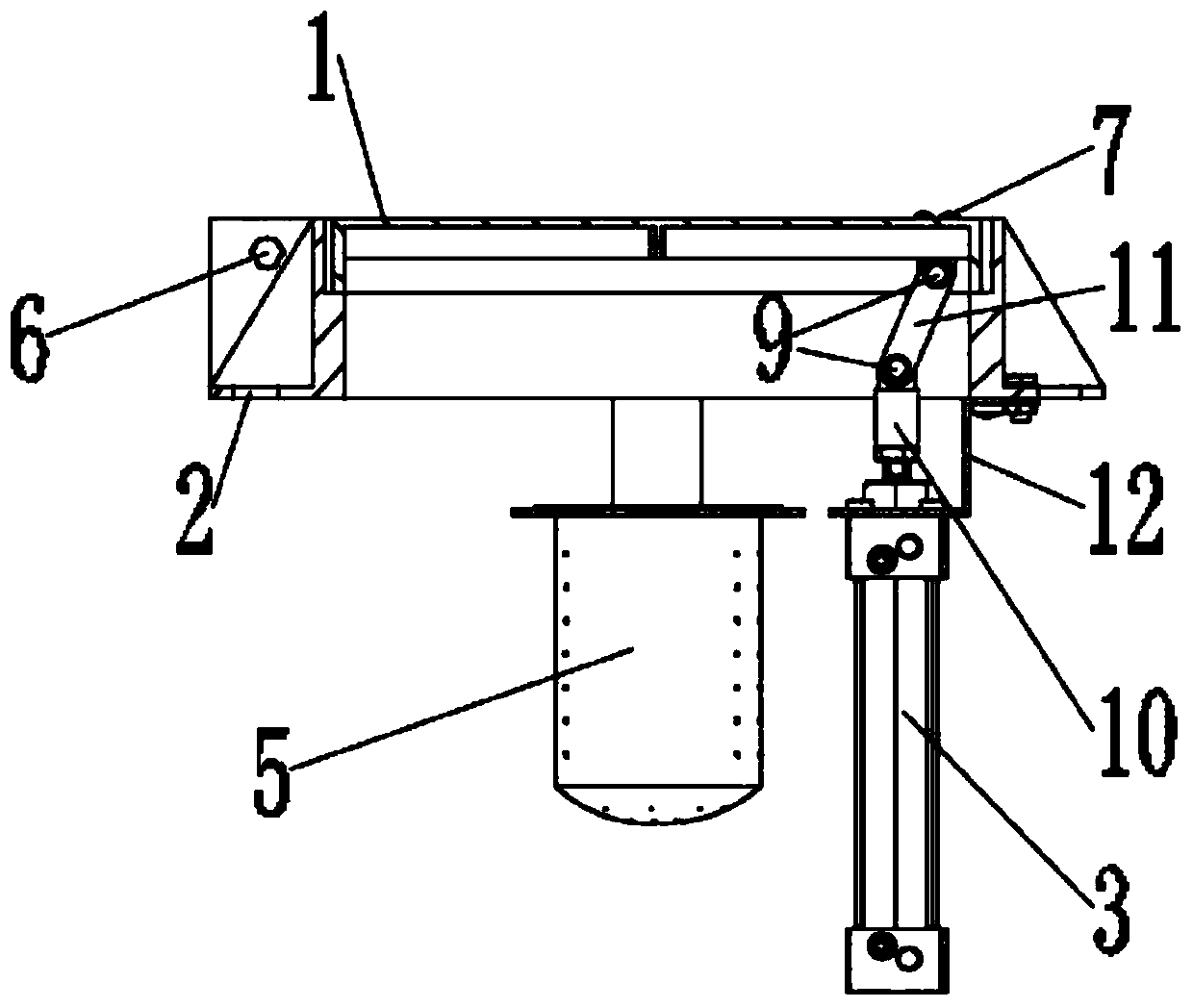

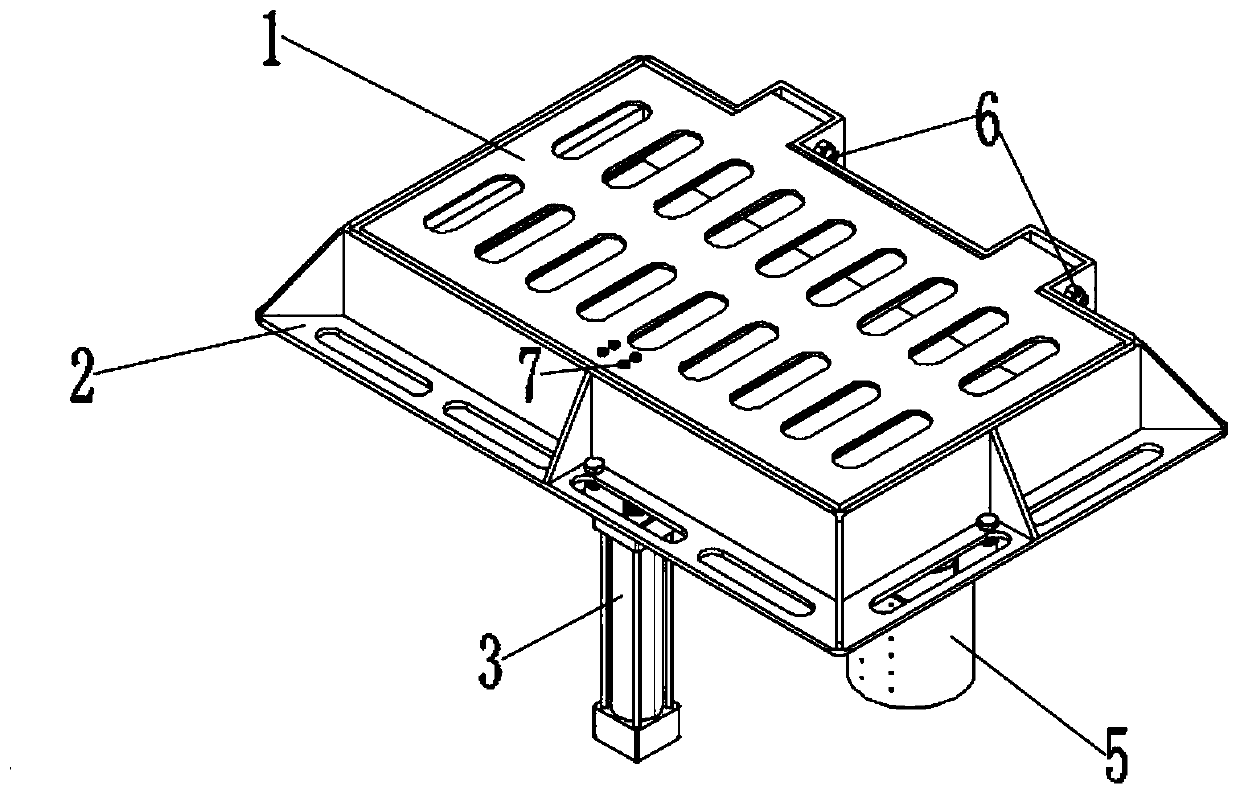

Automatic drainage grate and method

The invention provides an automatic drainage grate and method. The automatic drainage grate comprises a grate body, a grate base, a jacking mechanism and a control mechanism, wherein the grate body and the grate base are connected in a turnover manner through a grate hinge pin; the jacking mechanism is arranged on the other side, relative to the grate body, of the grate hinge pin, the control mechanism is electrically connected with the jacking mechanism, the jacking mechanism is used for controlling the grate body to bounce or fall at a certain angle according to the instruction of the control mechanism, the jacking mechanism further has compressibility, and the jacking mechanism is automatically pressed down and bounced according to external pressure; and the control mechanism comprisesa rainfall detection device, and the control mechanism automatically controls opening and closing of the jacking mechanism according to the rainwater water flow pressure transmitted through the rainfall detection device. The grate can be automatically controlled, time and labor are saved, and the risk of overall cover opening is reduced; and due to the fact that the grate body is fixed, the risk that the grate body is lost is reduced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

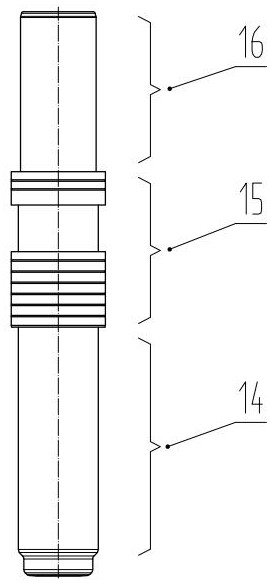

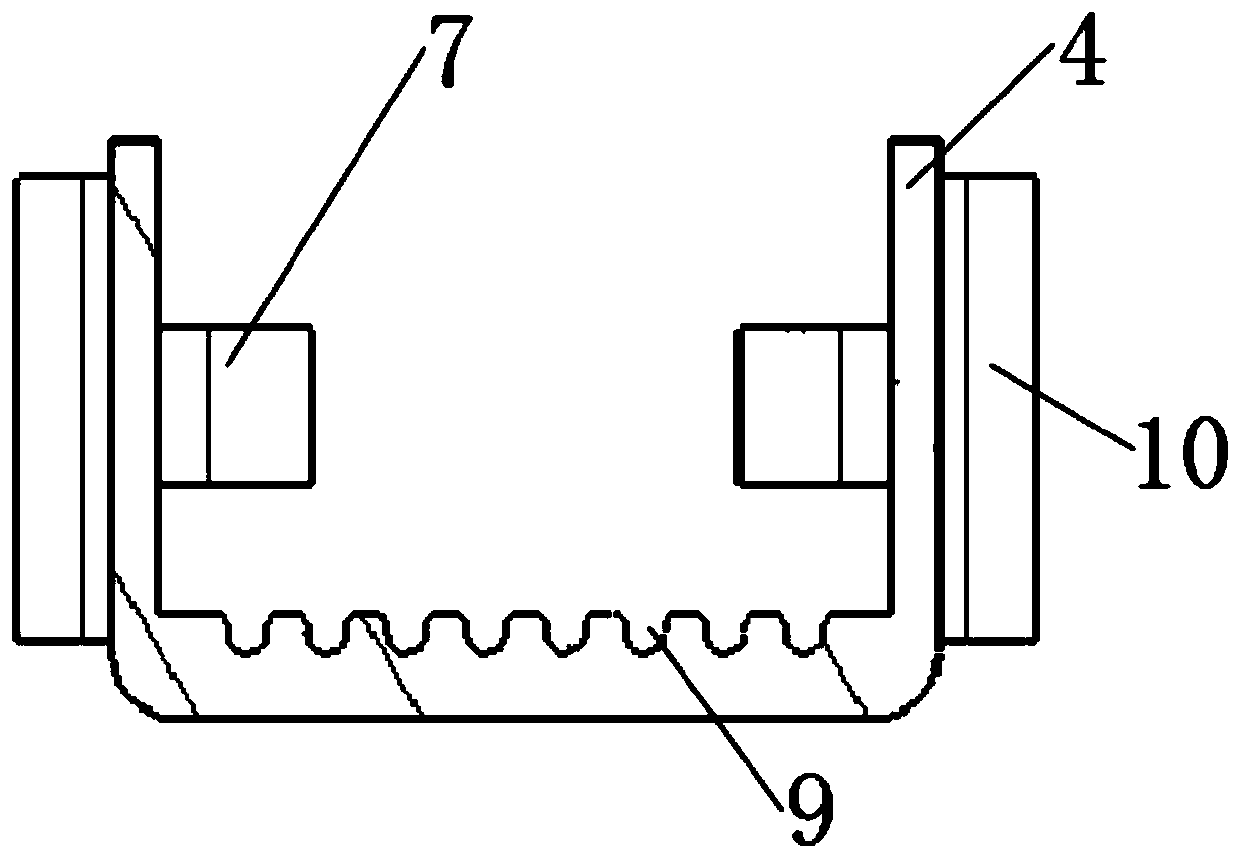

Hydraulic mandrel for grinding end surfaces of slender pipe fittings

InactiveCN102528656ACompressibleLiquidGrinding work supportsPlane surface grinding machinesPipe fittingFree state

Disclosed is a hydraulic mandrel for grinding end surfaces of slender pipe fittings. An elastic sleeve is sleeved on the outside of a mandrel, semi-solid media are filled between the elastic sleeve and the mandrel, a plug is disposed at the outer end of the elastic sleeve, a plunger is connected with the mandrel by a screw, and a screw-plug is further mounted on the plunger. The plunger is a thin-walled part made of non-metal abrasion-resistant materials. An outer circle of the elastic sleeve and center holes of two ends of the mandrel are coaxial when in a free state. The characteristic that a semi-solid body has compressibility and fluidity under the effect of external force and can uniformly transmit the external force is utilized, the thin-walled part can plastically deform under certain external force to clamp a workpiece, a workpiece clamping range is large, the workpiece is clamped reliably, machining quality can be effectively guaranteed, the quantity of tools is reduced, machining cost is lowered, and the service lives of the tools are prolonged.

Owner:CSIC ZHONGNAN EQUIP

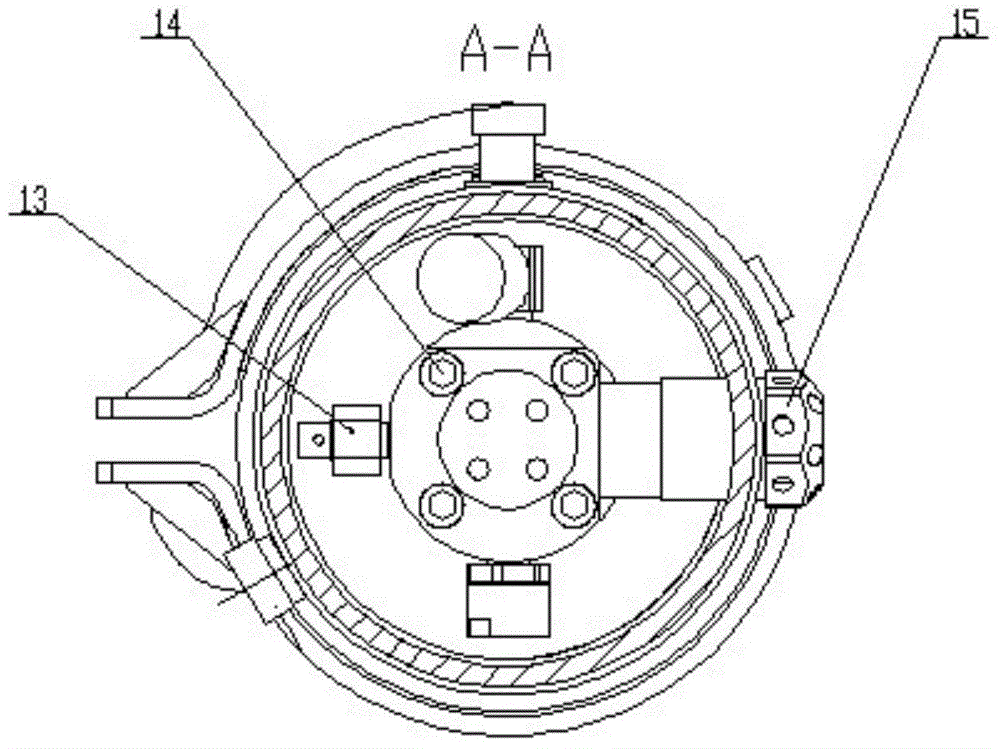

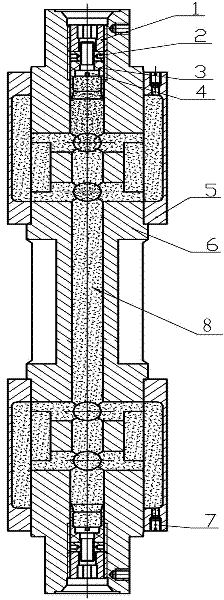

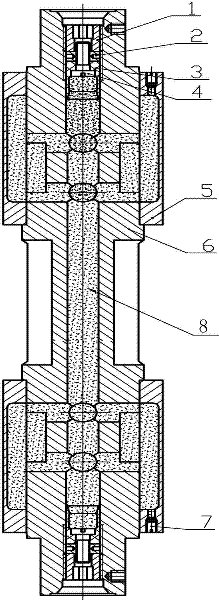

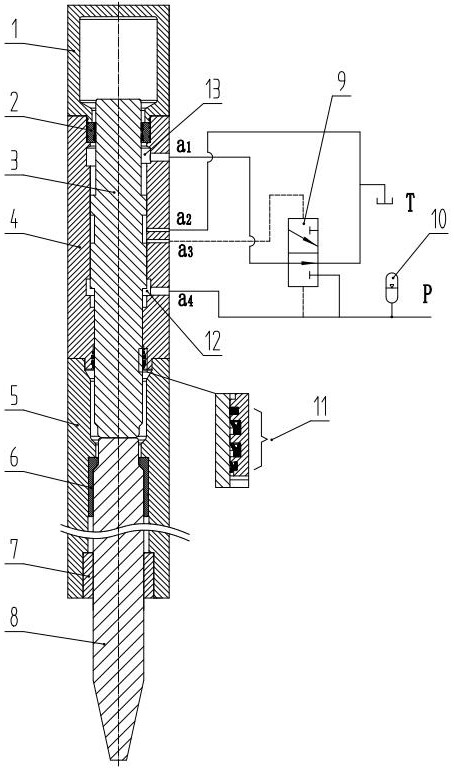

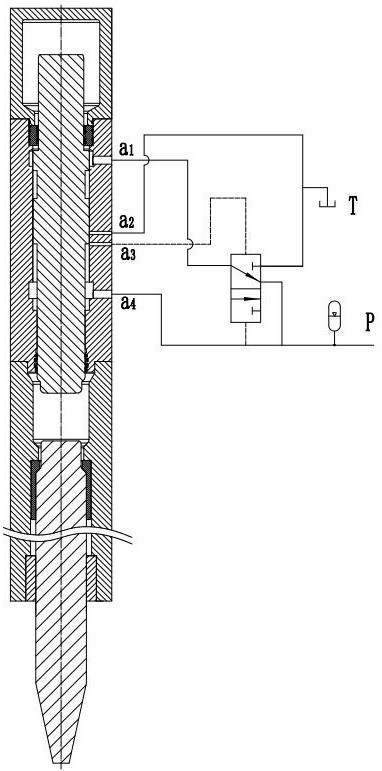

Static pressure suspension piston type hydraulic breaking hammer

PendingCN114687402AAvoid intensityReduce processing stepsSoil-shifting machines/dredgersReciprocating motionClassical mechanics

The invention discloses a static pressure suspension piston type hydraulic breaking hammer which comprises a piston, a cylinder body, a drill rod seat, an inner sleeve, an outer sleeve and a drill rod. The piston reciprocates in the cylinder body to strike the drill rod; a drill rod for crushing rocks, an inner sleeve and an outer sleeve are arranged in the drill rod seat, wherein the inner sleeve and the outer sleeve play a guiding role, and meanwhile the inner sleeve and the outer sleeve have the effect of protecting the drill rod seat from being abraded. More than or equal to two circles are arranged in the area where the cylinder body is matched with the head of the piston, and more than two static pressure suspension cavities are evenly distributed in each circle and used for supporting the piston. The piston floats in the cylinder body through the static pressure suspension bearing, it is guaranteed that the matching faces of the piston and the cylinder body are separated by hydraulic oil when the piston is under a certain load and at any speed, and contact and strain are avoided.

Owner:赵德朝

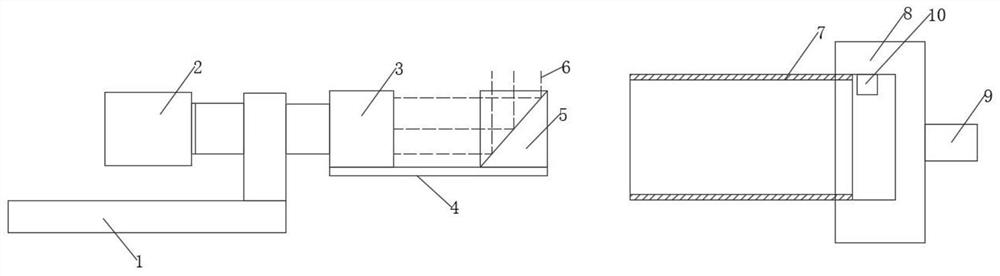

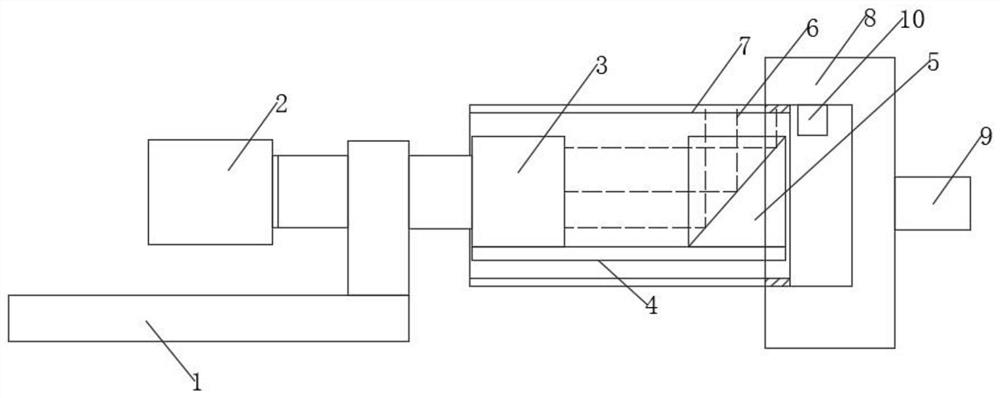

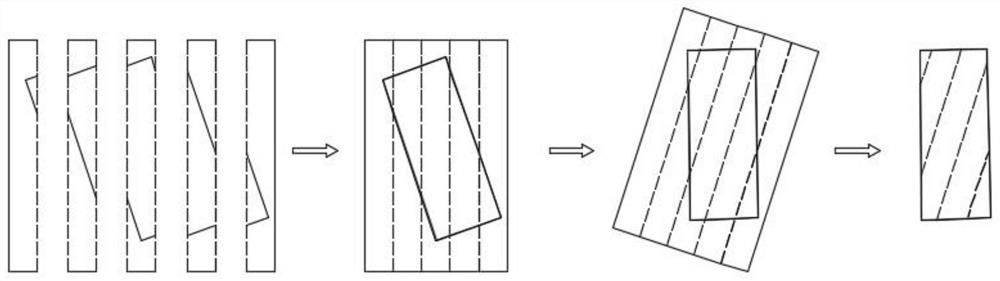

Inner diameter spiral scanning defect detection device

PendingCN112858306AStrong anti-skidStrong protectionOptically investigating flaws/contaminationSpiral scanningMetal cylinder

The invention discloses an inner diameter spiral scanning defect detection device, and the device comprises a camera capable of linearly moving and a clamping mechanism capable of rotating around a circle; a low-angle strip-shaped light source is used for supplementing a light source to the inner wall of a detected metal cylinder, low-angle light supplementing is used, so the camera is in a bright field, the defect is clearer, a light source irradiates on the inner wall of the metal cylinder to be detected and is received by the reflecting prism, light received by the reflecting prism is reflected to the telecentric lens, the telecentric lens realizes a low-distortion image, defect reduction is realized more accurately, the telecentric lens restores the image to the camera, so as to detect the inner diameter defects of a detected metal cylinder; the first driving unit is combined with the second driving unit to achieve spiral scanning of the detected metal cylinder; in the device, spiral rapid detection is achieved in a two-axis linkage mode, scanned irregular images are spliced through rear-end image processing, the rigidity change of the images is performed, and a cylindrical surface complete graph is extracted.

Owner:HEFEI JUNDA HI TECH INFORMATION TECH

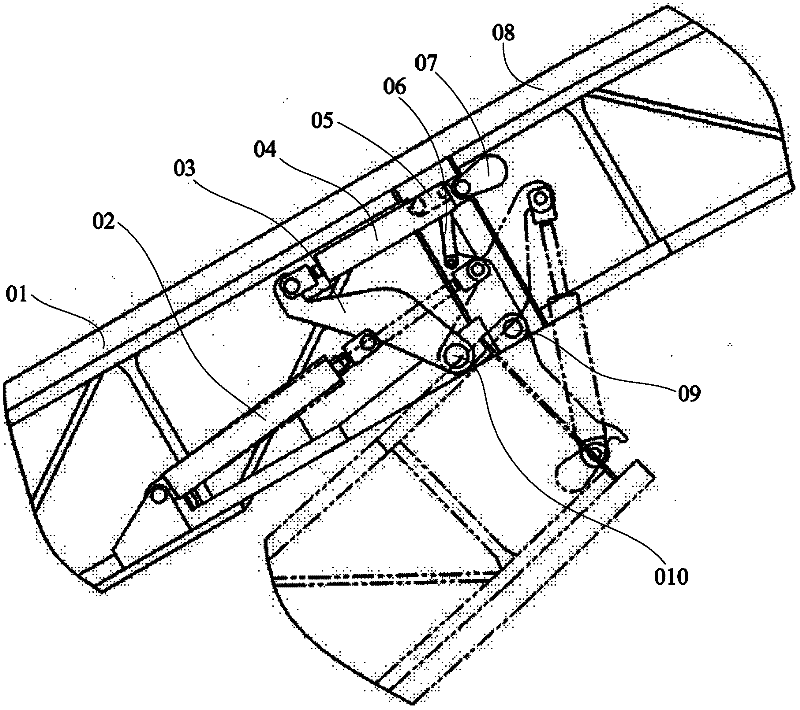

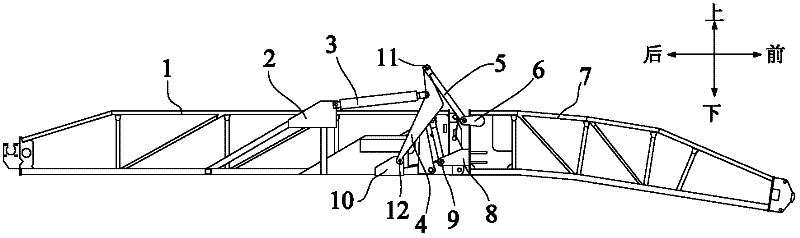

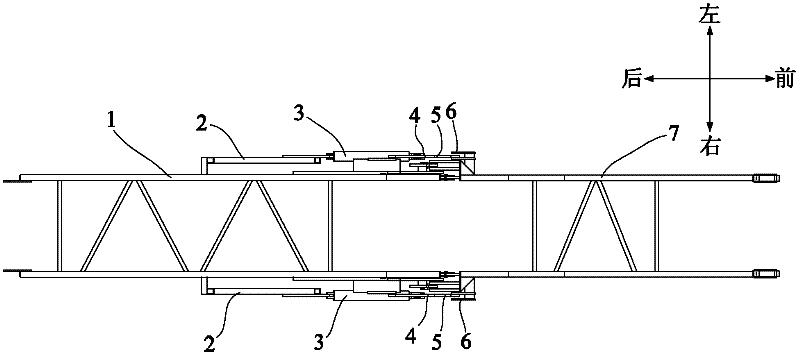

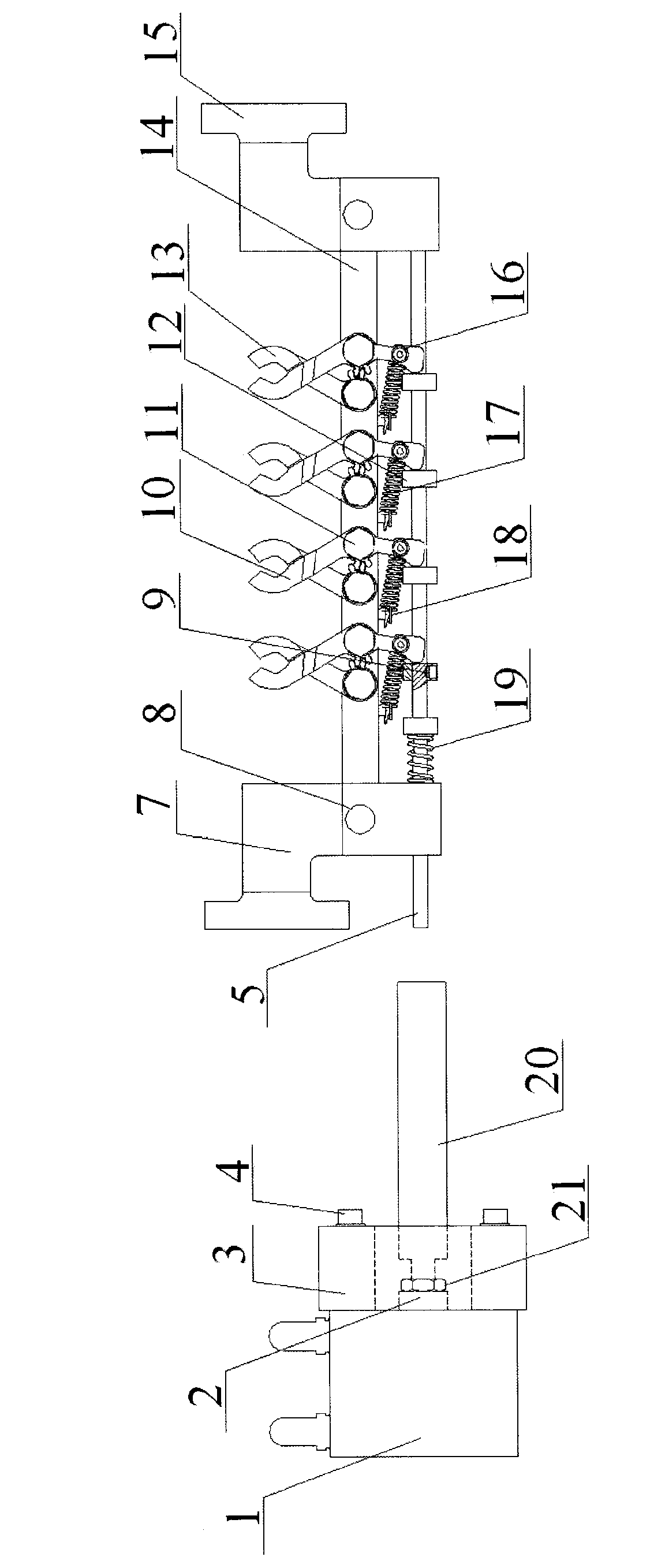

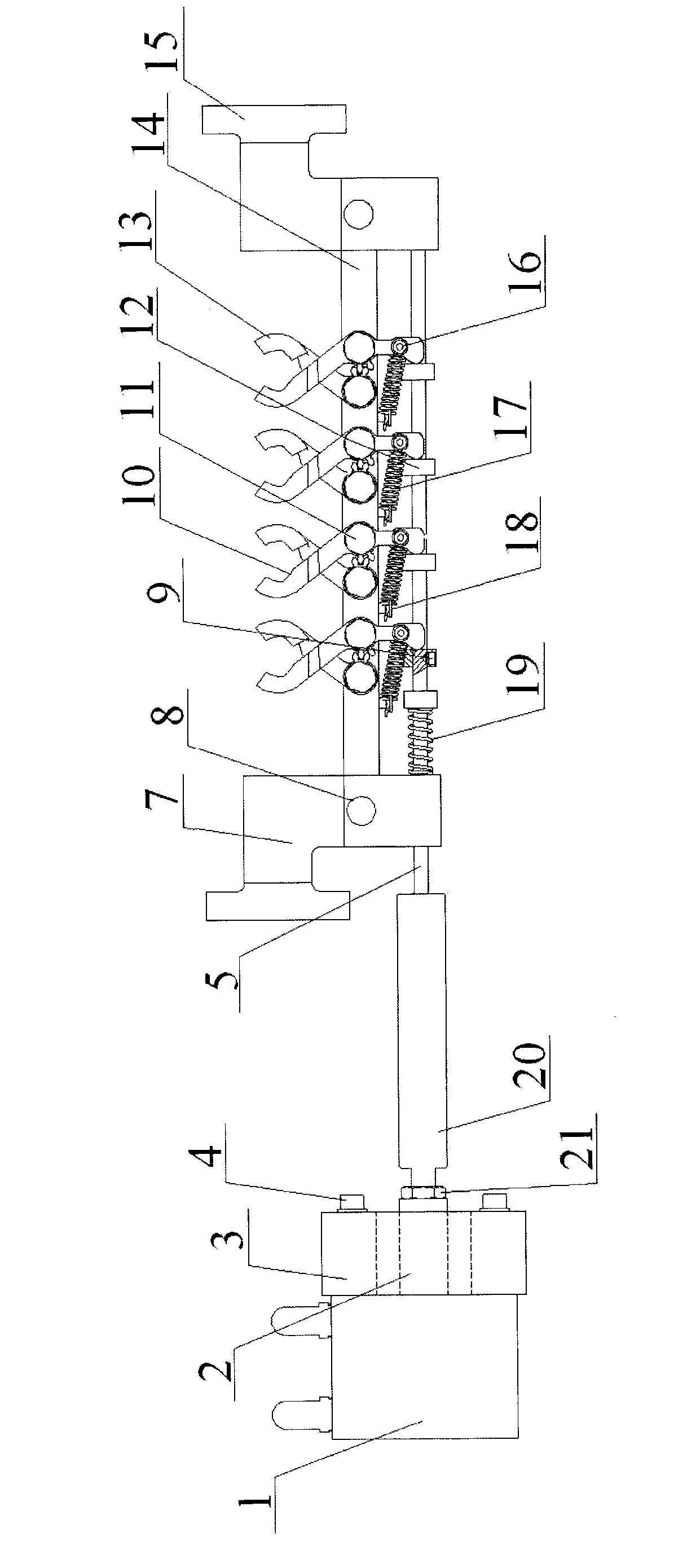

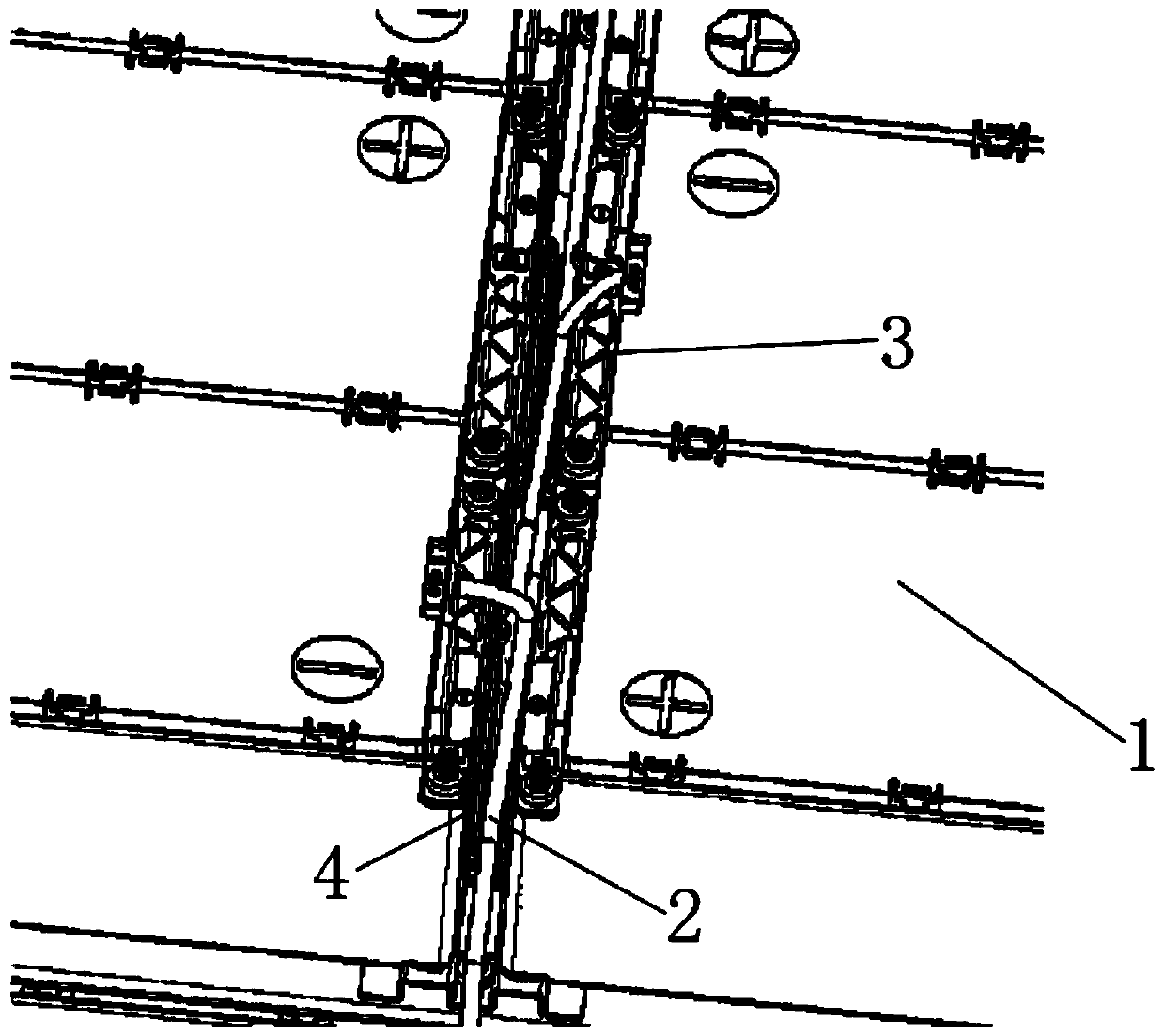

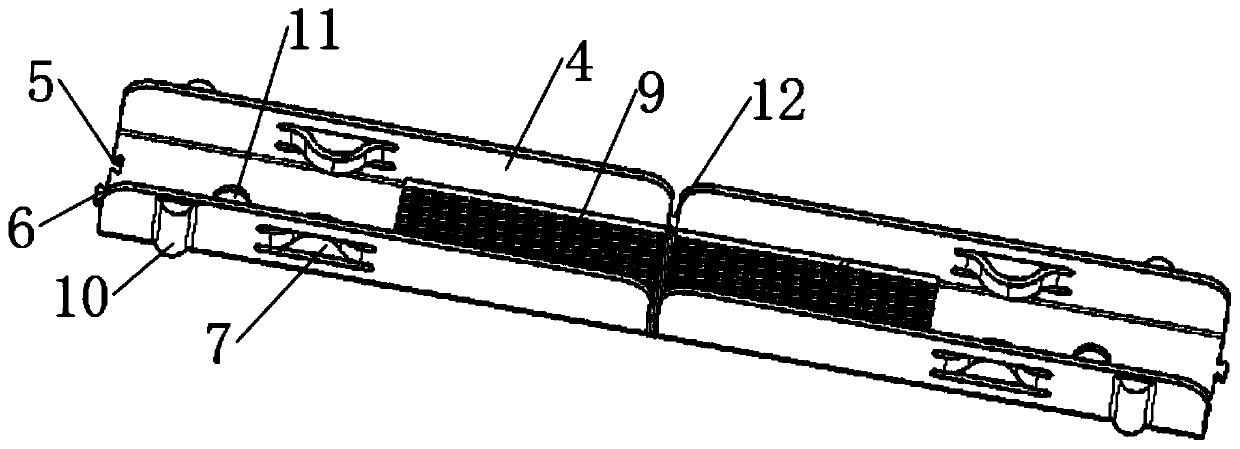

Folding system for secondary transfer machine of milling machine and milling machine

ActiveCN102518031AReduce in quantityReduce failureConveyorsRoads maintainenceControl systemAgricultural engineering

The invention provides a folding system for a secondary transfer machine of a milling machine. The folding system comprises a folding execution system and a folding hydraulic control system, wherein the folding execution system comprises a fixed arm and a foldable arm hinged with the fixed arm, and further comprises a connection plate, a pull rod and two driving oil cylinders, wherein the connection plate is eudipleural to the middle line of the fixed arm; the lower end of the connection plate is hinged to the lower part of the fixed arm; the upper end of the connection plate is hinged to the upper end of the pull rod; the lower end of the pull rod is hinged to the upper end of the foldable arm; the rear end of each driving oil cylinder is hinged to the upper part of the fixed arm; the front end of the driving oil cylinder is hinged to the connection plate; and the driving oil cylinders drive the foldable arm to be folded through the connection plate and the pull rod. According to the invention, the quantity of oil cylinders and the cost are reduced, and the genealogical reliability is improved. The folding hydraulic control system drives the oil cylinders to lock each other through a hydraulic lock and a flow distributing and collecting valve; and the speeds of the oil cylinders are synchronous through the flow distributing and collecting valve, so as to prevent the transfer machine from inclining laterally. The invention further provides the milling machine comprising the folding system for the secondary transfer machine.

Owner:SANY HEAVY IND CO LTD (CN)

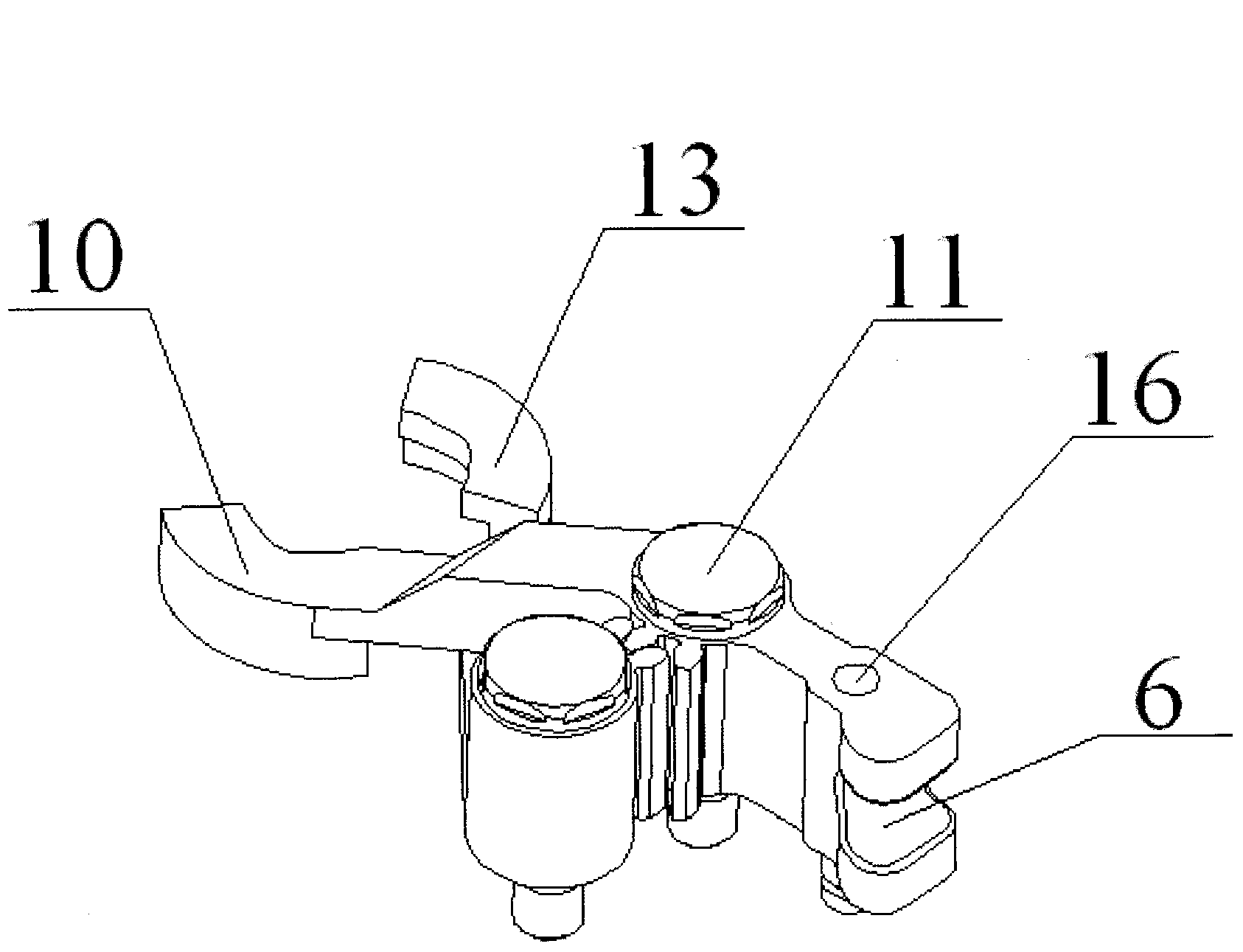

Bottle clamp mechanism

The invention discloses a bottle clamp mechanism which is characterized by comprising a cylinder. The cylinder is arranged on a cylinder fixing base, a cylinder piston rod on the cylinder is connected with one end of a push rod, a bottle clamp driving shaft is arranged on one side of the other end of the push rod, the bottle clamp driving shaft penetrates through a tail through hole of a bottle clamp installation left fixed block and a tail through hole of a bottle clamp installation right fixed block, the bottle clamp installation left fixed block and the bottle clamp installation right fixed block are connected through a bottle clamp installation plate, the bottle clamp installation plate is connected with a primary bottle clamp and a secondary bottle clamp through bottle clamp rotating pins, teeth of the primary bottle clamp and teeth of the secondary bottle clamp are meshed with each other, and the tail of the primary bottle clamp is contacted with the bottle clamp driving shaft. The bottle clamp mechanism has the advantages of being simple in structure, stable to operate, adjustable in bottle clamp opening, capable of performing overload protection, wide in application range and the like.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Battery pack wire harness protecting and fixing assembly

PendingCN111355197AAvoid swingingCompressibleElectrical apparatusElectric/fluid circuitElectrical batteryBattery pack

The invention discloses a battery pack wire harness protecting and fixing assembly. The assembly comprises a battery pack and a battery pack wire harness, the battery pack is connected to an inner side of the box body cross beam through a bolt; protective fixing pieces are connected to the middle positions of the box body cross beam through bolts; a connecting groove is formed in one side of an end of each protective fixing piece, the protective fixing pieces are made of insulating materials, connecting grooves and clamping heads which are connected are designed at ends of the fixing pieces, and in the actual use process, the multiple protective fixing pieces can be connected in series for use due to different lengths and are fixed through push pin buckles; outer elastic pieces outside thefixing pieces are made of elastic materials such as a rear-mounted piece or double-shot molding TPU, has certain compression performance, can be clamped in a module gap, and can be suitable for assembly of different gap values by adjusting the size and the physical performance of the elastic pieces. The protective fixing pieces can protect wire harness from being rubbed and damaged, the trend ofthe wire harness is controlled, and the wire harness is prevented from being suspended in a narrow space.

Owner:江西优特汽车技术有限公司

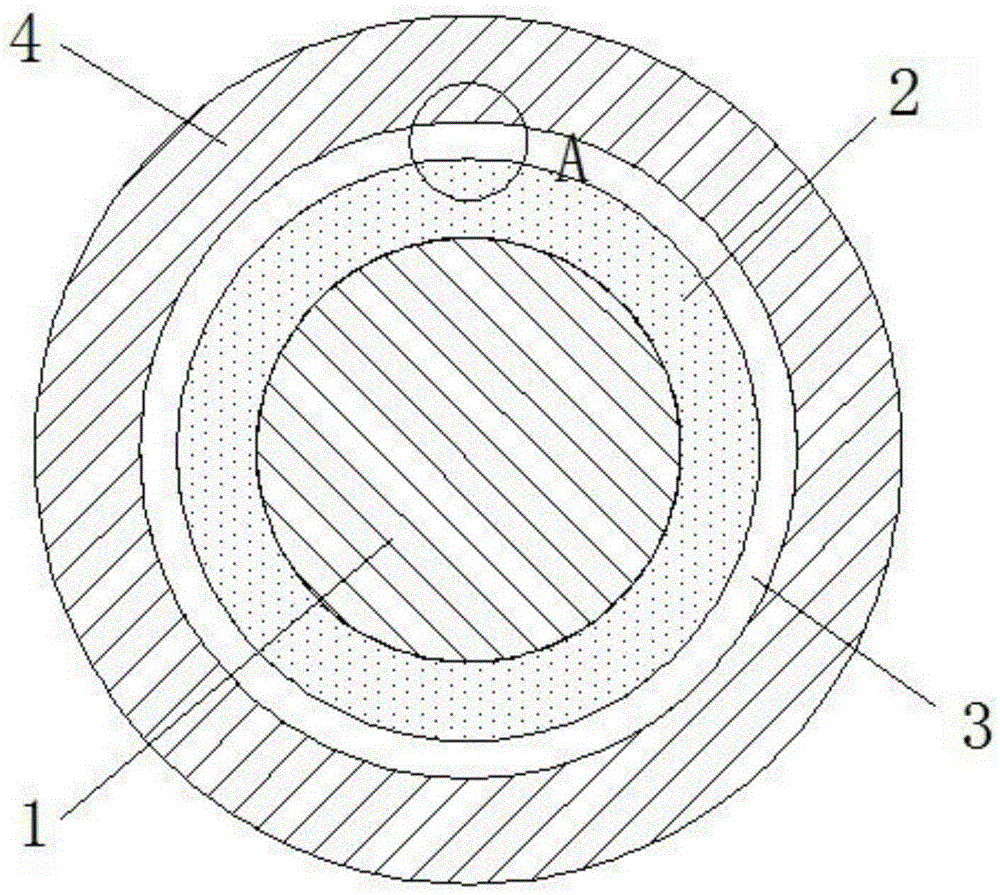

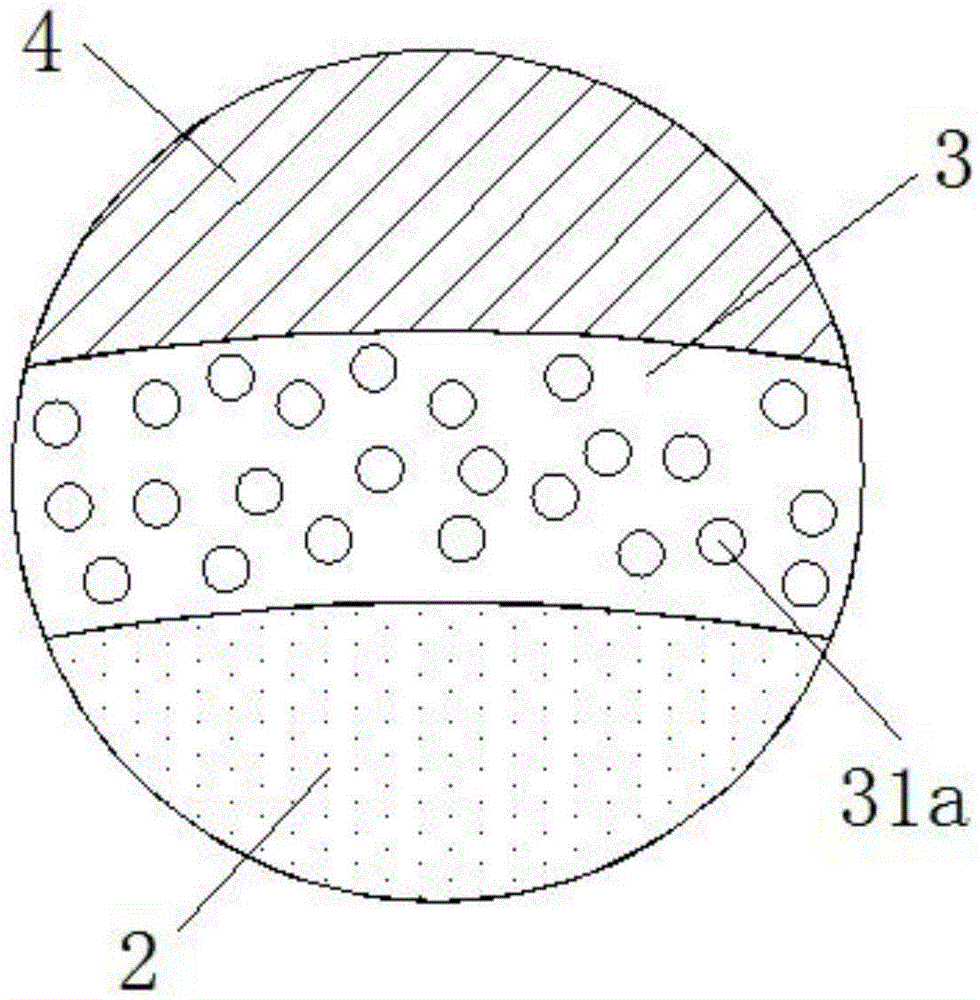

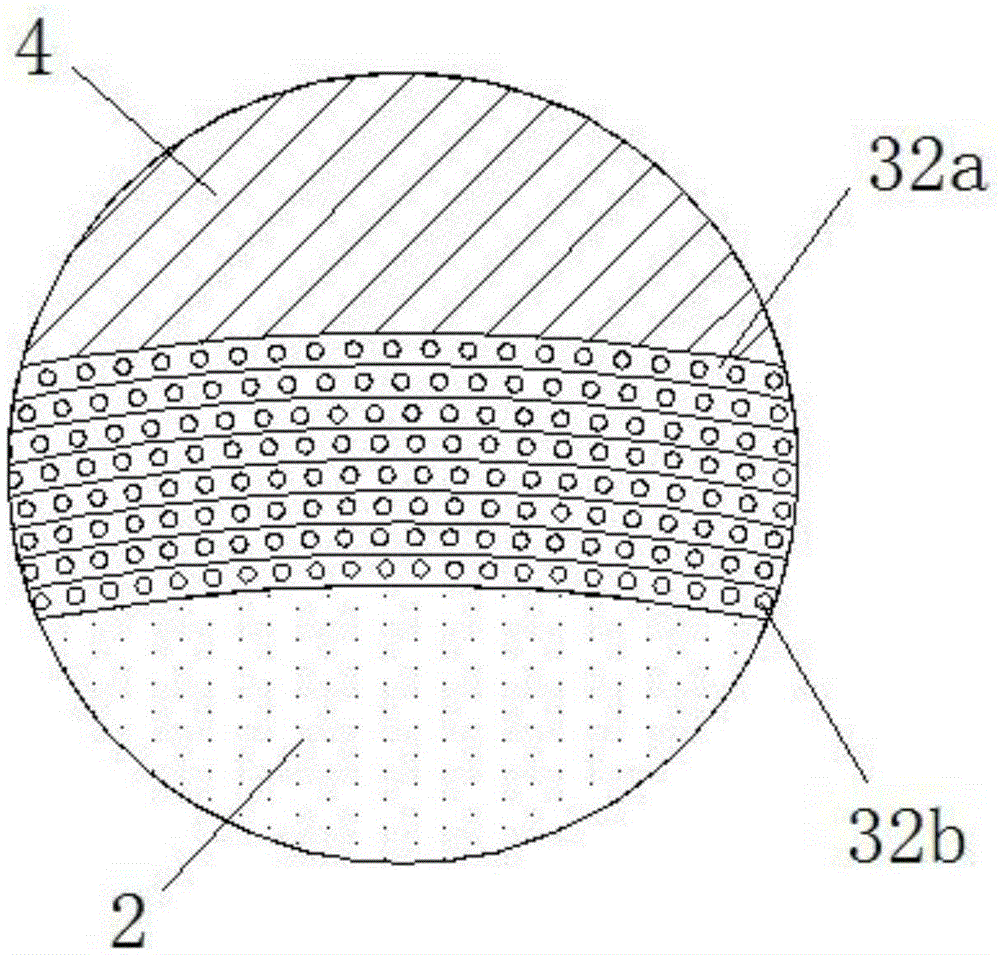

Cracking prevention semi-hard cable

ActiveCN105405521APrevent burstGuaranteed service lifeInsulated cablesInsulated conductorsElectrical conductorCoaxial cable

The invention belongs to the technical field of a coaxial cable and relates to a cracking prevention semi-hard cable. The cracking prevention semi-hard cable comprises an inner conductor, a dielectric layer and an outer conductor, wherein the dielectric layer wraps outside the inner conductor, the outer conductor wraps outside the dielectric layer, and a buffer layer is further arranged between the dielectric layer and the outer conductor and made of a continuous solid material with pores. The buffer layer of the cracking prevention semi-hard cable is provided with a buffer structure which can be used for preventing the outer conductor from bursting, and the service lifetime of the cable in an extreme working condition is guaranteed.

Owner:江苏安胜达航天科技股份有限公司

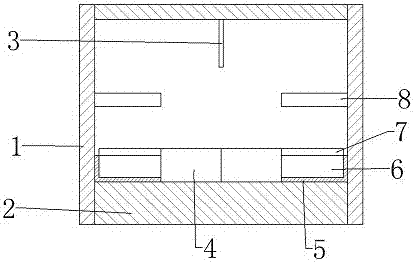

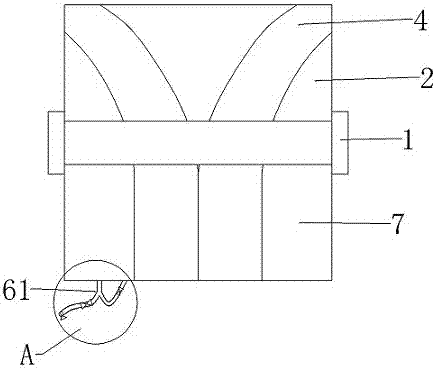

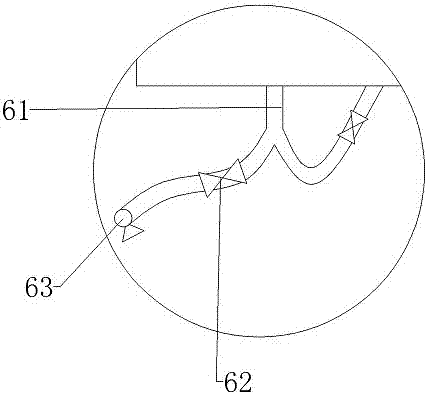

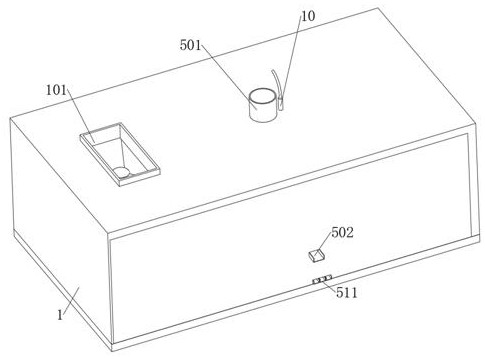

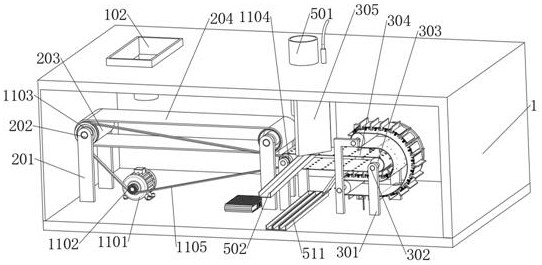

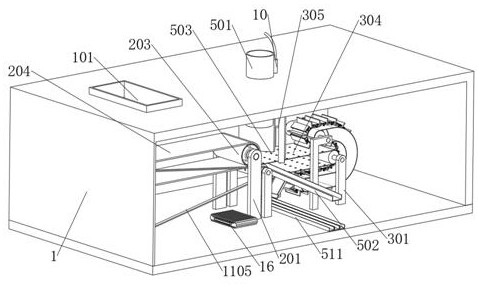

AI-based intelligent coal and gangue separation equipment

The invention discloses AI-based intelligent coal and gangue separation equipment, and relates to the technical field of coal production. The AI-based intelligent coal and gangue separation equipment comprises a box body, a feeding opening is formed in the top of the box body, a first conveying mechanism and a second conveying mechanism which are used for conveying coal and gangue are arranged in the box body, and the first conveying mechanism and the second conveying mechanism are both driven by a driving mechanism; a detection mechanism for detecting the compressibility of the coal and the gangue and a separation mechanism for separating the coal and the gangue are arranged in the box body; and the detection mechanism comprises two L-shaped plates which are fixedly connected to the lower side wall of the box body and are symmetrically arranged. According to the AI-based intelligent coal gangue separation equipment, continuous intelligent separation of the coal and the gangue can be achieved, the separation efficiency and effect are improved, in the separation process, grade separation can be conducted on the coal according to the coalification degree of the coal, and the value of the coal is improved.

Owner:深圳市时维智能装备有限公司

Full-section closed-type deep-shallow coupling yielding anchoring and grouting support method for broken soft rock roadway

InactiveCN105178981BImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningStructure of the EarthCoupling

The invention relates to a full-section closed-type deep-shallow coupling yield pressure anchor grouting support method for broken soft rock roadway. The pressure-reinforced arch, the full-section closed grouting reinforcement ring and the deep grout diffusion reinforcement arch, the suspension effect of the high-strength grouting anchor cable will combine the four to form a multi-level effective composite arch, which will support the pressure, anchor and grouting The organic combination of the advantages of deep-shallow coupling support has significantly improved the bearing range, integrity and bearing capacity of the support structure. The deformation characteristics such as pressure around the rock and obvious bottom drum have outstanding control effects, and can effectively control various deformations of the surrounding rock of the broken soft rock roadway. It is especially suitable for deep mine large-section broken soft rock roadways. The cost is low, and it has high on-site promotion and application value.

Owner:CHINA UNIV OF MINING & TECH

Improved carbonaceous mud for patching blast furnace hearth

The invention relates to an improved carbonaceous mud that is used for repairing a blast furnace hearth, which comprises anthracite culm, graphite powder, electrode powder and coal tar. According to weight percentage, the carbonaceous mud comprises 25 percent to 28 percent of the anthracite culm, 5 percent to 8 percent of the graphite powder, 13 percent to 23 percent of the electrode powder, and the residue is the coal tar. The carbonaceous mud has indentation property, on the premise of no destruction to the liner refractory structure of the side wall of the furnace hearth, the indentation material can be pressed and sent to the furnace smoothly by using certain pressure, and the indentation rate of the carbonaceous mud at the side wall of the furnace hearth and the iron notch can reach 100 percent. The carbonaceous mud can be pressed-in smoothly whether the liner seam is small or big.

Owner:上海盛江特种耐火材料有限公司 +1

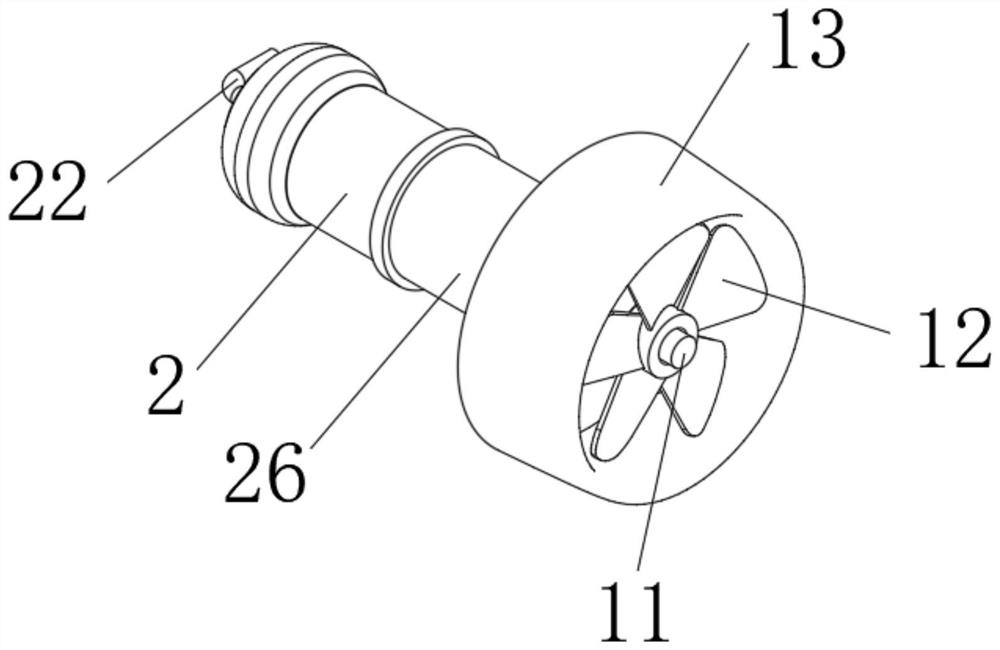

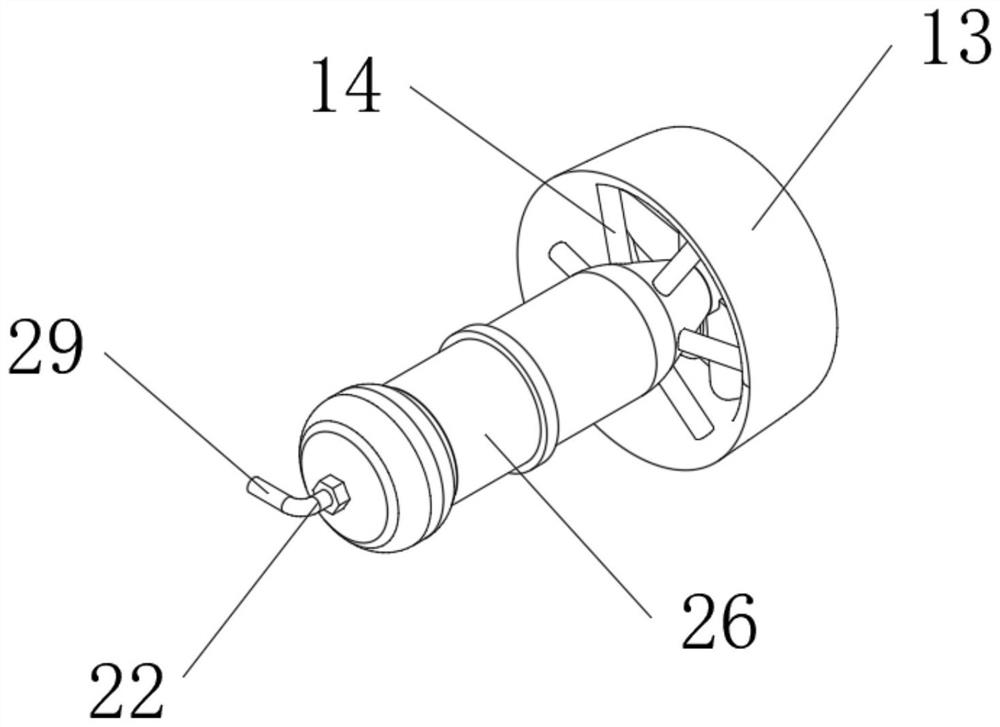

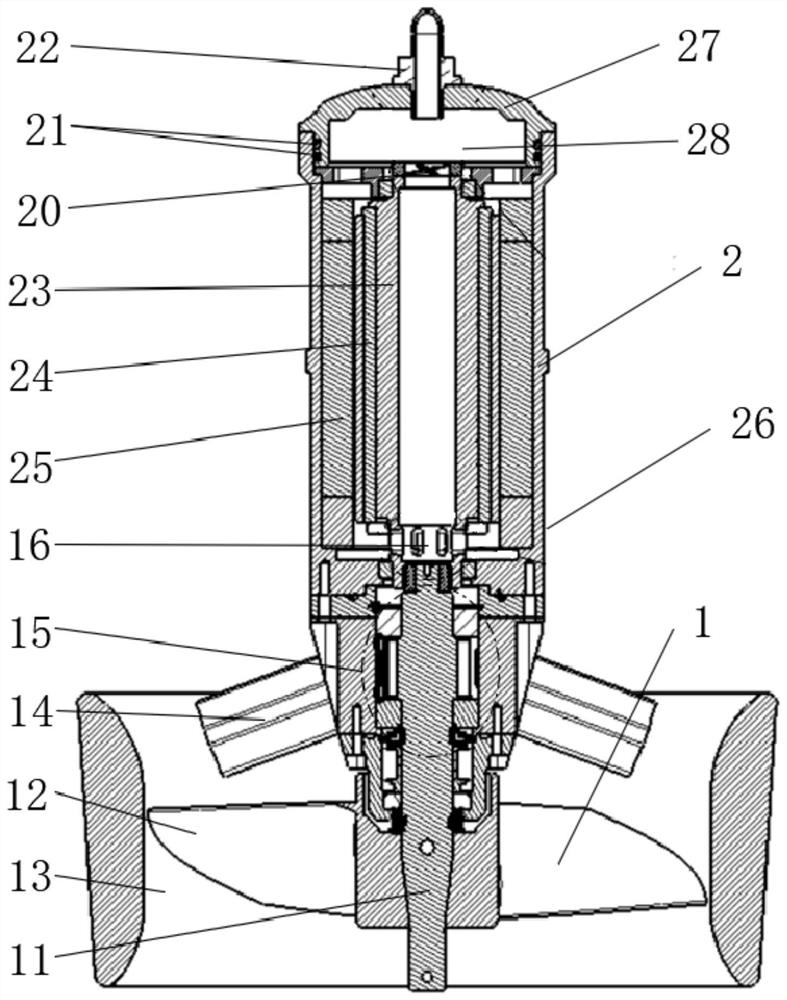

Novel underwater propeller

PendingCN113937954AImprove the thermal environmentHigh efficiency heat dissipationPropulsive elementsMechanical energy handlingPhysicsCorrosion resistant

The invention provides a novel underwater propeller. The novel underwater propeller comprises a propelling assembly and a heat dissipation sealing assembly; a heat dissipation sealing assembly is arranged in the propelling assembly; the heat dissipation sealing assembly comprises a small propeller, a sealing ring, a watertight pipe connector, a motor hollow shaft, a motor rotor, a motor stator, a shell, a cover body, a cavity and a macromolecule sealing hose; and the motor stator is bonded to the inner side wall of the shell, the motor rotor is arranged in the motor stator, the motor hollow shaft is fixedly connected to the interior of the motor rotor, and the small propeller is fixedly connected to the bottom of the motor hollow shaft. According to the novel underwater propeller, internal circulation is achieved by designing the motor hollow shaft and the small propeller, the thermal environment in the motor is improved, and heat dissipation with higher efficiency is achieved; pressure compensation is achieved through the macromolecule sealing hose, a compensator is replaced, and the mechanism of the novel underwater propeller is simplified; a large propeller and a fairing are made of high polymer materials, are high in strength and resistant to corrosion, and are ingeniously matched with each other to achieve higher efficiency.

Owner:深圳市德创水下智能装备有限公司

Winding machine base for winding of dry-type transformer high-voltage coil

InactiveCN108597854AImprove work efficiencyAvoid the problem of easily smashing and injuring workersCoils manufactureWinding machineTransformer

The invention relates to the technical field of transformer manufacturing equipment, and especially relates to a winding machine base for winding of a dry-type transformer high-voltage coil. The winding machine base comprises a fixed circular plate; the central position of the fixed circular plate is vertically connected with a conical rotary positioning base; the inner wall of the conical rotarypositioning base is sleeved with the outer surface of a conical positioning rotating block; the top of the conical positioning rotating block is fixedly connected to the central position of the bottomof a rotary circular plate; the top of the rotary circular plate is fixedly connected with the bottom of a winding machine body; and the right side of the conical rotary positioning base is fixedly connected with one side of a No. 1 cylindrical stop lever. According to the winding machine base for the winding of the dry-type transformer high-voltage coil provided by the invention, through the conical rotary positioning base fixedly connected with the top of the fixed circuit plate and the conical positioning rotating block fixedly connected with the bottom of the rotary circular plate, the rotary circular plate is very good in stability during the rotating process, thus compared with a traditional rotating mechanism, the winding machine base is more suitable for turn-around of a winding machine.

Owner:汪辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com