Calcining filler processing method and system

A processing method and technology of a processing system, applied in the field of filler processing, can solve problems such as environmental pollution, loss of raw materials, and low selectivity of filler raw materials, so as to improve bulk density and mechanical strength, reduce shrinkage speed, and improve the production and operation environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

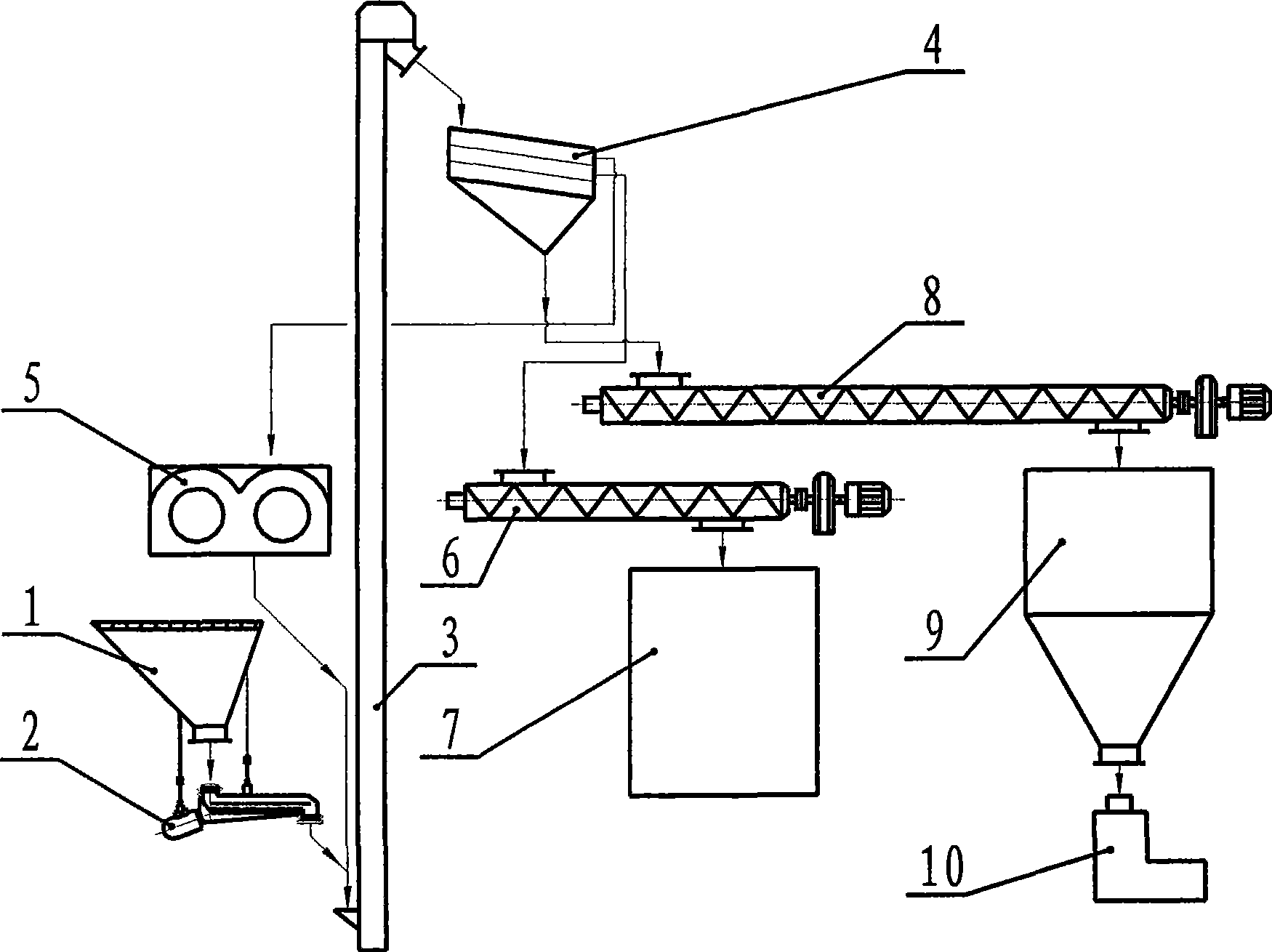

[0028] The invention relates to a method for processing roasting filler, which comprises the following process steps: sending the metallurgical coke to a screening device for screening, and the metallurgical coke screened by the screening device is first screened by a grid sieve hopper and then sent to the screening device , the metallurgical coke screened by the grid sieve hopper is sent to the bucket elevator by the feeding equipment and then sent to the screening equipment. The processing equipment is used for processing. The screening equipment used is equipped with double-layer screens. The metallurgical coke in the bottom layer is sent to the powder screw conveyor; the metallurgical coke in the middle layer is sent to the finished product screw conveyor. The metallurgical coke is sent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com