Improved carbonaceous mud for patching blast furnace hearth

A blast furnace, an improved technology, applied in the field of metallurgy, can solve problems such as insufficient fixed carbon deposition, and achieve the effect of improving thermal conductivity and construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

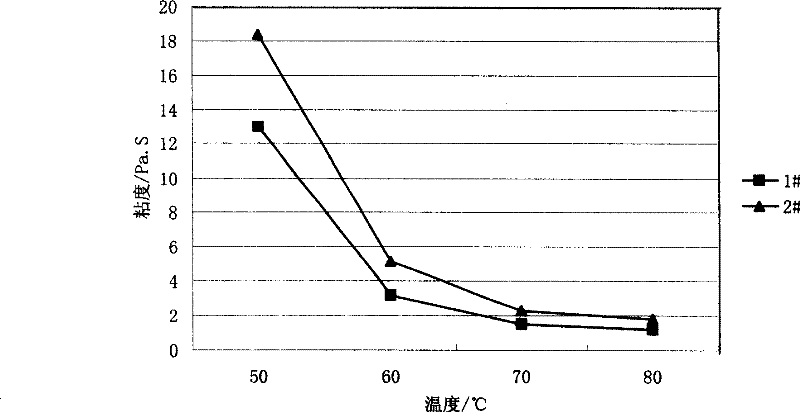

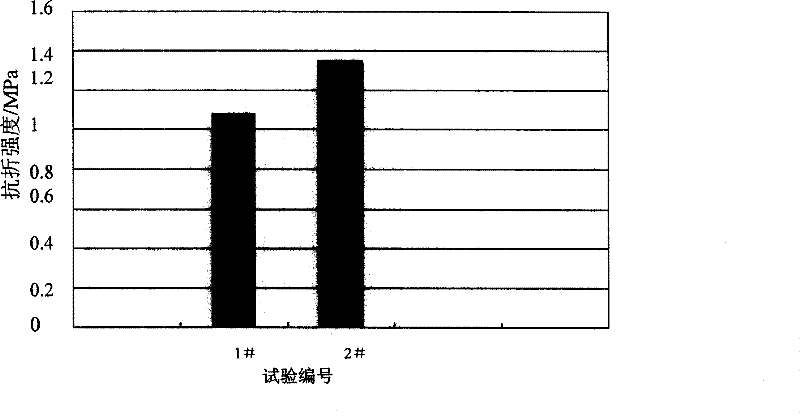

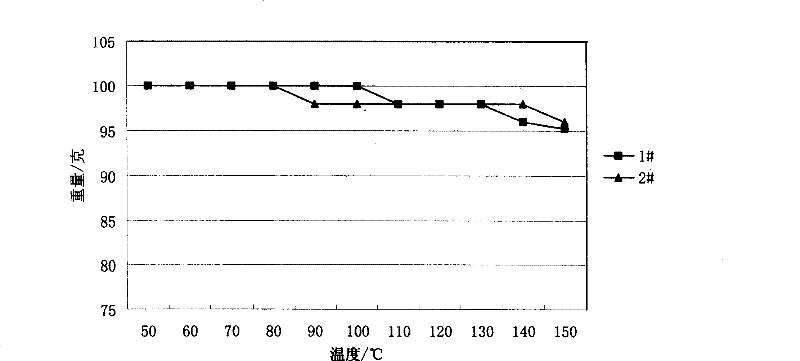

Embodiment 1

[0020] The present invention is an improved carbonaceous mud for repairing the hearth of a blast furnace, which is composed of anthracite powder, graphite powder, electrode powder and coal tar, and the weight percentage of the anthracite powder in the carbonaceous mud is 26% , the weight percentage of the graphite powder in the carbonaceous mud is 6%, the weight percentage of the electrode powder in the carbonaceous mud is 14%, and the balance is the coal tar. A kind of production technology of the improved carbonaceous mud that is used for repairing blast furnace hearth of the present invention is: at first weigh the weight of each component according to weight ratio, secondly, carry out dry mixing with anthracite coal powder, graphite powder and electrode powder, fully After mixing, coal tar is added for kneading to obtain the improved carbonaceous slurry for repairing the hearth of the blast furnace. This product is suitable for use when the gaps in the lining of the blast f...

Embodiment 2

[0022] The present invention is an improved carbonaceous mud for repairing the hearth of a blast furnace, which is composed of anthracite powder, graphite powder, electrode powder and coal tar, and the weight percentage of the anthracite powder in the carbonaceous mud is 26% , the weight percentage of the graphite powder in the carbonaceous mud is 6%, the weight percentage of the electrode powder in the carbonaceous mud is 22%, and the balance is the coal tar. A kind of production technology of the improved carbonaceous mud that is used for repairing blast furnace hearth of the present invention is: at first weigh the weight of each component according to weight ratio, secondly, carry out dry mixing with anthracite coal powder, graphite powder and electrode powder, fully After mixing, coal tar is added for kneading to obtain the improved carbonaceous slurry for repairing the hearth of a blast furnace. This product is suitable for use when the gap in the lining of the blast fur...

Embodiment 3

[0024] The present invention is an improved carbonaceous mud for repairing the hearth of a blast furnace, which is composed of anthracite powder, graphite powder, electrode powder, pitch and coal tar, and the weight percentage of the anthracite powder in the carbonaceous mud is: 26%, the weight percentage of the graphite powder in the carbonaceous mud is 6%, the weight percentage of the electrode powder in the carbonaceous mud is 22%, and the pitch is in the The weight percentage in the carbonaceous mud is 0.25%, and the balance is the described coal tar. A kind of production technology of the improved carbonaceous mud that is used for repairing blast furnace hearth of the present invention is: at first weigh the weight of each component according to weight ratio, secondly, carry out dry mixing with anthracite coal powder, graphite powder and electrode powder, fully After mixing, coal tar and pitch are added for mixing to obtain the improved carbonaceous slurry for repairing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com