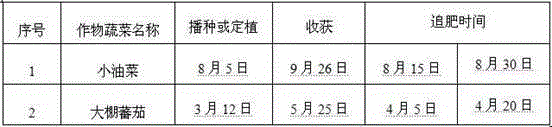

Patents

Literature

73results about How to "Improve the production operating environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing multistage micron structure on titanium implant surface

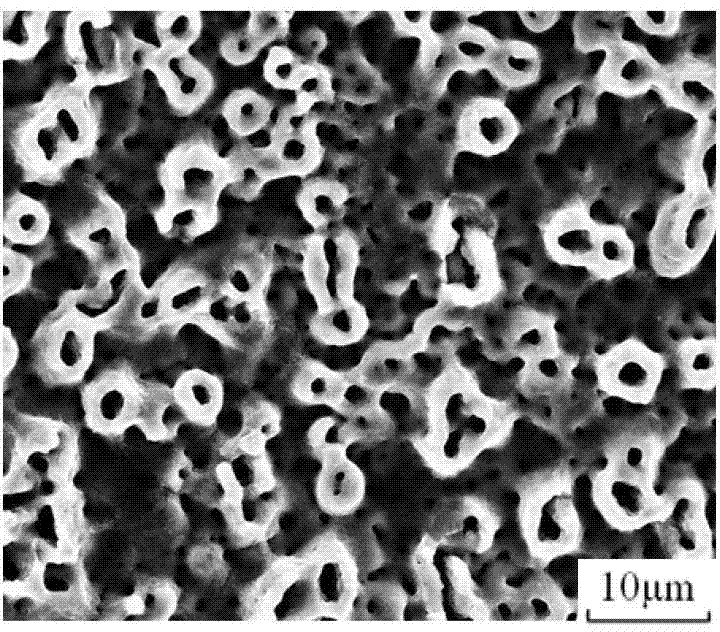

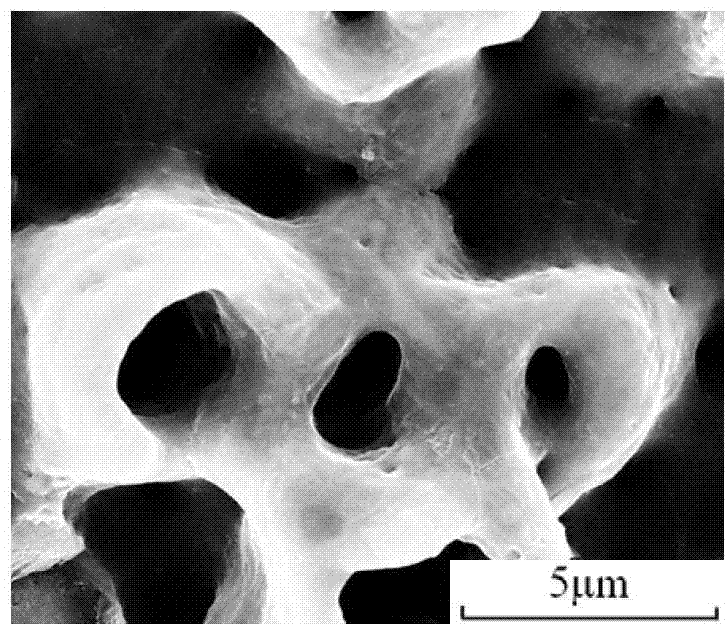

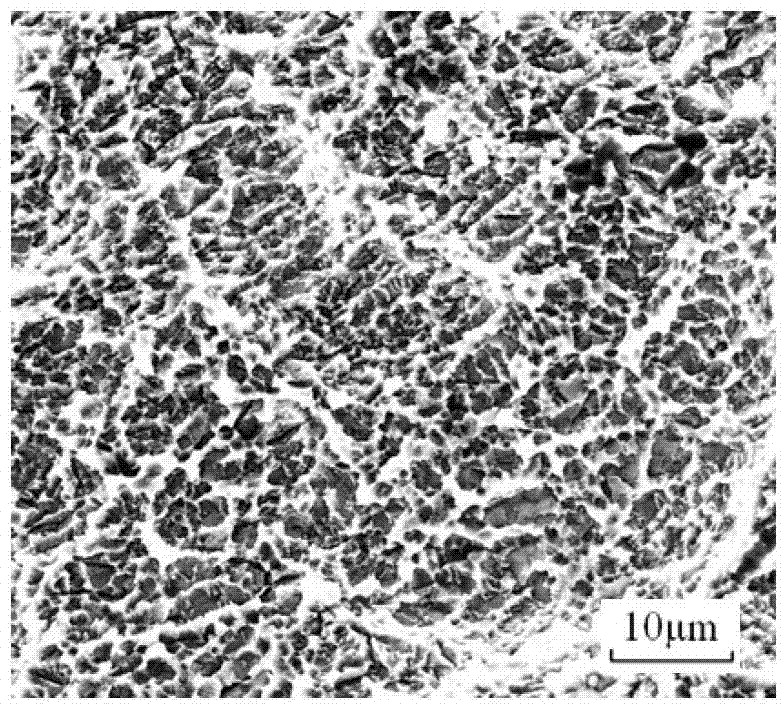

ActiveCN102921037ARich morphologyImprove the production operating environmentProsthesisTitanium implantImplant surface

The invention discloses a method for preparing a multistage micron structure on a titanium implant surface and relates to a titanium implant. The method includes polishing the titanium implant surface, performing oil removing treatment, and cleaning; subjecting the titanium implant which is subjected to the oil treatment and cleaning to acid dipping treatment in a mixed solution containing a nitric acid, a hydrofluoric acid and hydrogen peroxide; subjecting the titanium implant surface to sand blasting treatment; cleaning the titanium implant which is subjected to the sand blasting treatment; subjecting the cleaned titanium implant to acid etching post-treatment in an acid etching solution; and subjecting the titanium implant to heat treatment and cooling the titanium implant to the normal temperature to obtain the titanium implant with the surface in the multistage micron structure. According to the method for preparing the multistage micron structure on the titanium implant surface, the contact area between the titanium implant and bone tissues is increased, osteoblast ingrowth is facilitated, and thereby the forming of bone closure is facilitated; processing devices are easy to obtain, the operation process is simple, the environmental pollution is small, and the industrialization is easy to achieve; and the appearance is abundant, and the hydrophilic performance is excellent.

Owner:百齿泰(厦门)医疗科技有限公司

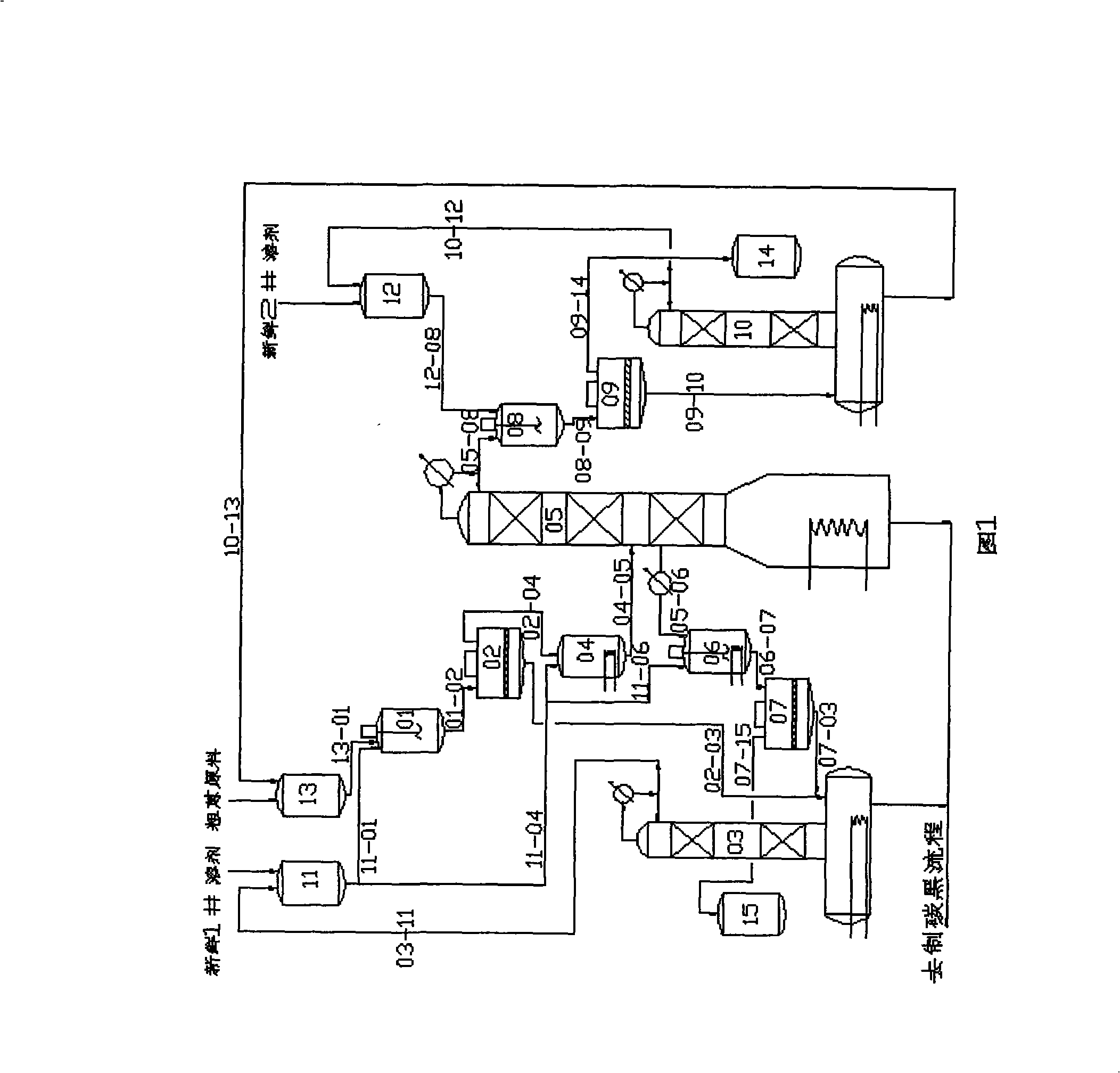

Production process of high-quality carbazol and anthracene

InactiveCN101302187APrevent engineering problems such as crystallization blockingThe method is novel and uniqueDistillation purification/separationHydrocarbonsAnthracenePhenanthrene

The present invention discloses a manufacture process for high quality carbazole and anthracene. The method is to wash the raw material once for removing a number of light constituent, phenanthrene, carbazole derivatives, a small quantity of anthracene and part of heavy constituent, and the loss of the carbazole is less. Afterwards, a vacuum rectification tower with siding withdrawing is adopted for withdrawing the carbazole from the siding at a proper height of the tower. The purity can reach 90 to 95 weight percent, and meanwhile a mixture with the overall purity of the anthracene and phenanthrene being up to more than 90 weight percent is obtained from the top of the tower. The two materials are respectively washed by a No.1 solvent and a No.2 solvent, and the trace impurities contained in the materials are removed. After centrifugalized, fine carbazole and fine anthracene products which are better than the first grade product (carbazole of more than 97 weight percent and fine anthracene of more than 95 weight percent) according to the national standard can be obtained. The solvent wash is operated at a normal temperature, the solvent can be withdrawn for periodic duty, is less in loss quantity, and does not pollute environment. Not only the large-scale successive industrial production of fine carbazole and fine anthracene can be realized easily, but also the process is economic in investment, low in energy dissipation and friendly in environment.

Owner:NANJING UNIV

Functional masterbatch of halogen-free intumescent flame retardant, and preparation method thereof

The invention relates to functional masterbatch of a halogen-free intumescent flame retardant, and a preparation method thereof. The halogen-free intumescent flame retardant in the functional masterbatch is a phosphorus-nitrogen series intumescent flame retardant, and a matrix in the functional masterbatch is a polyolefin resin. The functional masterbatch comprises, by weight, 50-90 parts of the halogen-free intumescent flame retardant, 20-45 parts of the polyolefin resin, 1-5 parts of a compatibilizer; 1-5 parts of a lubricant and 1-5 parts of a surface treatment agent. According to the present invention, dust pollution due to the flame retardant is fundamentally overcome; the flame-retardant masterbatch and polypropylene have good dispersions, such that purposes of environmental protection and no pollution are achieved; heavy metal contents of the functional masterbatch accord with requirements of the report of societe generale de surveillance S.A. (SGS); and the functional masterbatch has a good flame retardant property and high economy.

Owner:SHANGHAI RES INST OF CHEM IND

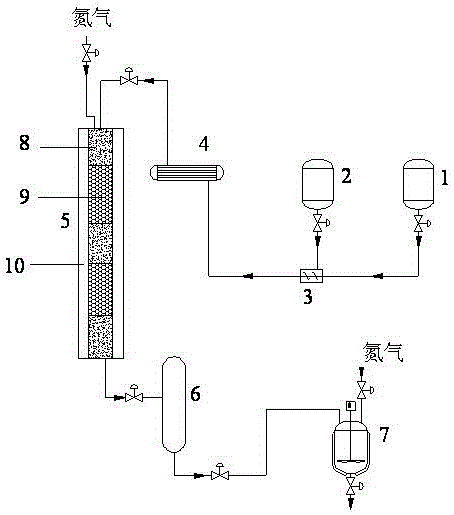

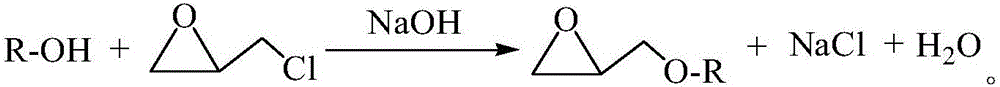

A continuous ring-opening production process for epoxy-terminated polyether

The invention relates to a continuous ring-opening production process for epoxy-terminated polyether and belongs to the technical field of organic polymer compounds. Allyl alcohol polyoxyethylene ether and epichlorohydrin are adopted as raw materials. The process includes mixing the allyl alcohol polyoxyethylene ether and the epichlorohydrin, heating, continuously feeding the mixture to a two-stage fixed bed reactor, performing a ring-opening reaction under catalysis of a solid superacid, adding a product collected by a collecting tank at the lower end of the reactor to a reaction kettle through a metering pump every 2-4 h, adding an alkali and a quaternary ammonium salt catalyst, stirring for 1-4 h while maintaining the temperature, filtering to obtain a crude product, performing vacuum distillation to recover the epichlorohydrin, and purifying to obtain a qualified product. The process is applied for producing the epoxy-terminated polyether, and has advantages of a high equipment utilization rate, a high production efficiency, and the like.

Owner:ZHEJIANG HUANGMA TECH

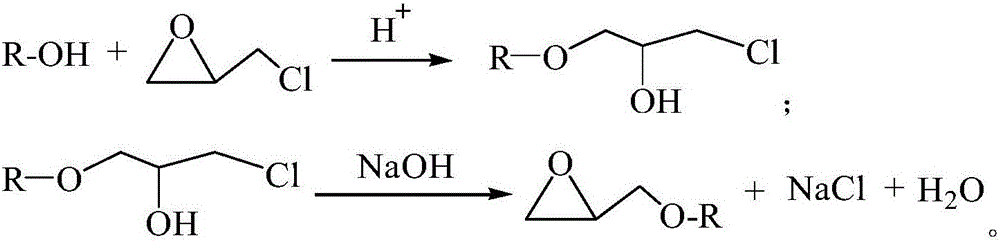

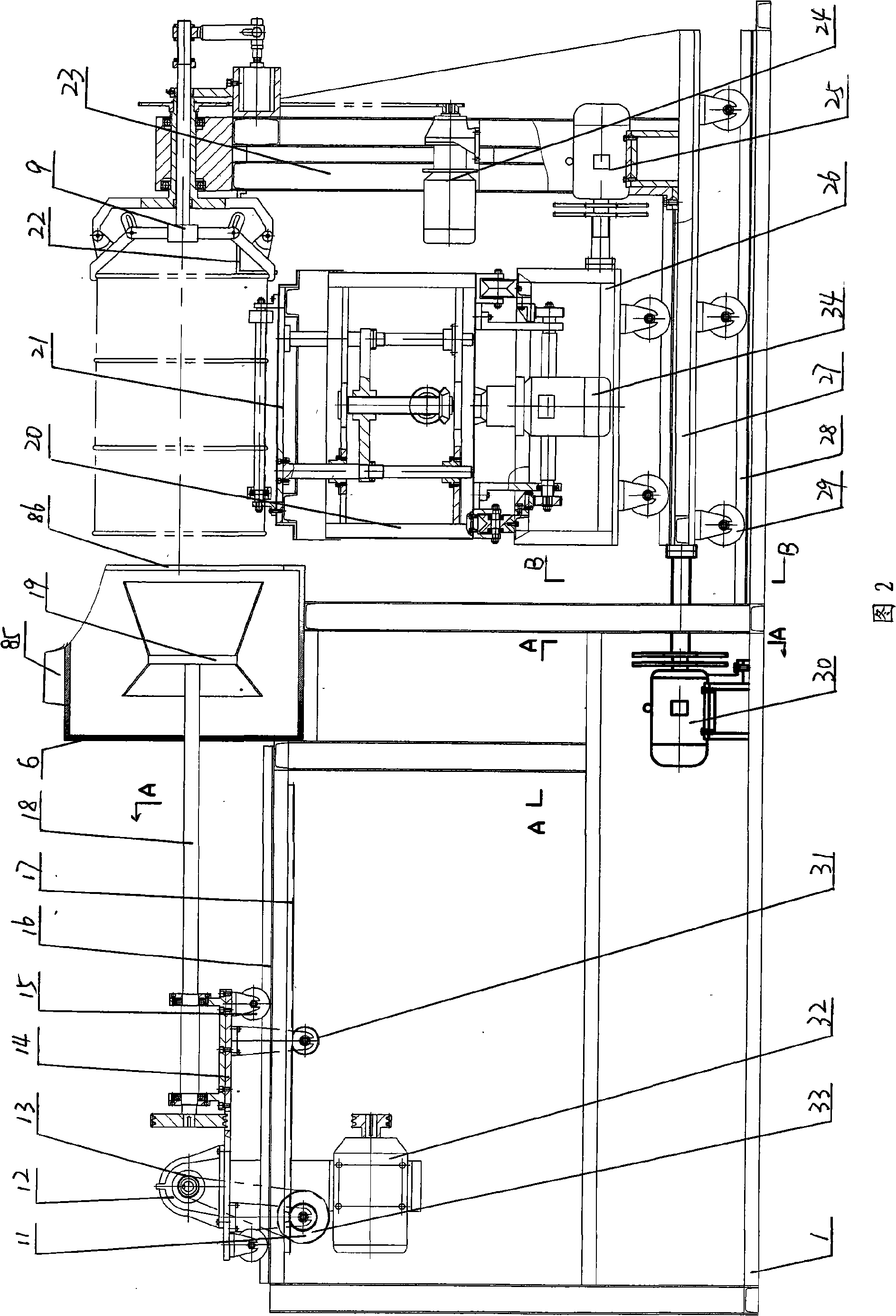

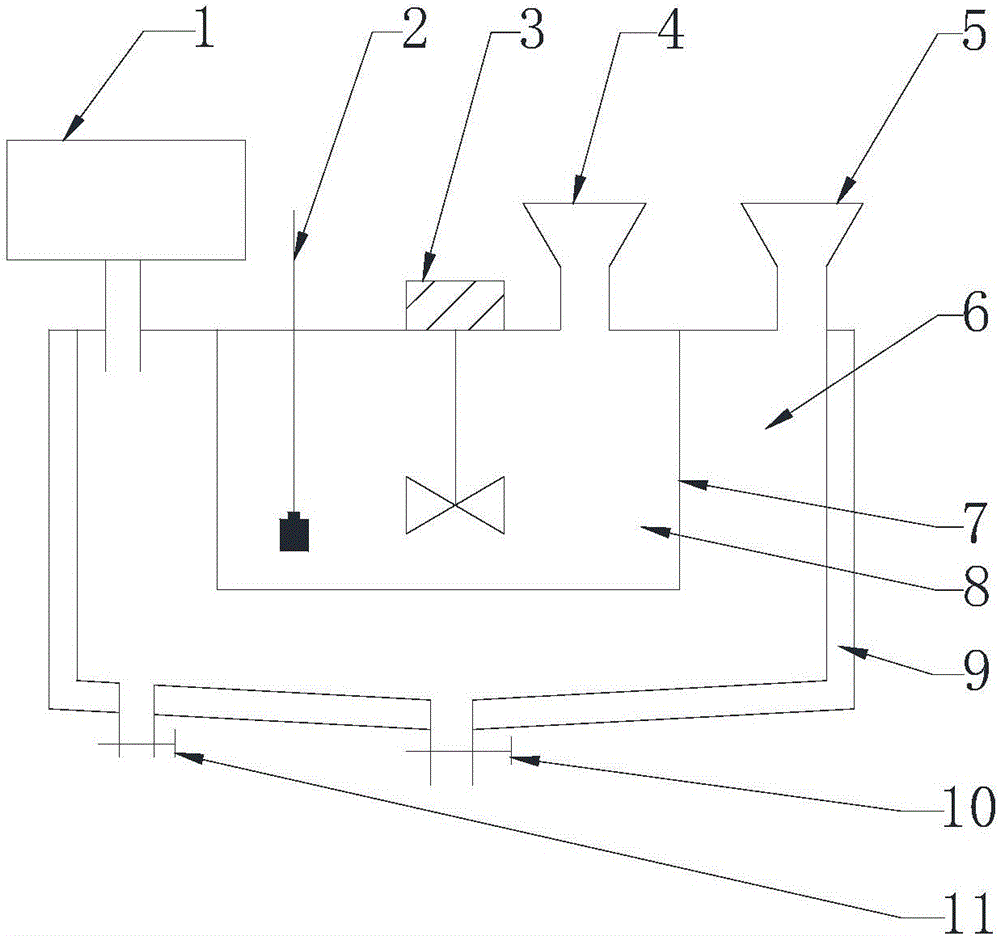

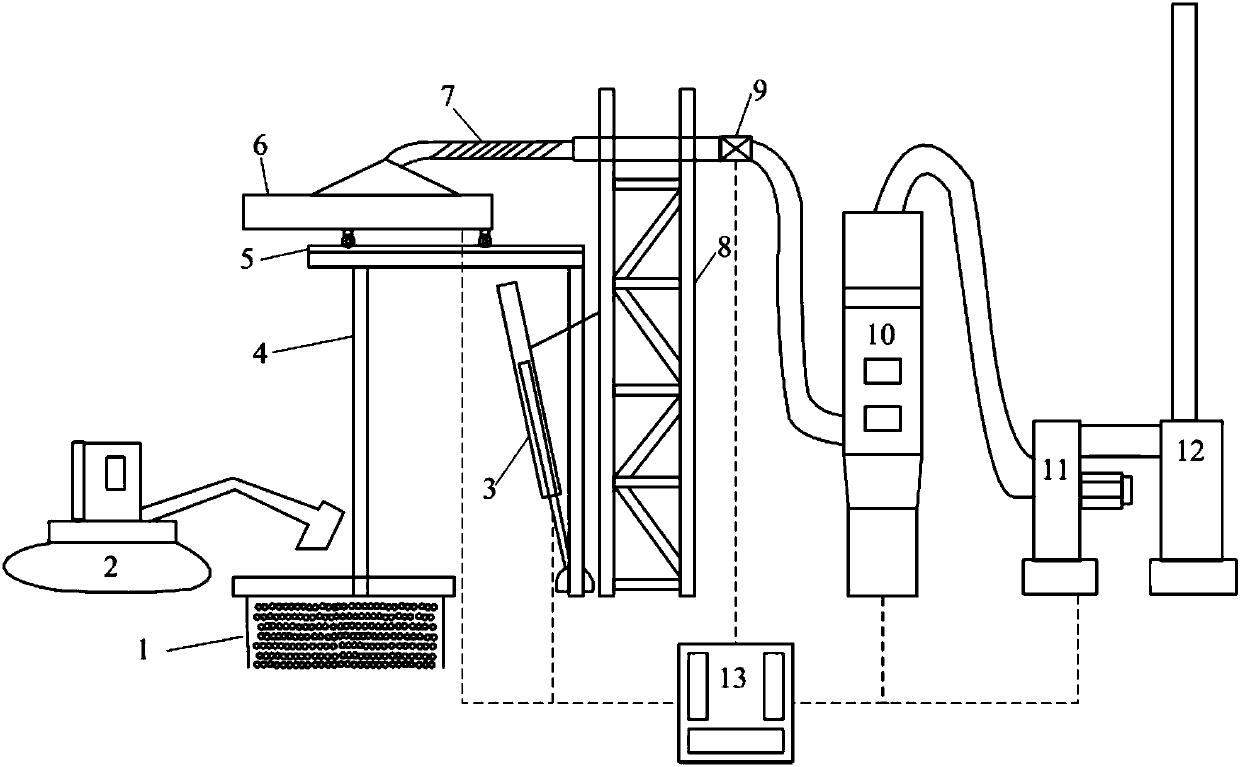

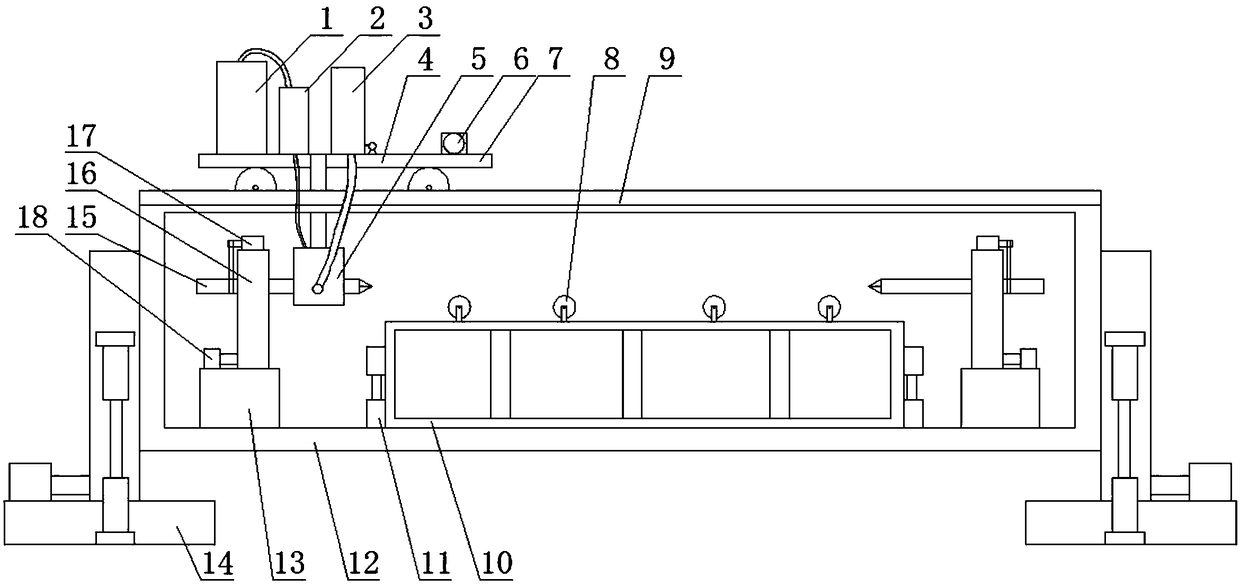

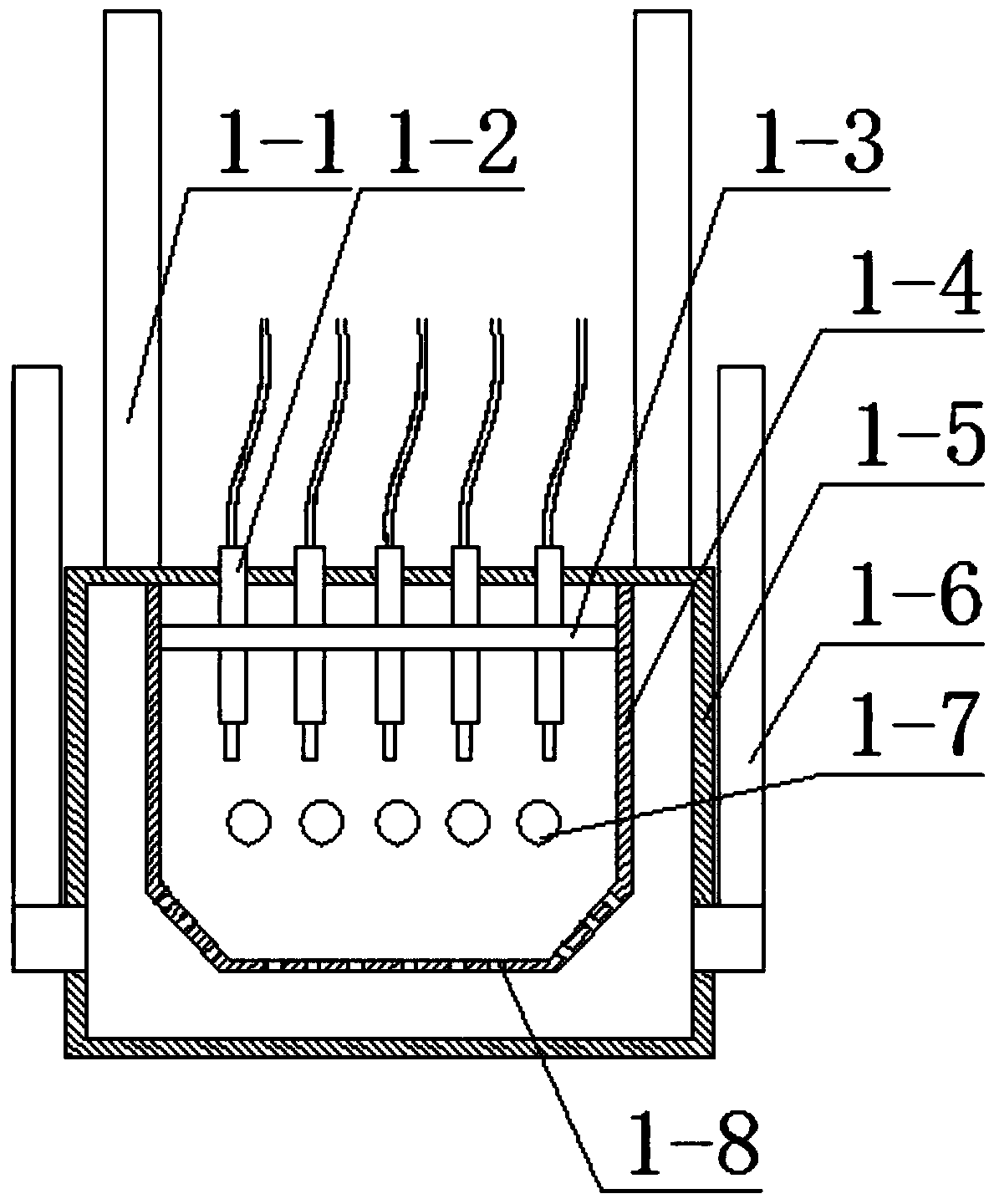

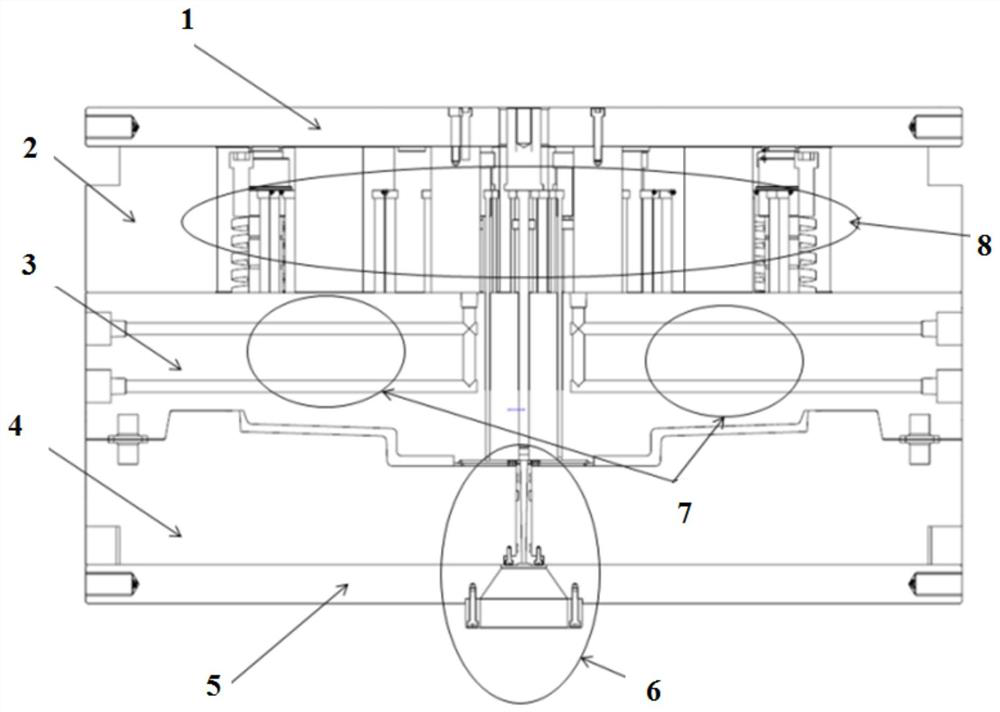

System for processing steel drum renovation

InactiveCN101298075AImprove securityAvoid misalignmentHollow article cleaningEngineeringOperating environment

The invention discloses a processing system for renewing steel barrels, which aims at providing a processing system that carries out flaming and scrubbing separately, has high reliability of barrel shift and is convenient to use and beneficial to environment protection in renewing steel barrels. The processing system comprises at least one group of barrel brushing system composed of a barrel brushing unit and a barrel holding unit, at least one group of flaming system composed of a flaming unit and a holding unit and a shift unit for ascending and descending the barrels which comprise a barrel supporting bracket; at least two groups of barrel supporting shafts are arranged on the barrel supporting bracket; each barrel supporting shaft is provided with a barrel supporting wheel which can freely rotate; the barrel supporting bracket is connected with the barrel ascending and descending mechanism which is arranged on an upper layer bracket; the upper layer bracket is connected with a longitudinal drive mechanism and a horizontal drive mechanism of the upper layer bracket; a middle layer bracket is connected with a horizontal drive mechanism of the middle layer bracket. The flaming and scrubbing of the system are carried out at different working stations, thereby increasing the safety of the production, improving the operating environment for production; the shift movement is of high reliability and accurate; productivity is increased.

Owner:TIANJIN LYUBOTE ENVIRONMENTAL PROTECTION EQUIP MFG

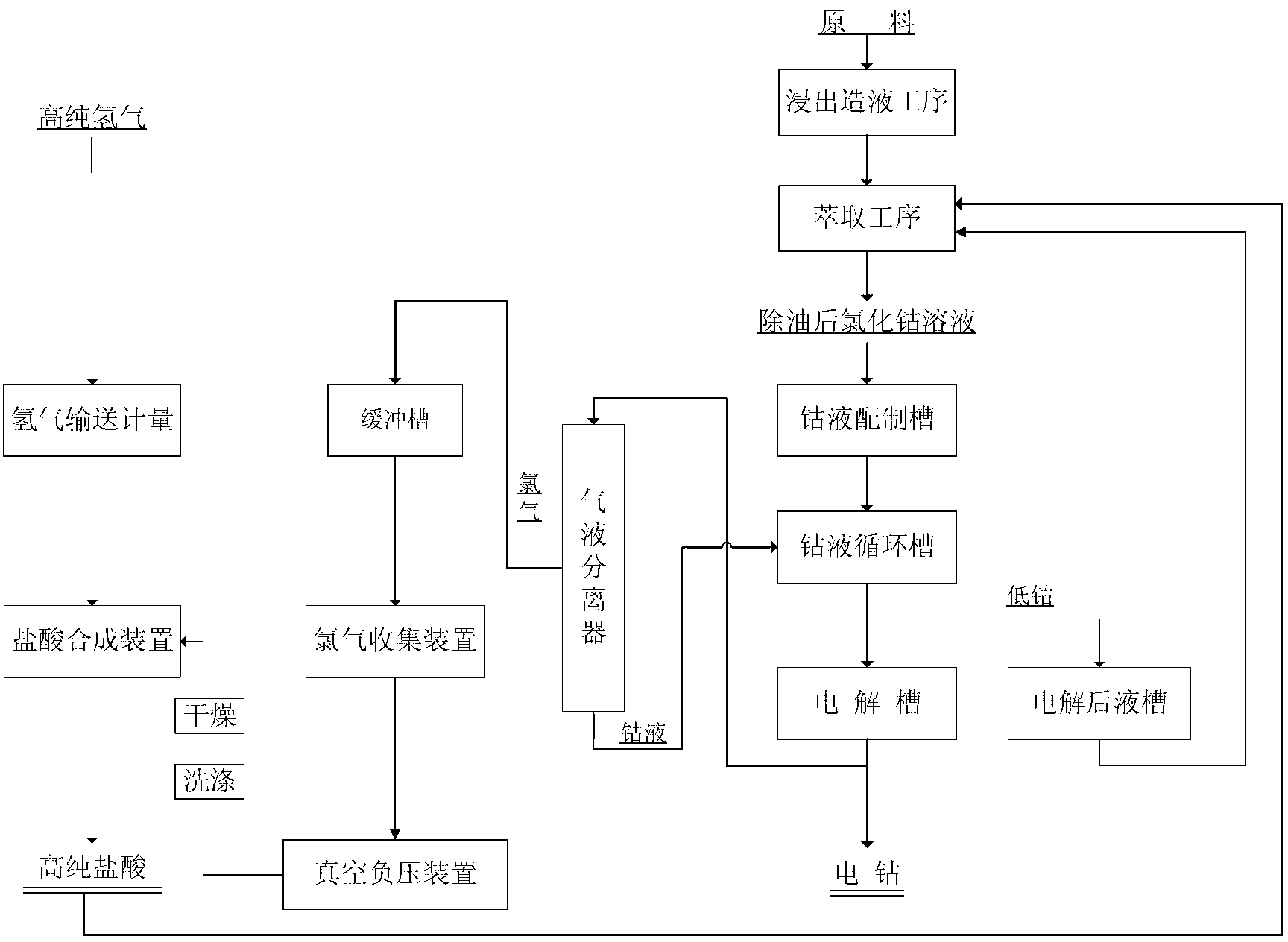

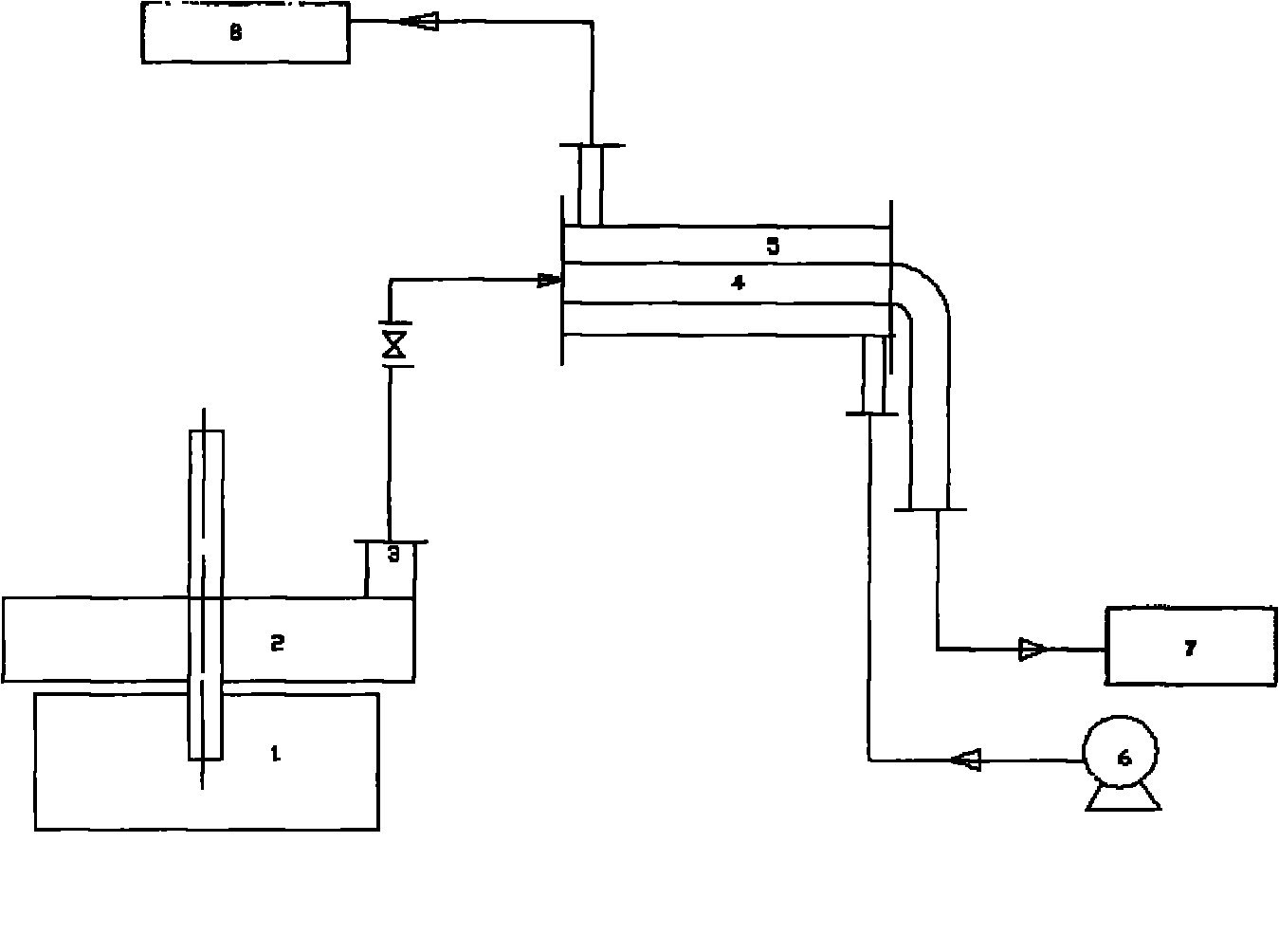

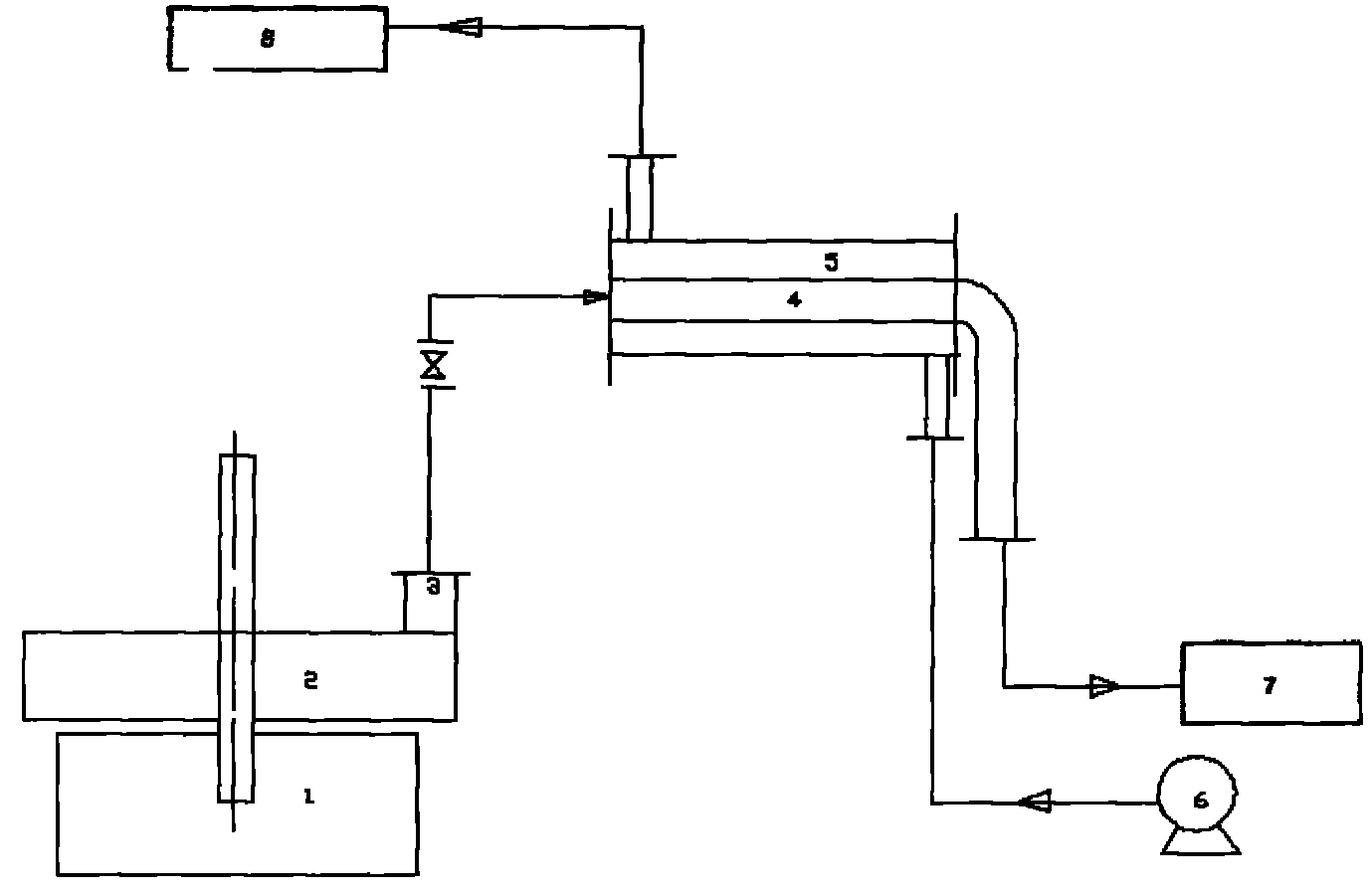

Method for preparing electrodeposited cobalt under large flow

ActiveCN103060842AImprove current efficiencyReduce cathodic polarizationPhotography auxillary processesWater chlorinationHydrometallurgy

The invention discloses a method for preparing electrodeposited cobalt under a large flow. In conventional production methods for electrodeposited cobalt, the process of processing has the disadvantages of low current efficiency and long electrodeposition time, and purity and a recovery rate of produced electrodeposited cobalt hardly reach requirements. A technical scheme employed in the invention is as follows: a deoiled cobalt chloride solution produced in wet metallurgy is used as a raw material and is diluted with pure water so as to allow the concentration of Co<2+> in the cobalt chloride solution to be 30 to 100 g / L, and the diluted cobalt chloride solution is used as electrodeposition pre-liquid; and electrodeposition is carried out on the electrodeposition pre-liquid in an enclosed electrodeposition apparatus under the conditions of a large flow of 5 to 15 m<3> / h.m<2> and a negative pressure. According to the invention, the large flow is employed in the process of preparation of electrodeposited cobalt, so cathodic polarization is reduced, high current efficiency as high as more than 95% is obtained, and direct current consumption is low; utilization of the large flow enables chlorine and oxygen generated by an anode to be taken away in time, and oxidation of the cathode cobalt by chlorine and oxygen is prevented, thereby guaranteeing product quality.

Owner:ZHEJIANG HUAYOU COBALT +1

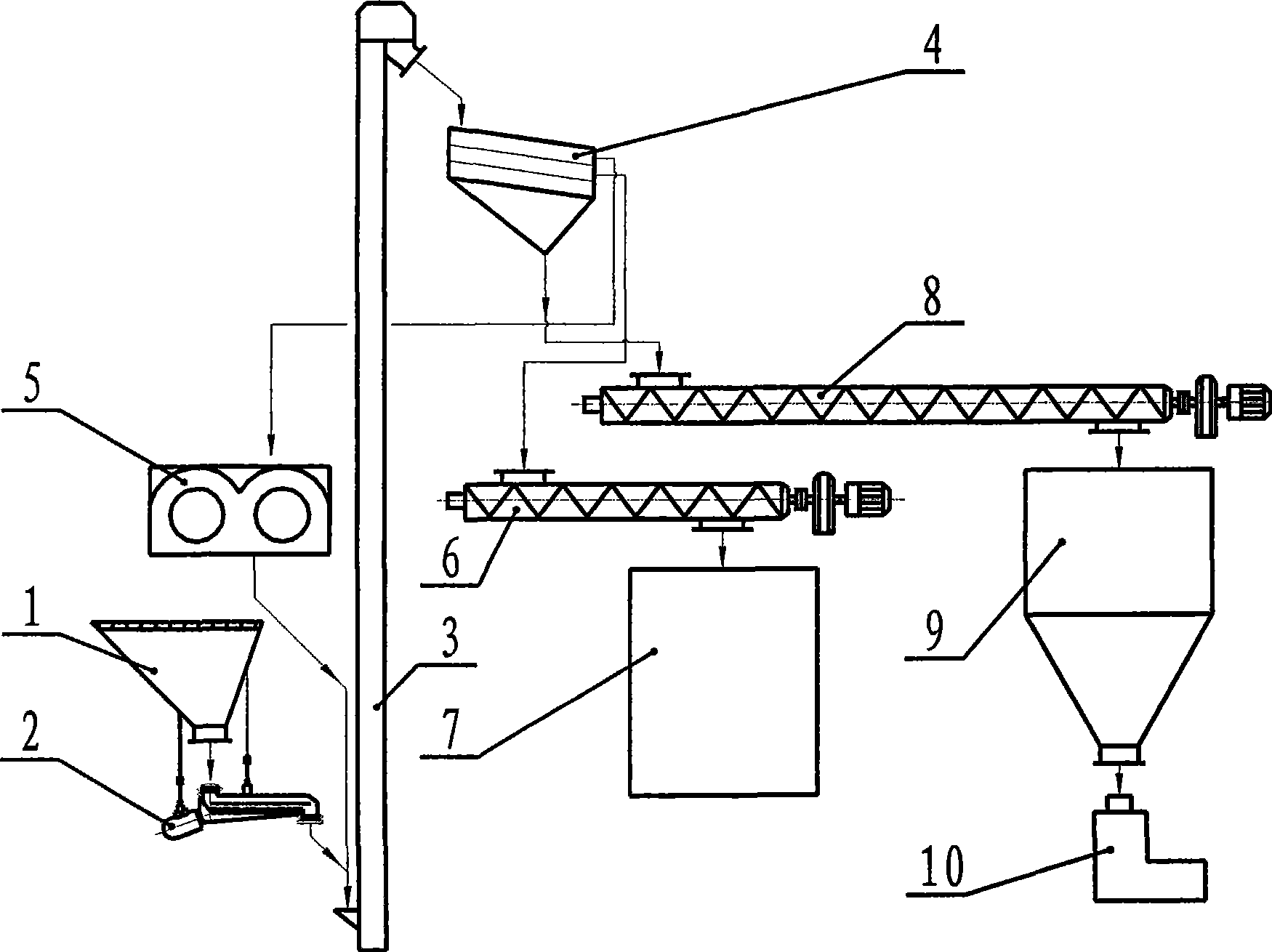

Calcining filler processing method and system

The invention discloses a packing material for baking and particularly relates to a processing method and a processing system for the packing material for baking applicable to producing anodes, cathodes and electrodes for aluminum. The processing method for the packing material for baking comprises the following steps: sending metallurgical coke to sieving equipment for sieving; sending the metallurgical coke with qualified sieve size into a finished product screw conveyer; sending the metallurgical coke with unqualified sieve size to the processing equipment for processing; and sending the metallurgical coke which is sent to the metallurgical coke to a finished product silo. The invention adopts processing technology of the packing material for baking to process the metallurgical coke through crushing and sieving into a finished packing material product with optimum matching which has a size fraction of between 0.5 and 6 millimeters and has compressibility, adsorptivity and gas permeability, improves the volume density and the mechanical strength of a baked product and reduces the contraction rate of a green body. The method improves production operation environment. The method effectively solves technical problems that raw materials of the packing material have small selectivity and high cost, and the packing material can cause serious environmental pollution and raw material loss during the transportation.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

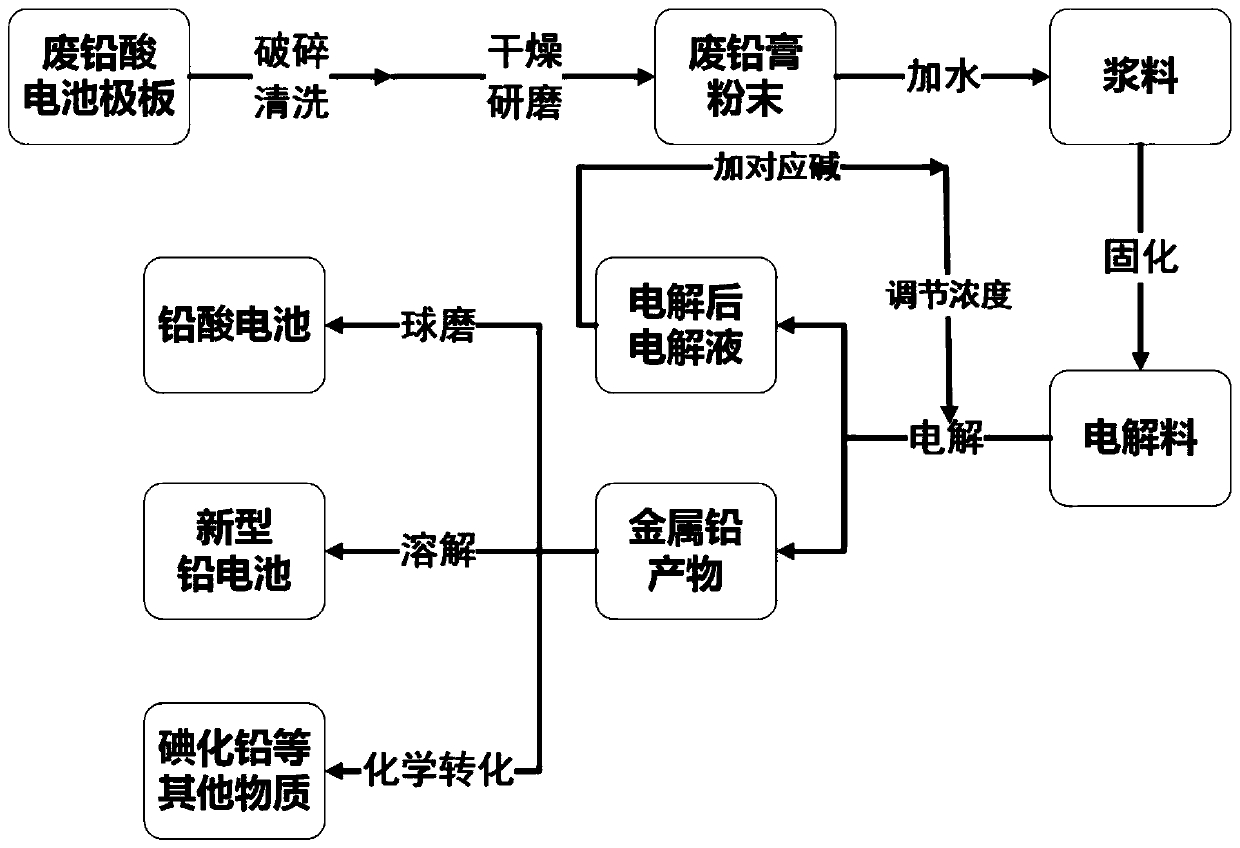

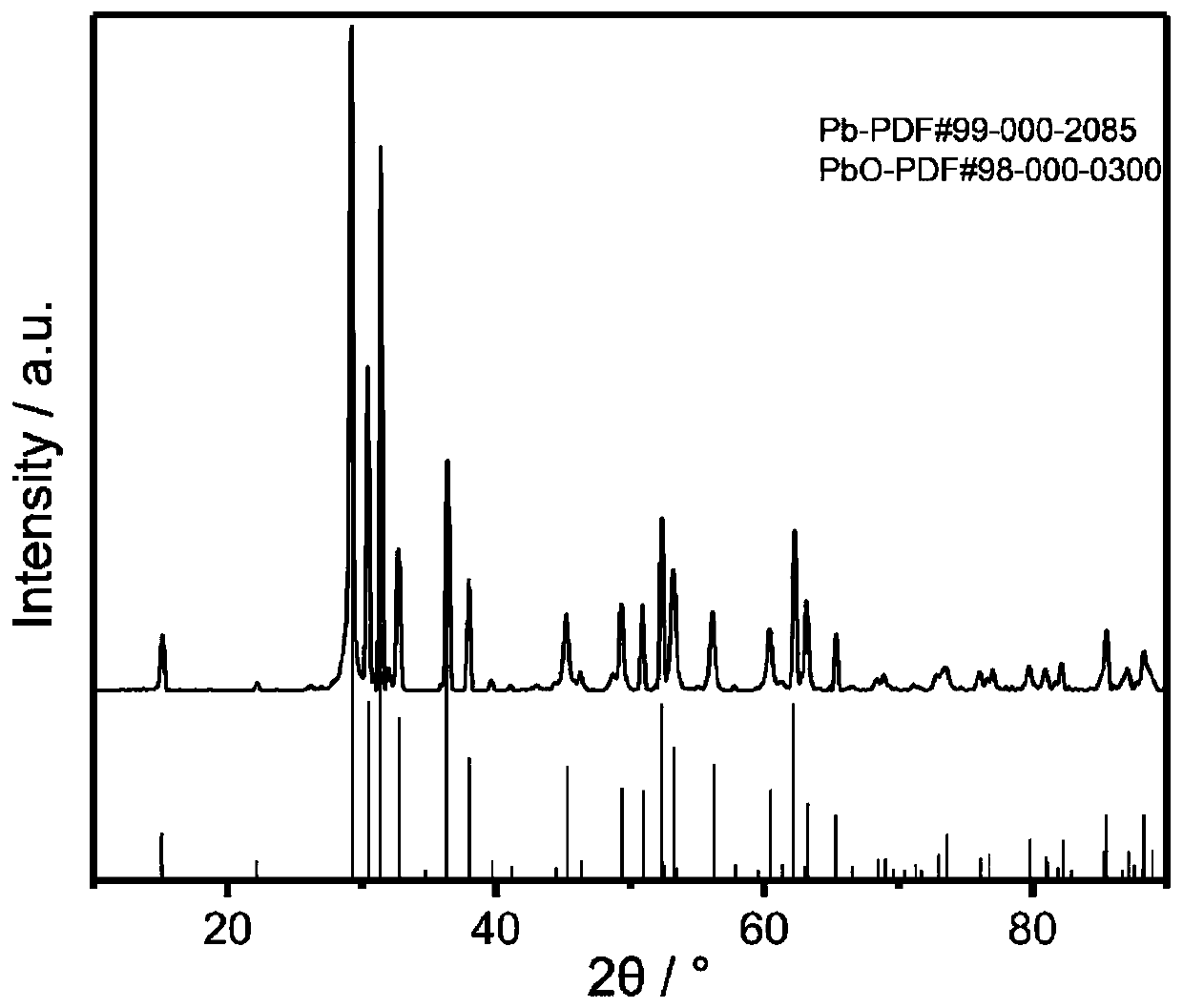

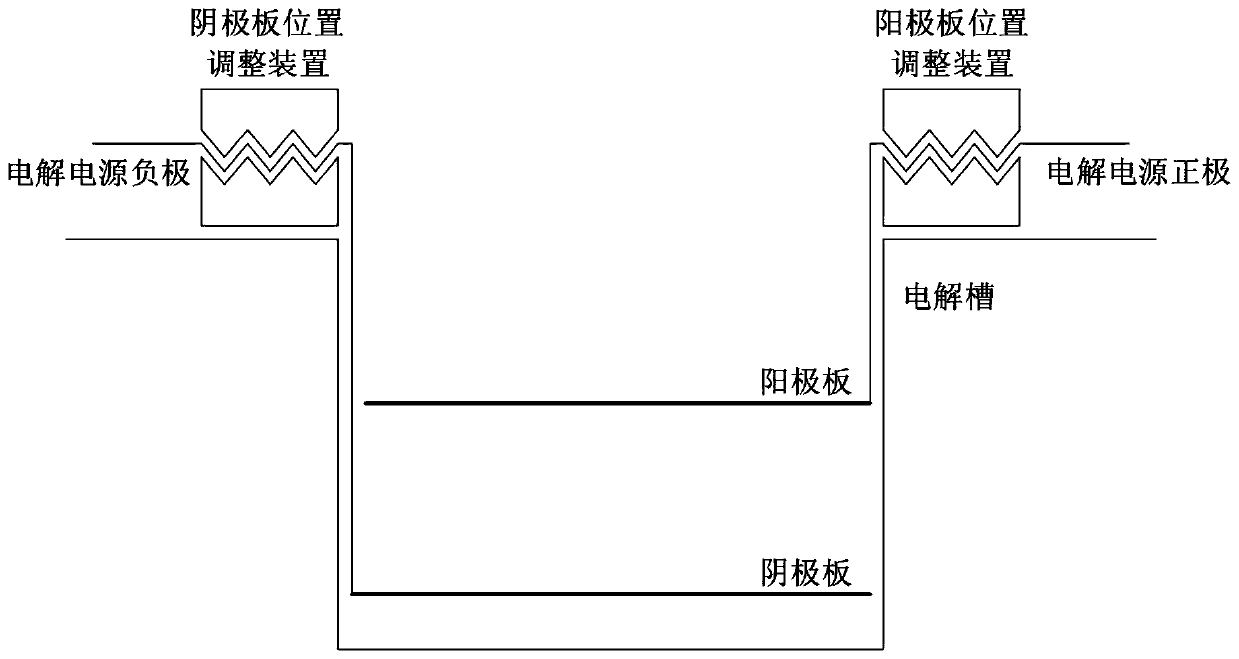

Method for recovering lead from waste lead paste by solid phase electrolysis method

ActiveCN111455404AReduce consumptionSimple processPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentLead dioxide

The invention discloses a method for recovering lead from waste lead paste by a solid phase electrolysis method, and belongs to the technical field of lead resource recovery. The method for recoveringthe lead from the waste lead paste by the solid phase electrolysis method comprises the steps that the waste lead paste is first made into a paste waste lead paste electrolytic material and a cathodeplate is coated with the waste lead paste electrolytic material; electrolyte is added to an electrolytic cell; the cathode plate coated with the electrolytic material is inserted into the electrolyte, and an anode is inserted into the electrolyte; the anode is an electrode with oxygen evolution electrocatalysis; the cathode plate and the anode are connected with a negative electrode and a positive electrode of a direct current power supply separately to make electrolysis in the electrolytic cell; and water at the anode loses electrons and precipitates oxygen, the electrolytic material on thecathode plate obtains the electrons and is reduced in situ to a lead single substance and attached to the cathode plate, that is, the lead is recovered from the waste lead paste. The method for recovering the lead from the waste lead paste by the solid phase electrolysis method directly electrolyzes the waste lead paste after simple pulping, lead sulfate, lead dioxide and lead oxide in the waste lead paste obtain the electrons and form in situ the lead simple substance, a large number of pretreatment processes are saved, the consumption of reagents is reduced, the process is simple, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

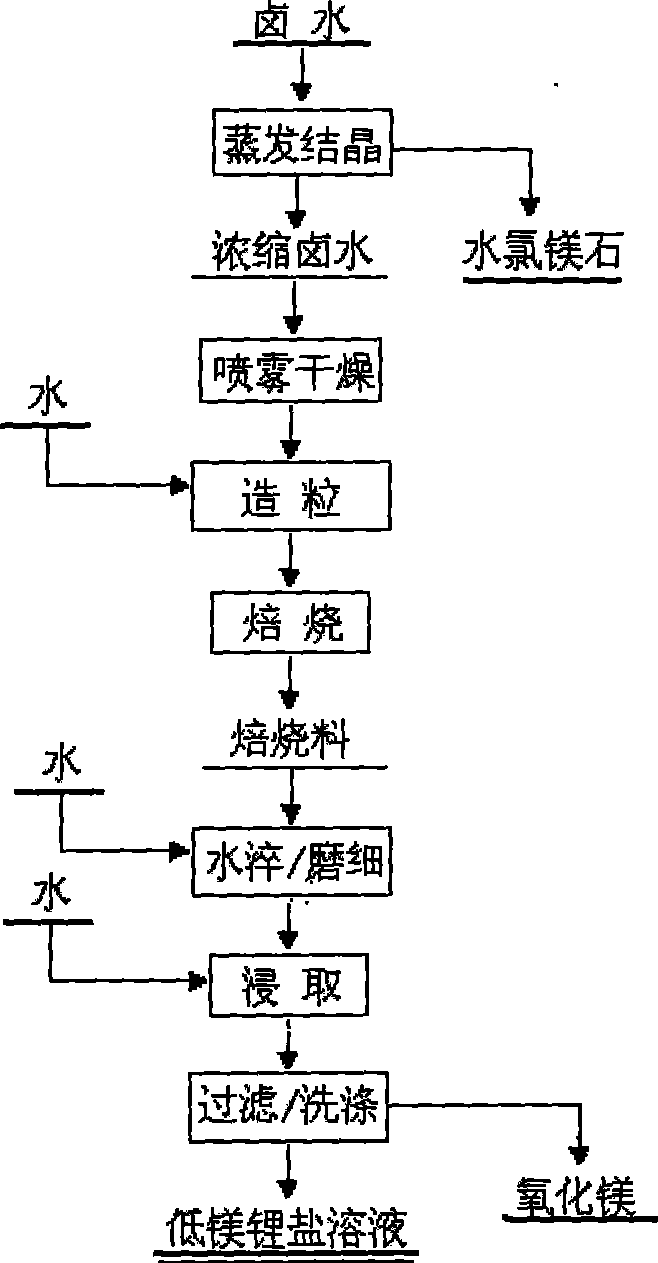

Method for pre-de-magnesium enriched lithium from salt lake bittern with high-magnesium-lithium ratio with dry method de-magnesium

ActiveCN101508449ARealize pre-demagnesium enrichment of lithiumReduce lossesMagnesium chloridesAlkali metal chloridesHigh magnesiumLithium chloride

The invention relates to a method for removing magnesium-enriched lithium in advance from saline lake brine with a high magnesium-lithium ratio through dry-process magnesium removal. The method is to take the saline lake brine with the high magnesium-lithium ratio as a raw material and adopt the technological steps of brine concentration, spray drying, granulation, roasting, water leaching, and the like to remove most magnesium in the brine, so that lithium can be conveniently extracted with low cost. The main technical points of the method comprises that: the dry-process magnesium removal is based on a high-temperature hydrolysis principle of magnesium chloride to convert most soluble magnesium compounds into magnesium compounds (MgO) which are difficult to be dissolved in water, and magnesium oxychloride (MgOHCl) which is hydrolyzed in the water, so that soluble lithium chloride and magnesium chloride (which are mainly generated by hydrolysis under the condition of the water leaching of the magnesium oxychloride) are dissolved out through the water leaching, and the removal of the magnesium-enriched lithium in the brine in advance is realized. The method comprehensively utilizes magnesium resources and lithium resources of saline lakes, has the characteristics of high magnesium removal efficiency, good enriching effect of lithium salts, high recovery rate, low energy consumption, low cost, small project investment, and the like, and is particularly suitable for industrial production on a large scale. In addition, the whole process is simple, clean and environment-friendly.

Owner:CENT SOUTH UNIV

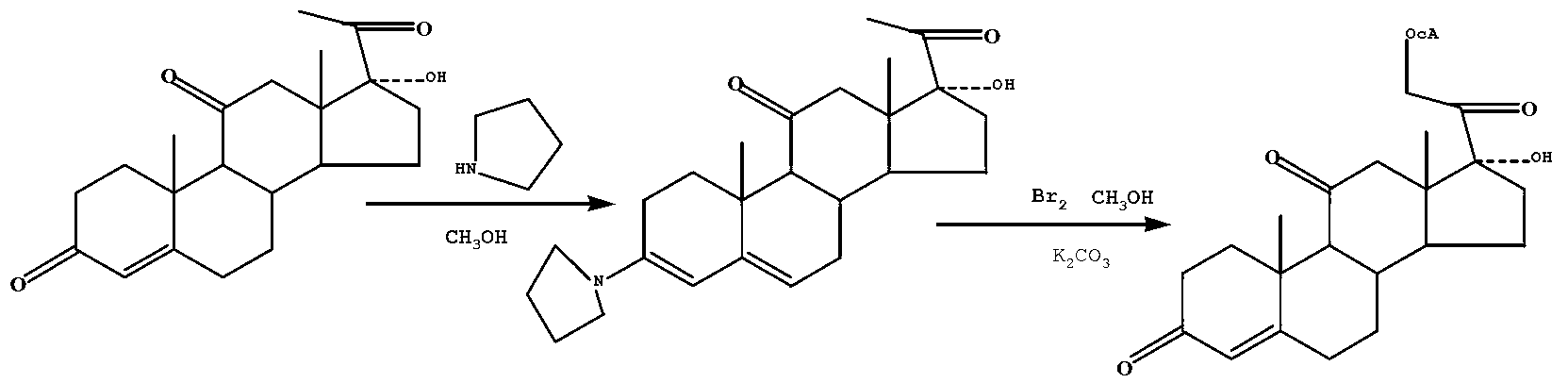

Preparation method of cortisone acetate

ActiveCN103232514AReduce manufacturing costImprove the production operating environmentSteroidsEpoxyKetone

The invention discloses a preparation method of cortisone acetate, which comprises the following steps: preparing the raw material 11-hydroxy-16,17-epoxy-4-ene-3,20-dione into 17-alpha-hydroxy-4-pregnene-3,11,20-trione; and carrying out substitution and replacement reaction on the 17-alpha-hydroxy-4-pregnene-3,11,20-trione with raw materials bromine, potassium acetate and the like to obtain the cortisone acetate. The method specifically comprises the following steps:(a) in an inert gas protective atmosphere, reacting 17-alpha-hydroxy-4-pregnene-3,11,20-trione with pyrrolidine by using alcohol as a solvent to obtain an intermediate compound A; and (b) in an inert gas protective atmosphere and in the presence of catalysts methylsulfonic acid and triethyl orthoformate, carrying out substitution reaction on the intermediate compound A and bromine by using alcohol as a solvent, and carrying out replacement reaction on the product and postassium acetate to obtain the cortisone acetate. The new process disclosed by the invention can greatly lower the production cost of cortisone acetate.

Owner:河北远大九孚生物科技有限公司

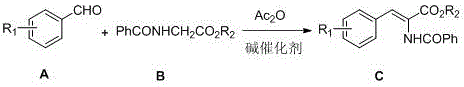

Method for synthesizing 2-benzamido-3-aryl acrylate

InactiveCN106631867AReduce production stepsShort reaction timeOrganic compound preparationCarboxylic acid amides preparationChemical synthesisAryl

The invention discloses a method for preparing 2-benzamido-3-aryl acrylate, and belongs to the field of organic chemical synthesis. The method is mainly implemented by the following steps: adding aromatic aldehyde, ethylhippurate, acetic anhydride and an alkali catalyst into a three-mouth flask according to a certain proportion under the protection of argon, and performing condensation reaction under a certain temperature condition to obtain a 2-benzamido-3-aryl acrylate compound by one step. According to the method, production steps are shortened, the method is easy to operate and control, the production operation environment is improved, the yield and the quality of a product are improved, and the reaction time is shortened; the 2-benzamido-3-aryl acrylate is mainly used for evaluation of the activity of a chiral ligand and catalyst thereof, medicinal synthesis, a pesticide, a photoelectric material and the like.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

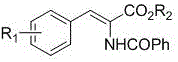

Method for continuously preparing 1,5-naphthalene diisocyanate

InactiveCN103214397AReduce labor intensityReduce pollutionIsocyanic acid derivatives preparationOrganic compound preparationPollutionCrystallization

The invention discloses a method for continuously preparing 1,5-naphthalene diisocyanate, and the method comprises the following steps of: firstly mixing a 1,5-naphthalene diisocyanate solution and a di(trichloromethyl) carbonate solution into a reaction raw material, and then carrying out continuous charging; enabling the reaction raw material to firstly flow through a tubular reactor at the temperature of 25-100 DEG C and then flow through 3-8 stage series-connected combined slot type reactors, and enabling an obtained mixture to flow out of the last-stage reactor; and filtering, and then concentrating and crystallizing filter liquor to obtain the 1,5-naphthalene diisocyanate. The method disclosed by the invention has the advantages of high reaction yield, high product purity, short reaction time, high equipment utilization ratio, low production cost, no pollution, continuous production and industrialized application.

Owner:XIANGTAN UNIV

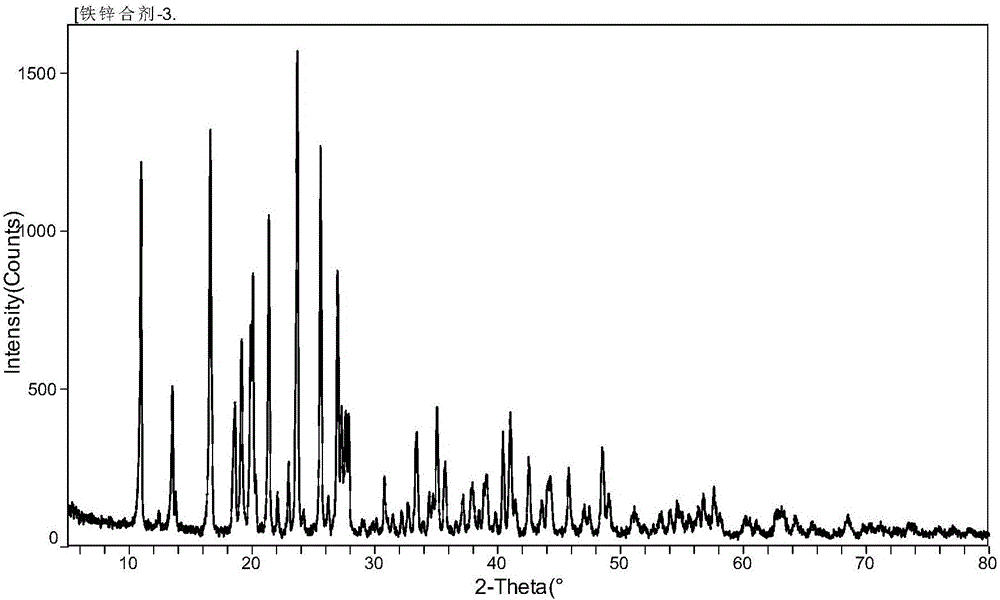

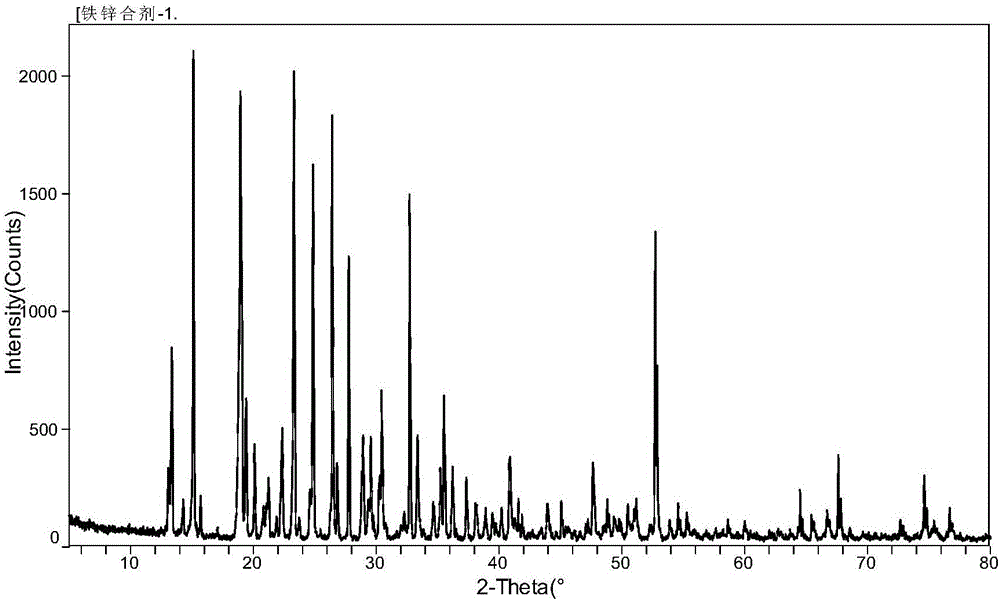

Preparation method for iron and zinc glycine complex

ActiveCN105061244AReduce exposureReduce parts exposed to airOrganic compound preparationAmino-carboxyl compound preparationGlycineReaction temperature

The invention discloses a preparation method for a iron and zinc glycine complex. The preparation method comprises the following steps: adding glycine, a zinc raw material, ferrite and a solvent into a reaction device, wherein the mole ratio of a zinc element in the zinc raw material to an iron element in the ferrite is controlled to be 1: 5-5: 1, and a ratio of the mole number of the glycine to the total mole number of the zinc element and the iron element is 1: 1-2.2: 1; after uniform stirring, controlling the reaction temperature and the pH value in the whole process, performing discharging, cooling, crystallization and separation after the reaction is fully completed, washing crystals, and performing drying, smashing and screening to obtain the finished product, namely the iron and zinc glycine complex. The preparation method disclosed by the invention has the advantages of simple technical step, low cost, greenness, environment friendliness, high product purity, stable quality, less possibility in color change in producing and preparing process and the like.

Owner:昕嘉生物技术(长沙)有限公司

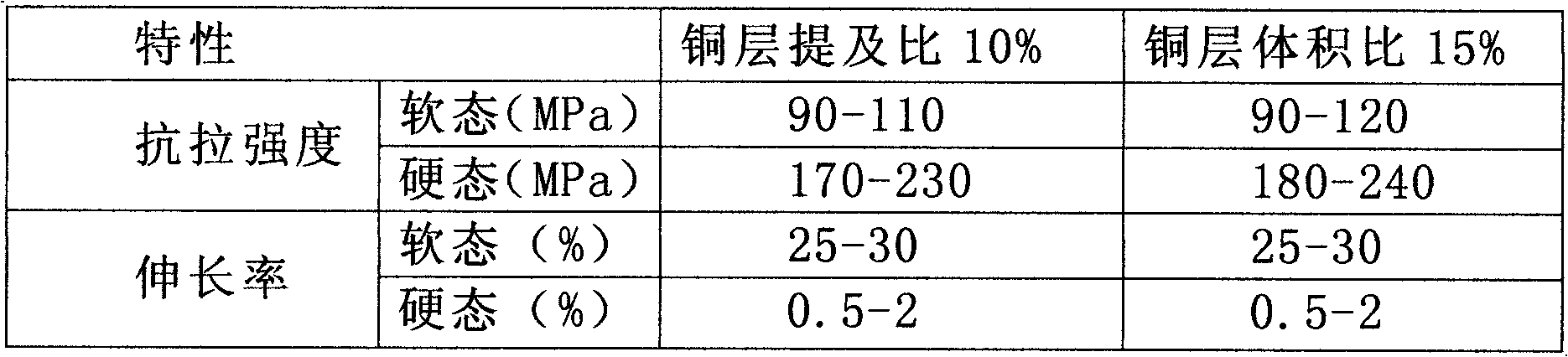

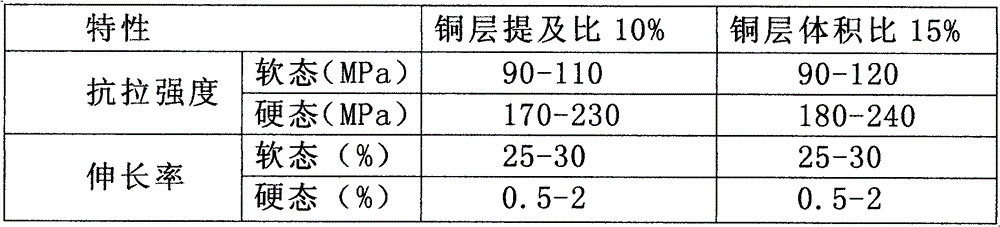

Production process of copper coated aluminum-magnesium bimetallic conductor

InactiveCN102324276AImprove conductivityConductivity adjustmentCable/conductor manufactureCopper platingSide reaction

The invention relates to the technical field of metal conductor processing, in particular to a production process of a copper coated aluminum-magnesium bimetallic conductor, solving the technical problems of unreasonable prior art and the like. The production process comprises the following steps of: A, surface preprocessing; B, zinc deposit preprocessing; C, cyanogens-free nickel preplating; D, silicate copper plating; and E, postprocessing. The production process of the copper coated aluminum-magnesium bimetallic conductor has the advantages that: 1, the surface activity of an aluminum-magnesium alloy is better regulated, operation quality in a subsequence electroplating process and stability in a drawing process are ensured; 2, the problem of broken wires of electroplating intermediate products in a subsequent drawing process is solved, yield of final products is increased; and 3, electroplating is carried out by adopting a pulse modulation power supply, a microstructure of electrocrystallization copper is improved, compactness of a copper coating is improved, and hydrogen evolution side reaction is inhibited.

Owner:HANGZHOU ZHENDA HARDWARE MACHINERY

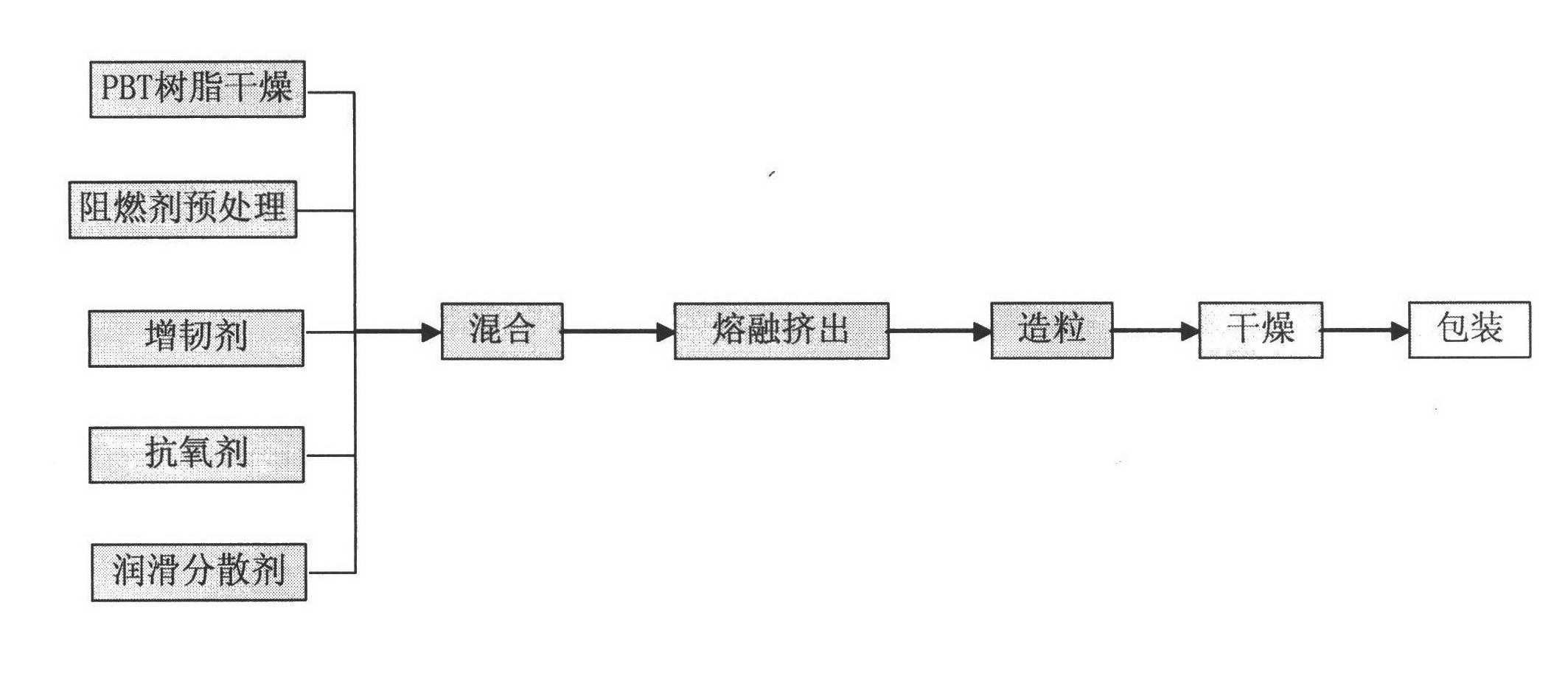

Halogen-free phosphorus-free flame-retarding toughening master batch special for PBT (polybutylene terephthalate) and preparation method thereof

InactiveCN102532830AImprove flame retardant performanceModification of the combustion processPolyethylene terephthalateAntioxidant

The invention provides a halogen-free phosphorus-free flame-retarding toughening master batch special for PBT (polybutylene terephthalate) and a preparation method thereof. The master batch is characterized in that the raw material formulation comprises the following components in percentage by weight: 20-60% of PBT resin, 70-35% of halogen-free phosphorus-free flame retardant, 5-10% of toughening agent, 0.2-0.6% of antioxidant, 1-3% of lubricating and dispersing agent and 0.2-1% of coupling agent. In the preparation method, PBT is used as a carrier, and PDPTP is used as the halogen-free phosphorus-free flame retardant; after surface treatment is carried out, the toughening agent, the dispersing agent and the antioxidant are added, and extrusion and granulation are carried out through two screws so as to prepare the halogen-free phosphorus-free flame-retarding toughening master batch special for PBT. According to the invention, the environment-friendly index of the prepared master batch meets the requirements of European Union RoHS (Restricted of Hazardous Substances), IEC (International Electrotechnical Commission) halogenation-free and Reach laws; and the prepared master batch can be used for modification of PBT, thus the flame-retarding grade of PBT reaches American UL 940.8mm V-0 grade, the CTI (comparative cracking index) value reaches more than 425V, the glowing filament experiment temperature reaches 750 DEG C but firing is not generated, and match color is not influenced.

Owner:SUZHOU CUIZHI NEW TECH DEV

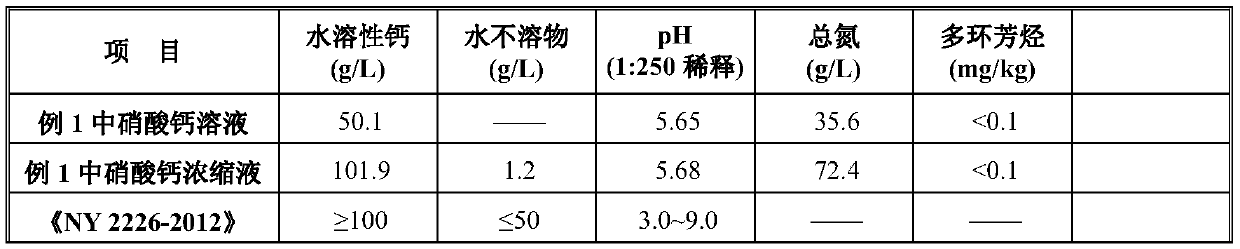

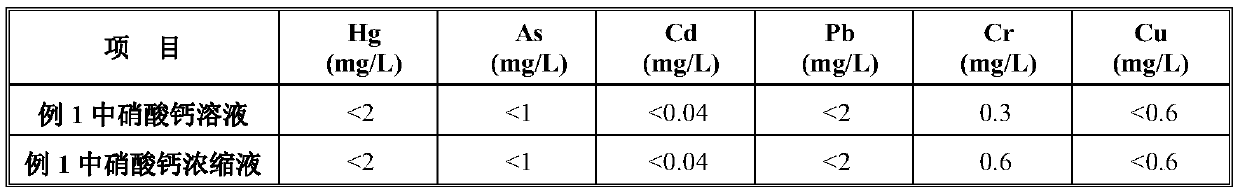

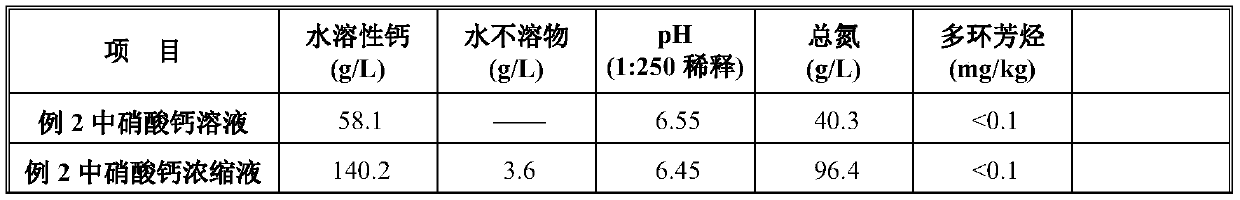

Preparation method of medium element water-soluble fertilizer liquid product containing calcium nitrate

InactiveCN111187099ARealize resourcesReduce foulingNitrate fertilisersLiquid productActivated carbon

The invention relates to a preparation method of a medium element water-soluble fertilizer liquid product containing calcium nitrate. The method comprises the following steps: 1, adding a small amountof clear water as a base solution into a reactor, adding deplating waste nitric acid and 20-25% of lime milk in a parallel flow mode, keeping the pH value of the reaction solution at 5-7, and stopping feeding after reaching the set volume; 2, taking 10-20 ml of the reaction slurry, filtering, adding 0.1 ml of a heavy metal trapping agent into the filtrate in a dropwise manner, and if a black precipitate is generated, continuously adding the deplating waste nitric acid and the heavy metal trapping agent into the reactor according to a ratio of 1000:2 (V / V); 3, repeating the step 2 until the filtrate has no black precipitate, and filtering the slurry to obtain a calcium nitrate crude solution; 4, adding active carbon into the calcium nitrate crude solution to remove organic impurities, andfiltering; and 5, evaporating and concentrating the calcium nitrate solution until the specific gravity is 1.28-1.45, and cooling to room temperature to obtain a medium element water-soluble fertilizer liquid product with the calcium content of 100-160 g / L.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Environment-friendly printing ink for POF shrink film printing

The invention discloses environment-friendly printing ink for POF shrink film printing. The printing ink is composed of a printing ink main body and diluent. The printing ink is characterized in that the weight ratio of the printing ink main body to the diluent is 1:1; the printing ink main body is prepared from the following components in percentage by weight: 25-35% of EVA resin solution, 10-20% of ethyl acetate, 10-30% of n-propyl acetate, 8-37% of pigments, 1-3% of polyethylene wax, 1-5% of dispersant, 10-20% of modified material and 1-3% of rosin resin. The POF shrinking film gravure printing ink prepared by the formula realizes industrial production of the POF shrinking films. The POF shrinking film is a safe and reliable soft shrinking film which is high in transparency, high in shrinking percentage, high in toughness, high in hot-sealing performance, and excellent in static resistance and cold resistance, so that the production and operation environments are greatly improved and the POF shrinking film is environment-friendly and sanitary.

Owner:DONGCHANG IND LINHAI CO LTD

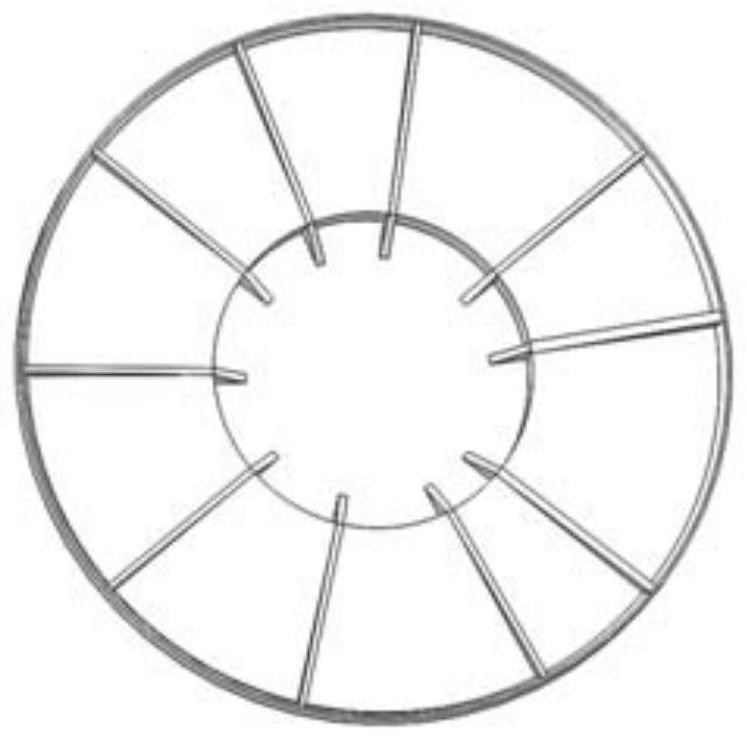

Movable slag hot-stew dust removal device and method

ActiveCN107723395AImprove the production operating environmentSmall footprintRecycling and recovery technologiesSlagSmall footprint

The invention relates to a movable slag hot-stew dust removal device and method. In the slag hot-stew treatment process, in the operations of deslagging, drossing and slag-out, top-suction exhaust isconducted on hot-stew smoke in a plant through a movable hood vehicle. The movable hood vehicle is combined with a rotating cover for dust removal, the movable hood vehicle can move on a movable trackin a reciprocating manner for dust removal without influencing the slag hot-stew operation under the condition of opening the rotating cover; and the movable hood vehicle is connected with a telescopic pipeline, and the smoke enters a wet type hydrocyclone through the pipeline, is subjected to dust removal and then is exhausted from a chimney under the effect of a fan. The movable slag hot-stew dust removal device and method have the beneficial effects that based on the device and method, up-to-standard emission of hot-stew dust removal of the slag is achieved, PLC remote control is adopted for the device, the occupied area is small, the degree of automation is high, and the production operation is convenient. By the adoption of the movable slag hot-stew dust removal device and method, the production operation environment of workers in the slag hot-stew process is improved, the exhaust dust concentration of the dust removal smoke is lower than 30 mg / m<3>, and the organized up-to-standard emission of the smoke in the slag hot-stew plant is achieved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +3

Copper-clad aluminum-magnesium bimetallic wire production process

InactiveCN102324276BImprove conductivityConductivity adjustmentCable/conductor manufactureCopper platingSide reaction

The invention relates to the technical field of metal conductor processing, in particular to a production process of a copper coated aluminum-magnesium bimetallic conductor, solving the technical problems of unreasonable prior art and the like. The production process comprises the following steps of: A, surface preprocessing; B, zinc deposit preprocessing; C, cyanogens-free nickel preplating; D, silicate copper plating; and E, postprocessing. The production process of the copper coated aluminum-magnesium bimetallic conductor has the advantages that: 1, the surface activity of an aluminum-magnesium alloy is better regulated, operation quality in a subsequence electroplating process and stability in a drawing process are ensured; 2, the problem of broken wires of electroplating intermediate products in a subsequent drawing process is solved, yield of final products is increased; and 3, electroplating is carried out by adopting a pulse modulation power supply, a microstructure of electrocrystallization copper is improved, compactness of a copper coating is improved, and hydrogen evolution side reaction is inhibited.

Owner:HANGZHOU ZHENDA HARDWARE MACHINERY

Method for recycling waste heat of silica fume

InactiveCN101839492AEfficient collectionSimple processCombustion technology mitigationStationary tubular conduit assembliesProcess engineeringLow input

The invention relates to a method for recycling waste heat of silica fume in the production process of an industrial silicon furnace, which is characterized by adopting reverse-flow heat exchanging technology to collect the waste heat as efficient as possible on the premise of not changing a conventional flue. The method has the advantages of simple process flow, low input cost and capability of reducing heat discharge in the production process of industrial silicon, lowering surrounding heat radiation and improving production and operation environment. Moreover, the recycled heat is used for drying raw materials, so cost can be further saved and benefits are created for enterprises.

Owner:LANXING SILICON MATERIALS

Functional masterbatch of halogen-free intumescent flame retardant, and preparation method thereof

The invention relates to functional masterbatch of a halogen-free intumescent flame retardant, and a preparation method thereof. The halogen-free intumescent flame retardant in the functional masterbatch is a phosphorus-nitrogen series intumescent flame retardant, and a matrix in the functional masterbatch is a polyolefin resin. The functional masterbatch comprises, by weight, 50-90 parts of the halogen-free intumescent flame retardant, 20-45 parts of the polyolefin resin, 1-5 parts of a compatibilizer; 1-5 parts of a lubricant and 1-5 parts of a surface treatment agent. According to the present invention, dust pollution due to the flame retardant is fundamentally overcome; the flame-retardant masterbatch and polypropylene have good dispersions, such that purposes of environmental protection and no pollution are achieved; heavy metal contents of the functional masterbatch accord with requirements of the report of societe generale de surveillance S.A. (SGS); and the functional masterbatch has a good flame retardant property and high economy.

Owner:SHANGHAI RES INST OF CHEM IND

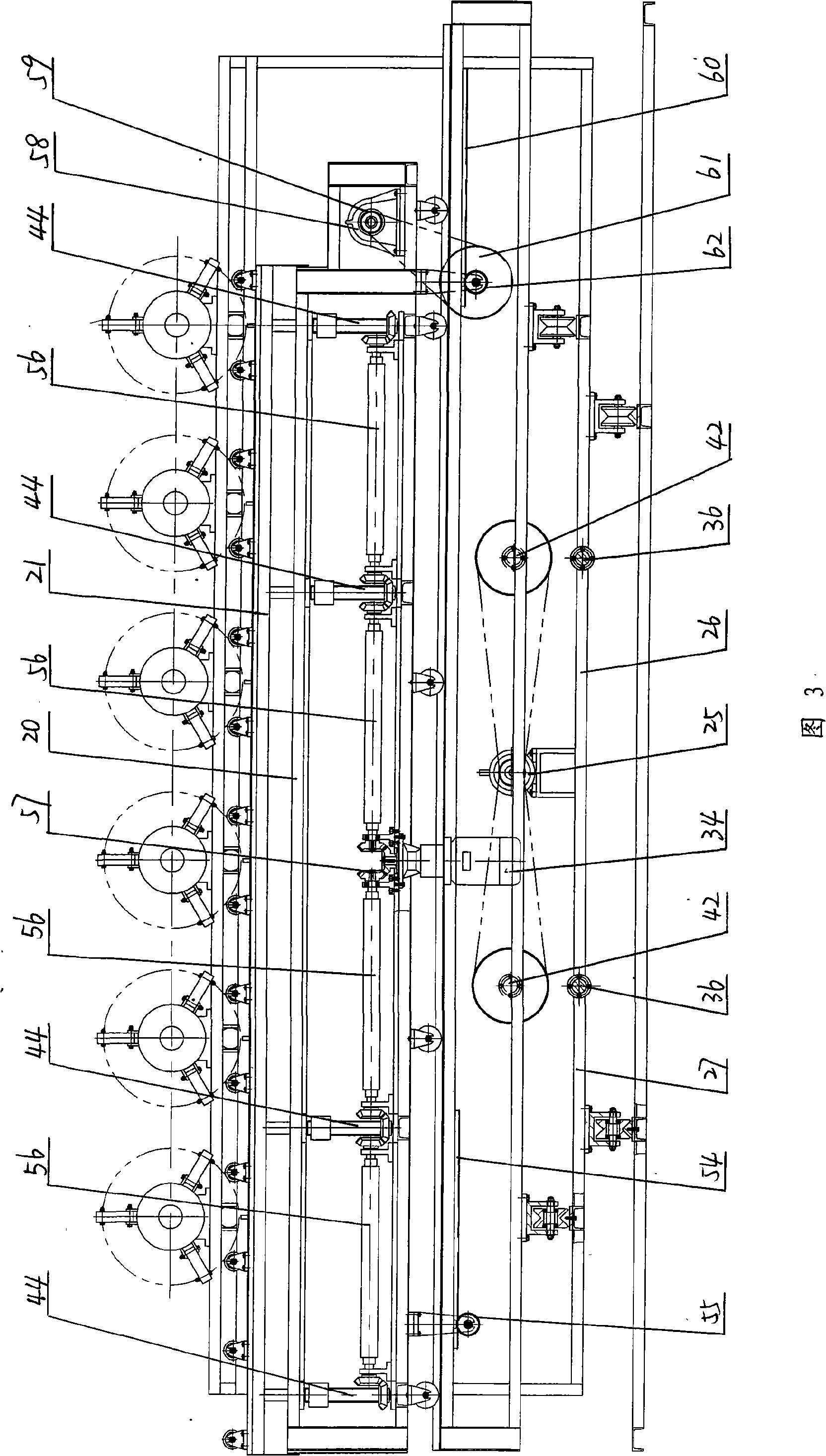

Suspended steel tube externally sprayed plastic powder recovery integrated spraying production line

PendingCN108097515AImprove cleanlinessEnsure physical and mental healthSpray boothsProduction lineMetallurgy

The invention relates to a suspended steel tube externally sprayed plastic powder recovery integrated spraying production line. The suspended steel tube externally sprayed plastic powder recovery integrated spraying production line comprises a base, a rack, a powder spraying moving box, a powder spraying moving box moving device, a steel tube conducting rack and a steel tube supporting rack, wherein the steel tube conducting rack drives a steel tube from a preheating furnace to move to the steel tube supporting rack; the steel tube supporting rack supports the steel tube from two ends and rotates at the same time; the powder spraying moving box moving device drives the powder spraying moving box to pass from the outer surface of the steel tube to spray the outer surface of the steel tube.The side wall of the spraying box in the production line provided by the invention is of double layers, a through hole is formed in the lower portion of the inner side of the box body, and residual powder after spraying can be recovered to the powder spraying box through a recovery isolating layer, so that powder is fully recycled, and the raw materials are saved.

Owner:天津昕田管道科技有限公司

Production process and application of silicon dioxide for choline chloride carrier

PendingCN112694092AImprove liquidityImprove adsorption capacitySilicaAccessory food factorsPhysical chemistrySeed crystal

The invention discloses a production process of silicon dioxide for choline chloride carriers, which comprises the following steps of seed crystal preparation, primary synthesis, secondary synthesis, semi-finished product preparation, final product preparation, screening to remove fine powder with the mesh number of more than 200 after the final product preparation is completed, and packaging in a vacuum negative pressure state to obtain the final product. In addition, the invention also discloses application of the silicon dioxide prepared by the preparation process as a choline chloride carrier. The silicon dioxide product prepared by the process is good in flowability, does not raise dust or cake in the choline chloride adsorption process, has outstanding adsorption performance, adsorbability and manufacturing cost which are obviously superior to those of an existing granular carrier, is good in flowability and dispersibility in premixed feed after adsorbing choline chloride, does not aggregate or cake, and the addition safety and the storage stability of choline chloride products are greatly improved, and the production operation environment is fundamentally improved.

Owner:山东联科卡尔迪克白炭黑有限公司

Preparation method for benzyltriphenylphospho

ActiveCN109912651AAvoid corrosionPrevent backflowGroup 5/15 element organic compoundsChemical industryBenzyl chlorideSolvent

The invention belongs to the technical field of fine chemical engineering, and specifically discloses a preparation method for benzyltriphenylphospho. The preparation method comprises the following steps: performing reflux reaction by utilizing reaction exotherm at a certain initial temperature in a mixed solution of water and benzyl chloride by taking triphenylphosphine and the benzyl chloride asraw materials; allowing standing still for layering, preserving heat and separating liquid, performing micro-membrane filtering, cooling and crystallizing, performing centrifugal separation and performing vacuum drying to obtain the benzyltriphenylphospho. The preparation method provided by the invention is simple in process, quick in reaction, mild in conditions, high in purity and high in yield. According to the preparation method, the water serving as the solvent and excessive benzyl chloride are recycled for utilizing; the reaction is accelerated by utilizing the reaction exotherm, so that energy conservation and emission reduction are realized; the cost is reduced; industrial production is facilitated better. The content of the benzyltriphenylphospho synthesized by the preparation method is 99% or higher, and the reaction yield is up to 98%.

Owner:自贡天龙化工有限公司

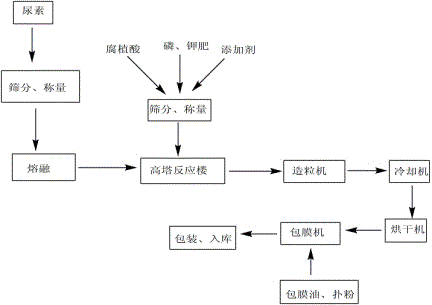

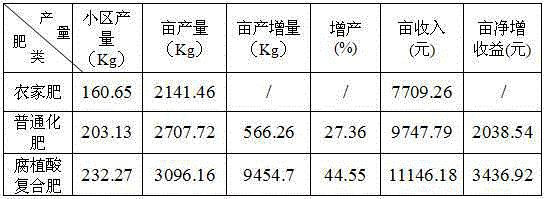

Synchronous slow-release humic acid fertilizer produced by using high tower process and production method of synchronous slow-release humic acid fertilizer

The invention relates to a production method of a slow-release fertilizer and particularly relates to a synchronous slow-release humic acid fertilizer and a production method thereof. The synchronous slow-release humic acid fertilizer comprises the following raw materials in parts by weight: 36-42 parts of urea, 7-12 parts of monoammonium phosphate, 7-12 parts of potassium hydroxide, 26-32 parts of humic acid, 6-10 parts of sodium hydroxide and 0.5-3 parts of trace elements. By using the synchronous slow-release humic acid fertilizer, a slow-release effect synchronous with a fertilizer demand curve of crops is achieved, the quality of soil can also be improved, the stress resistance of the crops is improved, and the quality of a fruit is improved.

Owner:史丹利化肥宁陵有限公司

Organic fertilizer slope fermentation method

InactiveCN110759765AImprove the production operating environmentReduce consumptionBio-organic fraction processingMicroorganism based treatmentAgricultural engineeringOrganic fertilizer

The invention discloses an organic fertilizer slope fermentation method. The organic fertilizer slope fermentation method comprises the following steps of first, and choosing a slope on a barren mountain with the natural fall of 5 meters or more, and selecting a part, with the length of 10 meters and the width of 30 meters, on an inclined plane of the slope as a fermentation filed; second, blending the raw materials needed for producing organic fertilizer according to a formula till the mixture comprises 45% to 70% of organic matter, 3% to 10% of nitrogen phosphorus and potassium, and 45% to 55% of moisture while the pH ranges from 5.5 to 7.0, and the carbon nitrogen ratio ranges from 1 to 25 to 1 to 30, and adding a fermentation decomposition agent according to the concentration of 5 kilograms per ton; third, mixing the raw materials in the second step with a loader and throwing the raw materials to the slope while the thickness of a material layer is 2 meters, and starting aeration after carrying out fermentation for two days; fourth, setting the fermentation cycle ranging from 10 days to 15 days; and fifth, carrying out decomposition for ten days after complete fermentation decomposition, and obtaining the commercial organic fertilizer after subpackaging the fertilizer. According to the organic fertilizer slope fermentation method, because a technology of adopting the inclined plane of the slope of a barren mountain for fermentation, the technological process of fermentation can be simplified, machine input, power consumption and land input are reduced, and the market competitiveness of products is improved.

Owner:YUNNAN YUNYE FERTILIZER +2

Process for producing O, S-dimethyl-N-acetylphosphoramidothioate

InactiveCN101691381AImprove the production operating environmentSimple process facilitiesGroup 5/15 element organic compoundsSodium carbonateChemistry

The invention discloses a new process for producing O, S-dimethyl-N-acetylphosphoramidothioate. In the prior neutralizing process for preparing the O, S-dimethyl-N-acetylphosphoramidothioate by adopting acetylation of O, S-dimethyl acetylphosphoramidothioate, the process adopts sodium carbonate solution or sodium bicarbonate solution to carry out neutralizing treatment; the process not only can effectively improve the production operating environment and simplify the process facilities, but also can facilitate the produced wastewater to be treated easily, and can reclaim sodium acetate conveniently with low cost so as to greatly reduce the production cost which can be reduced by about 5,000 yuan for each ton of O, S-dimethyl-N-acetylphosphoramidothioate; and the process is a new process which is economical and environmentally-friendly, is easy to be controlled and can be steadily operated for a long term.

Owner:陈兵

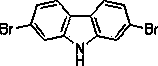

Method for preparing 2,7-dibromocarbazole

ActiveCN102875447BImprove the production operating environmentHigh yieldOrganic chemistryChemical synthesisIron salts

The invention discloses a method for preparing 2,7-dibromocarbazole, and belongs to the field of organic chemical synthesis. The method comprises the following steps: 2-nitro-4,4'-dibromobiphenyl is prepared by nitration reaction by taking 4,4'-dibromobiphenyl as a raw material, 1, 2-dichloroethane as a solvent, aluminum salt or iron salt as a catalyst and dilute nitric acid as a nitration reagent; and then, the oxygen closed ring of 2-nitro-4,4'-dibromobiphenyl is removed by taking dichlormethane as a solvent and one of 2-diphenylphosphine-biphenyl,tri(o-tolyl)phosphine or diphenyl-2-pyridylphosphine as a deoxidizer to obtain 2,7-dibromocarbazole. The reaction condition is mild and controllable, the cost is low, the operation is simple and the yield is high. The prepared 2,7-dibromocarbazole can be applied to the field of organic photoelectric materials and medicaments and is an important intermediate for carbazole photoelectric materials, medicaments and pesticides.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL +1

Environmentally-friendly acid-etching and descaling conditioning fluid used for bimetal composite wire processing

The invention belongs to the technical field of metal surface treatment, relates to aluminium magnesium alloy material surface treatment, and in particular relates to an environmentally-friendly acid-etching and descaling conditioning fluid used for bimetal composite wire processing. According to the conditioning fluid, the technical problems of unreasonable prior art and the like can be solved. The conditioning fluid comprises the following components: 500-600ml / L of 68% HNO3 solution, 300-350ml / L of H3PO4, 10-15g / L of inorganic ammonium salt, 15-25g / L of organic amido-contained compound, 5-10g / L of surfactant and the balance of water. The conditioning fluid has the advantage of reasonable compatibility, a surface oxidation film on the surface of the aluminium magnesium alloy can be effectively removed in the acid etching and descaling process, and the aluminium magnesium alloy can be protected from excess corrosion. In comparison with the traditional technology, nitric oxide pollutant amount is reduced by above 90%, thereby greatly improving production and operation environment.

Owner:HANGZHOU ZHENDA HARDWARE MACHINERY

Injection molding process machining method for large composite material reinforced thin-wall support structure

InactiveCN112372931AReduce production energy consumptionReduce manufacturing costCoatingsMolten stateInjection molding machine

The invention provides an injection molding process machining method for a large composite material reinforced thin-wall support structure. The method comprises the following steps that an injection molding machine heats raw materials to enable the raw materials to be in a molten state; a mold is closed under the action of high pressure, the injection molding machine injects the molten materials into a pouring system, wherein a cooling system is always in a working state while the mold is closed; after the injection action of the injection molding machine is completed, the mold is opened aftermaintaining pressure for a period of time; and an ejection system ejects out a workpiece. According to the method, the process of directly carrying out injection molding through the mold when the thermoplastic materials are in a viscous flow state is adopted, the product performance requirement is equivalent to that of a metal product, the production energy consumption is reduced, the productionoperation environment is excellent, mass production in a short time can be realized, and the production cost is greatly reduced.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com