System for processing steel drum renovation

A technology for processing systems and steel drums, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems that affect production efficiency, inconvenient use, complex structure, etc., to improve production efficiency and safety performance, increase the effect of the dust cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

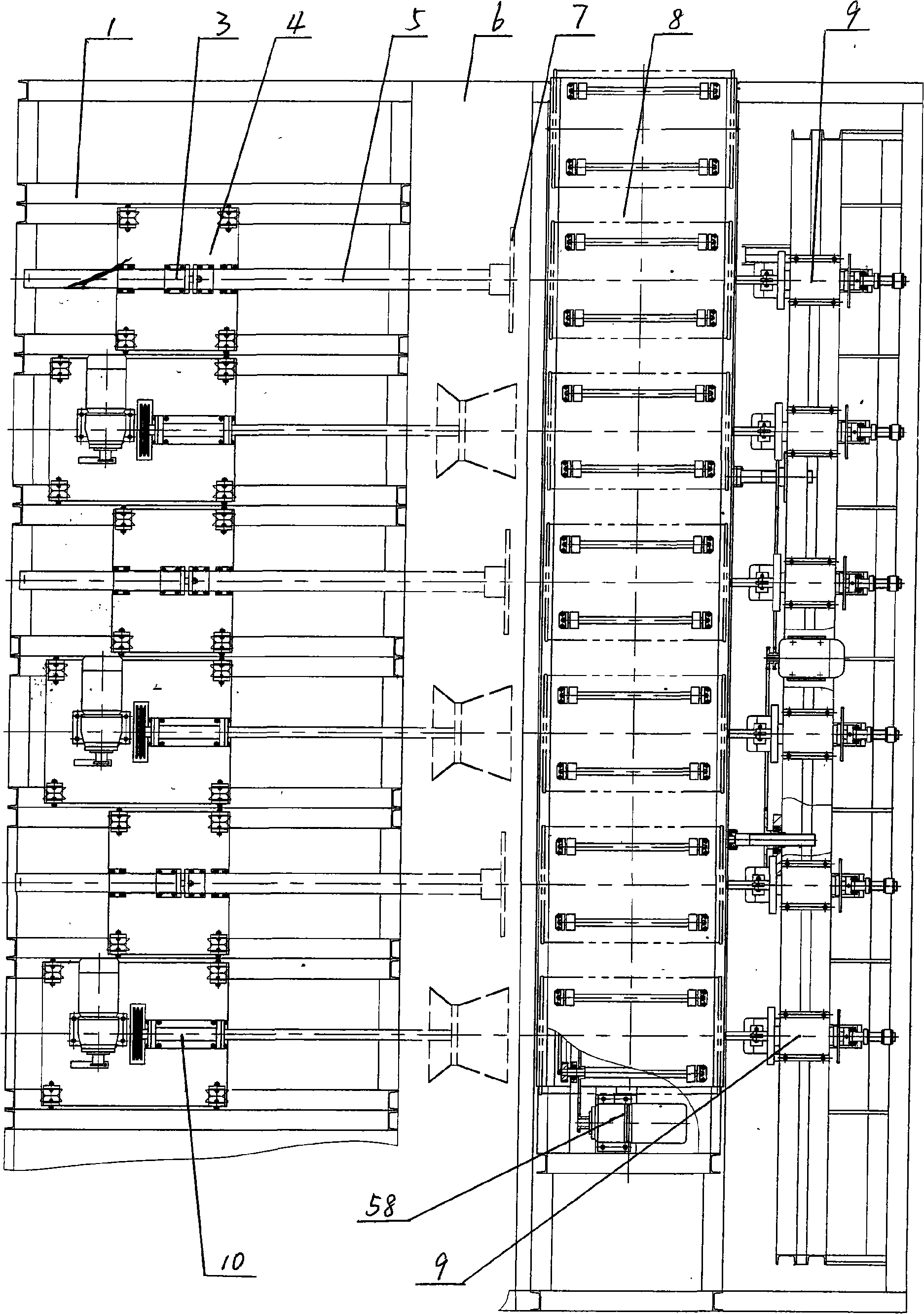

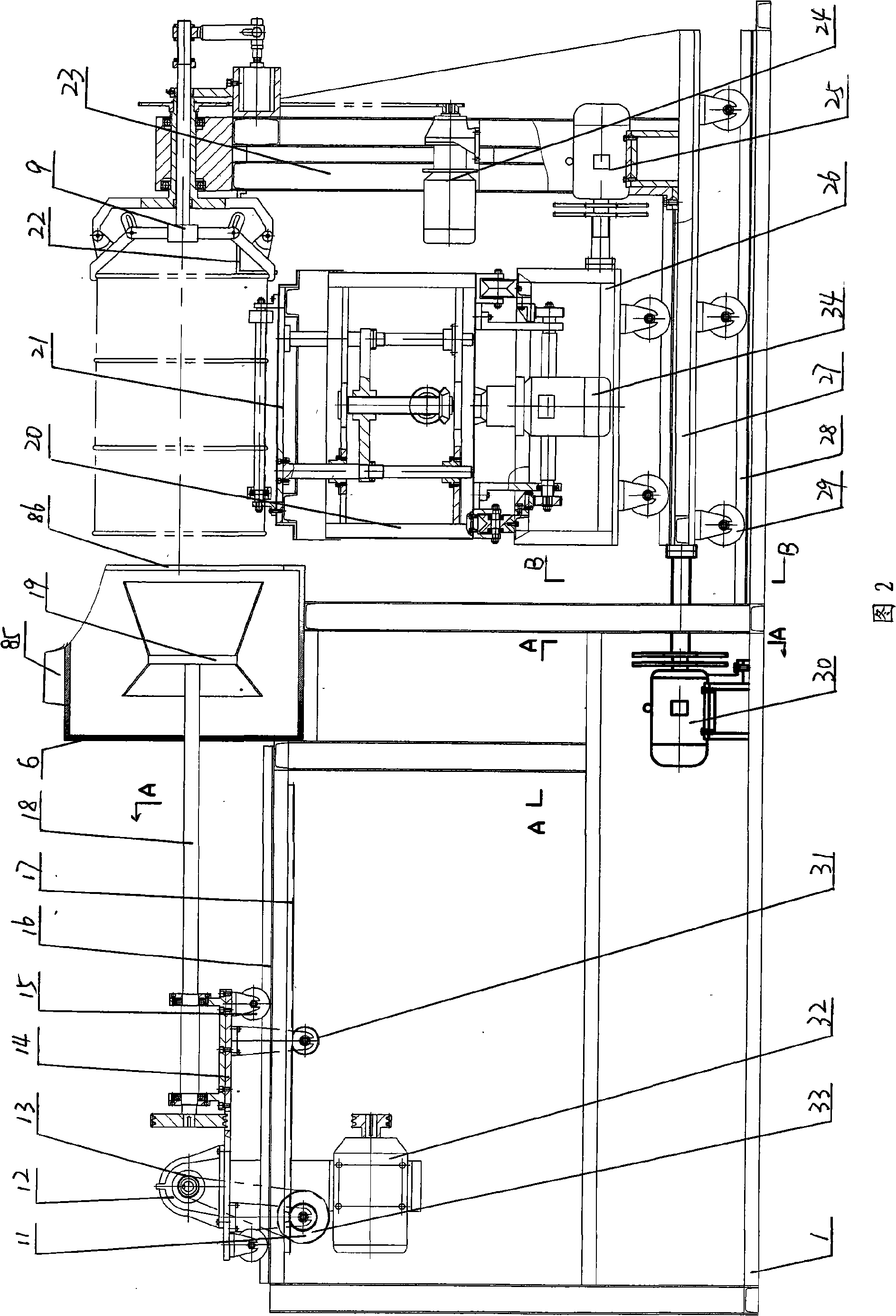

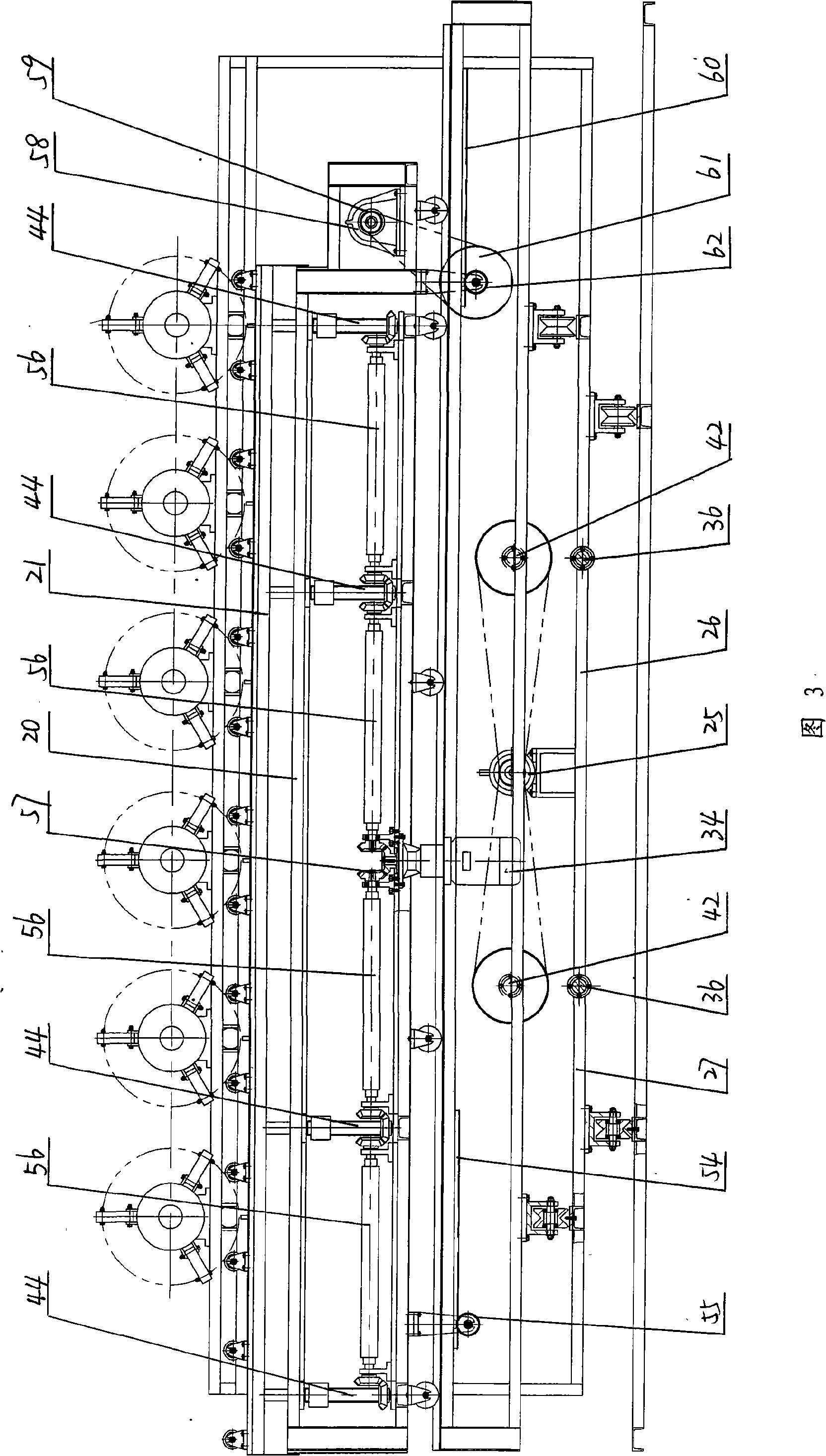

[0028] The schematic diagram of the refurbishment processing system of the steel drum of the present invention is as figure 1 , shown in Fig. 2, Fig. 3, Fig. 4, comprise at least one group of brush barrel system that is made up of brush barrel unit 10 and card barrel unit 9, at least one group is made of flame spraying unit 3 and the card barrel with the same structure as brush barrel system Unit 9 consists of fire spraying system, barrel lifting and shifting unit 8. When multi-station is used, the bucket brush system and the fire spray system are arranged alternately, the first station is the fire spray system, the second station is the scrubbing system, the third station is the fire spray system, and the fourth station is the brush scrubbing system , arranged accordingly.

[0029] The brush bucket unit includes a brush bucket trailer 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com