Method for preparing multistage micron structure on titanium implant surface

A technology of titanium implants and micron structures, which is applied in the field of preparing multi-level micron active surfaces, can solve problems such as health damage of operators, corrosion of workshops and equipment, environmental pollution, etc., to improve the environment of production operations, with little environmental pollution, The effect of excellent hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Grind the surface of the titanium implant with sandpaper or a grinding wheel, and then ultrasonically clean the polished titanium implant in acetone, ethanol, and deionized water for 10 minutes;

[0045] (2) After cleaning, titanium implants with a mass fraction of 10% HN0 3 , 2%HF, 1%H 2 o 2 in aqueous solution, pickling for 2min;

[0046] (3) After pickling, the surface of the titanium implant was sandblasted with a 1:1 mixture of 80 mesh and 180 mesh ceramic sand in a sandblasting machine with a pressure of 5 bar and a distance of 0.5 cm;

[0047] (4) For titanium implants after sandblasting, ultrasonically clean them with acetone, ethanol, and deionized water for 10 minutes;

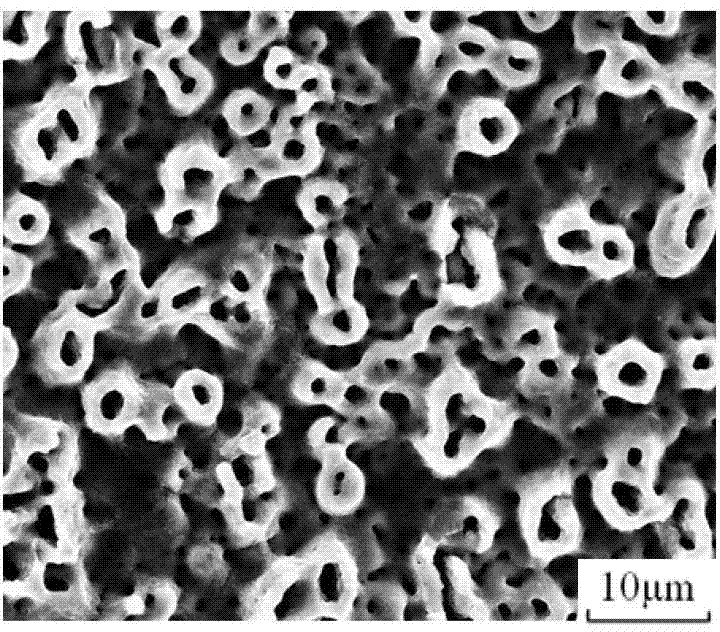

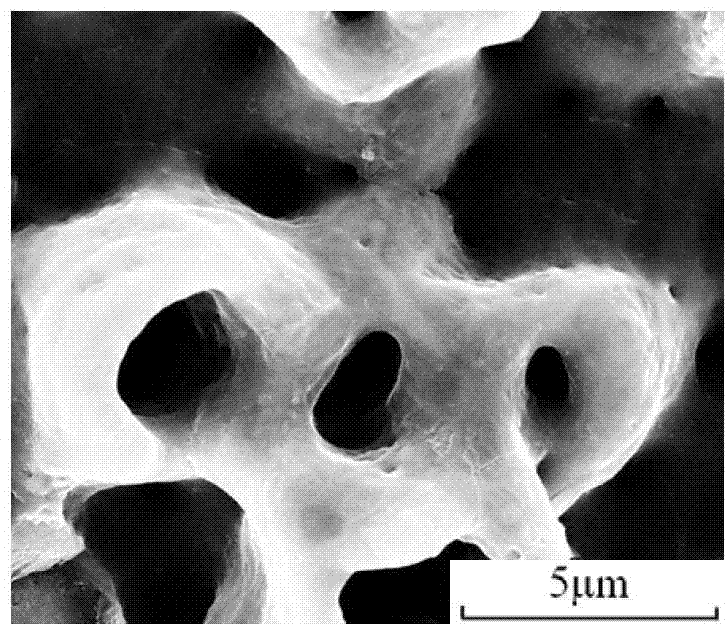

[0048] (5) Place the sample after sandblasting cleaning in a solution containing 15% H 2 SO 4 , 8%HCl, 1%HNO 3 , 0.2% ethylene glycol, 0.2g / L perfluorooctane sulfonate potassium, and the rest in deionized water solution, the acid etching temperature is 50°C, and the acid etching time...

Embodiment 2

[0052] (1) Polish the surface of the titanium implant with sandpaper or a grinding wheel, and then ultrasonically clean the polished titanium implant for 12 minutes in acetone, ethanol, and deionized water;

[0053] (2) After cleaning, the titanium implant was placed in the 3 , 2%HF, 1%H 2 o 2 in aqueous solution, pickling for 2min;

[0054] (3) After pickling, the surface of the implant was sandblasted by mixing 90 mesh and 150 mesh ceramic sand 2:1 in a sandblasting machine at a pressure of 6 bar and a distance of 0.5 cm;

[0055] (4) For titanium implants after sandblasting, ultrasonically clean them again in acetone, ethanol, and deionized water for 12 minutes;

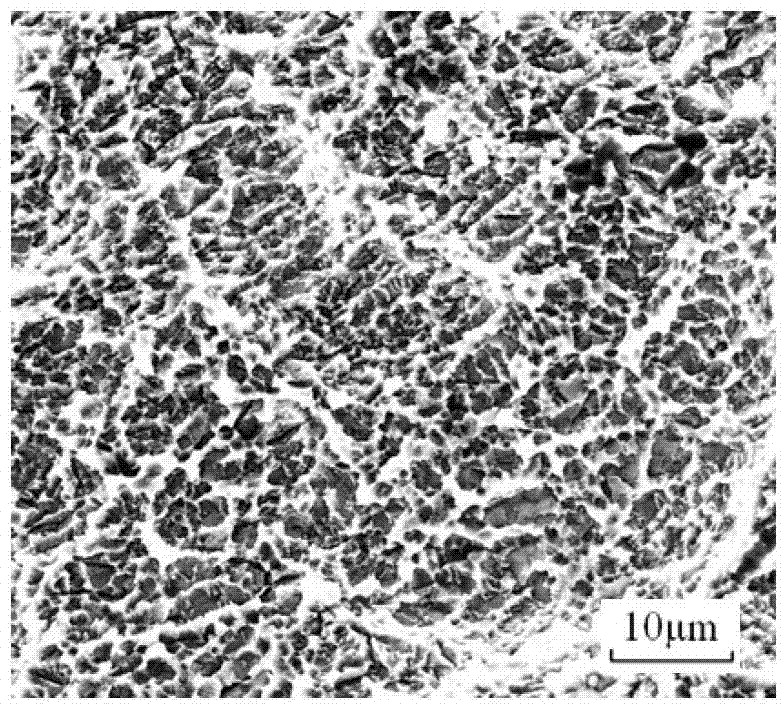

[0056] (5) Put the sample after sandblasting cleaning in the 2 SO 4 , 6%HCl, 2%HNO 3 , 1% ethylene glycol, 0.03g / L perfluorooctane sulfonate potassium, and the rest in a solution of deionized water, the acid etching temperature is 60°C, and the acid etching time is controlled at 50 minutes;

[0057] (6) Aft...

Embodiment 3

[0059] (1) Grind the surface of titanium implants with sandpaper or grinding wheel, and then ultrasonically clean the polished titanium implants in acetone, ethanol, and deionized water for 15 minutes respectively;

[0060] (2) After cleaning, titanium implants with a mass fraction of 15% HN0 3 , 3%HF, 2%H 2 o 2 in aqueous solution, pickling for 1min;

[0061] (3) After pickling, the surface of the titanium implant was sandblasted with a 1:1 mixture of 100 mesh and 160 mesh ceramic sand in a sandblasting machine at a pressure of 7 bar and a distance of 1 cm;

[0062] (4) For titanium implants after sandblasting, ultrasonically clean them again in acetone, ethanol, and deionized water for 15 minutes;

[0063] (5) Put the sample after sandblasting cleaning in the mass fraction of 25%H 2 SO 4 , 5%HCl, 3%HNO 3 , 2% ethylene glycol, 0.05g / L perfluorooctane sulfonate potassium, and the rest in deionized water solution, the acid etching temperature is 60°C, and the acid etching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com