Method for recycling waste heat of silica fume

A technology of waste heat recovery and micro-silicon fume, which is applied in the direction of indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve problems such as environmental pollution and resource waste, and achieve convenient construction, cost saving and low investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

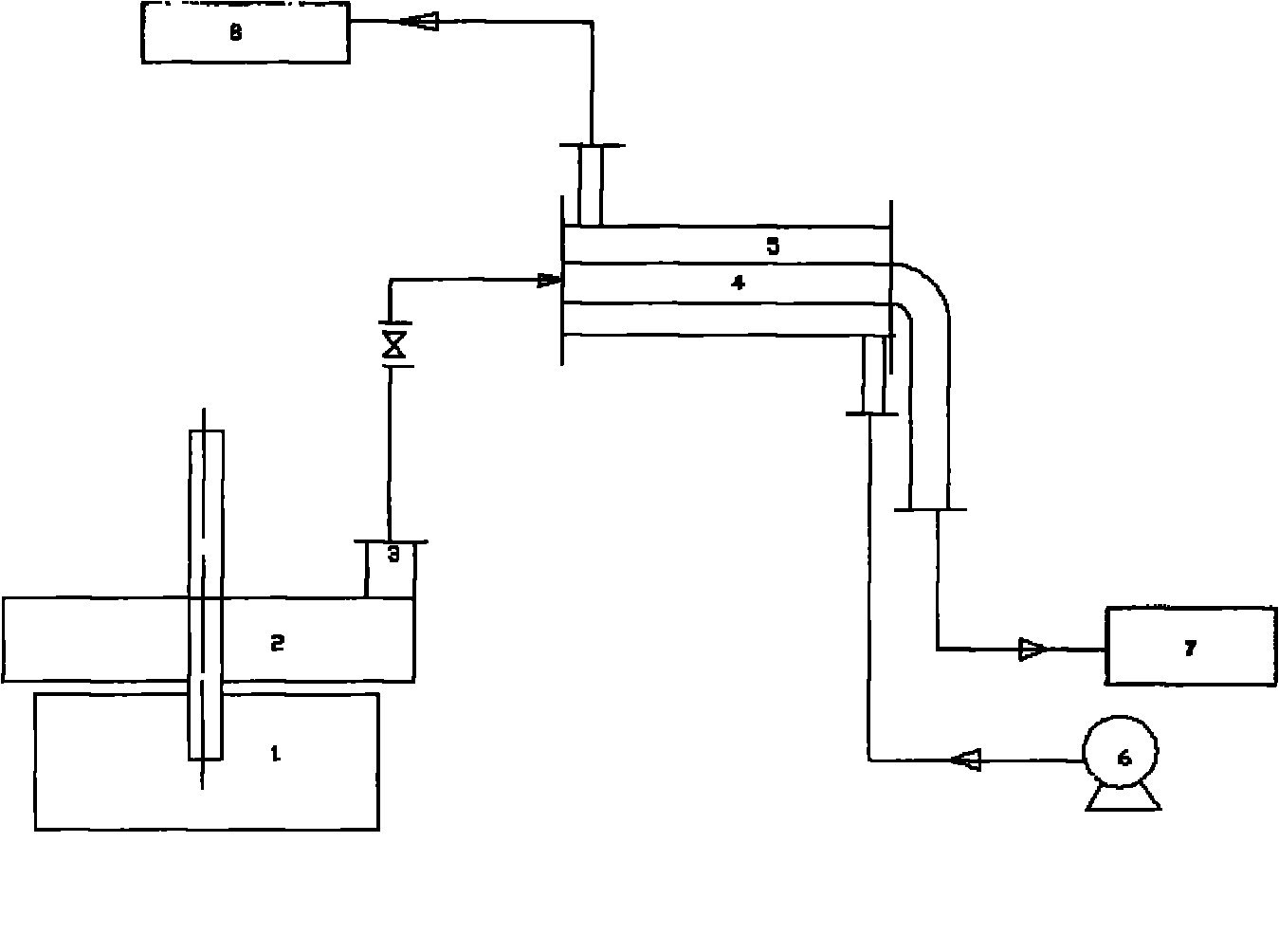

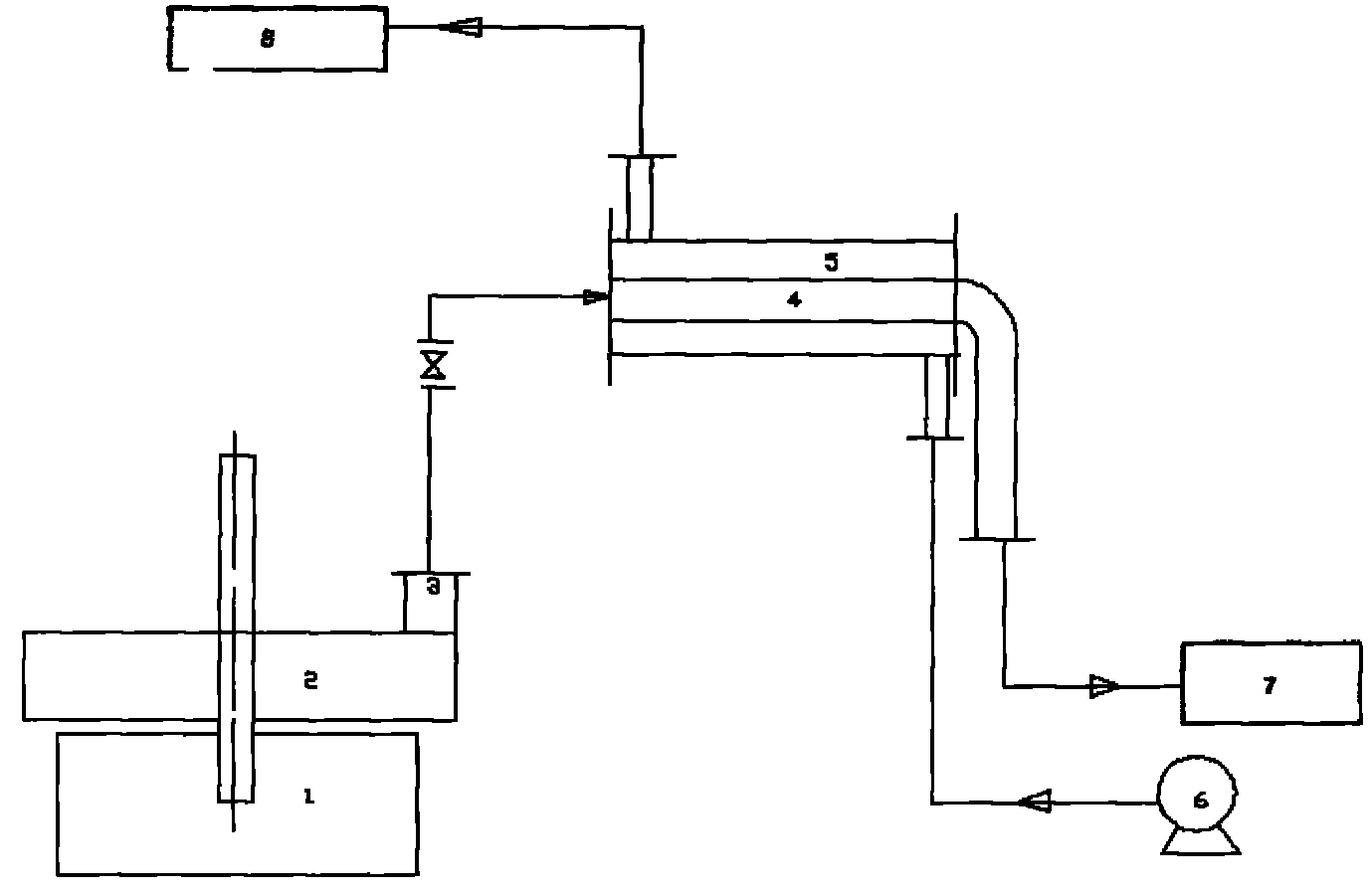

[0019] Such as figure 1 As shown, the high-temperature micro-silicon fume flue gas with an average temperature of 550°C from the industrial silicon furnace 1 enters the main pipe of the flue 2 and enters the air cooler 4 connected to the flue 2. The parameters of the air cooler 4 are Φ2820mm, δ8mm, and length 30 meters. The outside of the air cooler 4 is covered with a sleeve-type heat exchanger 5, and the outer wall of the sleeve-type heat exchanger 5 is covered with a heat-insulating material layer, and the heat-insulating material is aluminum-skinned rock wool. At the same time, the heat-collecting air enters the blower 6 through the inlet valve of the blower 6, and after the pressure is increased, it is collected into the outlet main pipe of the blower through the outlet valve of the blower 6 and sent to the casing heat exchanger 5. The flow rate of heat collecting air is 12000Nm 3 / h, the air velocity in the control tube is 10m / s.

[0020] In the sleeve-type heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com