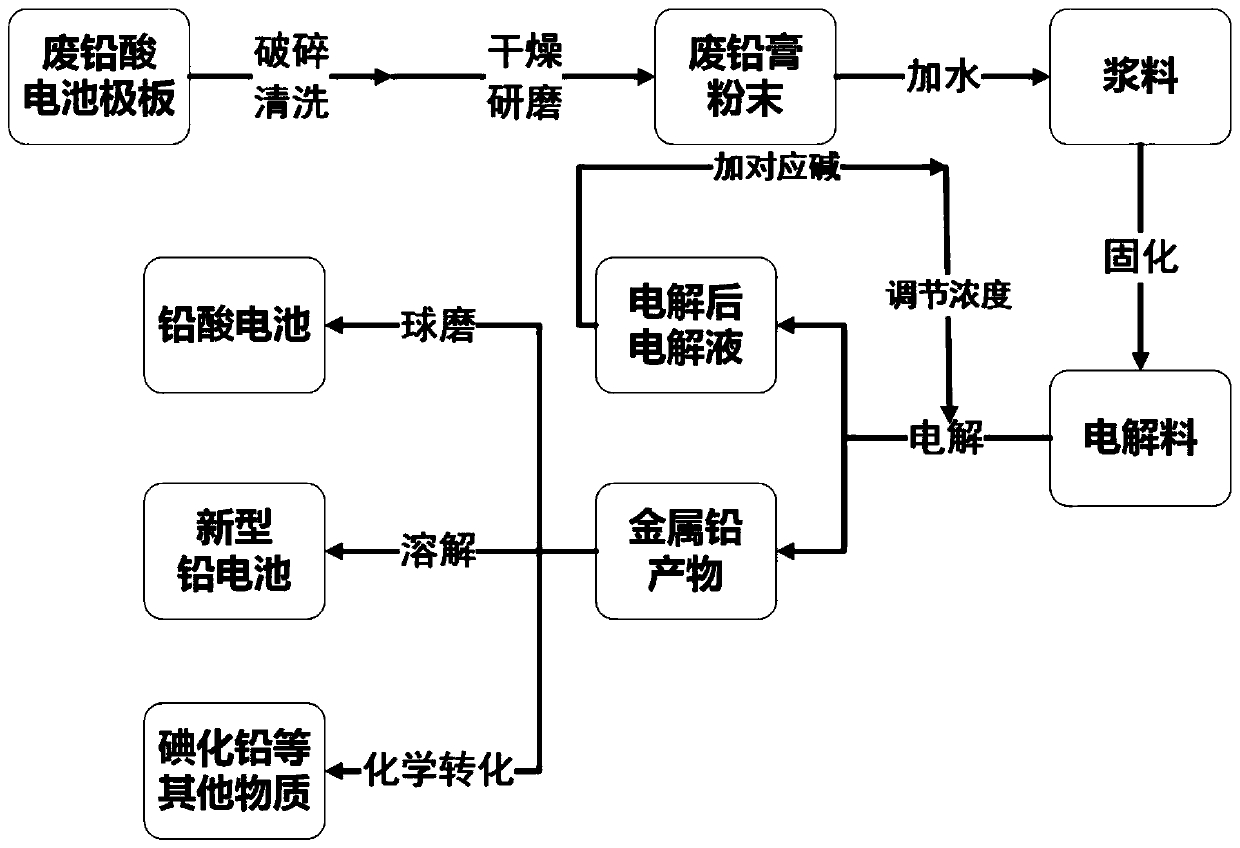

Method for recovering lead from waste lead paste by solid phase electrolysis method

A technology of solid-phase electrolysis and waste lead paste is applied in the field of lead recovery, which can solve the problems of large pollution, high cost, and high energy consumption for lead recovery, and achieve the effects of high conductivity, lower recovery costs, and lower reagent consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

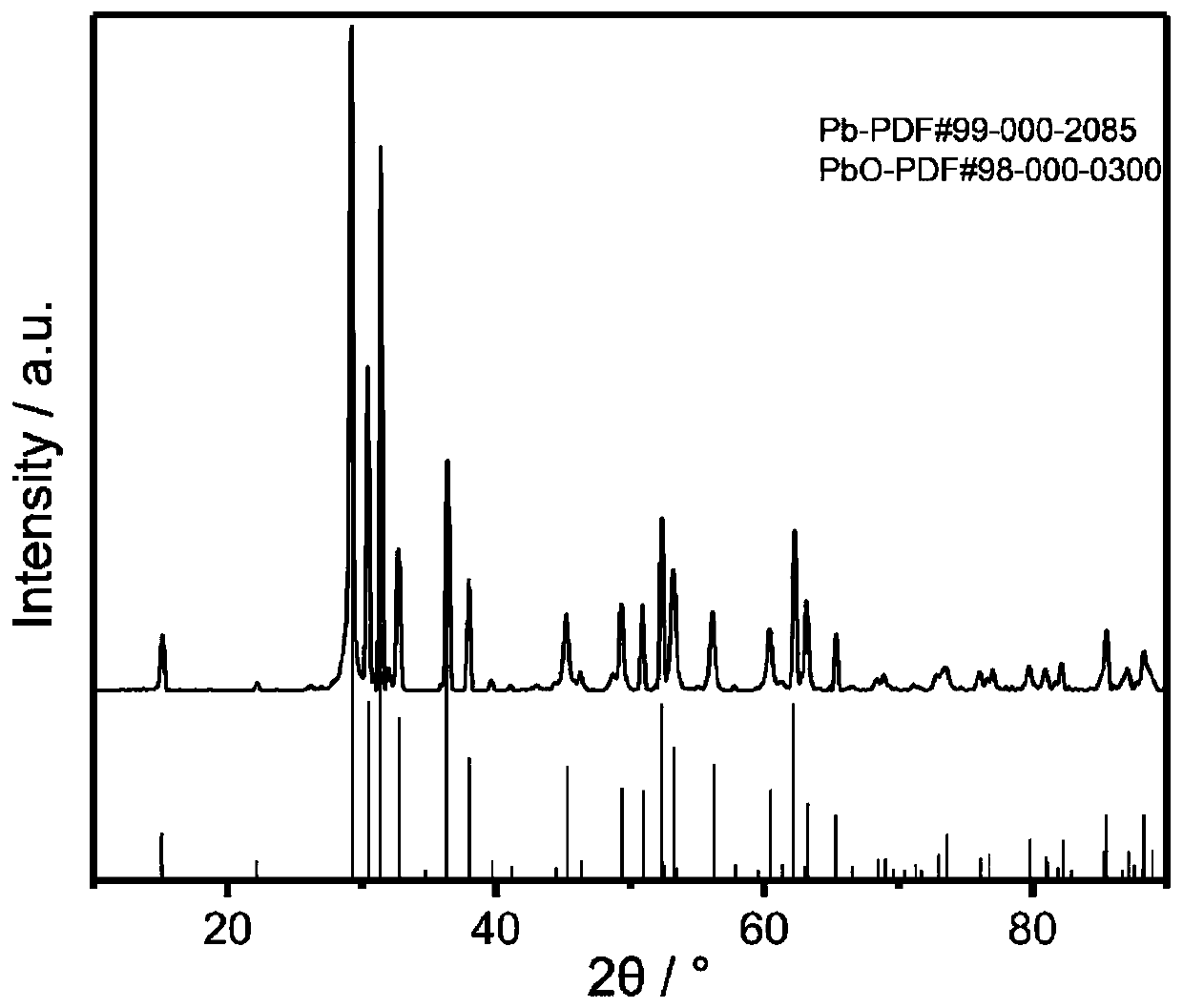

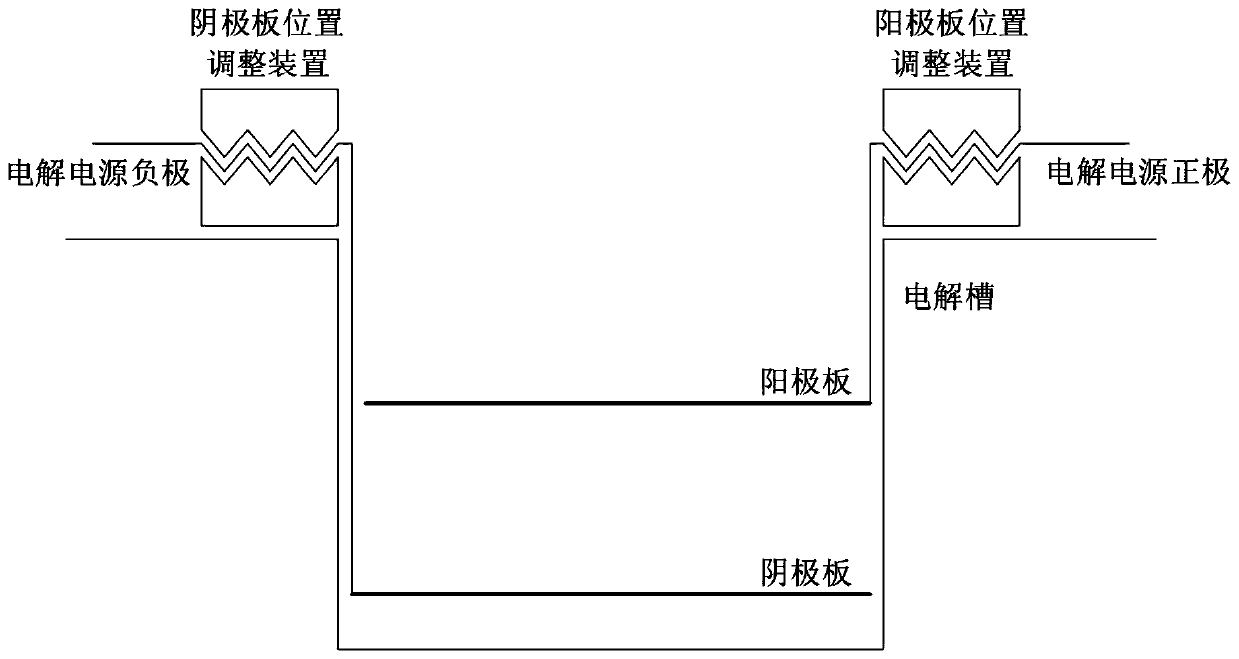

[0037]The recovered 12V, 14AH waste lead-acid batteries were crushed and separated to obtain 2.4kg waste lead paste. First, the waste lead paste is crushed by a pulverizer to obtain lead paste particles. Take 30 g of the crushed lead paste particles and put them into the reaction tank, add 3 g of water, and after stirring evenly, use a coater to evenly coat the mixture in the reaction tank to A stainless steel cathode plate with a thickness of 1.0 cm, put the coated cathode plate into an oven and cure at 80-100° C. for 1 hour to obtain the cathode part.

[0038] Put the cathode into the electrolytic cell. There are 400mL electrolyte and magnetic stirring rotor in the electrolytic cell. Fix the position of the anode in parallel at 2cm above the cathode for electrolysis. The electrolytic cell is a cylindrical container with a diameter of 7 cm and a height of 10 cm. The anode is a circular titanium-based iridium-coated tantalum mesh with a diameter of 6.5 cm. The electrolyte is 2...

Embodiment 2

[0040] The recovered 12V, 14AH waste lead-acid batteries were crushed and separated to obtain 2.4kg waste lead paste. First, the waste lead paste is crushed by a pulverizer to obtain lead paste particles. Take 10 g of the crushed lead paste particles and put them into the reaction tank, add 10 g of water, and after stirring evenly, use a coater to evenly coat the mixture in the reaction tank to The cathode plate is framed by a titanium plate with a thickness of 0.5 cm. The coated cathode plate is put into an oven and cured at 80-100° C. for 3 hours to obtain the cathode part.

[0041] Put the cathode into the electrolytic cell. There are 1000mL electrolyte and magnetic stirring rotor in the electrolytic cell. Fix the anode position in parallel at 5cm above the cathode for electrolysis. The electrolytic cell is a cylindrical container with a diameter of 10cm and a height of 8cm. The anode is a circular platinum mesh with a diameter of 6.5cm. The electrolyte is a mixed solution ...

Embodiment 3

[0043] The recovered 12V, 14AH waste lead-acid batteries were crushed and separated to obtain 2.4kg waste lead paste. First, the waste lead paste is crushed by a pulverizer to obtain lead paste particles. Take 50g of the crushed lead paste particles and put them into the reaction tank, add 2.5g of water, and after stirring evenly, use a coater to evenly coat the mixture in the reaction tank. To the cathode plate of the stainless steel lead-plated frame, the thickness is 2cm, put the coated cathode plate into an oven and cure it at 80-100°C for 0.5h to obtain the cathode part.

[0044] Put the cathode into the electrolytic cell, and there are 250mL electrolyte and magnetic stirring rotor in the electrolytic cell, fix the position of the anode in parallel at 2.5cm above the cathode, and perform electrolysis. The electrolytic cell is a cylindrical container with a diameter of 7 cm and a height of 10 cm. The anode is a circular gold mesh with a diameter of 6.5 cm. The electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com