Patents

Literature

37results about How to "Flexible recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft storage allocation method for hybrid automatic repeat request process of long term evolution system

InactiveCN102255712ASave storage resourcesFlexible allocationError prevention/detection by using return channelCoding blockComputer network

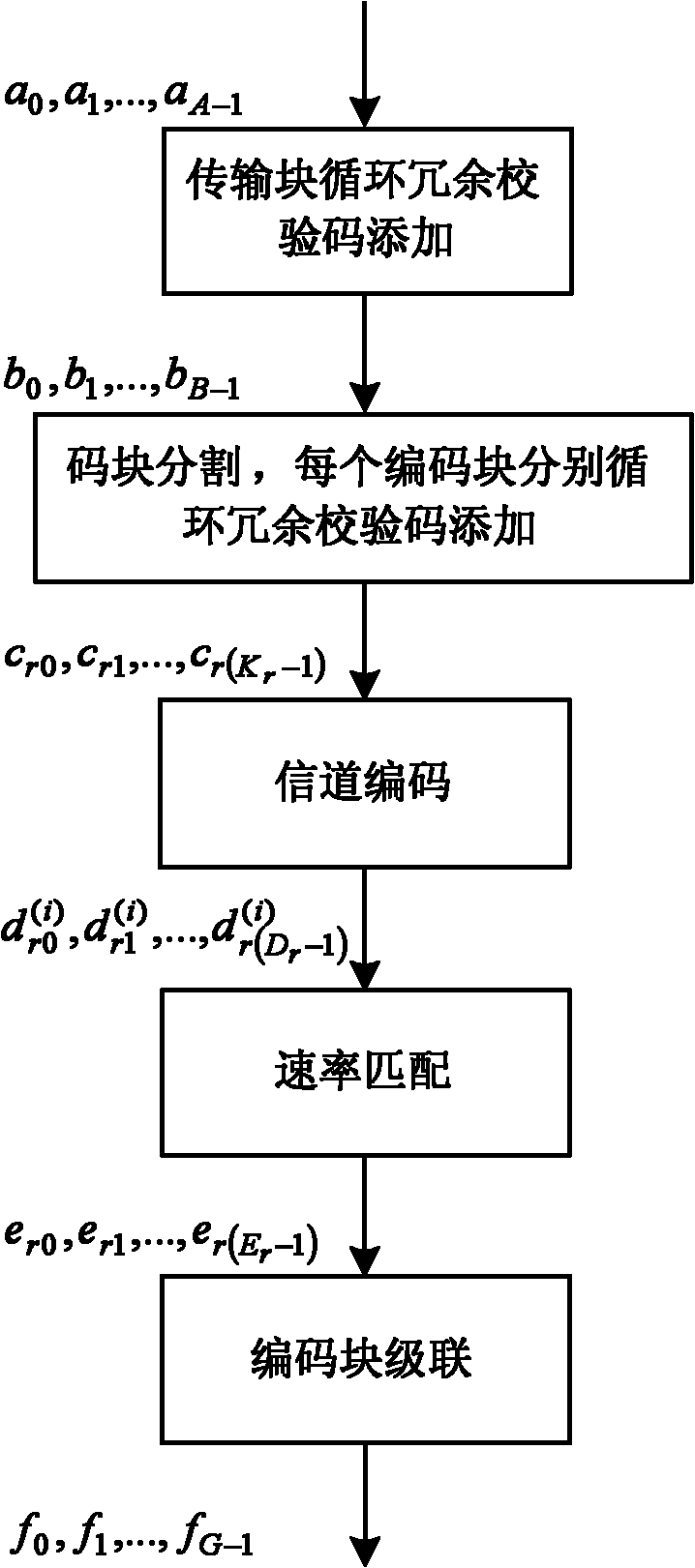

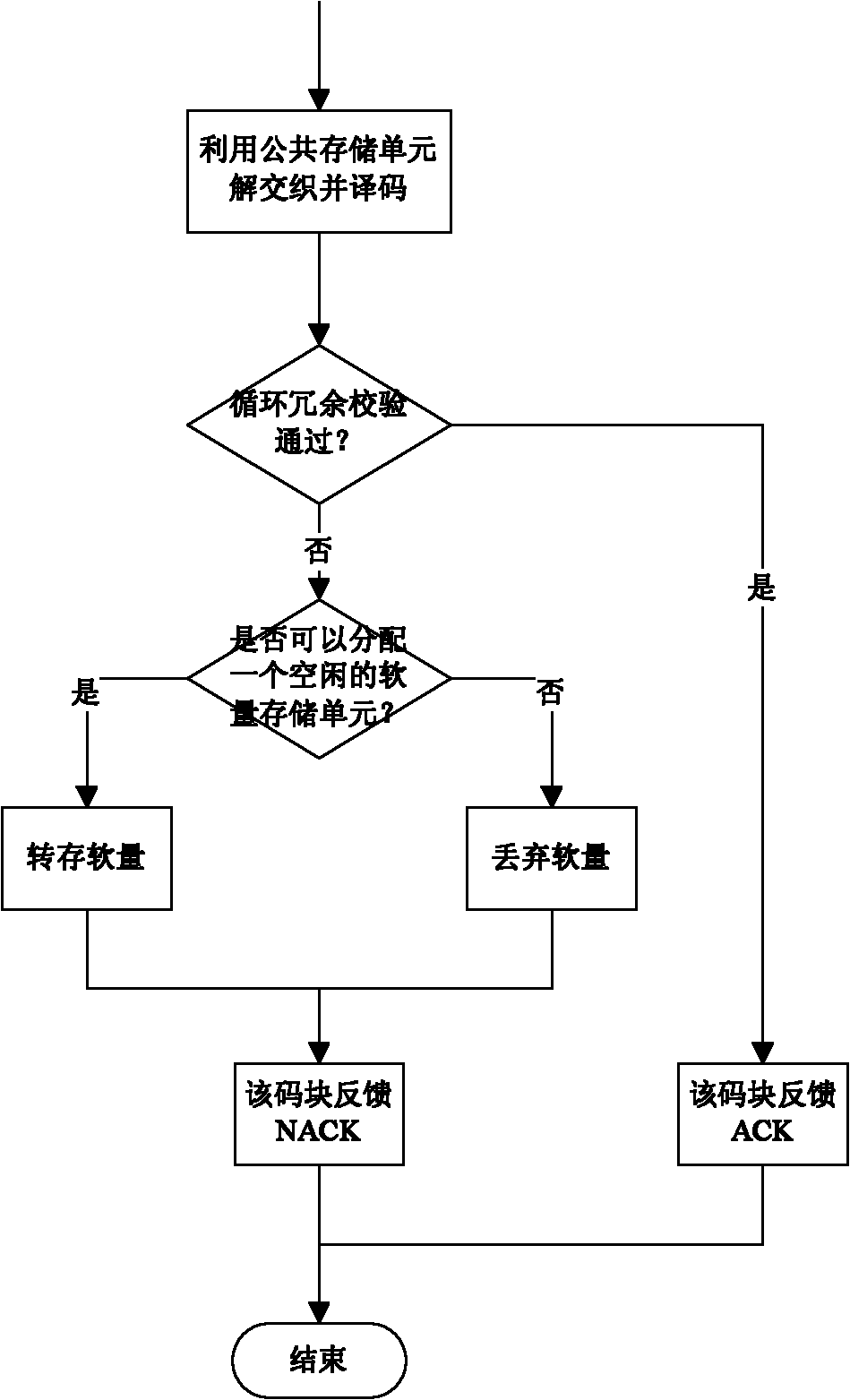

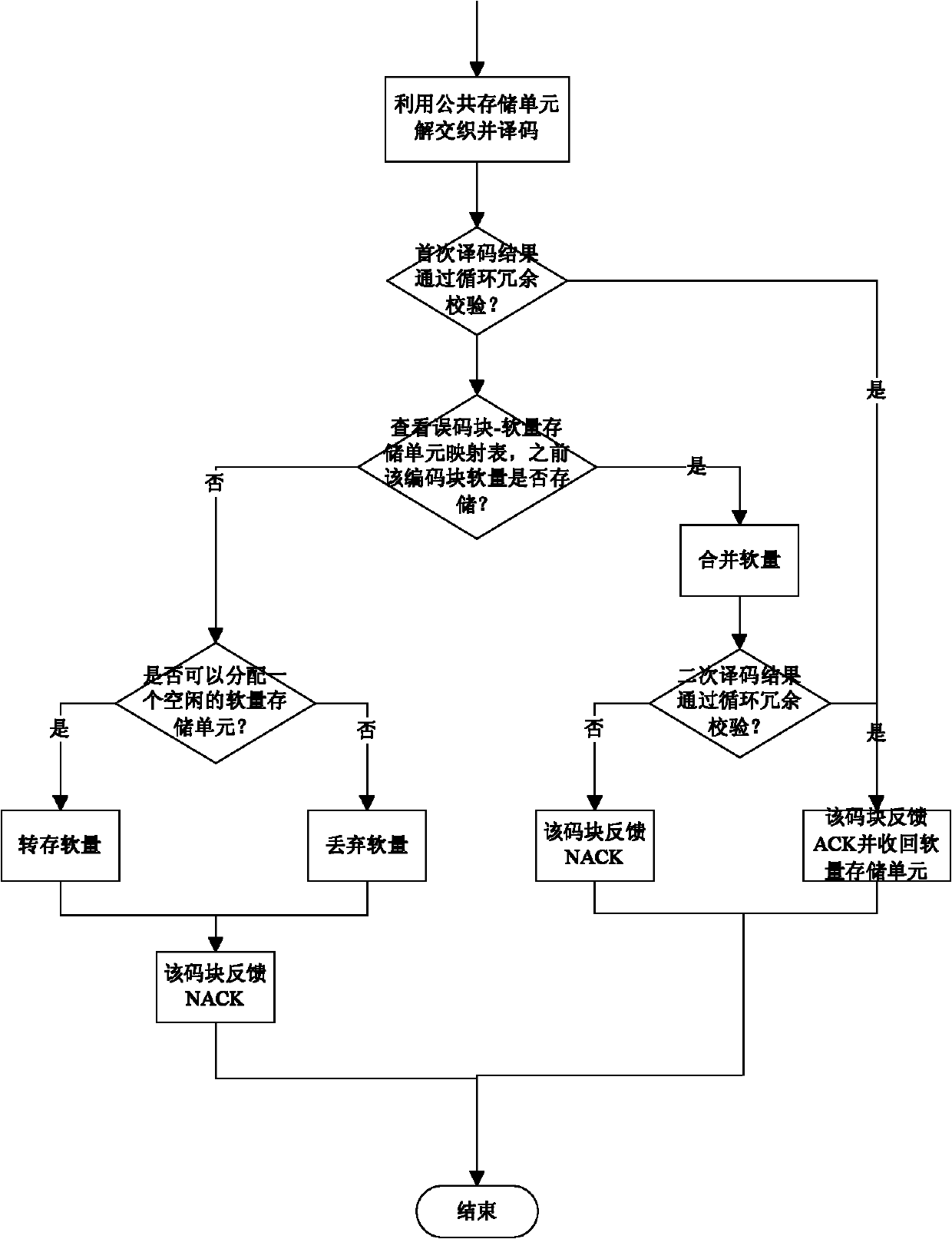

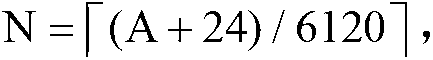

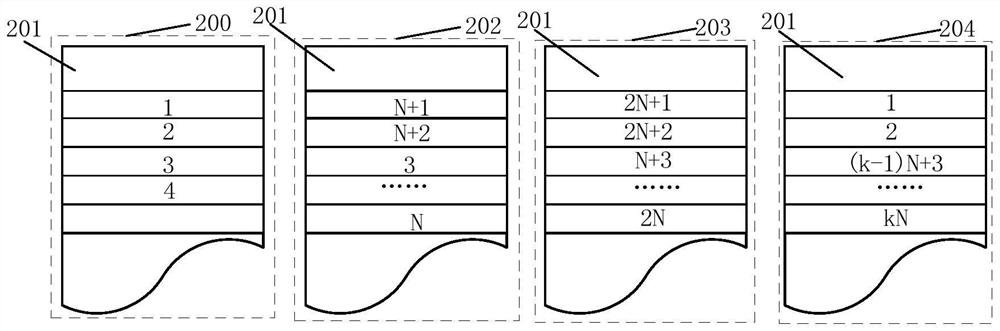

The invention discloses a soft storage allocation method for the hybrid automatic repeat request process of a long term evolution system. The method comprises the following steps of: a downlink shared channel of the long term evolution system adopts a multi-process hybrid automatic repeat request technology and maximally performs transmission for 4 times, a transmitter transmits a redundancy version of a transmission block every time and can transmit two transmission blocks at a time in a space division multiplexing mode, wherein the transmission block TB can be divided into N coded blocks CB1, CB2, ..., and CBN, [] represents rounding-up and A is the number of information bits of the transmission block; and only one process of a receiver in any downlink sub-frame receives a currently transmitted transmission block. By the method, soft storage resources required by the multi-process hybrid automatic repeat request process are effectively reduced. The method is applied to various usage scenarios of the long term evolution system, and is highly robust.

Owner:SOUTHEAST UNIV

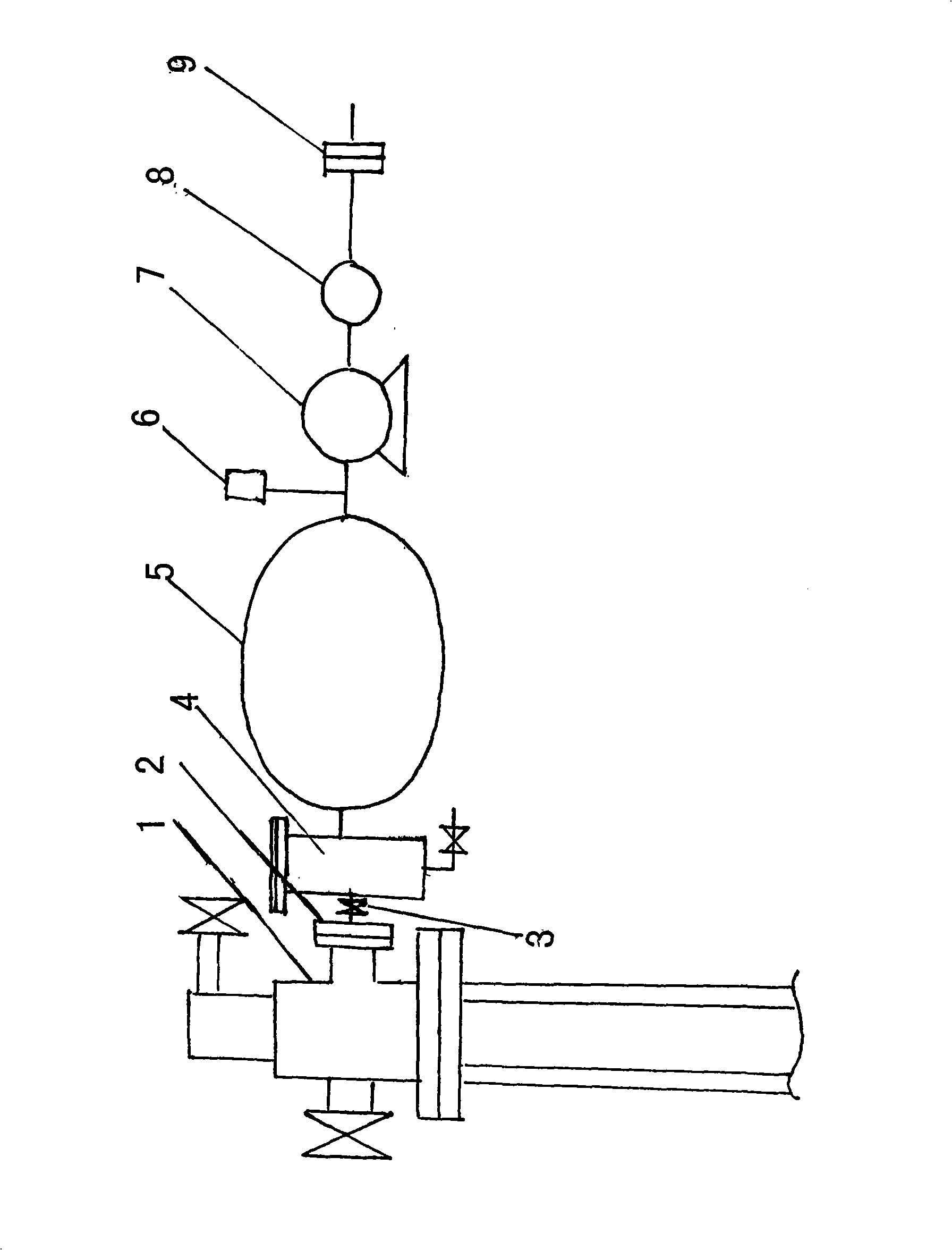

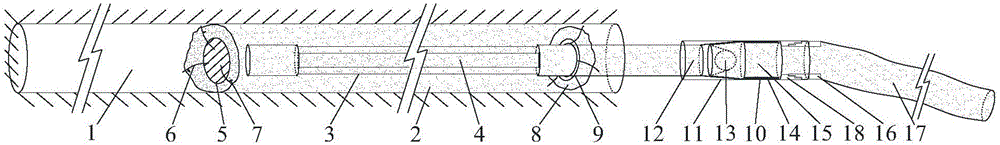

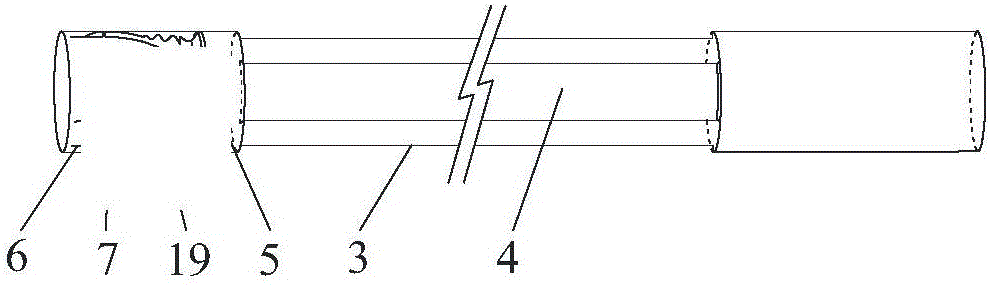

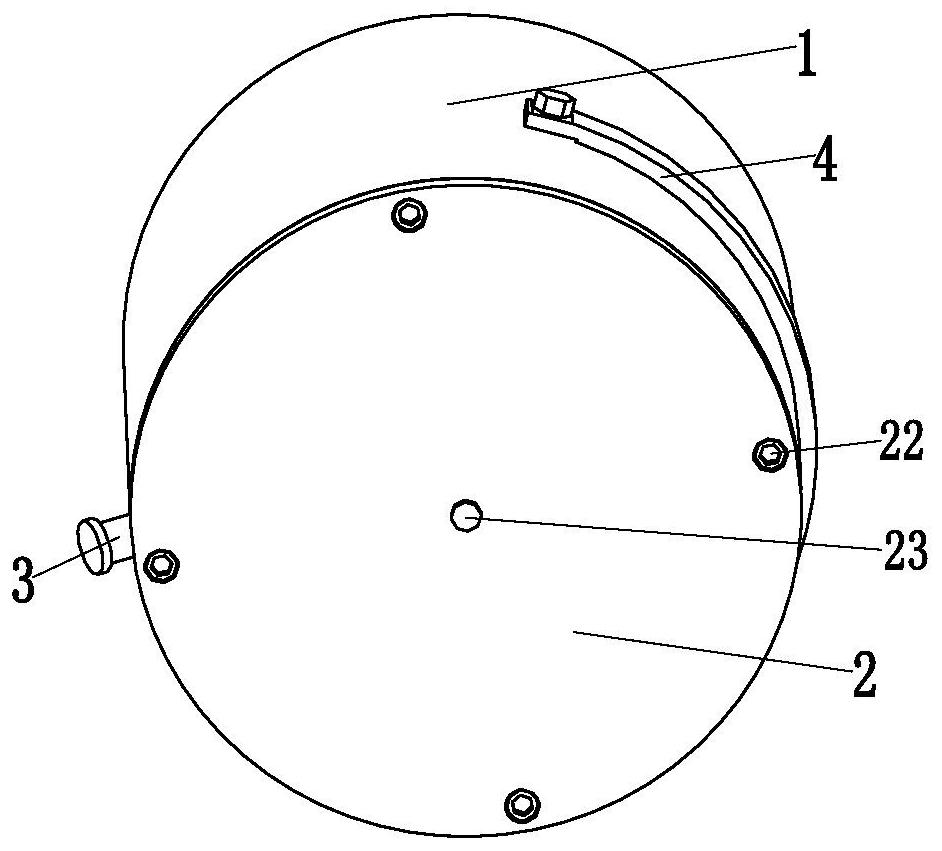

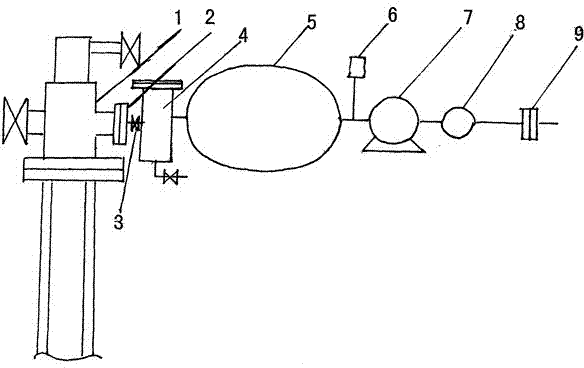

Oil-well waste gas recovery device

The invention relates to an oil-well waste gas recovery device which comprises a prizing block, a hoop, a filter, a gas collecting bladder, a safety valve, a natural gas compressor, a gas flow meter and a quick joint. The oil-well waste gas recovery device is characterized in that an inlet of the gas collecting bladder is connected with an outlet of the filter by a high-pressure hose, an inlet of the filter is connected with an outlet of a sleeve pipe by a control valve and the hoop or a flange, an outlet of the gas collecting bladder is connected with an inlet of the natural gas compressor by a connecting pipeline, an outlet of the natural gas compressor is connected with the gas flow meter, an outlet of the gas flow meter is connected with the quick joint, and the safety valve is arranged on the pipeline which is used for connecting the gas collecting bladder and the natural gas compressor. The oil-well waste gas recovery device has simple structure and strong flexibility, is portable, can flexibly recover sleeve pipe gas of various oil wells, avoids the pollution of the environment by the sleeve pipe gas and the energy wastage and recovers natural gas.

Owner:胜利油田华胜环保产业有限责任公司

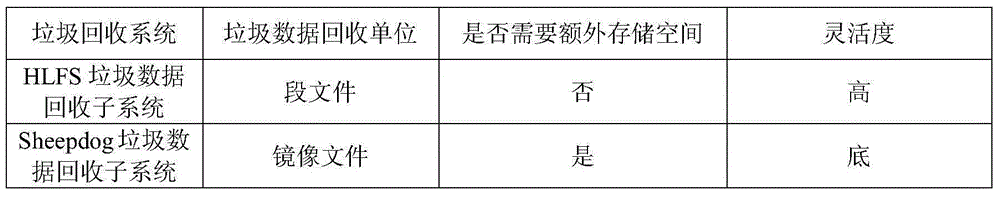

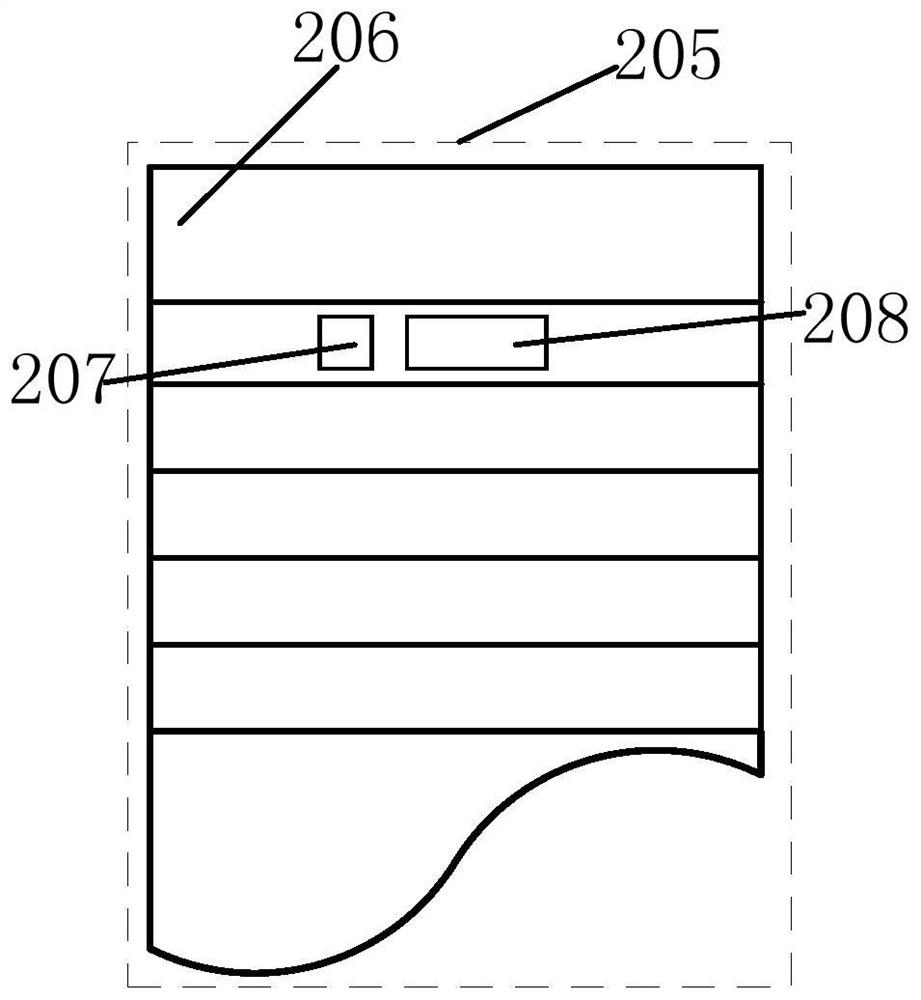

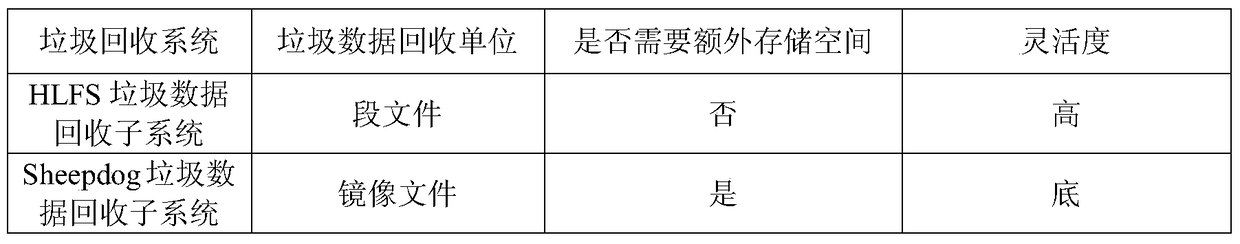

Method for recovering junk data in cloud storage log file system

ActiveCN105045850AFlexible recyclingIncrease profitSpecial data processing applicationsRecovery methodInode

The invention discloses a method for recovering junk data in a cloud storage log file system, used for solving the technical problem that the storage space of the existing junk data recovery method is poor in utilization rate. The technical scheme provided by the invention is as follows: the junk data is judged at first; a new log is established when the file system is updated; an index node in the log comprises a three-grade index structure; each file corresponds to one index node; an index address of a data block is stored in the three-grade index structure; the junk data is searched by taking the latest log as the base; the index addresses in the logs are sequentially compared from the earliest log; the data is stored in the log by the cloud storage log file system; the log is also stored in a segment storage file; and the junk data is recovered when the junk data amount of the segment storage file is more than a threshold value. According to the invention, the junk data is recovered manually or automatically; manual configuration of a segment file recovery threshold value is supported; the storage space occupied by the junk data can be recovered at any time; and thus, the utilization rate of the storage space is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

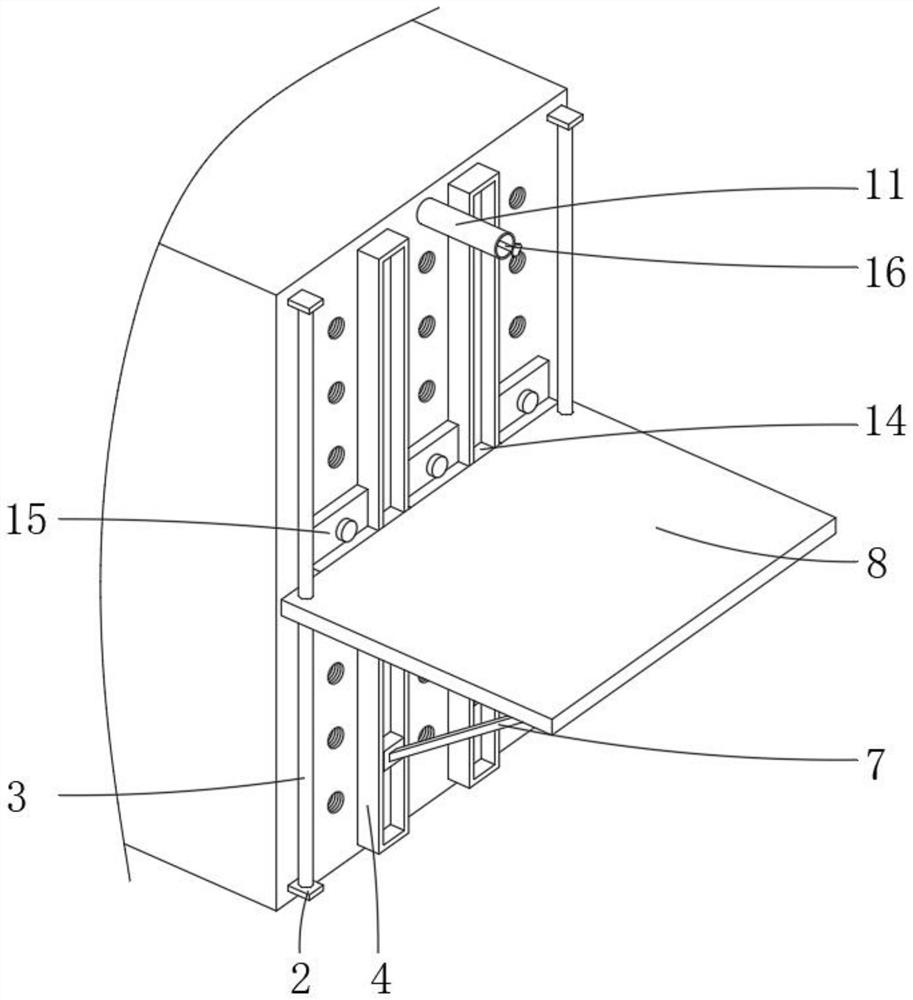

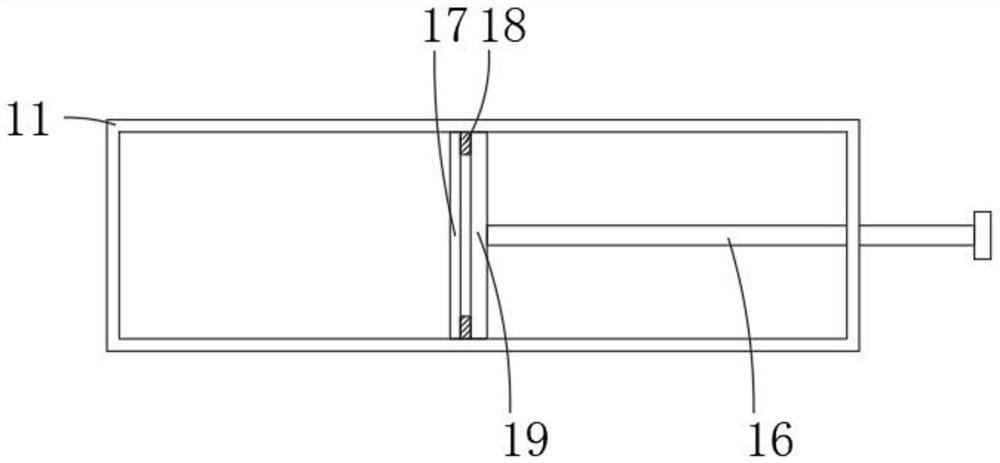

Flexible plastic quick grouting hole sealing device and method

ActiveCN106401522ARaise the initial pressureFlexibleDrilling rodsWell/borehole valve arrangementsSlurryMechanical engineering

The invention discloses a flexible plastic quick grouting hole sealing device and method. The device is mainly composed of an umbrella buckle type plugging device, a slotting flexible plastic grouting pipeline and a double-cone pipe connector device. The initial grout pressure in pipes is positively stored in a sealed mode through the differential flow of grout fed into and discharged out of the grouting pipes, and the processes of automatic pushing out, spreading and plugging of a convex angle umbrella buckle are completed. A flexible plastic pipe capable of being coiled is adopted to be inserted into a drill hole at a time, and the primary quick hole sealing operation requirement is met. According to the flexible plastic quick grouting hole sealing device and method, the process of traditional hole sealing operation is simplified, operation is convenient and quick, the cost is low, and the device and the method are novel hole sealing device and method which have wide application and popularization value.

Owner:CHINA UNIV OF MINING & TECH

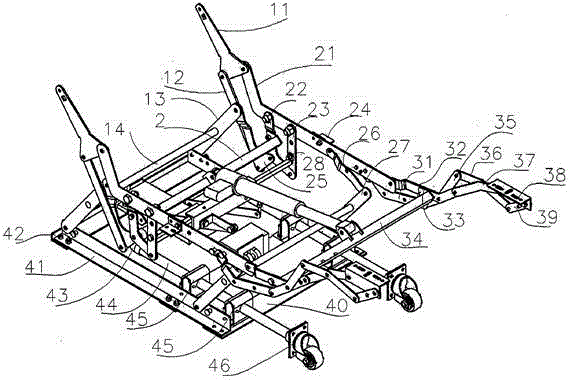

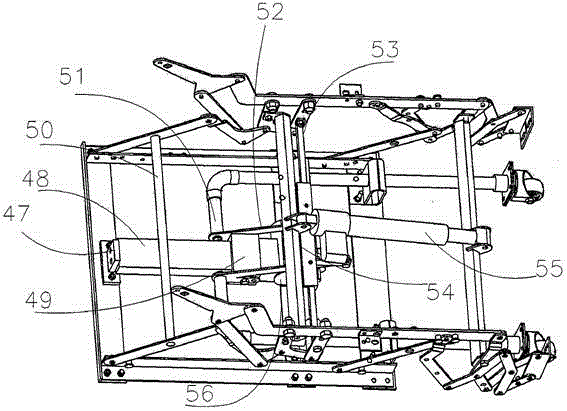

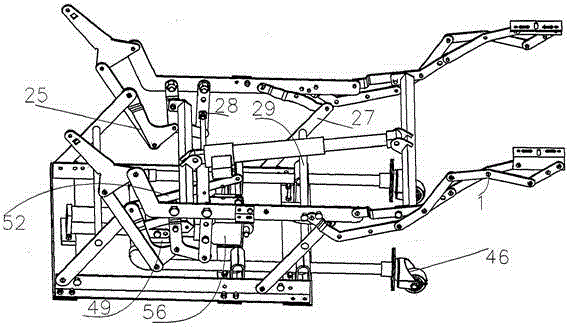

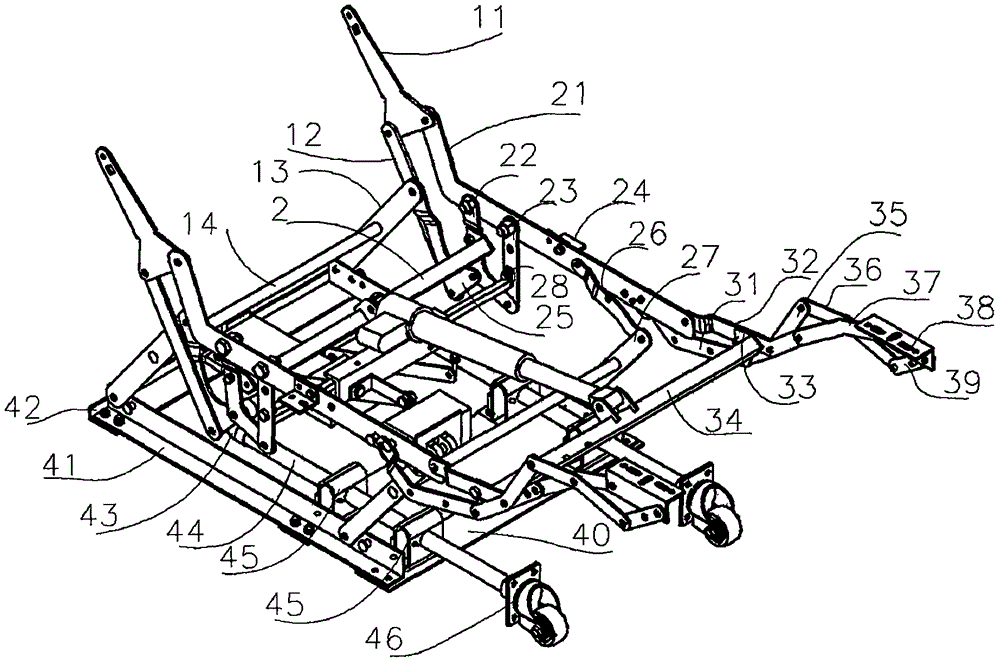

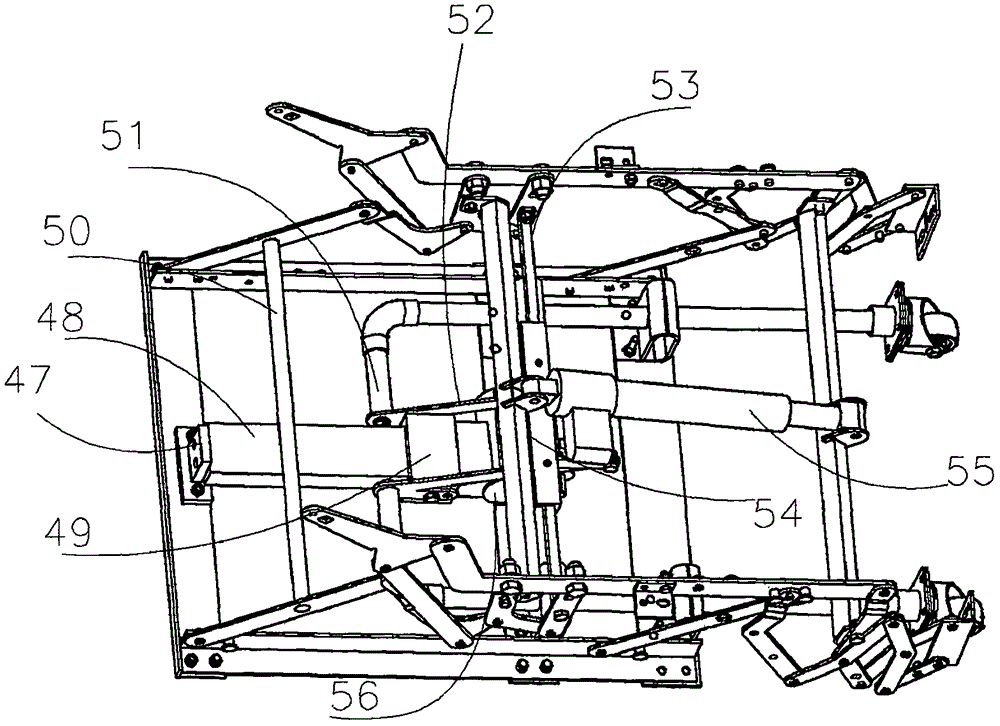

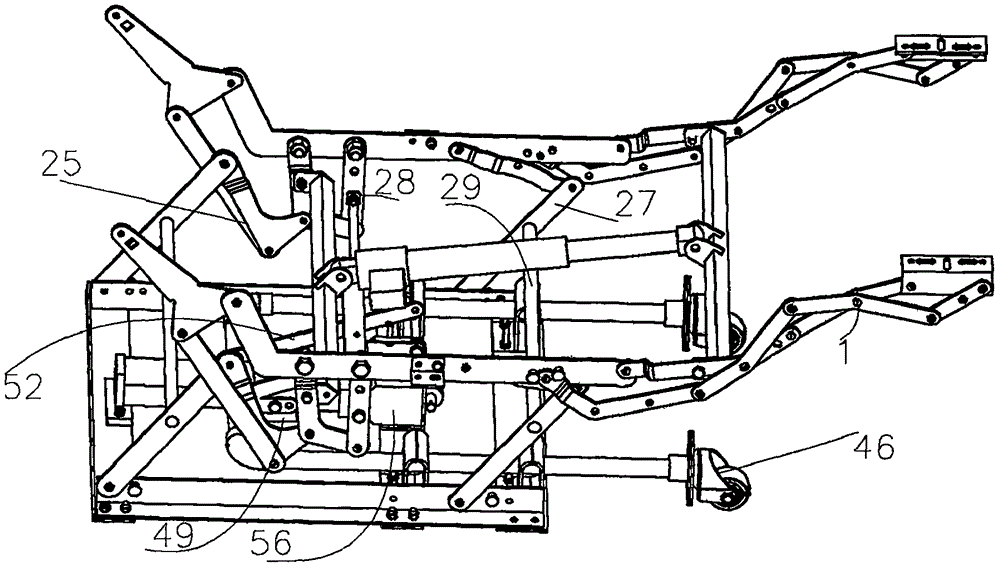

Anti-falling dual-motor functional sofa

Owner:HENGLIN HOME FURNISHINGS CO LTD

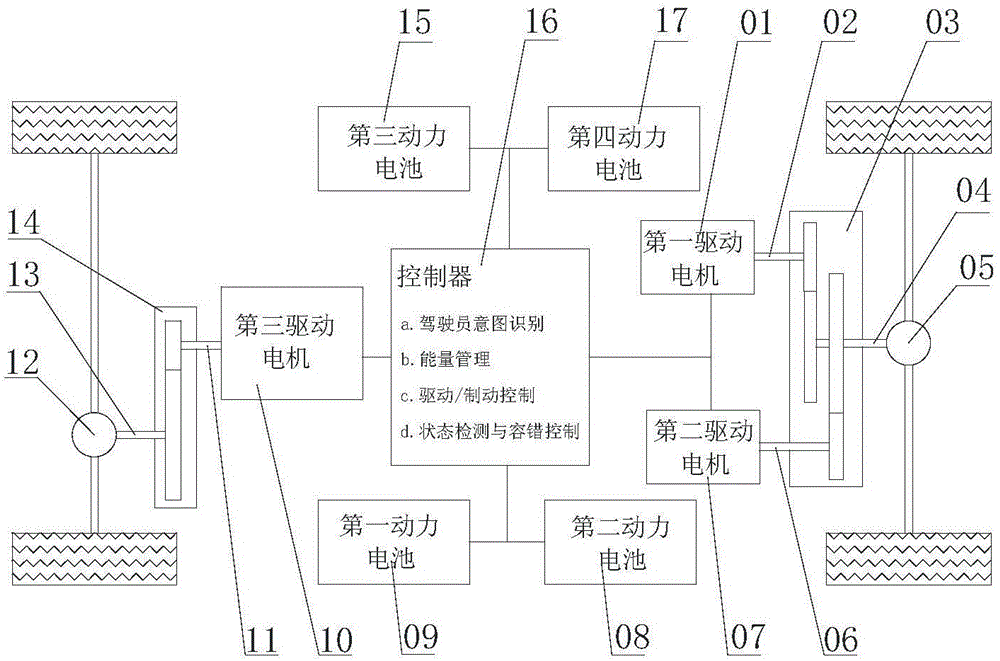

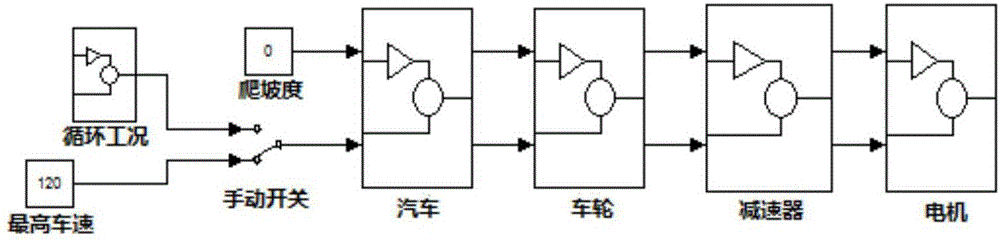

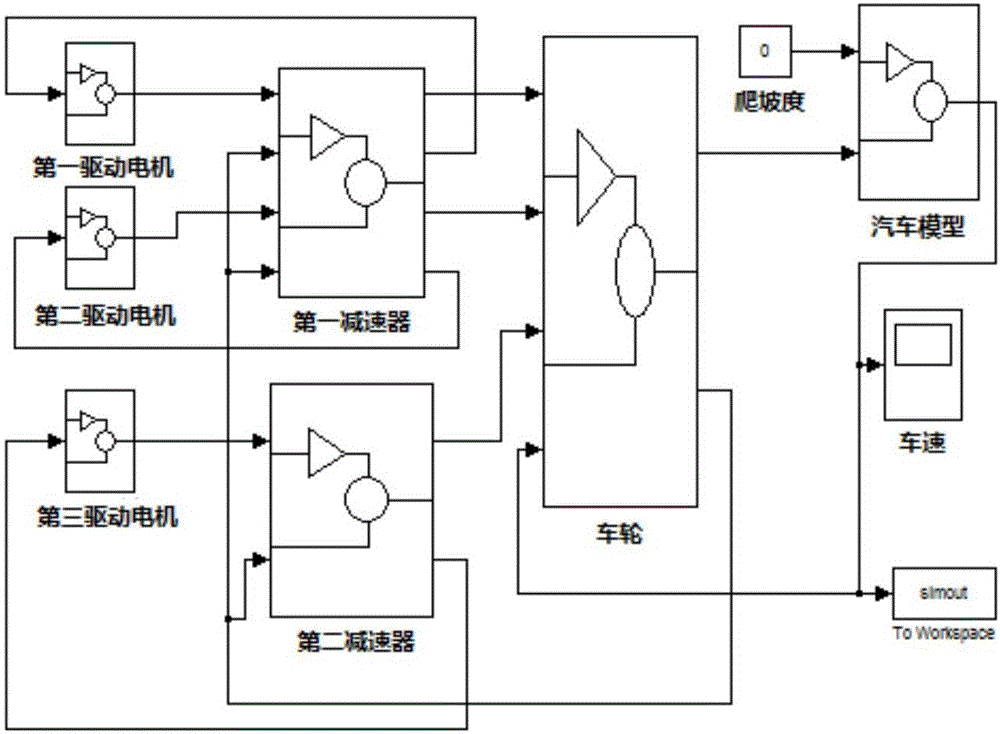

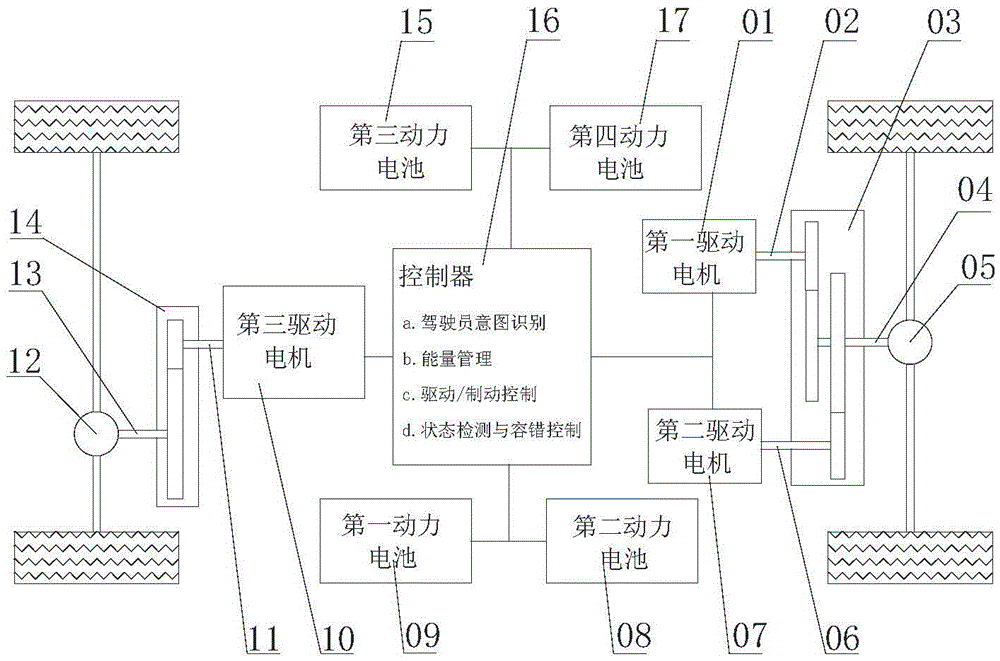

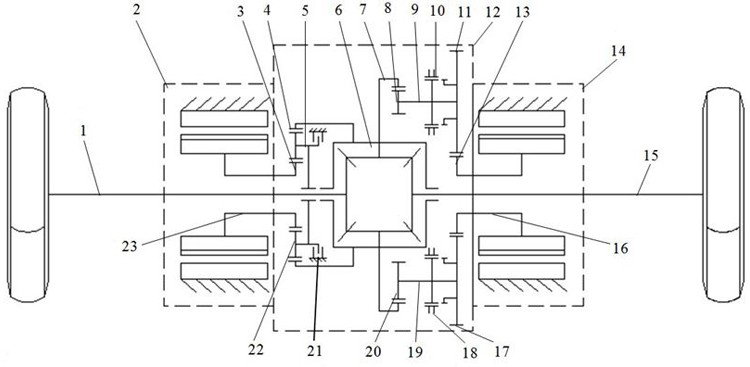

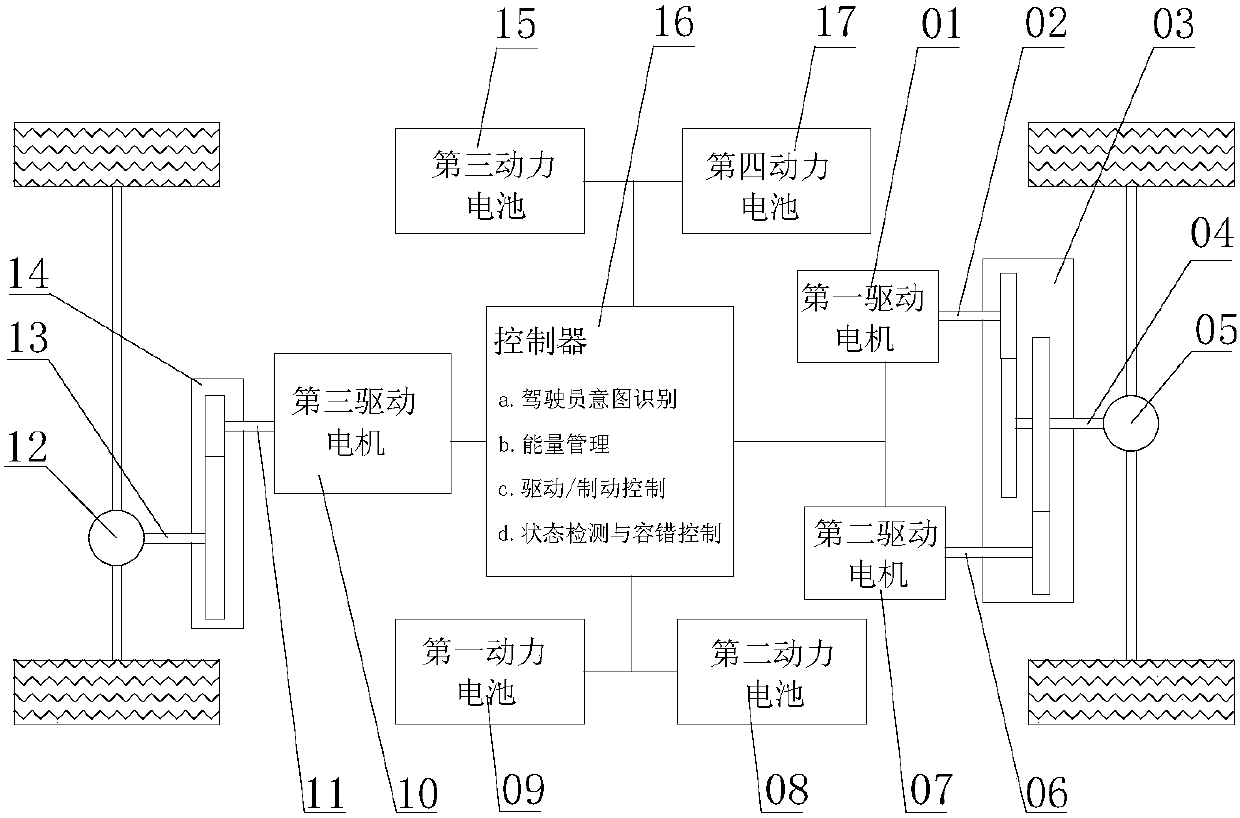

Three-motor combination drive type truck and power system parameter matching method

InactiveCN105667346AReduce manufacturing difficultyFlexible recyclingSpeed controllerElectric devicesPower batteryElectric machine

The invention relates to a three-motor hybrid drive truck and a power system parameter matching method. The three-motor hybrid drive truck is composed of a first drive motor, a first input shaft, a first reducer, a first output shaft, a vehicle front axle, a second input shaft, a second drive motor, a first power battery, a second The power battery, the third drive motor, the third input shaft, the rear axle of the vehicle, the second output shaft, the second reducer, the third power battery, the controller and the fourth power battery are assembled and constituted; the parameter matching of the power system in the present invention In the process, the parameter matching method of the first drive motor, the second drive motor, the third drive motor and the reducer of the three-motor hybrid drive truck is given, which provides a theoretical basis for the development of the power system of the three-motor hybrid drive truck. . The invention can reduce the capacity of the driving motor, the difficulty of motor manufacture, and reduce the cost, and at the same time, through the reasonable matching of the powers of the three motors, the power and economy of the whole vehicle can be significantly improved.

Owner:JILIN UNIV

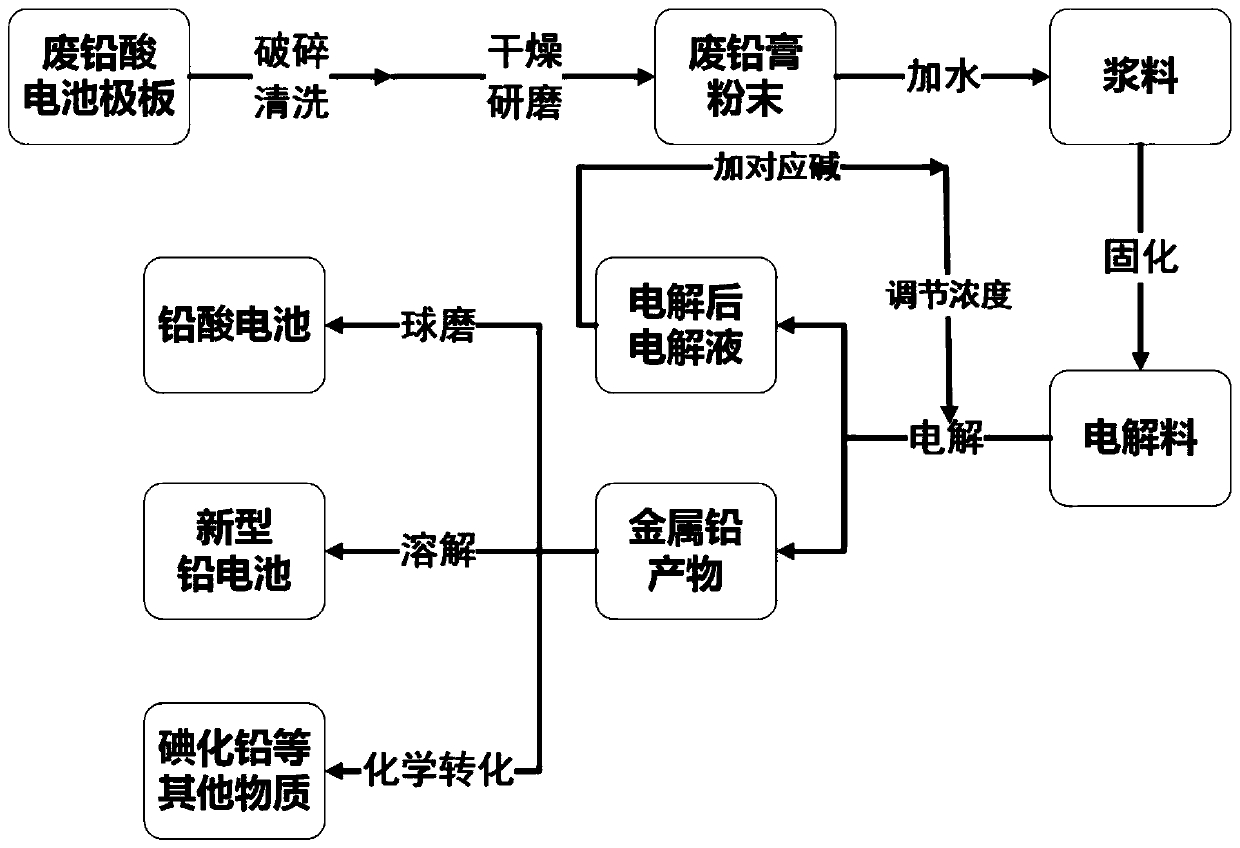

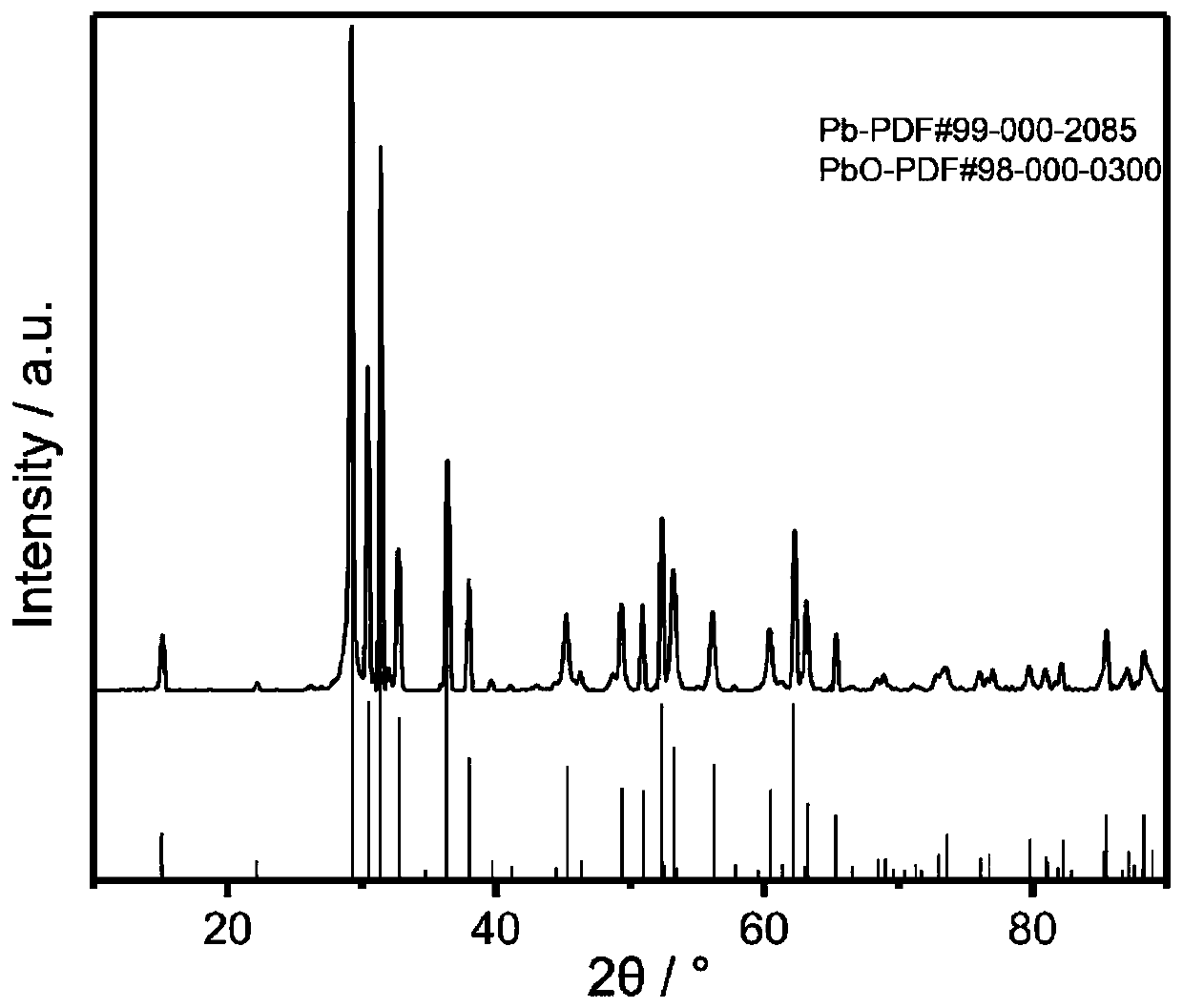

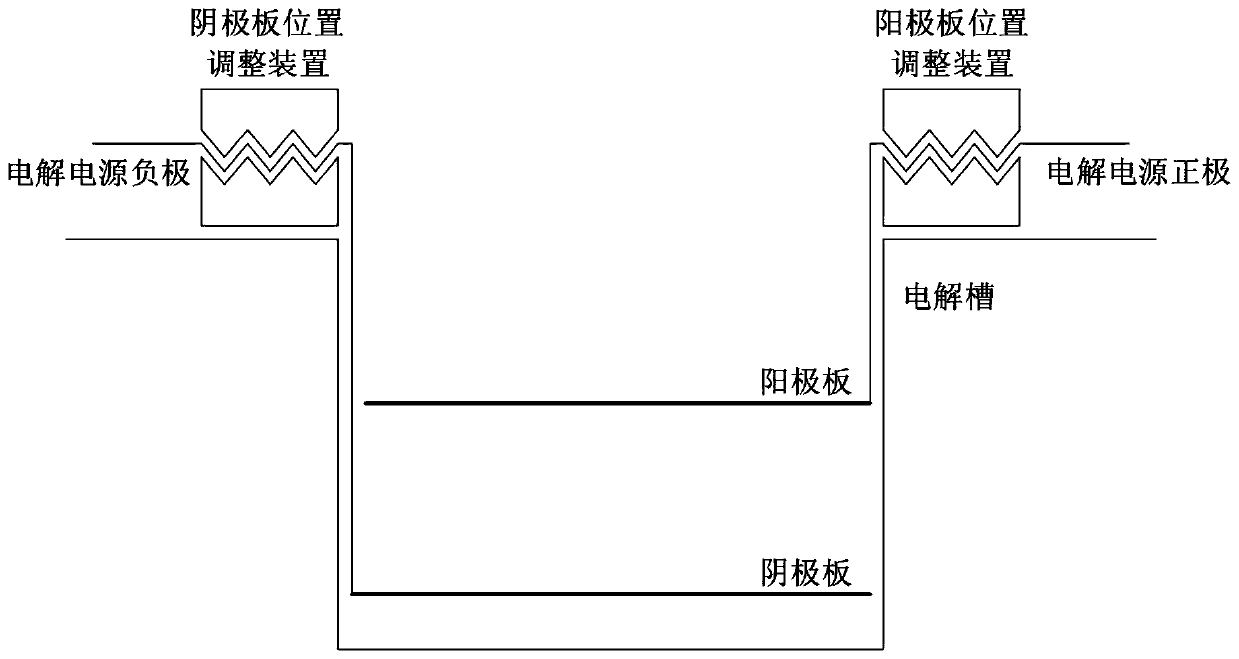

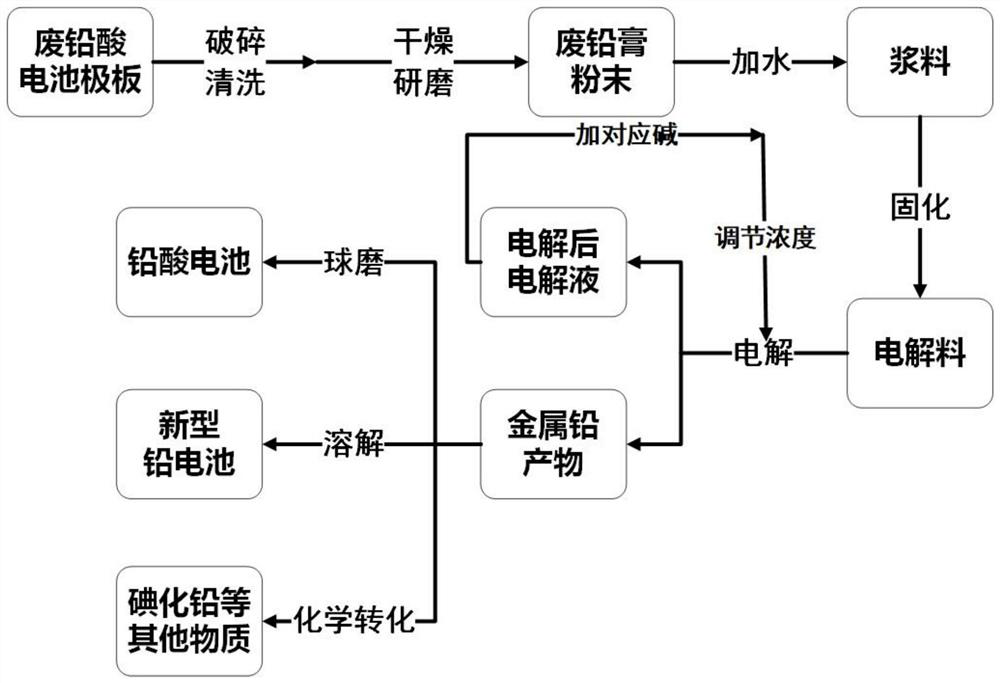

Method for recovering lead from waste lead paste by solid phase electrolysis method

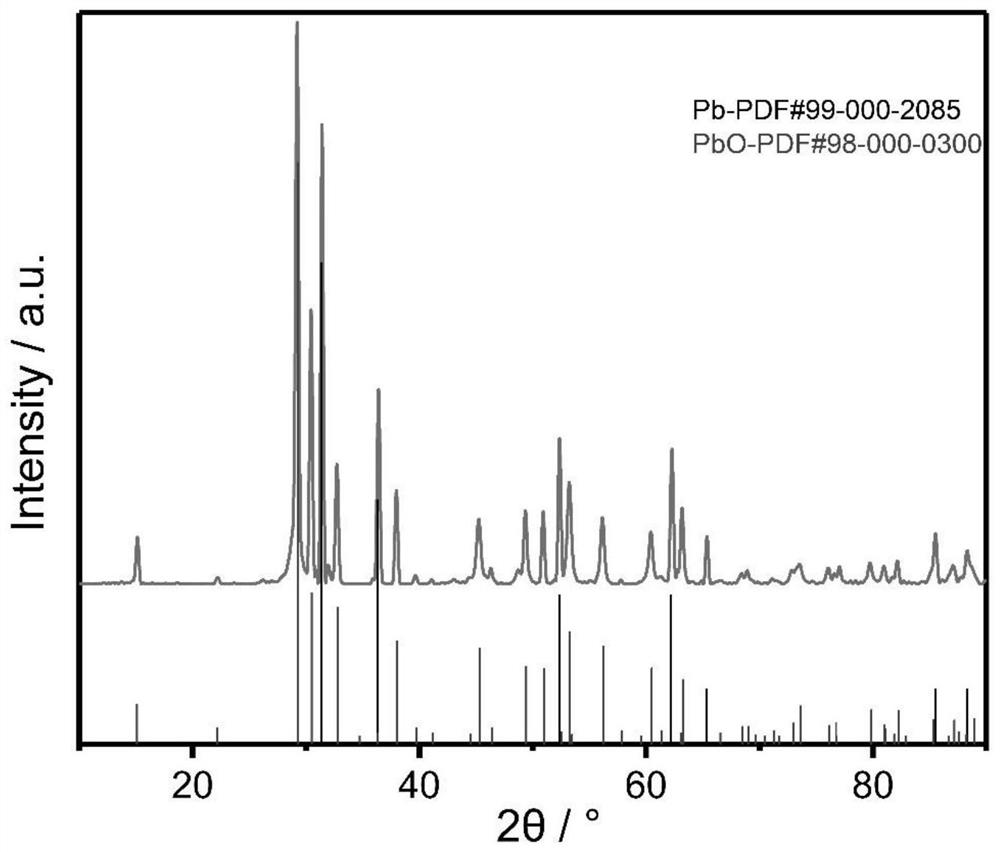

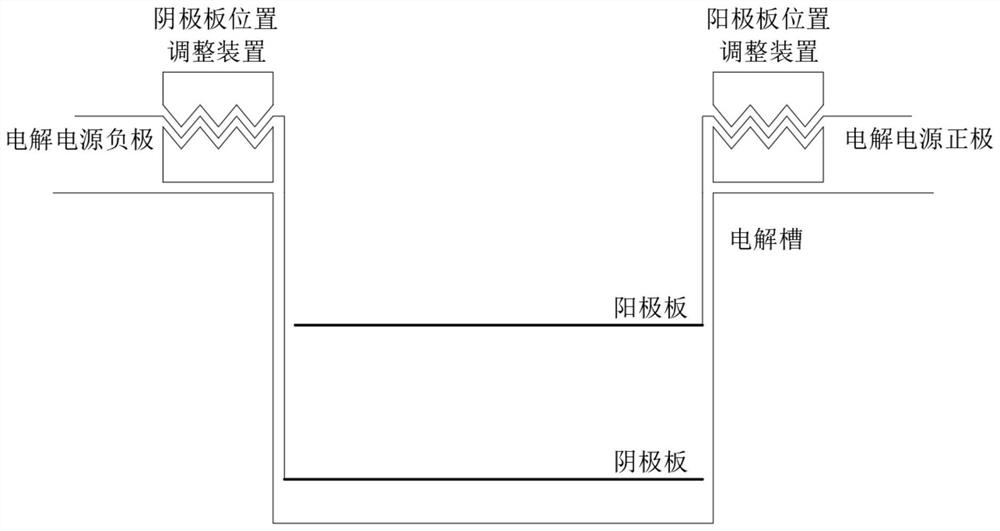

ActiveCN111455404AReduce consumptionSimple processPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentLead dioxide

The invention discloses a method for recovering lead from waste lead paste by a solid phase electrolysis method, and belongs to the technical field of lead resource recovery. The method for recoveringthe lead from the waste lead paste by the solid phase electrolysis method comprises the steps that the waste lead paste is first made into a paste waste lead paste electrolytic material and a cathodeplate is coated with the waste lead paste electrolytic material; electrolyte is added to an electrolytic cell; the cathode plate coated with the electrolytic material is inserted into the electrolyte, and an anode is inserted into the electrolyte; the anode is an electrode with oxygen evolution electrocatalysis; the cathode plate and the anode are connected with a negative electrode and a positive electrode of a direct current power supply separately to make electrolysis in the electrolytic cell; and water at the anode loses electrons and precipitates oxygen, the electrolytic material on thecathode plate obtains the electrons and is reduced in situ to a lead single substance and attached to the cathode plate, that is, the lead is recovered from the waste lead paste. The method for recovering the lead from the waste lead paste by the solid phase electrolysis method directly electrolyzes the waste lead paste after simple pulping, lead sulfate, lead dioxide and lead oxide in the waste lead paste obtain the electrons and form in situ the lead simple substance, a large number of pretreatment processes are saved, the consumption of reagents is reduced, the process is simple, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

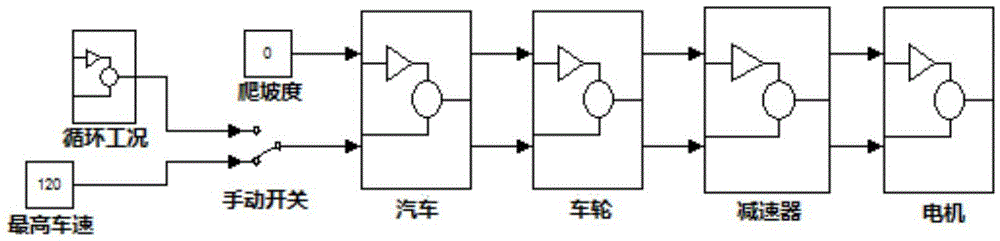

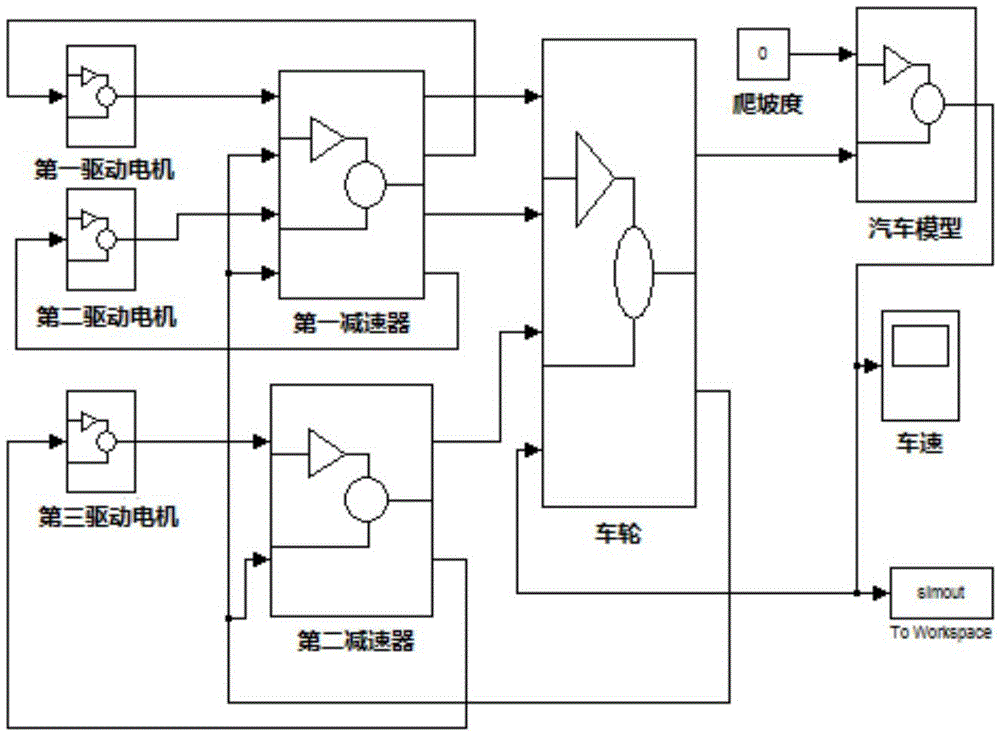

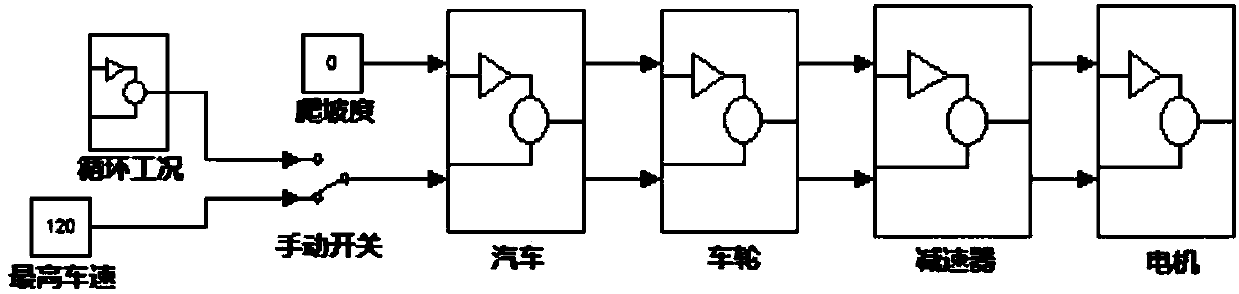

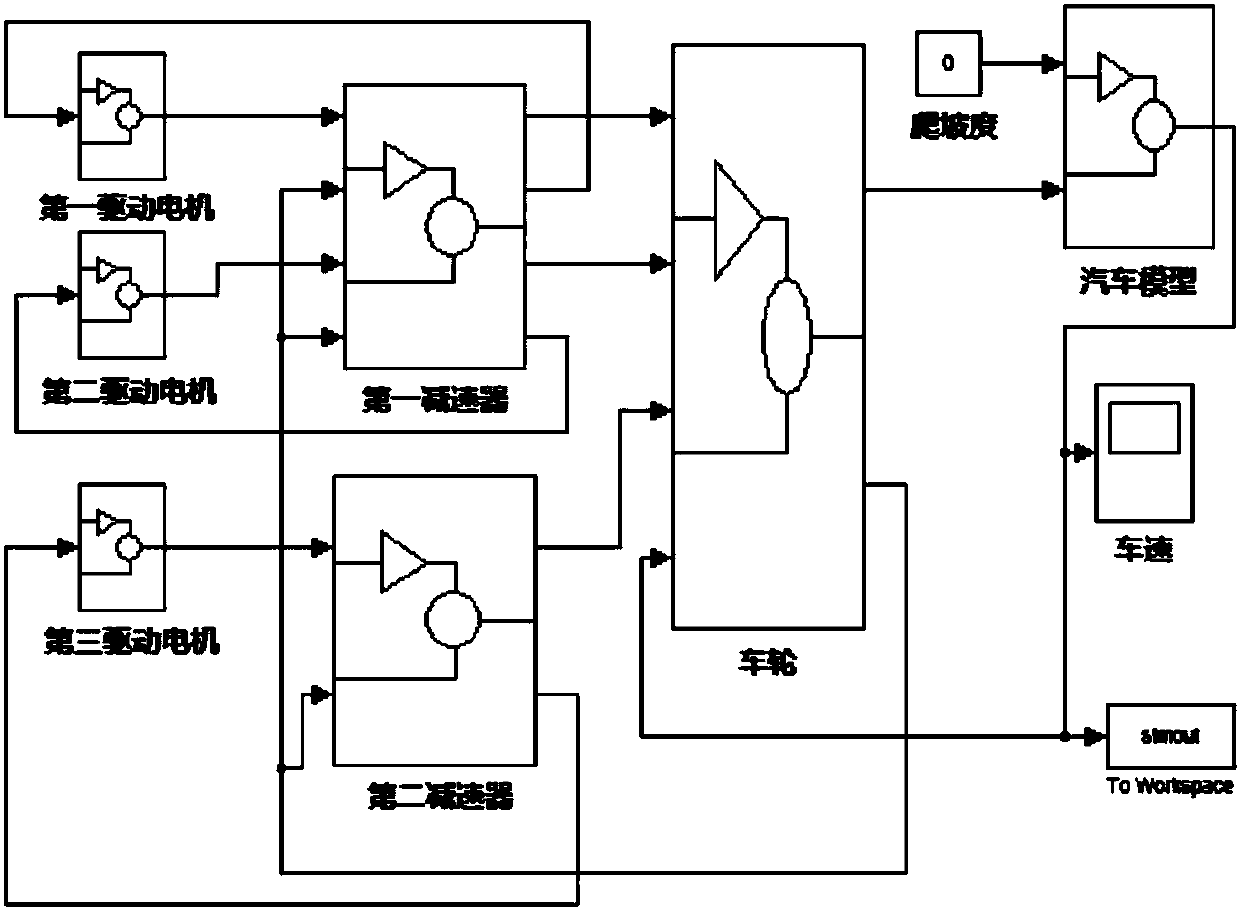

Three-motor hybrid truck and power system parameter matching method

InactiveCN105620310ALow powerReduce manufacturing difficultySpeed controllerElectrodynamic brake systemsTruckMotor power

The invention relates to a three-motor hybrid truck and a power system parameter matching method. The three-motor hybrid truck is assembled by using a first driving motor, a first input shaft, a first speed reducer, a first output shaft, an automobile front axle, a second input shaft, a second driving motor, a first power cell, a second power cell, a third driving motor, a third input shaft, an automobile rear axle, a second output shaft, a second speed reducer, a third power cell, a controller and a fourth power cell. According to the invention, in the parameter matching process of a power system, analog computation is carried out on power system power demand under a CYC-UDDS circulating condition of the truck by using a vehicle backward simulation model so as to ensure the reasonability of the design. According to the invention, the capacity of the single driving motor can be obviously reduced, the motor manufacturing difficulty is reduced and the cost is also reduced; and meanwhile, through reasonable power matching of the three motors, the dynamic property and economic efficiency of the truck can be obviously improved.

Owner:JILIN UNIV

Anti-falling dual-motor transfer chair

Owner:HENGLIN HOME FURNISHINGS CO LTD

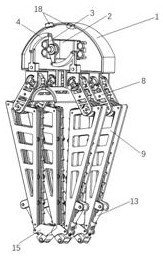

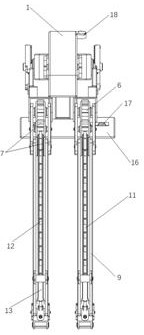

Translation pull-in type mechanical claw for recycling AUV

The invention discloses a translation pull-in type mechanical claw for recycling an AUV. The mechanical claw comprises a crescent transmission mechanism, a semicircular shell is connected to the periphery of the crescent transmission mechanism in a nested mode, a binocular camera is fixedly connected to the top end of the semicircular shell, and a steering engine body is arranged in the semicircular shell. The bottom of the semicircular shell is fixedly connected with a glider recovery channel, and the interior of the glider recovery channel is in shaft connection with a recovery channel roller. According to the translation pull-in type mechanical claw for recycling the AUV, the movement of a steering engine middle transmission mechanism and the crescent transmission mechanism can be controlled in real time through a steering engine main body, then the triangular mechanical claw is driven to do translation pull-in type movement, and the translation amplitude can be adjusted according to the posture of a glider so as to be adapted to the specifications of the AUV. And moreover, a driven wheel rotates and meanwhile drives a crawler belt attached to the triangular mechanical claw to conduct rolling conveyance, flexible recycling of the AUV is achieved, and the recycled AUV is automatically conveyed to a subsequent receiving device through the recycling channel.

Owner:GUANGDONG OCEAN UNIVERSITY

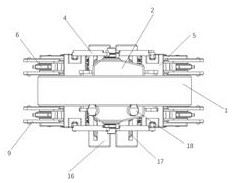

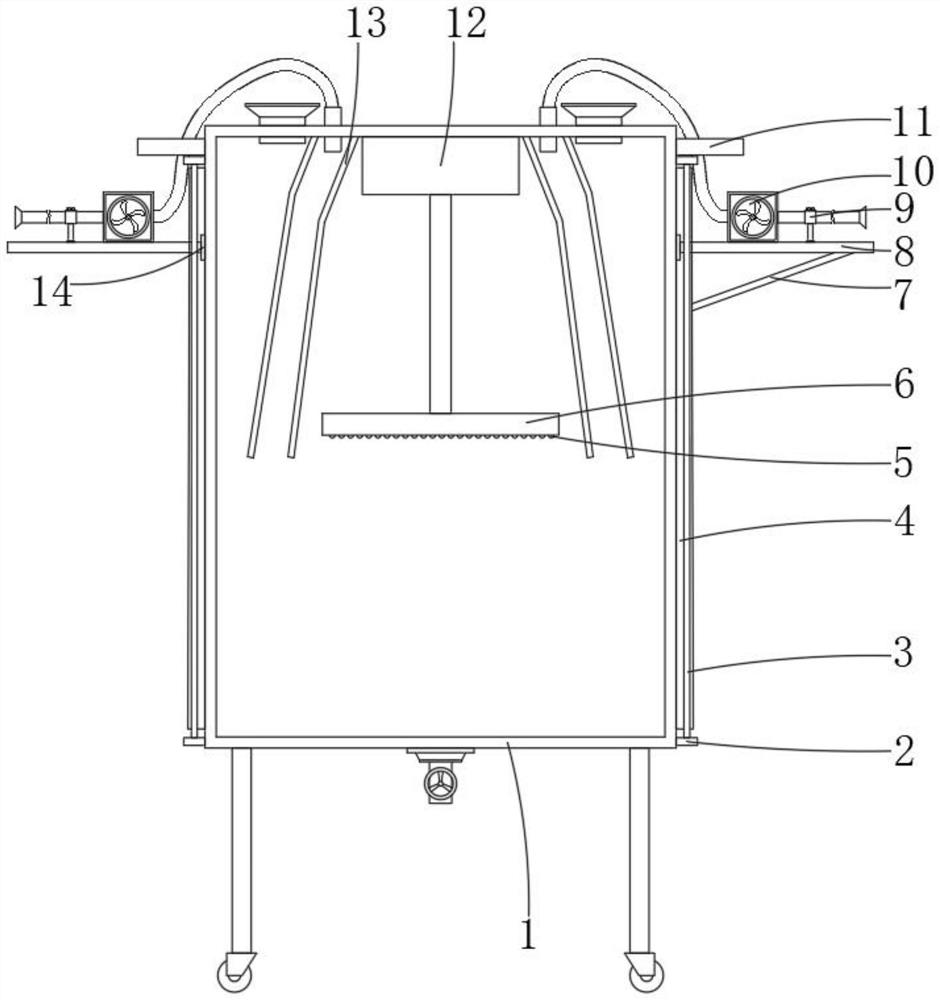

Wiring-harness hot-melting recycling processing device

InactiveCN106782931AEasy to moveFlexible moving processBasic electric elementsElectronic waste recyclingHot meltMetal

The invention discloses a wiring-harness hot-melting recycling processing device. The wiring-harness hot-melting recycling processing device comprises a bottom plate, a fusing pool is arranged on the bottom plate, a plurality of fixing bases are arranged on the inner side wall of a turning cover, magnetic attraction bases are arranged at the lower portions of the fixing bases, and magnetic attraction layers are arranged at the lower portions of the magnetic attraction bases; a plurality of positioning bases are arranged on the side wall of the fusing pool, a plurality of flame-gun positioning cylinders are arranged on the positioning bases, flame spraying guns are installed at the flame-gun positioning cylinders, and flame spraying openings in the flame spraying guns are formed inside the fusing pool; an inserting groove is formed in the middle of the fusing pool, and a filtering net plate is connected to the inserting groove in an inserted mode and arranged below the magnetic attraction bases; a recycling vehicle is arranged at the inner bottom of the fusing pool. By means of the wiring-harness hot-melting recycling processing device, wiring-harness hot metal cores can be extracted, fused substances flow on the filtering net plate, and can flow in the recycling vehicle through filtering of the filtering net plate, and can be conveniently recycled through the recycling vehicle.

Owner:南通锦星汽车零部件有限公司

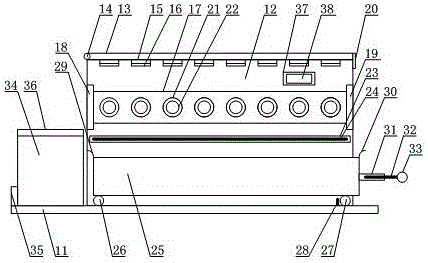

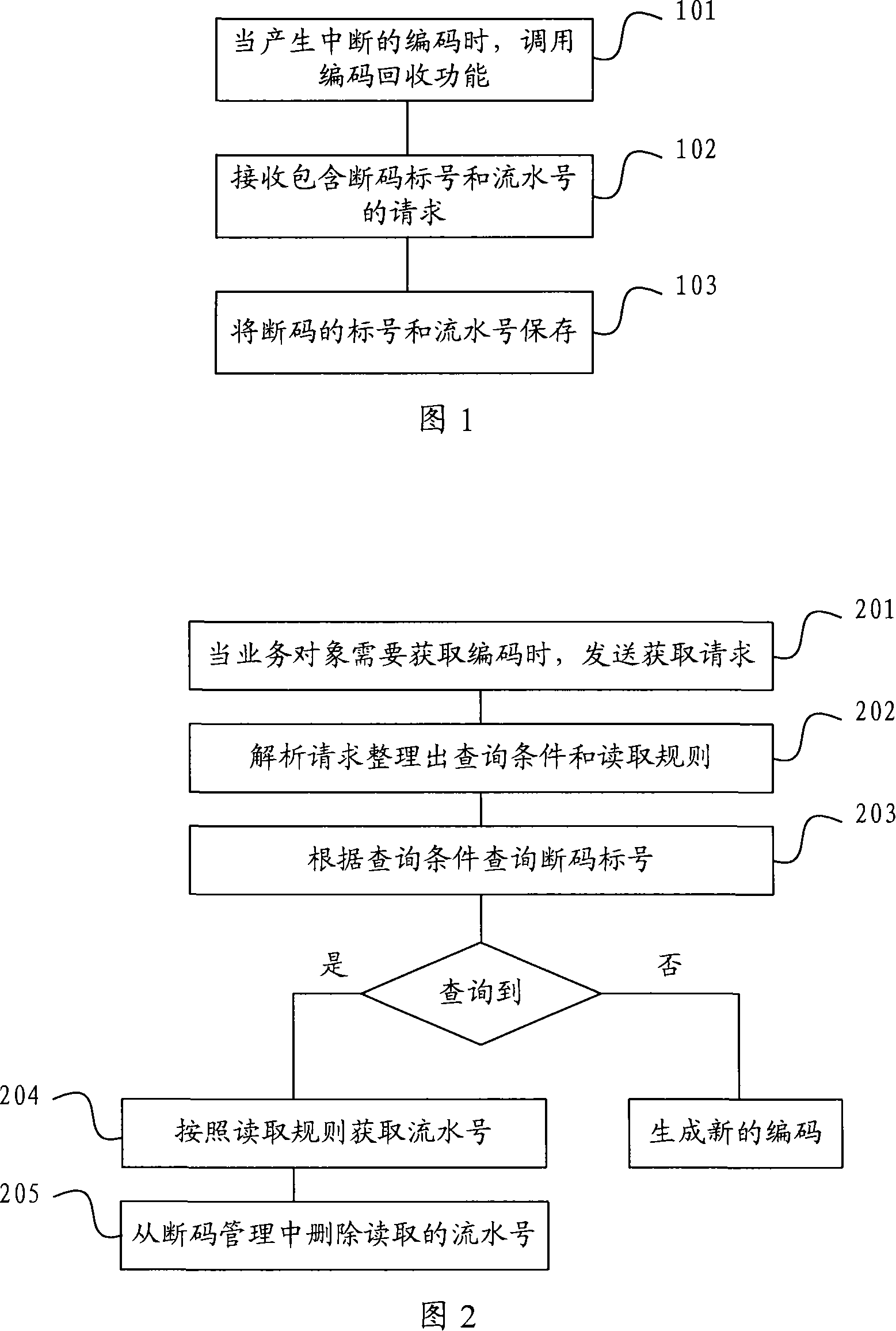

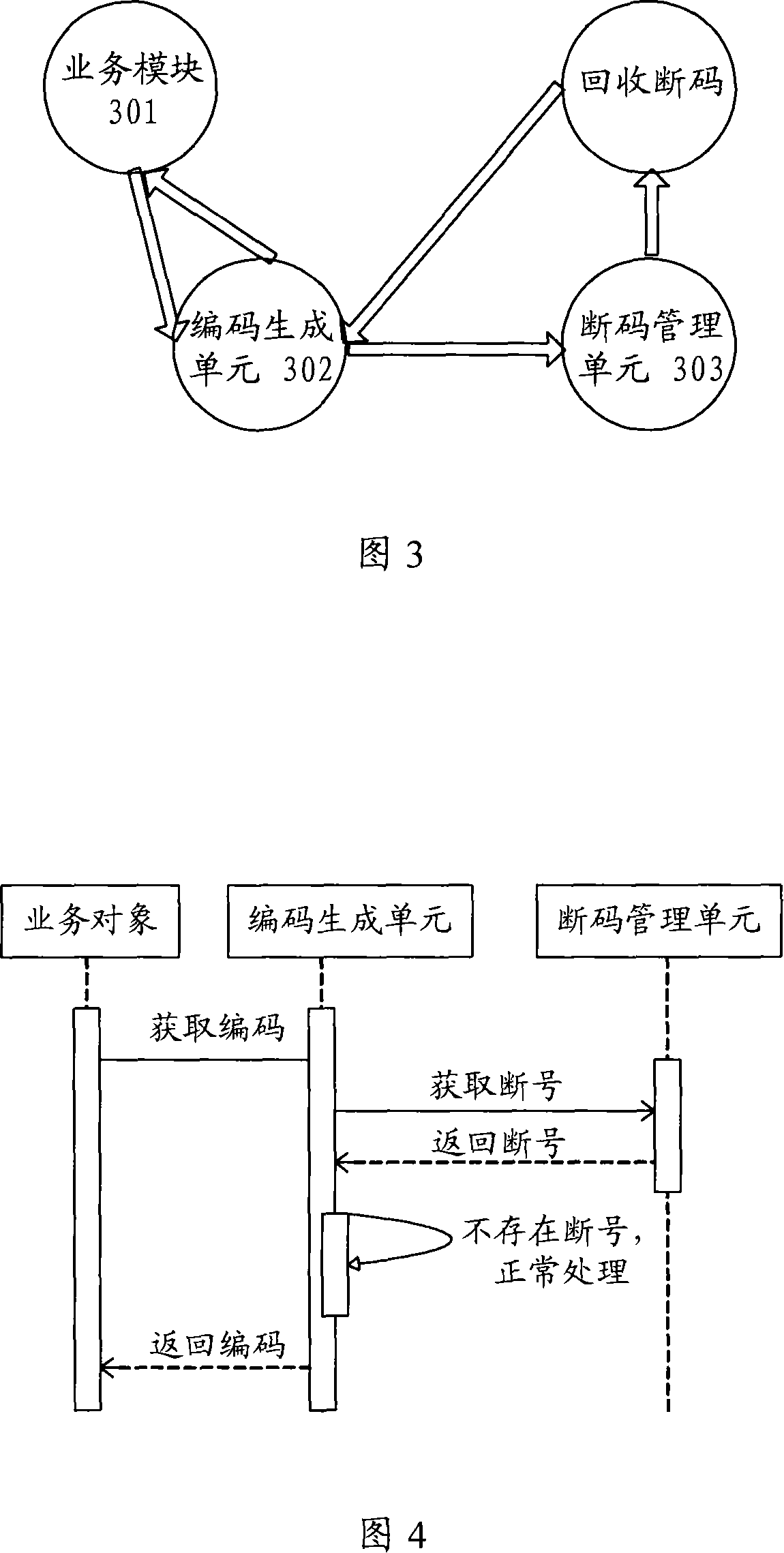

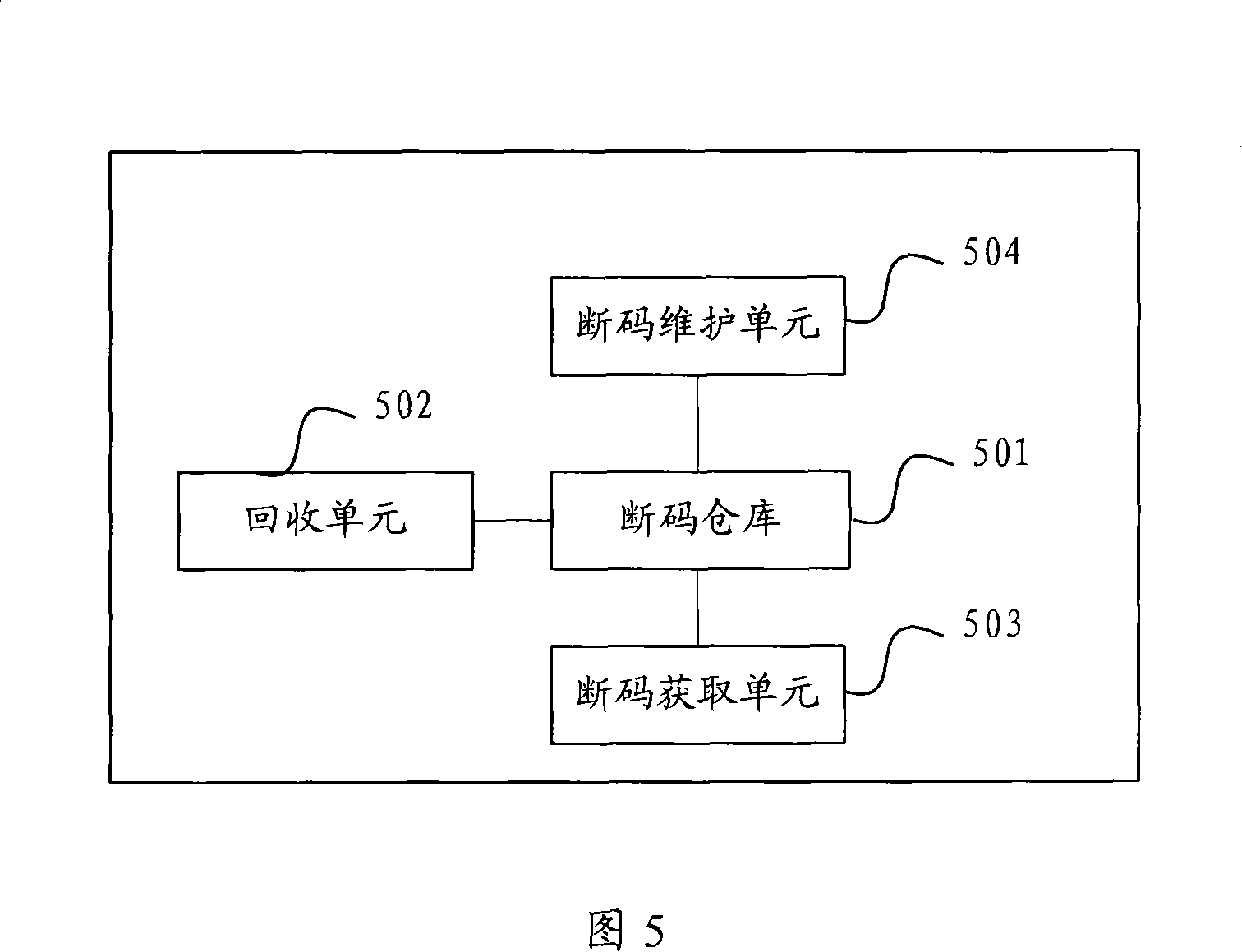

Method and system for treating intermittent code

InactiveCN101149824ASolve the broken code problemDoes not affect operationSpecial data processing applicationsProgramming language

The method and system for processing break code in coding course includes: restore and store break codes; when object to be coded fetches code, first inquires whether there are break codes, if yes it fetches the restored break codes and if no it produces new codes. Advantage: resolved break code problem in coding course and raised performance of coding system.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

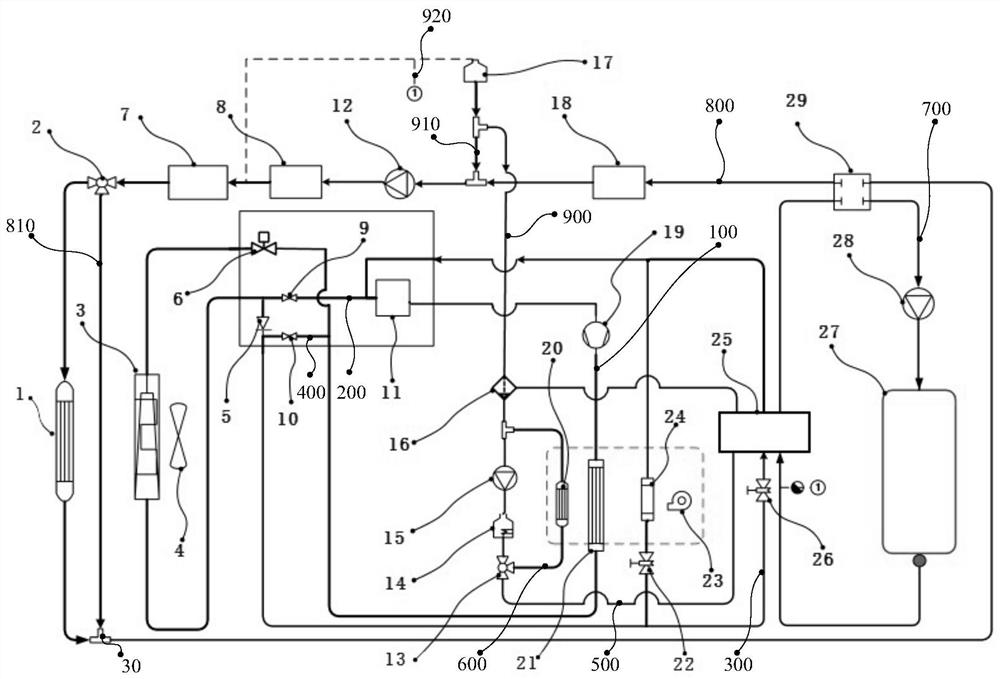

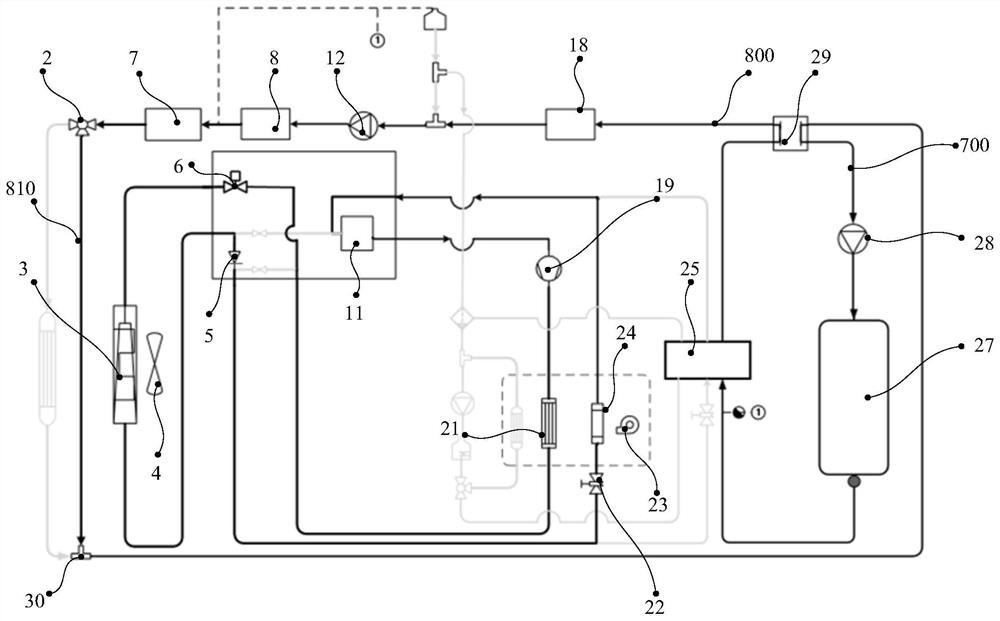

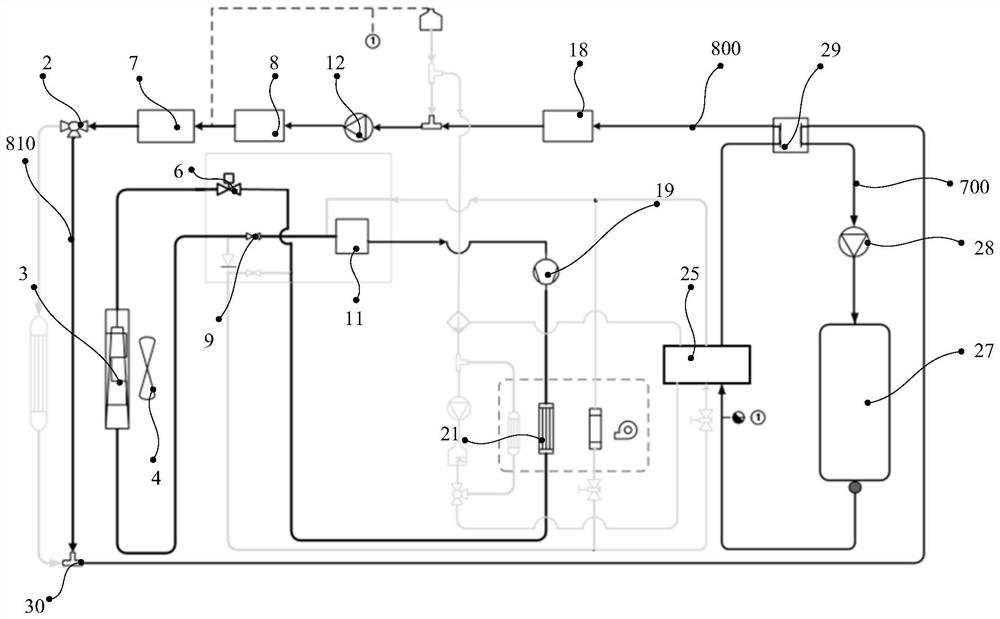

Heat pump system, energy-saving control method of heat pump system and vehicle

ActiveCN113237249ASolve the lack of heating capacitySolve insufficient heating capacityAir-treating devicesMechanical apparatusElectric driveIn vehicle

The invention provides a heat pump system, an energy-saving control method of the heat pump system and a vehicle. The problem that a vehicle heat pump system cannot meet the energy-saving and environment-friendly requirements is solved. The heat pump system comprises a main refrigerant loop, wherein a compressor, an internal condenser, a first electromagnetic valve, an external condenser, a first throttling device and an evaporator are mounted on the main refrigerant loop; a first refrigerant pipeline, wherein a second electromagnetic valve is arranged on the first refrigerant pipeline; a second refrigerant pipeline, wherein a heat exchange device and a second throttling device are arranged on the second refrigerant pipeline; a third refrigerant pipeline, wherein a third electromagnetic valve is arranged on the third refrigerant pipeline; a first cooling liquid pipeline, wherein a first suction device, a cooling liquid heating device and a three-way proportional valve are mounted on the first cooling liquid pipeline; a second cooling liquid pipeline, wherein a warm air core body is mounted on the second cooling liquid pipeline; a battery cooling pipeline, wherein second suction device, a power battery and a four-way valve are mounted on the battery cooling pipeline; and an electric driving pipeline, wherein an electric automobile vehicle-mounted charger, a third suction device, a high-voltage electric control module, a driving motor cooling device, a radiator and a third cooling liquid pipeline are arranged on the electric driving pipeline.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

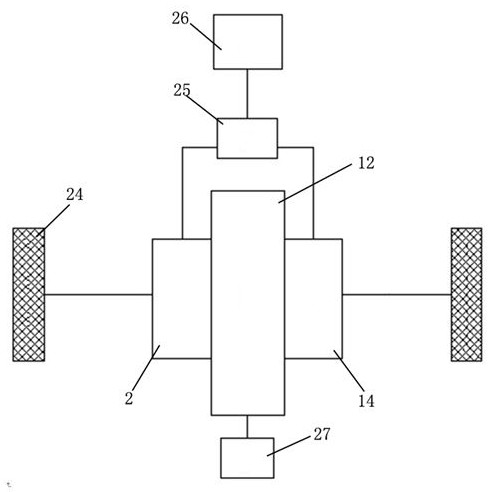

Electric driving system and electric vehicle

ActiveCN112277612ATaking into account the powerTake into account the requirementsElectric propulsion mountingControl devicesElectric machineryElectric cars

The invention relates to the field of pure electric vehicles, and in particular relates to an electric driving system and an electric vehicle. The electric driving system comprises a first motor, a second motor and a speed change mechanism. The speed change mechanism comprises a differential mechanism, a gear shifting mechanism and a planetary speed reducing mechanism. A first motor shaft of the first motor is connected with a sun gear of the planetary speed reducing mechanism, and a front gear ring of the planetary speed reducing mechanism is connected with the input end of the differential mechanism. A second motor shaft of the second motor is connected with the input end of the differential mechanism through the gear shifting mechanism; the two output ends of the differential mechanismdrive wheels to rotate through a left half shaft and a right half shaft respectively. A planet carrier of the planetary speed reducing mechanism is provided with a locking clutch so as to achieve locking and unlocking of the planet carrier. When the electric driving system is used on the vehicle, the requirement for motor power is low, cost is reduced, one motor can provide torque compensation forthe other motor during gear shifting, and power interruption is avoided; and the switching of working modes can be realized through the locking clutch.

Owner:ZHENGZHOU YUTONG BUS CO LTD

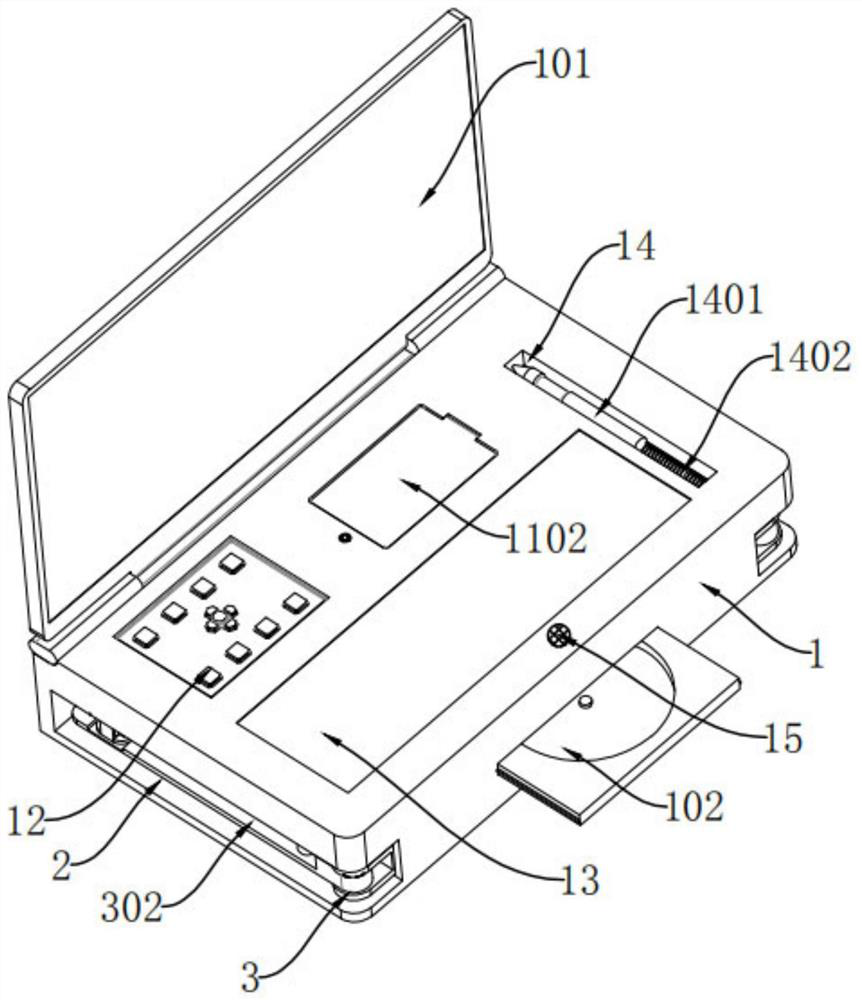

Spoken English and listening training device and method

ActiveCN112863269AFlexible recyclingProtect your healthElectrical appliancesTeaching apparatusDirect touchPhysical medicine and rehabilitation

The invention provides a spoken English and listening training device and method, and belongs to the technical field of English training. The spoken English and listening training device comprises a machine body, a display screen is movably hinged to the upper end of the machine body through a hinge shaft, an optical disc driver is installed at the front end of the machine body, a second installation groove is formed in the upper end of the machine body, a tape reader is installed in the second installation groove, the inner wall of the second installation groove is movably hinged to a gland through a hinge shaft, a positioning mechanism is arranged in the machine body, the positioning mechanism and the gland are connected to be used for fixedly mounting the second installation groove, first installation grooves are formed in the left end and the right end of the machine body, first U-shaped seats are fixedly connected to the inner walls, away from each other, of the two first installation grooves, a first movable plate is rotationally connected between the inner walls of the first U-shaped seats, direct contact of ears can be avoided, meanwhile, the training effect is not affected, and the English level of a user is effectively improved.

Owner:QINGDAO HUANGHAI UNIV

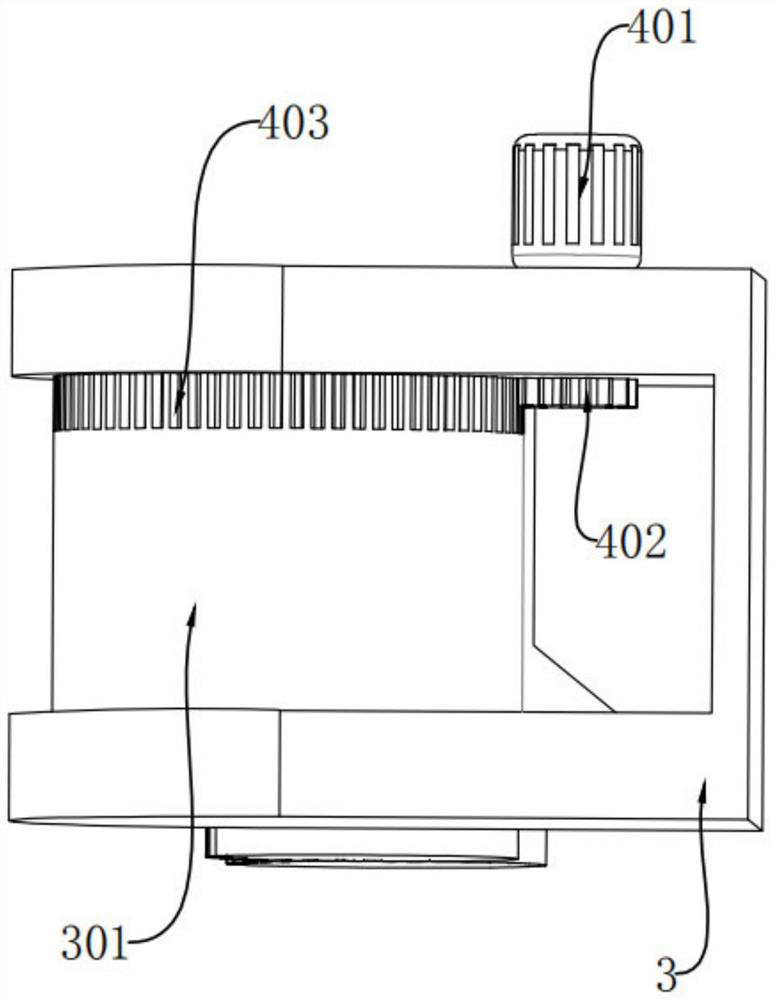

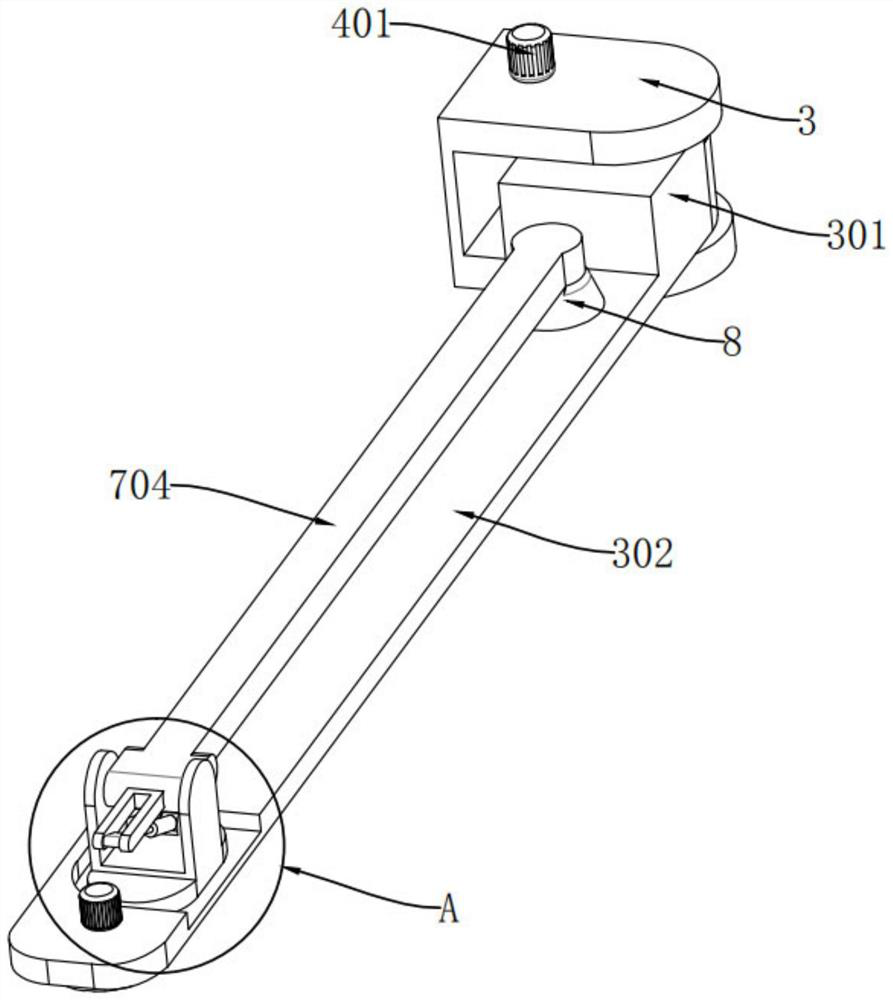

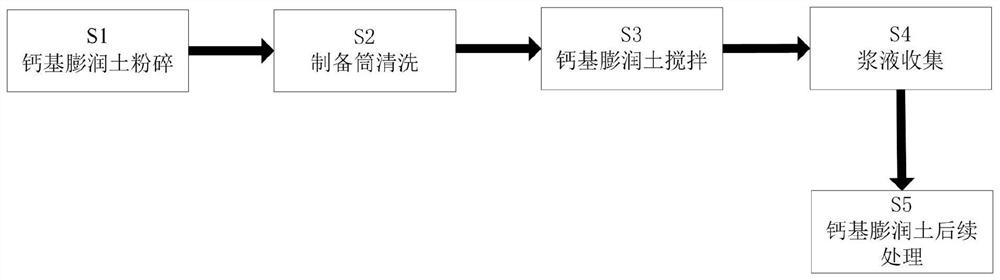

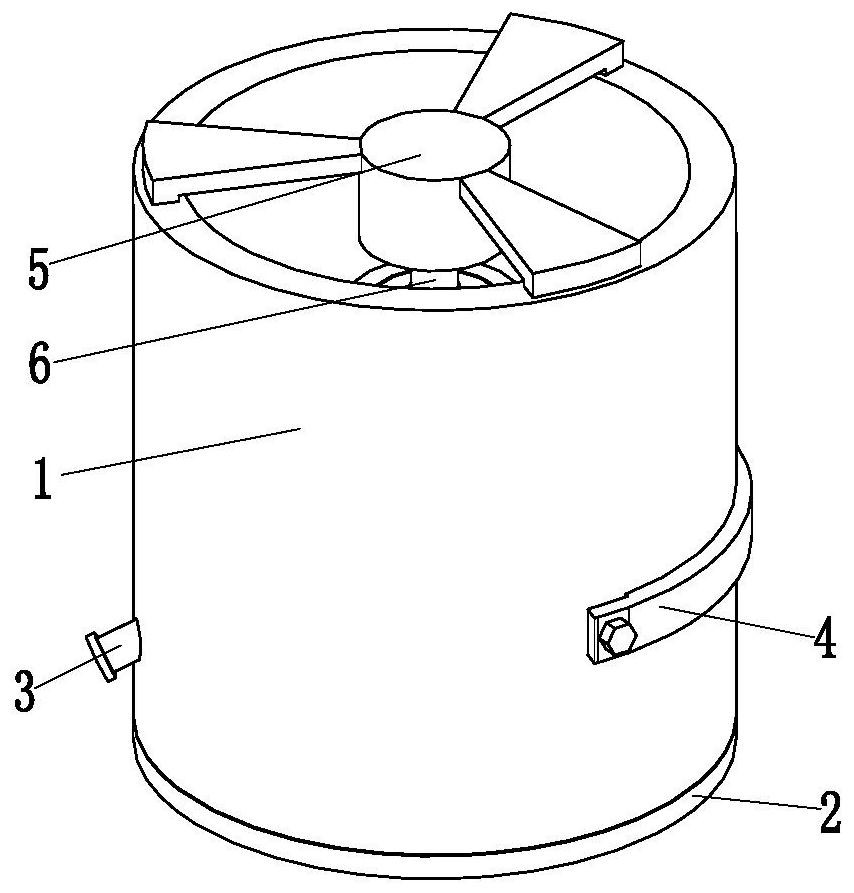

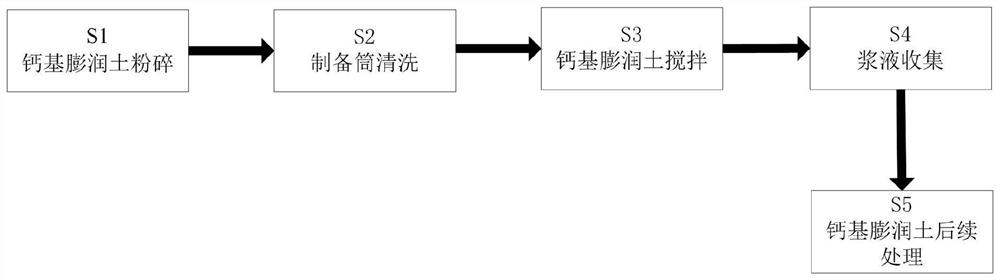

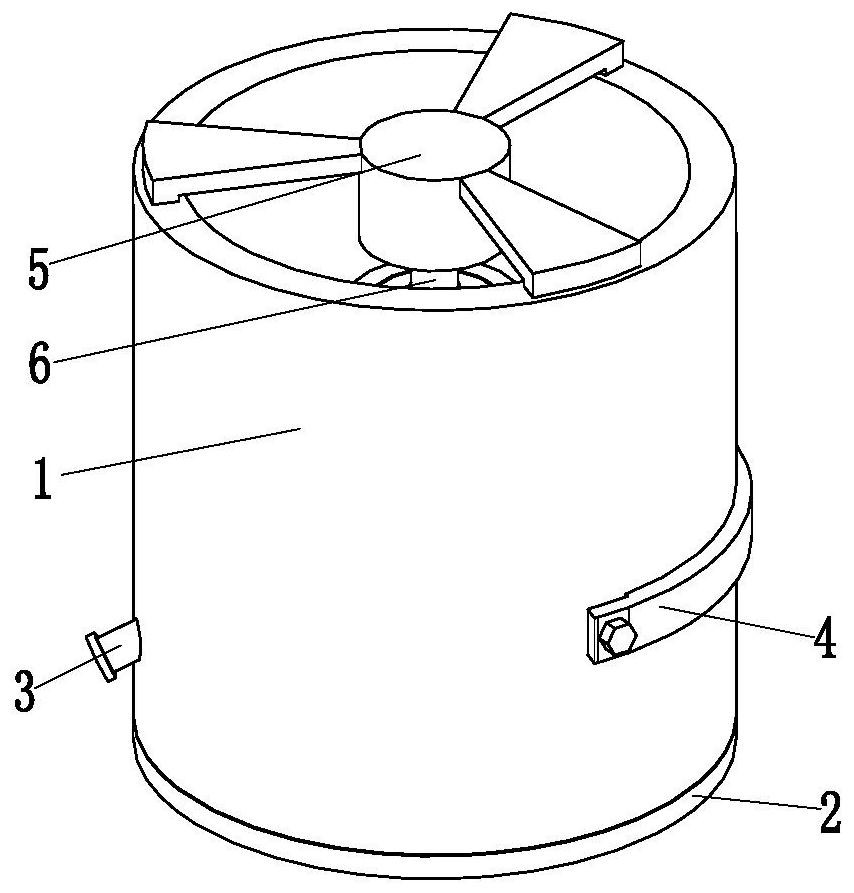

Preparation process of calcium-based bentonite

The invention relates to a preparation process of calcium-based bentonite. The preparation process of calcium-based bentonite adopts a calcium-based bentonite preparation device, and the calcium-basedbentonite preparation device comprises a preparation cylinder, a bottom plate, a plugging block, a sealing frame, a stirring motor and a stirring mechanism. The preparation process of the calcium-based bentonite by adopting the calcium-based bentonite preparation device comprises the following steps: S1, crushing calcium-based bentonite; S2, cleaning the preparation cylinder; S3, stirring the calcium bentonite; S4, collecting slurry; and S5, carrying out subsequent treatment on the calcium-based bentonite. The process can solve the problems that when purification operation is carried out in existing preparation of calcium-based bentonite, the calcium-based bentonite slurry is poured out together in a pouring mode when upper-layer suspension liquid of the calcium-based bentonite is discharged, the calcium-based bentonite slurry is poured out together in the pouring mode, and coarse slag at the bottom of the poured slurry can be moved to the calcium-based bentonite slurry again, and thelike.

Owner:瓦尼迈阿密(江西)化工有限公司

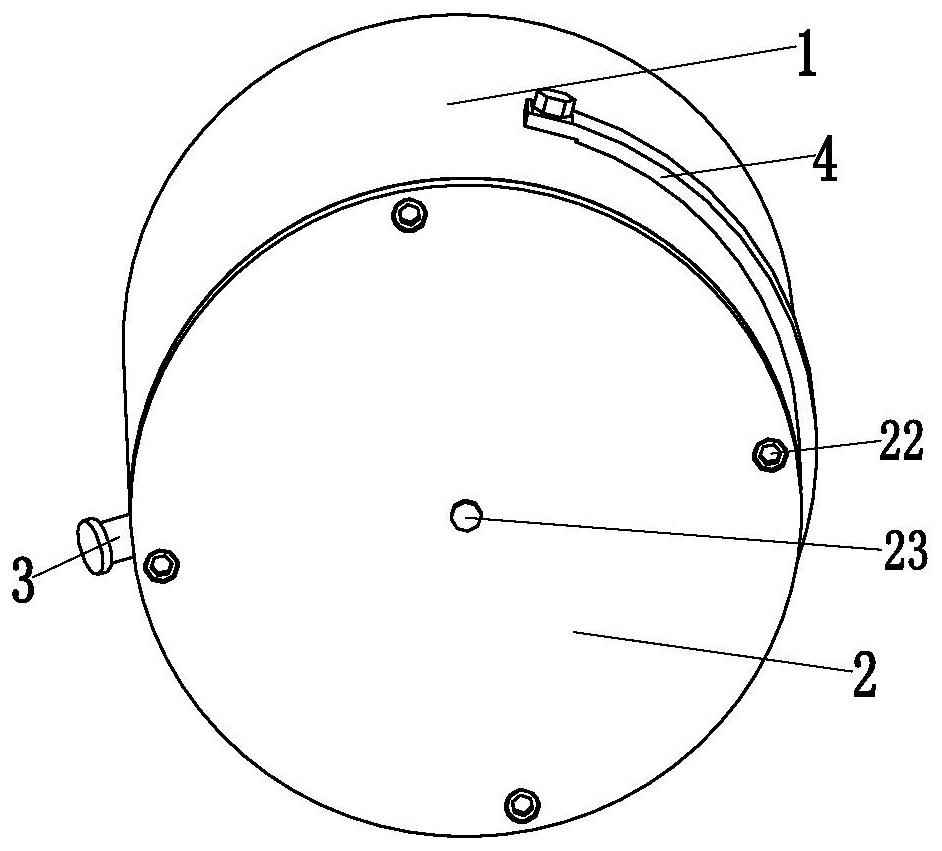

Recovery device of well casing exhaust gas

InactiveCN102477858ASimple structureEasy to carryFluid removalWell/borehole valve arrangementsExhaust gasProcess engineering

The invention relates to a recovery device of a well casing exhaust gas. The recovery device comprises a prying block, a hoop, a filter, a gas collecting bag, a safety valve, a natural gas compressor, a gas flow meter and a quick connector, and is characterized in that: an inlet of the gas collecting bag is connected with an outlet of the filter through a high-pressure hose, and an inlet of the filter is connected with an outlet of a casing through a control valve and the hoop or a flange; an outlet of the gas collecting bag is connected with an inlet of the natural gas compressor through a connecting pipeline, and an outlet of the natural gas compressor is connected with the gas flow meter; and an outlet of the gas flow outlet is connected with the quick connector, and the safety valve is arranged on the connecting pipeline of the gas collecting bag and the natural gas compressor. The recovery device has the advantages of simple structure, convenience in carrying, and strong mobility, can flexibly recover the casing gas of each well, avoids the pollution of the casing gas on the environment, and avoids the waste of energy by recovering natural gas.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

A method for recovering lead from waste lead plaster by solid-phase electrolysis

ActiveCN111455404BReduce consumptionSimple processPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentLead dioxide

The invention discloses a method for recovering lead from waste lead plaster by a solid-phase electrolysis method, belonging to the technical field of lead resource recovery. Firstly, the waste lead paste is made into a pasty waste lead paste electrolytic material, and coated on the cathode plate; the electrolyte solution is added to the electrolytic cell; the cathode plate coated with the electrolytic material is inserted into the electrolyte solution, and the anode is inserted into the electrolyte solution middle; the anode is an electrode with oxygen-evolving electrocatalysis; the cathode plate and the anode are respectively connected to the negative pole and the positive pole of the DC power supply, so that electrolysis takes place in the electrolytic cell; the water on the anode loses electrons to precipitate oxygen, and the electrolytic material on the cathode plate is obtained The electrons are reduced in situ to generate simple lead, which is attached to the cathode plate, that is, lead is recovered from waste lead paste. In the present invention, the waste lead paste is directly electrolyzed after simple pulping, and the lead sulfate, lead dioxide and lead monoxide in the waste lead paste are obtained by electrons to generate lead element in situ, which saves a large number of pretreatment procedures and reduces reagents. The consumption makes the process simple and reduces the cost.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of preparation technology of calcium-based bentonite

ActiveCN112093804BImprove the preparation effectPrevent outflowSilicon compoundsPhysical chemistrySlurry

The invention relates to a calcium-based bentonite preparation process. The calcium-based bentonite preparation process adopts the following calcium-based bentonite preparation device. The calcium-based bentonite preparation device includes a preparation cylinder, a bottom plate, a plugging block, a sealing frame, a stirring motor and a stirring mechanism; The preparation process of calcium-based bentonite by the above-mentioned calcium-based bentonite preparation device includes the following steps: S1, calcium-based bentonite pulverization; S2, preparation cylinder cleaning; S3, calcium-based bentonite stirring; S4, slurry collection; S5, calcium-based bentonite subsequent treatment . The present invention can solve the problem existing in the purification operation for the preparation of calcium-based bentonite: when the calcium-based bentonite is discharged from the upper suspension, it usually adopts the method of dumping, which will pour out the calcium-based bentonite slurry together, and after pouring The coarse slag at the bottom of the slurry will move back to the calcium-based bentonite slurry.

Owner:瓦尼迈阿密(江西)化工有限公司

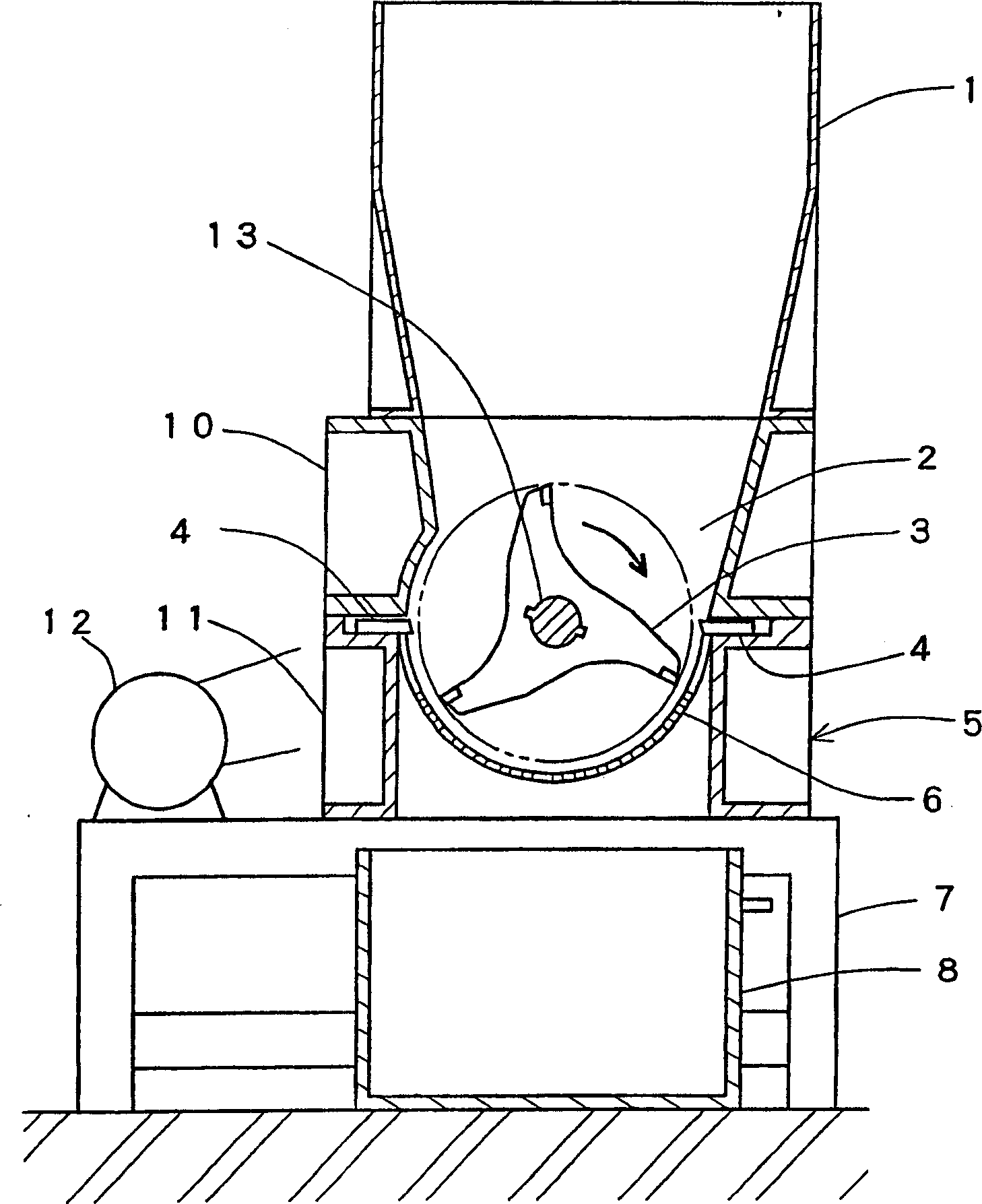

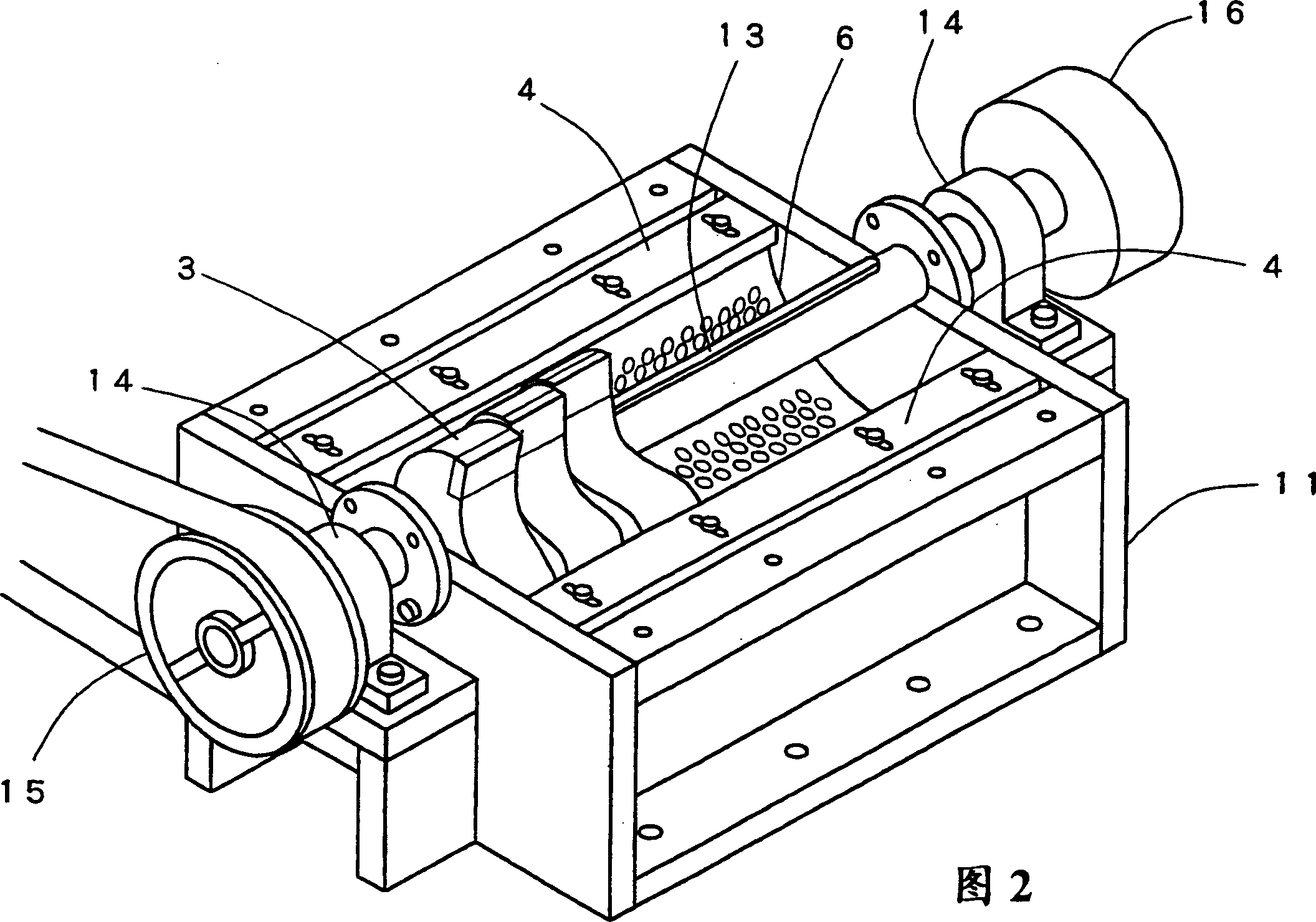

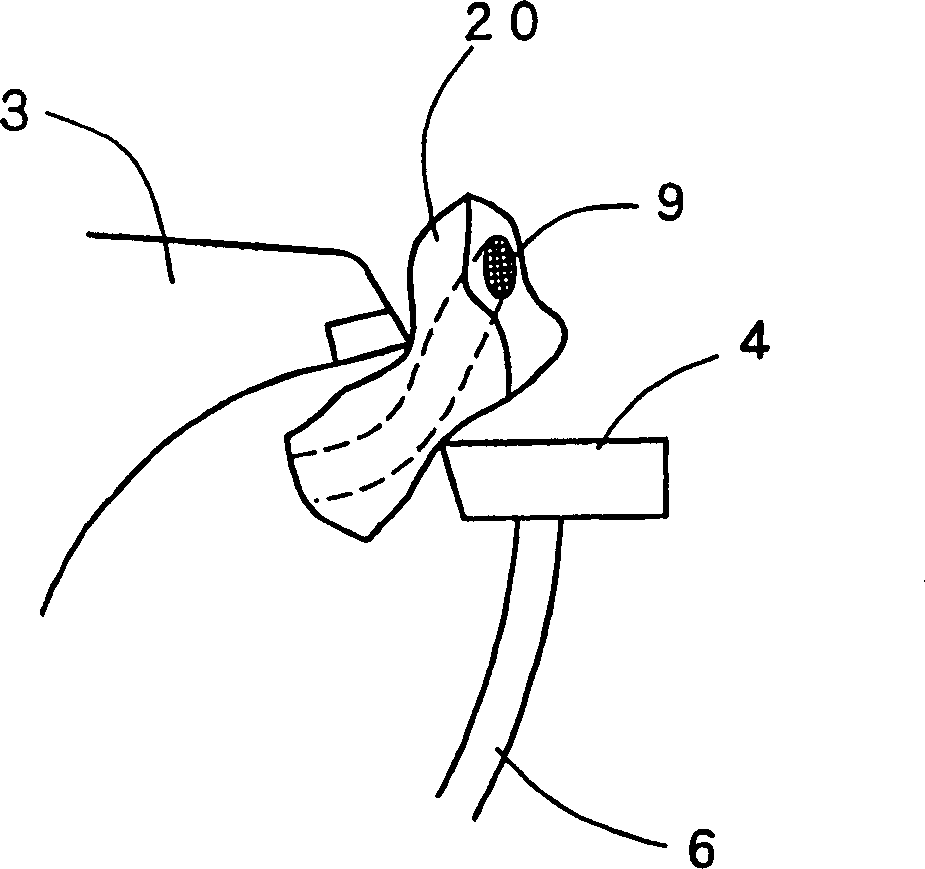

Method and device for crushing waste tyre

InactiveCN1118331CSimple production processLow costSolid waste disposalPlastic recyclingFiberPiano wire

The present invention provides a method and an apparatus for crushing and pulverizing tire chips roughly crushed to a size of 10 cm in length by completely separating to rubber components from iron components in a single crushing process. It is intended to extensively simplify the process to produce rubber powder from waste tires and to promote material recycling of the used tires. The method comprises the steps of catching the tire chips between monoaxial rotary blades 3 rotated within a casing 2 and fixed blades 4 and 4 fixed and arranged at opposed positions and maintaining a gap slightly larger than diameter of a piano wire 9 contained in the tires, rupturing only the rubber components without cutting piano wires and steel fibers, tearing and withdrawing rubber components by rotation of the rotary blade 3, and crushing while separating rubber components from iron components.

Owner:M DIA

Soft storage allocation method for hybrid automatic repeat request process of long term evolution system

InactiveCN102255712BWithout compromising transmission performanceSave storage resourcesError prevention/detection by using return channelAutomatic repeat requestTransmitter

The invention discloses a soft storage allocation method for the hybrid automatic repeat request process of a long term evolution system. The method comprises the following steps of: a downlink shared channel of the long term evolution system adopts a multi-process hybrid automatic repeat request technology and maximally performs transmission for 4 times, a transmitter transmits a redundancy version of a transmission block every time and can transmit two transmission blocks at a time in a space division multiplexing mode, wherein the transmission block TB can be divided into N coded blocks CB1, CB2, ..., and CBN, [] represents rounding-up and A is the number of information bits of the transmission block; and only one process of a receiver in any downlink sub-frame receives a currently transmitted transmission block. By the method, soft storage resources required by the multi-process hybrid automatic repeat request process are effectively reduced. The method is applied to various usage scenarios of the long term evolution system, and is highly robust.

Owner:SOUTHEAST UNIV

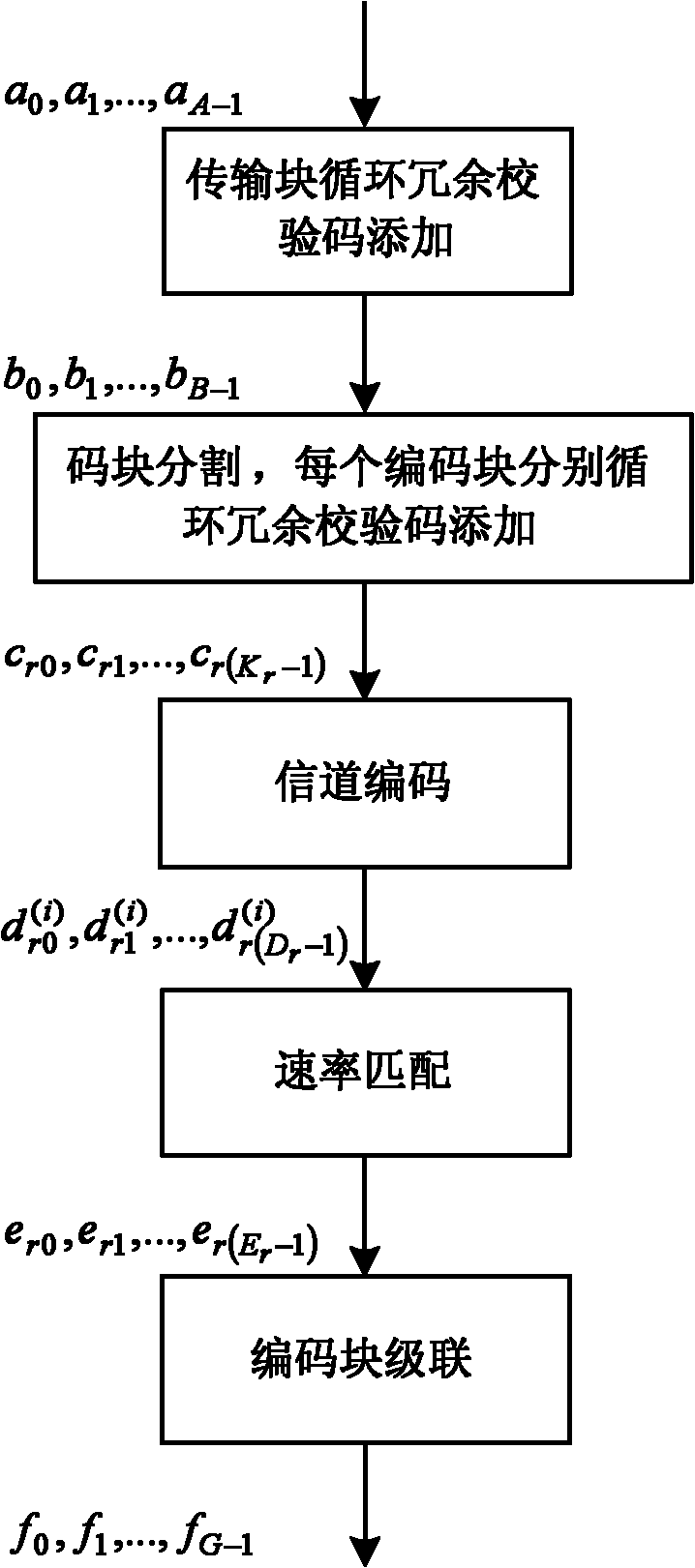

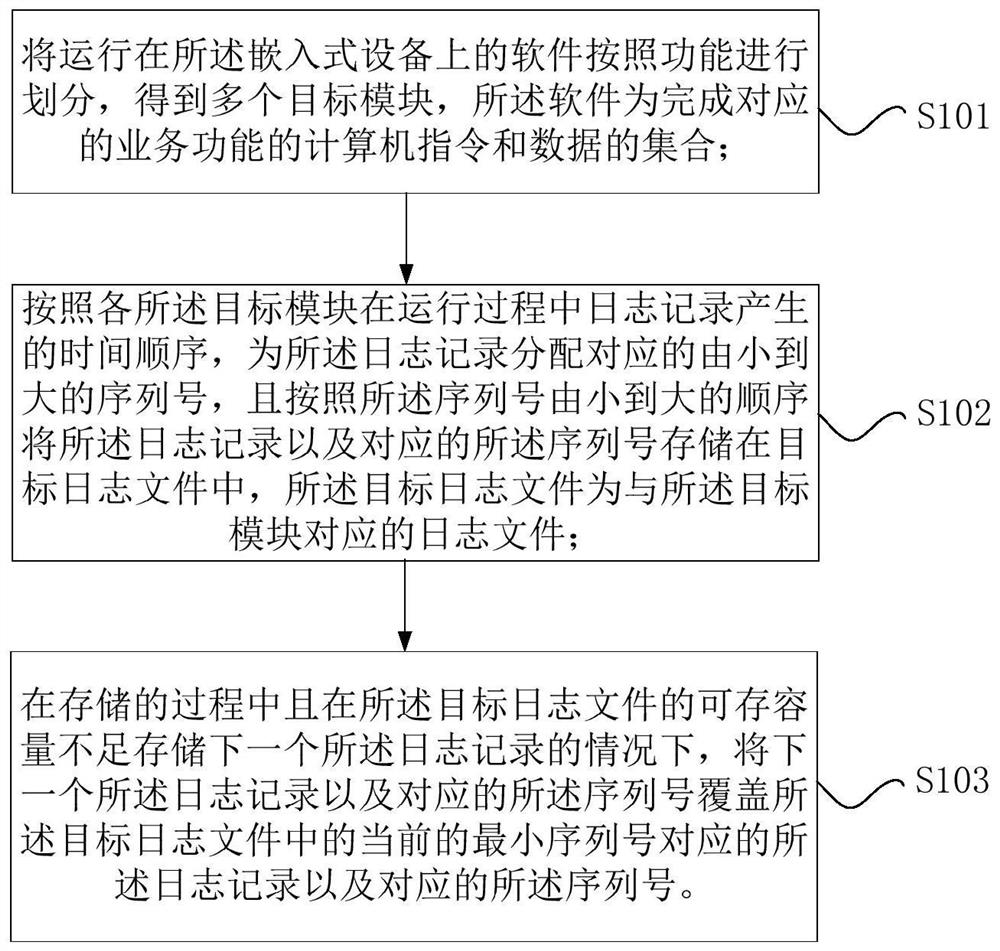

Log storage method and device based on embedded device and processor

PendingCN114756426ASave storage spaceFlexible storageHardware monitoringFile system functionsSerial codeRecord

The invention provides a log storage method and device based on an embedded device and a processor, and the method comprises the steps: dividing software running on the embedded device according to functions, and obtaining a plurality of target modules; according to the time sequence of log record generation in the operation process of each target module, distributing corresponding serial numbers from small to large for the log records, and storing the log records and the corresponding serial numbers in a target log file according to the sequence of the serial numbers from small to large; in the storage process and under the condition that the storable capacity of the target log file is insufficient to store the next log record, the next log record and the corresponding serial number cover the log record corresponding to the current minimum serial number in the target log file and the corresponding serial number; therefore, the problem that in the prior art, it is difficult to store the log records of the embedded device more flexibly under the condition that the storage space is saved is solved.

Owner:WEICHAI POWER CO LTD +1

Garbage data recovery method in cloud storage log file system

ActiveCN105045850BFlexible recyclingIncrease profitSpecial data processing applicationsRecovery methodInode

Owner:NORTHWESTERN POLYTECHNICAL UNIV

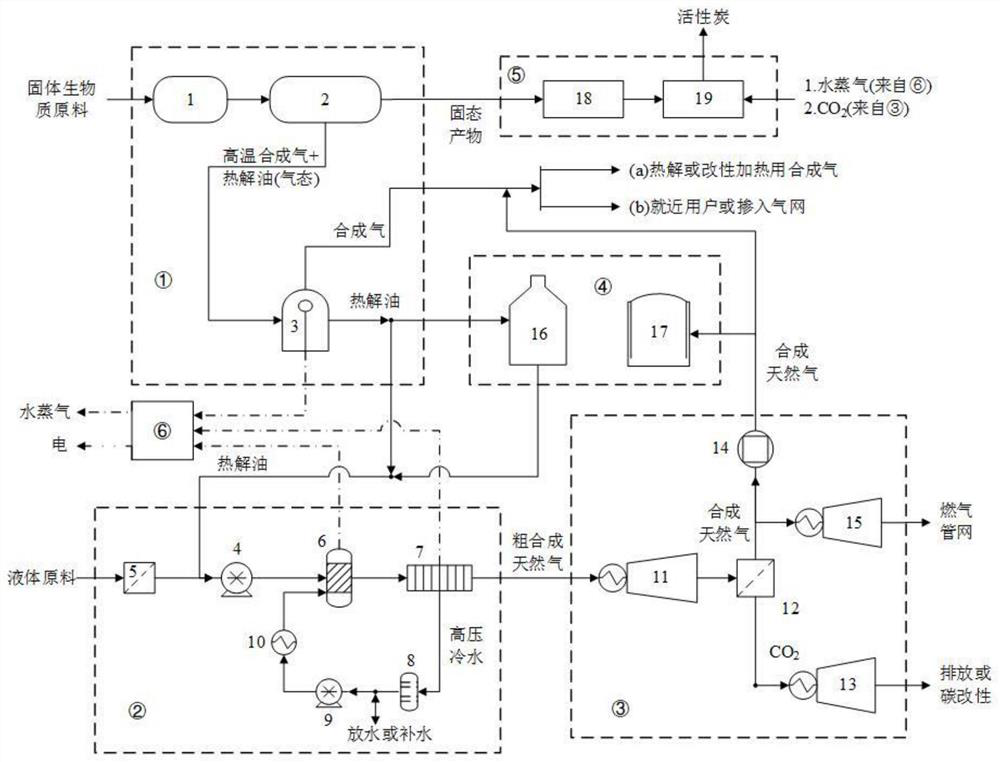

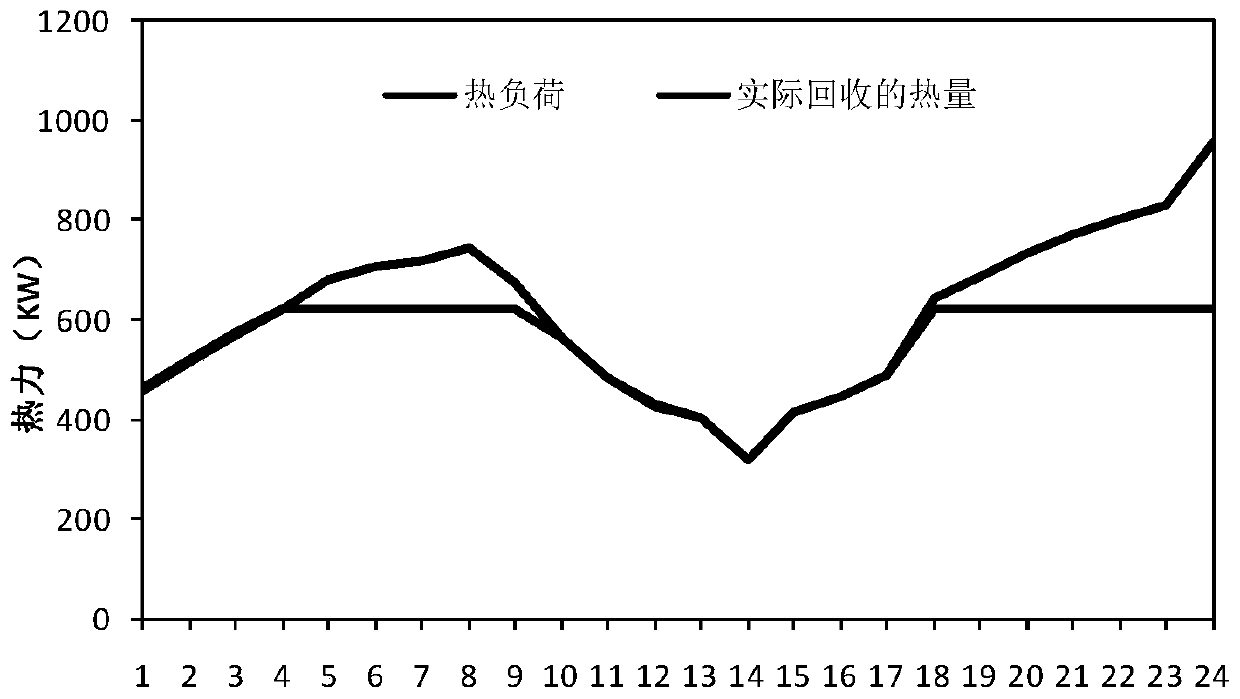

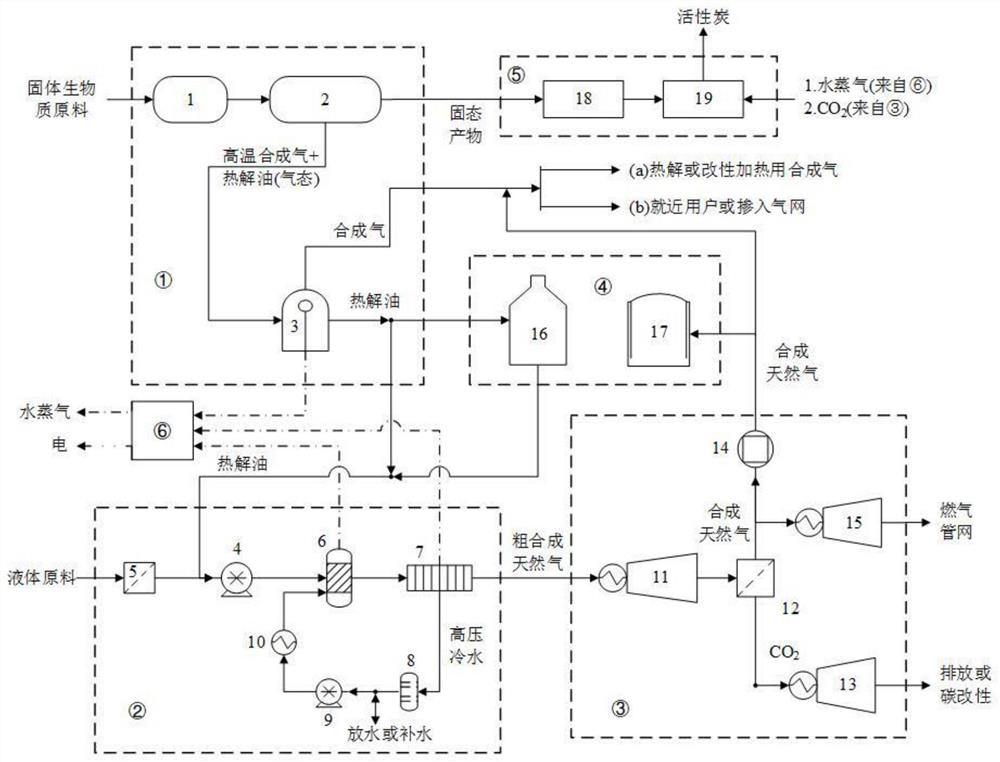

A Biomass Pyrolysis-Hydrothermal Methanation Cogeneration Process and Its Device with Interseasonal Energy Storage Function

ActiveCN111808624BWide range of raw materialsWith energy storage capacityCarbon compoundsBiofuelsMethanationEnergy recovery

The invention discloses a biomass pyrolysis-hydrothermal methanation poly-cogeneration process and its device with the function of inter-seasonal energy storage, including solid biomass fast pyrolysis and product separation unit, hydrothermal methanation unit, CO 2 Separation and pressure energy recovery unit, oil and gas energy storage unit, biochar modification unit, waste heat recovery and utilization unit. After the biomass is broken and dried, it undergoes rapid pyrolysis and product separation to obtain gas-solid-liquid three-phase products. The main product pyrolysis oil is pressurized and enters the hydrothermal methanation reactor to generate CH 2 and CO 2 Crude natural gas as the main component, and then remove CO after pressure regulation 2 , to obtain CH with high concentration 4 The SNG. Pyrolysis gas phase products, combined with part of SNG to provide heat for rapid pyrolysis and biochar modification. The solid phase products of pyrolysis are modified using physical methods. The invention has compact process, flexible operation mode, better energy storage capacity, and is suitable for comprehensive utilization of resources such as urban and rural agricultural and forestry wastes and household garbage.

Owner:江苏博斯泰德能源科技有限公司

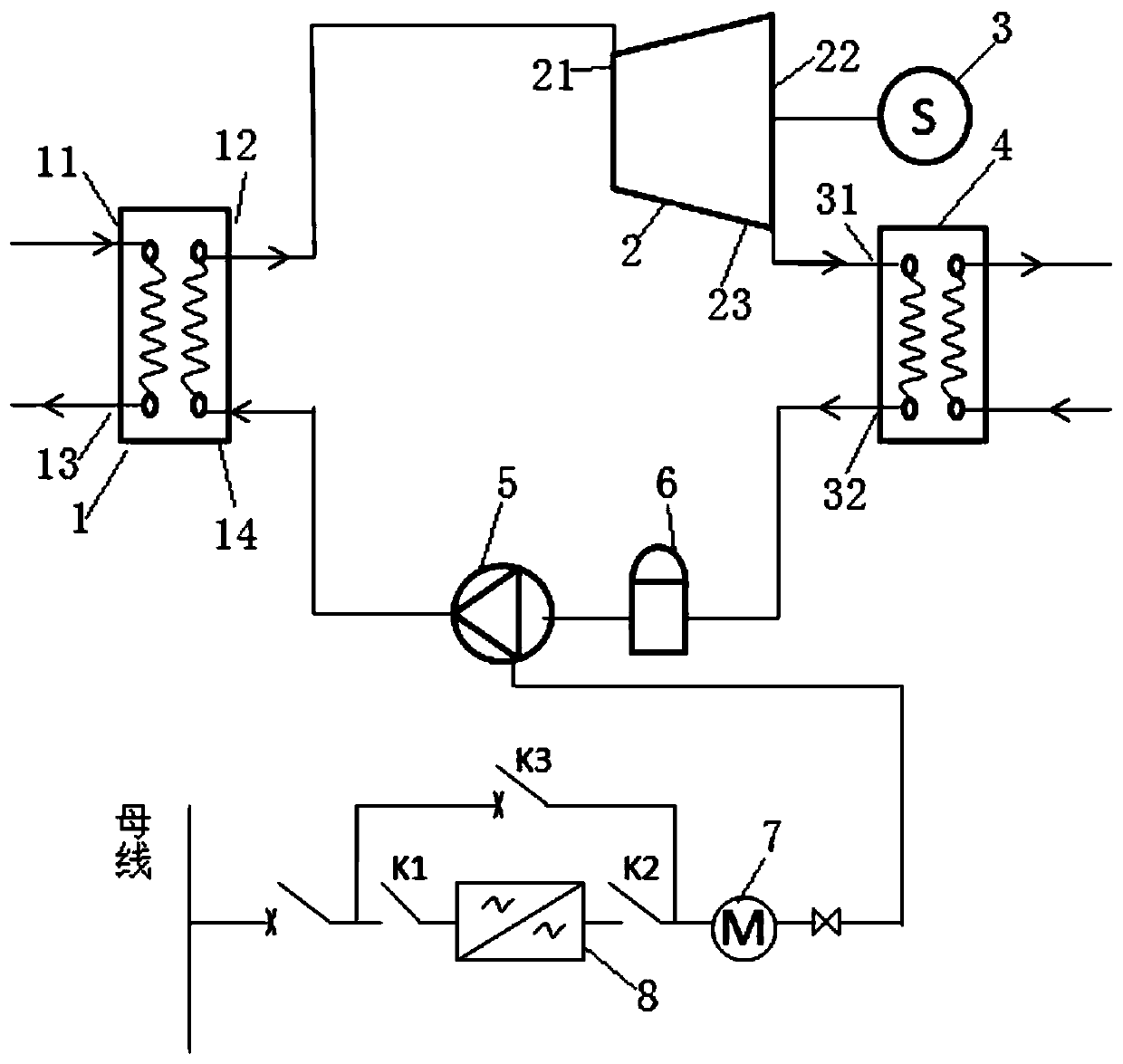

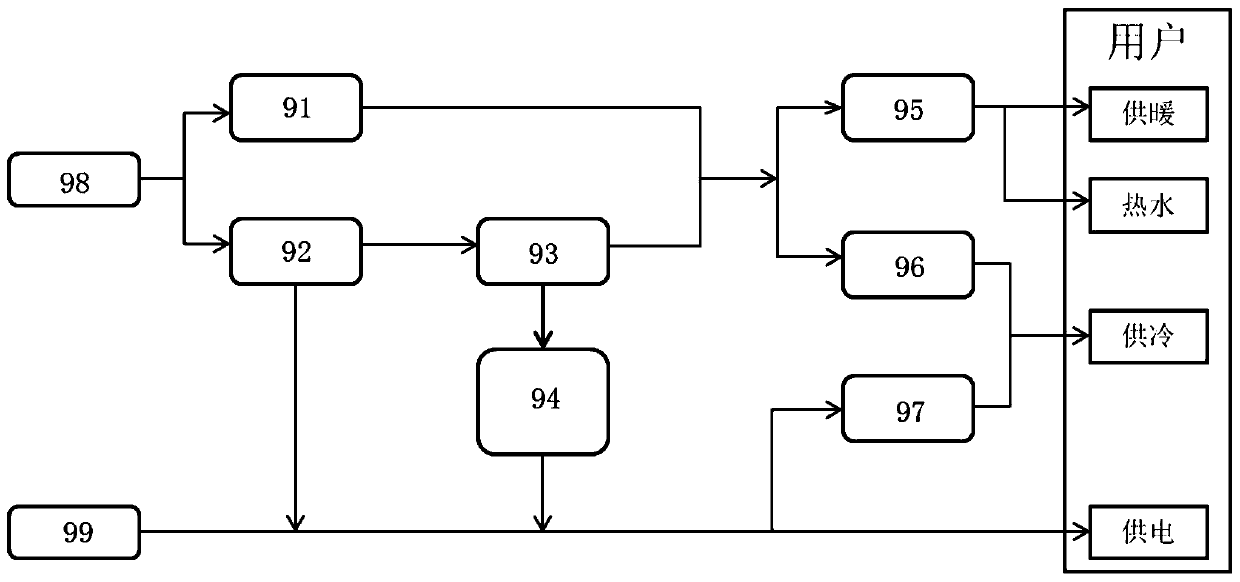

A Combined Cooling, Heating, Power and Organic Rankine Cycle System

ActiveCN108301887BIncrease profitMaximize utilizationSingle network parallel feeding arrangementsSteam engine plantsThermodynamicsOrganic Rankine cycle

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

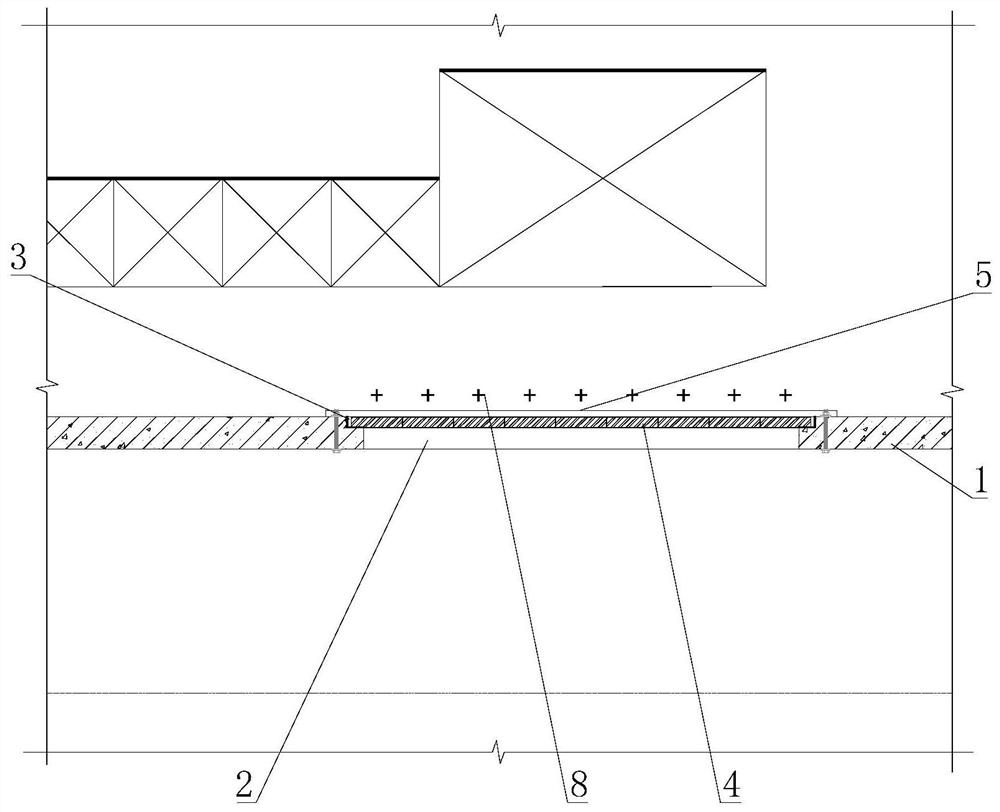

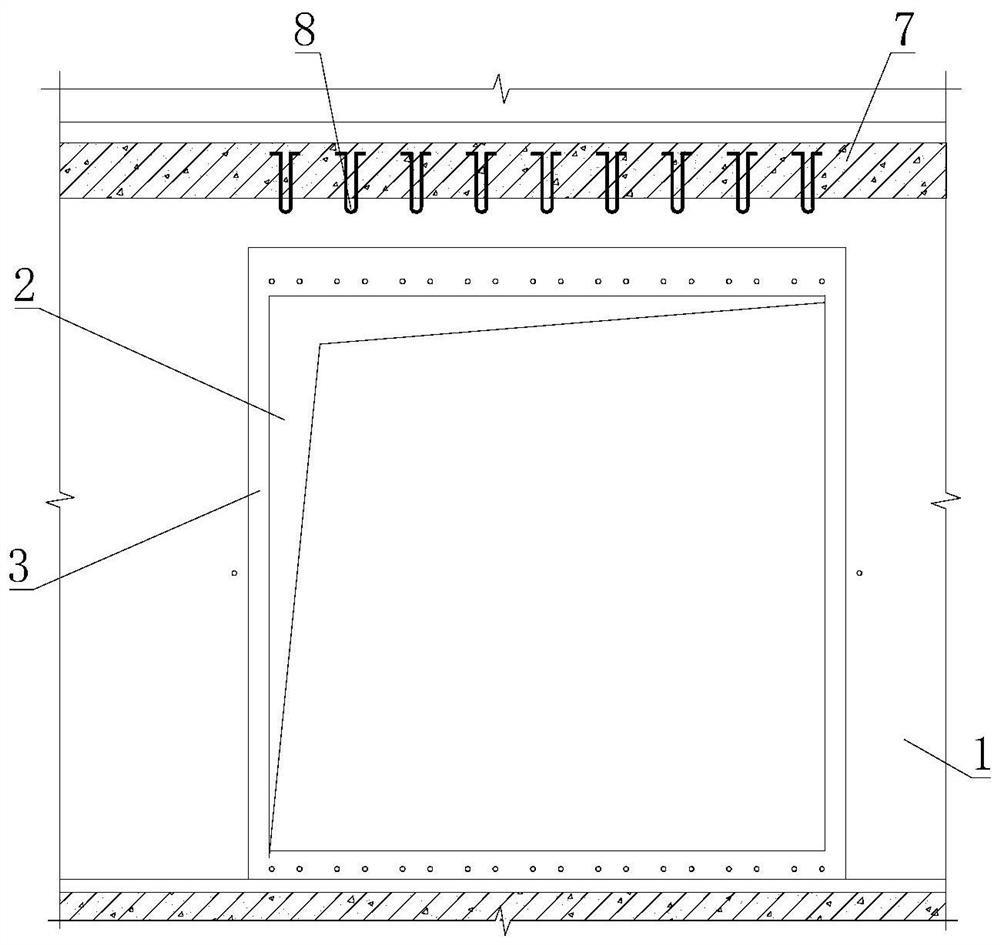

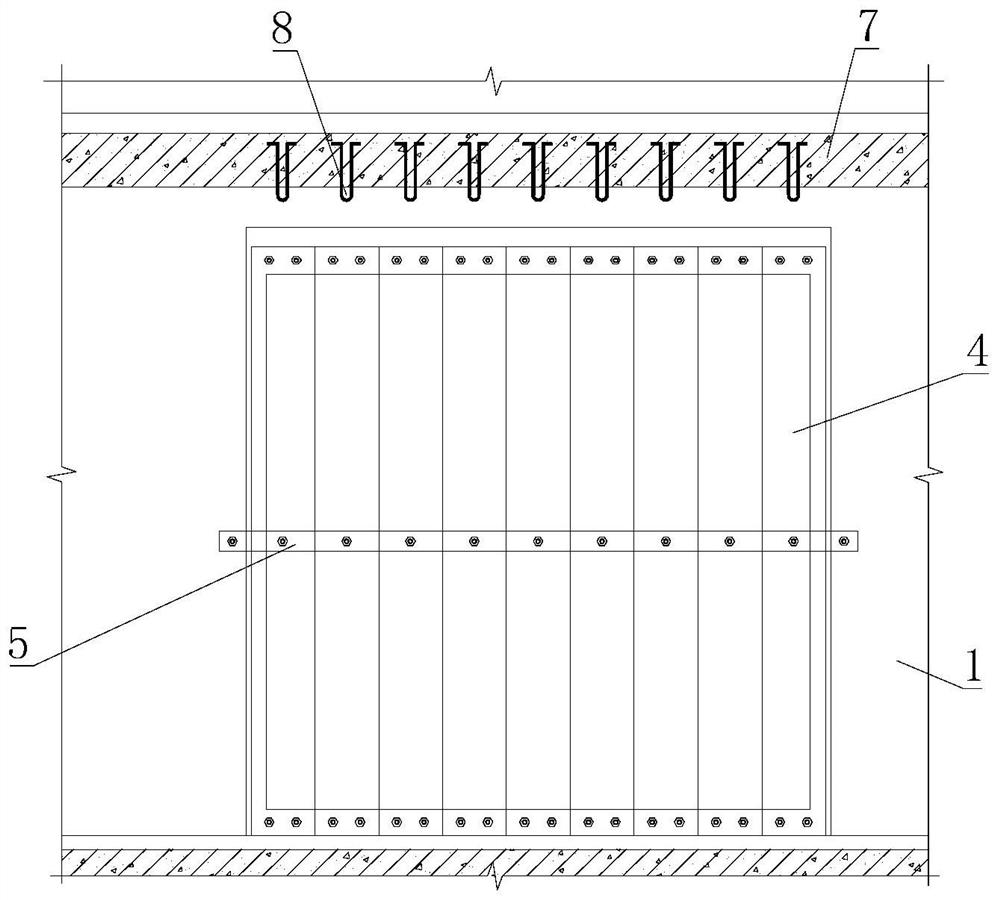

Blocking structure for transportation door opening of side wall equipment in subway rail traveling area

InactiveCN112253245ASave effective maintenance timeImprove maintenance efficiencyMining devicesArchitectural engineeringStructural engineering

The invention belongs to the technical field of rail traffic engineering, and particularly relates to a blocking structure for a transportation door opening of side wall equipment in a subway rail traveling area. According to the technical solution, the blocking structure for the transportation door opening of the side wall equipment in the subway rail traveling area comprises a structural wall, adoor opening is formed in the structural wall, rabbets are formed in the periphery of the door opening, a plurality of blocking plates are detachably installed among the rabbets, a reinforcing crossbeam further stretches across the middle of the door opening, and the two ends of the reinforcing cross beam are connected with the structural wall. The invention provides the blocking structure for the transportation door opening of the side wall equipment in the subway rail traveling area, which is convenient for equipment maintenance.

Owner:成都市建筑设计研究院有限公司

Waste treatment device for mechanical production

PendingCN114535256AAvoid damageIncrease capacityDispersed particle filtrationSolid waste disposalWaste treatmentWaste recovery

The invention discloses a waste treatment device for mechanical production, and relates to the technical field of machining, the waste treatment device comprises a collecting tank, sliding mechanisms are arranged on the two side faces of the collecting tank, carrying plates are slidably connected to the two side faces of the collecting tank through the sliding mechanisms, fans are fixedly mounted on the carrying plates, and the input ends of the fans fixedly communicate with air inlet pipes; and the output end of the fan is fixedly communicated with an air outlet pipe. According to the waste recovery device, the height and angle of the fan and the height and angle of the air inlet pipe communicated with the fan are adjusted through the sliding mechanism and the pipe clamp of the waste recovery device, so that waste recovery can be flexibly carried out on various types of mechanical appliances, and the situation that waste such as dust or fine chippings is mistaken when an operator operates the mechanical appliances is avoided; and in addition, waste materials in the collecting tank can be compacted through a hydraulic cylinder and a pressing plate of the device, so that the waste material collecting capacity of the device is improved, and then the practicability of the device is improved.

Owner:徐玉莉

Biomass pyrolysis-hydrothermal methanation poly-generation process with cross-seasonal energy storage function and device of process

ActiveCN111808624AWide range of raw materialsWith energy storage capacityCarbon compoundsBiofuelsMethanationAgricultural residue

The invention discloses a biomass pyrolysis-hydrothermal methanation poly-generation process with a cross-seasonal energy storage function and a device of the process. The device comprises a solid biomass rapid pyrolysis and product separation unit, a hydrothermal methanation unit, a CO2 separation and pressure energy recovery unit, an oil gas energy storage unit, a biochar modification unit and awaste heat recycling unit. Biomass is subjected to rapid pyrolysis and product separation after being crushed and dried, so that gas-phase solid-phase and liquid-phase products are obtained; the mainproduct pyrolytic oil is pressurized and then enters a hydrothermal methanation reactor, crude natural gas with CH2 and CO2 as main components is generated; the CO2 is removed after pressure regulation, and SNG containing high-concentration CH4 is obtained; the pyrolytic gas-phase product cooperates with part of SNG so as to provide heat for rapid pyrolysis and charcoal modification; and the pyrolytic solid-phase product is modified by a physical method. The process of the invention is compact, is flexible in operation mode, achieves the better energy storage capacity and is suitable for comprehensive utilization of urban and rural forestry and agricultural residues, household garbage and other resources.

Owner:江苏博斯泰德能源科技有限公司

A three-motor hybrid drive truck and its power system parameter matching method

InactiveCN105620310BReduce manufacturing difficultyFlexible recyclingSpeed controllerElectrodynamic brake systemsReduction driveReducer

The invention relates to a three-motor hybrid truck and a power system parameter matching method. The three-motor hybrid truck is assembled by using a first driving motor, a first input shaft, a first speed reducer, a first output shaft, an automobile front axle, a second input shaft, a second driving motor, a first power cell, a second power cell, a third driving motor, a third input shaft, an automobile rear axle, a second output shaft, a second speed reducer, a third power cell, a controller and a fourth power cell. According to the invention, in the parameter matching process of a power system, analog computation is carried out on power system power demand under a CYC-UDDS circulating condition of the truck by using a vehicle backward simulation model so as to ensure the reasonability of the design. According to the invention, the capacity of the single driving motor can be obviously reduced, the motor manufacturing difficulty is reduced and the cost is also reduced; and meanwhile, through reasonable power matching of the three motors, the dynamic property and economic efficiency of the truck can be obviously improved.

Owner:JILIN UNIV

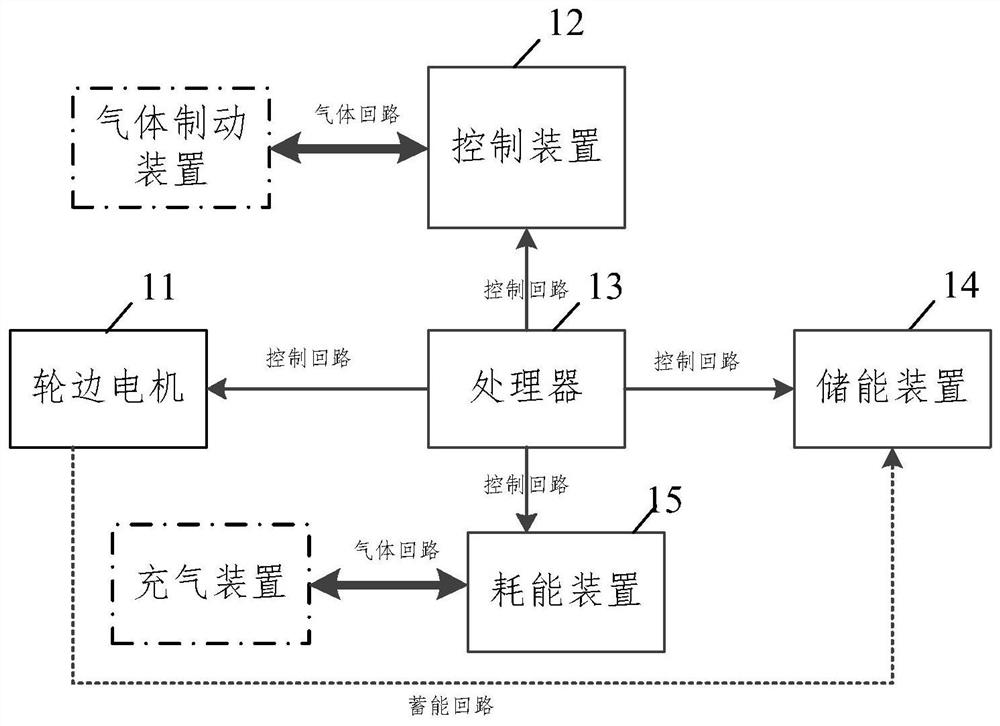

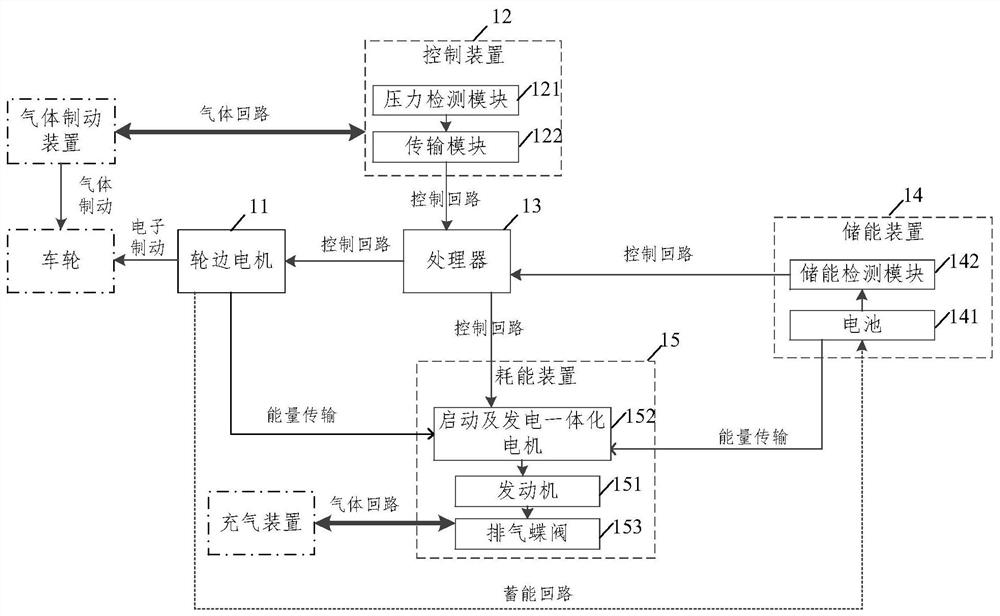

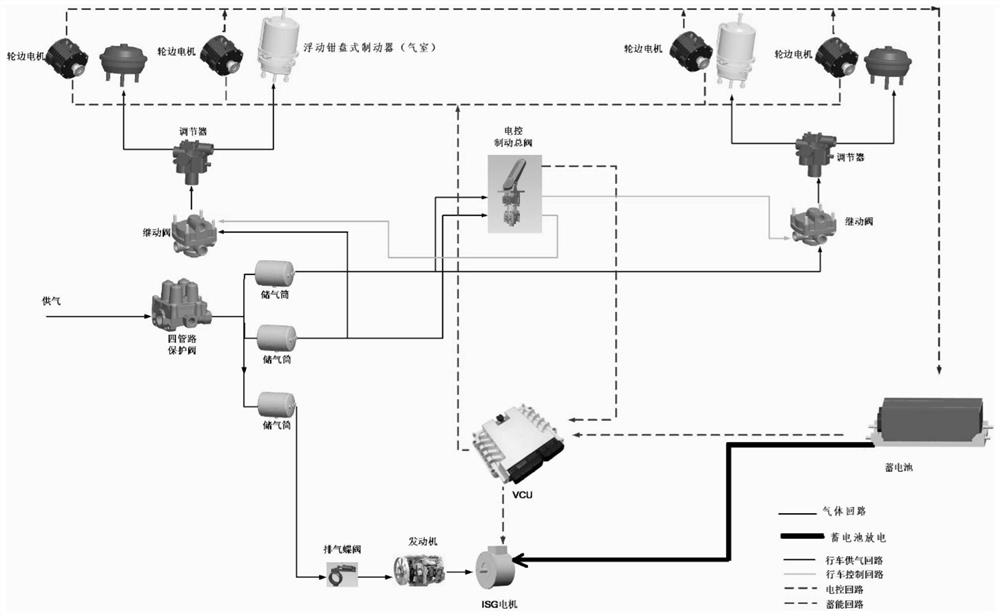

Vehicle energy regeneration system, energy regeneration control method based on vehicle energy regeneration system and storage medium

InactiveCN112297859AFlexible recyclingImprove regenerative abilityBraking action transmissionElectrodynamic brake systemsEnergy regenerationElectric machinery

The invention discloses a vehicle energy regeneration system, an energy regeneration control method based on the vehicle energy regeneration system and a storage medium. The vehicle energy regeneration system comprises at least four wheel-side motors, a control device, a processor, an energy storage device and an energy consumption device. The wheel-side motors are arranged near the wheels, each wheel-side motor corresponds to one wheel, and the wheel-side motors are connected with the energy storage device through an energy storage loop; the control device is connected with the processor through a control loop, and the control device is further arranged in a gas loop, connected with the gas braking device, of an inflation device in the vehicle. The processor is connected with the energy storage device through the control loop and further connected with the energy consumption device through the control loop. The energy consumption device is connected with an inflating device through agas loop. By means of the system, each wheel can be independently braked, resource waste caused by unified braking of all the wheels is avoided, and the energy recovery effect is improved.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com