Oil-well waste gas recovery device

A waste gas recovery and oil well technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of outer casing gas pollution, environmental energy, waste, etc., and achieve simple structure, avoid waste, and mobility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

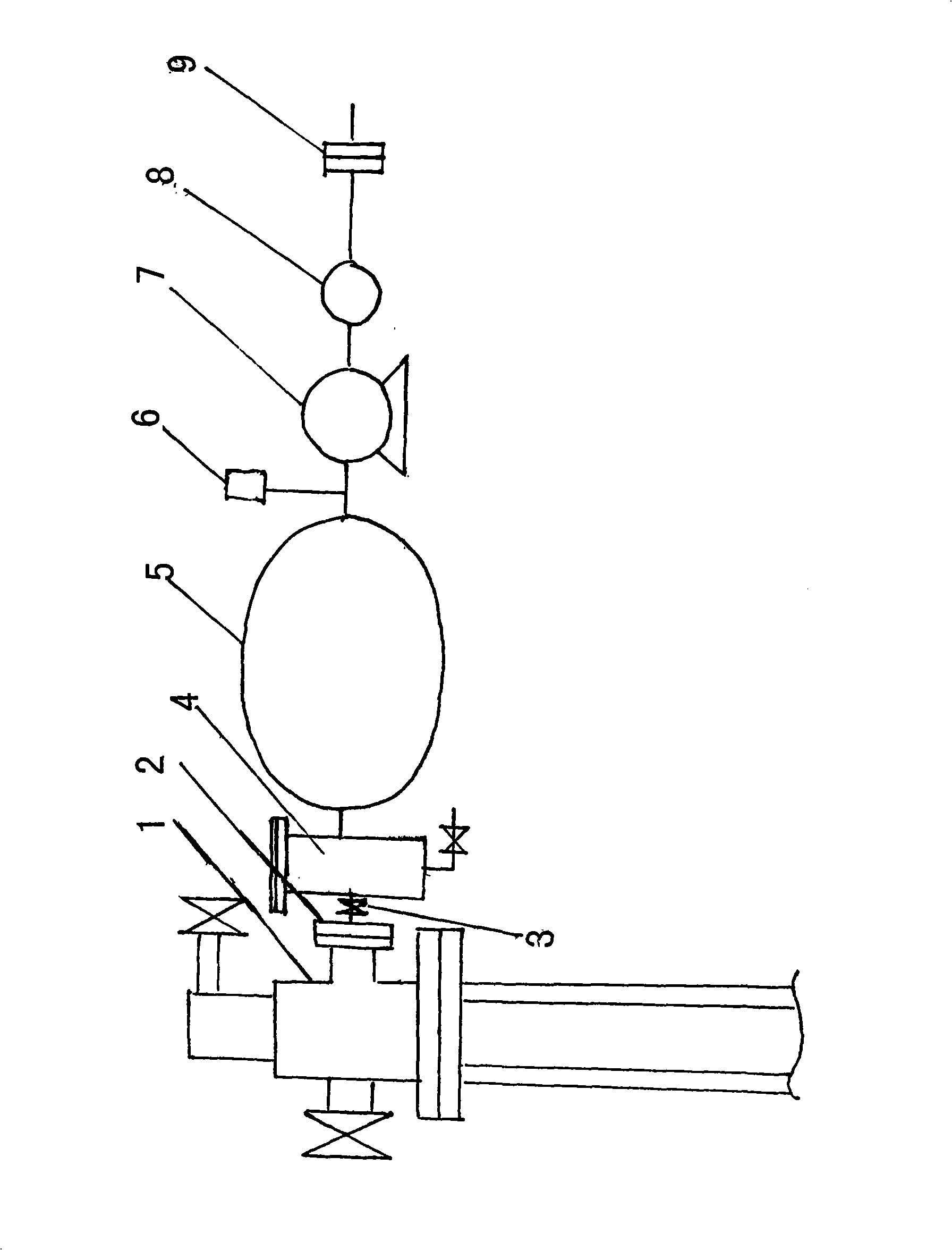

[0012] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0013] The present invention is composed of a skid block, a clamp 2, a control valve 3, a filter 4, an air receiving bladder 5, a safety valve 6, a natural gas compressor 7, a gas flow meter 8 and a quick connector 9, and is characterized in that the air receiving bladder 5 The inlet is connected to the outlet of the filter 4 through a high-pressure hose, the inlet of the filter is connected to the outlet of the casing through the control valve 3 and a clamp or flange, and the outlet of the air bag 5 is connected to the inlet of the natural gas compressor 7 through a connecting pipeline. The outlet is connected to the gas flowmeter 8, the outlet of the gas flowmeter 8 is connected to the quick connector 9, and a safety valve is provided on the pipeline connecting the air bag and the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com