Electric driving system and electric vehicle

A technology for electric drive systems and electric vehicles, applied to vehicle components, electric power devices, power devices, etc., can solve the problems of high motor power and low efficiency, and achieve the effects of weight reduction, flexible energy recovery, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The embodiments of the present invention will be further described below in conjunction with the drawings.

[0044]The specific embodiment of the vehicle of the present invention includes a frame on which wheels are mounted via a suspension. The frame is also equipped with a power supply, an electric drive system and a control system.

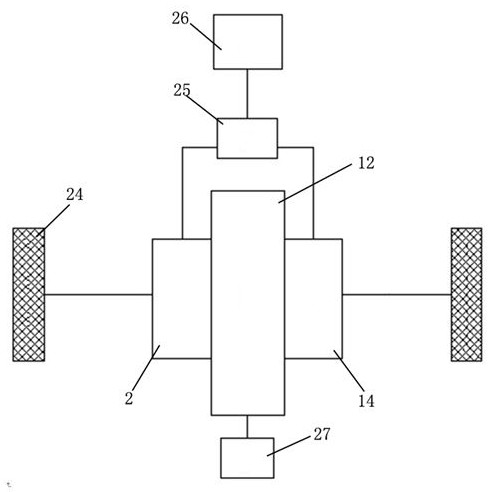

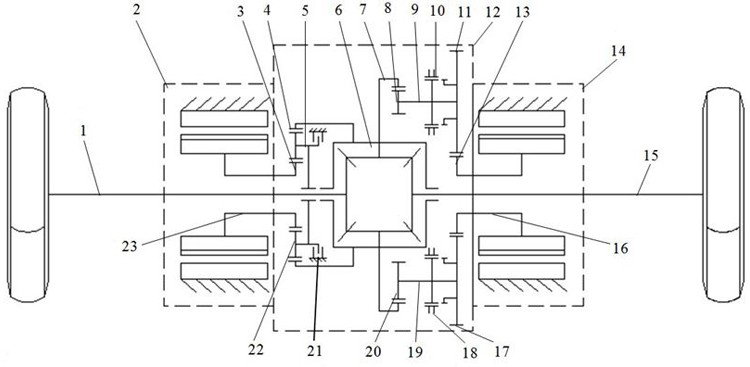

[0045]Such asfigure 1 Shown is a simplified diagram of the electric drive system of the vehicle of the present invention. It can be clearly seen from the figure that the electric drive system mainly includes a first motor 2, a second motor 14 and a speed change mechanism 12, the first motor, the second motor The motors are all drivingly connected to the speed change mechanism 12 and output torque to the wheels 24 through the speed change mechanism 12. The first motor 2 and the second motor 14 are arranged on opposite sides of the speed change mechanism 12. The shaft of the first motor 2 and the shaft of the second motor 14 are both hollow shafts for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com