A continuously variable valve lift hydraulic tappet mechanism for an engine

A technology of valve lift and hydraulic tappet, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of partially lifting the engine, high production cost, and inconvenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

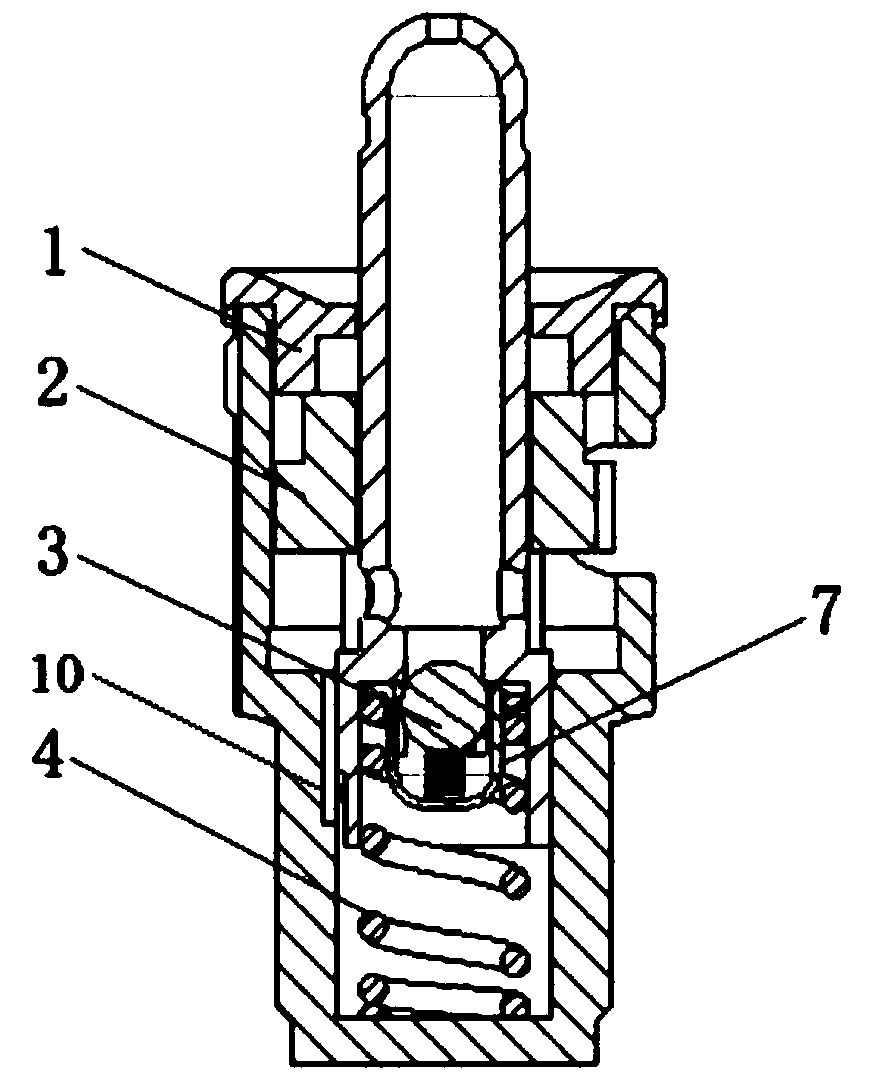

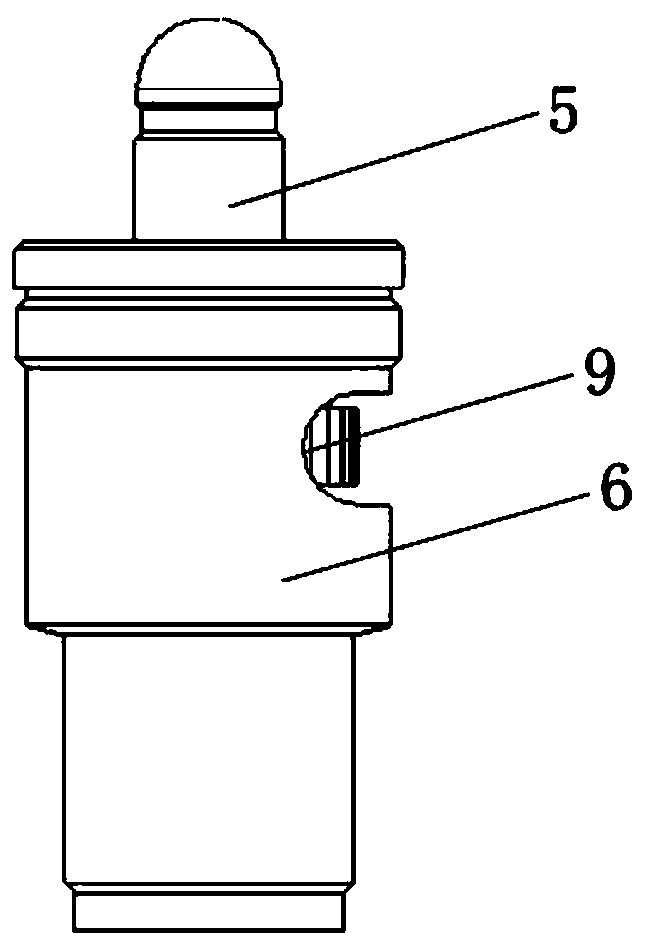

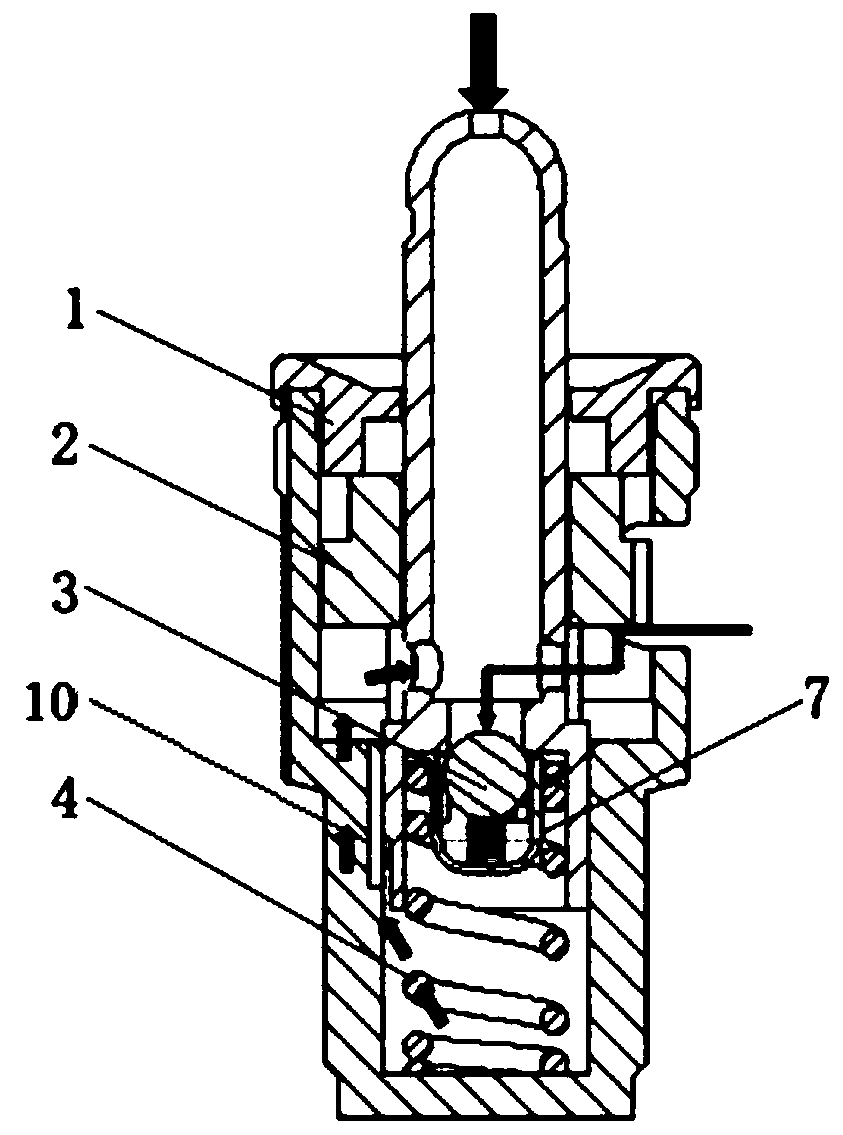

[0026] see figure 1 and figure 2 , This embodiment provides an engine continuously variable valve lift (CVHLA) hydraulic tappet mechanism, including an upper cover 1, a control wheel 2, a one-way valve 3, a return spring 4, a control valve rod 5 and a housing 6.

[0027] Wherein, the upper end cover 1 is threadedly connected with the casing 6 , and the casing 6 is provided with an oil drain channel and a groove 9 .

[0028] The control wheel 2 is arranged inside the housing 6. The control wheel 2 has an incomplete gear structure, and its angle is controlled by a rack. In this embodiment, the diameter of the control wheel 2 is 16 mm.

[0029] The center of the control wheel 2 is provided with a central hole, and the control valve rod 5 is passed through the central hole.

[0030] The one-way valve 3 is arranged at the bottom end of the control valve stem 5, and the outside of the one-way valve 3 is provided with a piston 7. In this embodiment, the diameter of the piston 7 is...

Embodiment 2

[0036] see figure 1 and figure 2 , This embodiment provides an engine continuously variable valve lift (CVHLA) hydraulic tappet mechanism, including an upper cover 1, a control wheel 2, a one-way valve 3, a return spring 4, a control valve rod 5 and a housing 6.

[0037] Wherein, the upper end cover 1 is threadedly connected with the casing 6 , and the casing 6 is provided with an oil drain channel and a groove 9 .

[0038] The control wheel 2 is arranged inside the housing 6. The control wheel 2 has an incomplete gear structure, and its angle is controlled by a rack. In this embodiment, the diameter of the control wheel 2 is 14 mm.

[0039] The center of the control wheel 2 is provided with a central hole, and the control valve rod 5 is passed through the central hole.

[0040]The one-way valve 3 is arranged at the bottom end of the control valve rod 5, and the outside of the one-way valve 3 is provided with a piston 7. In this embodiment, the diameter of the piston 7 is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com