Method and device for crushing waste tyre

A crushing device and technology for waste tires, applied in chemical instruments and methods, solid waste removal, tires, etc., can solve problems such as inability to eliminate iron components, and achieve the effects of simplified production process, less blade wear, flexible recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

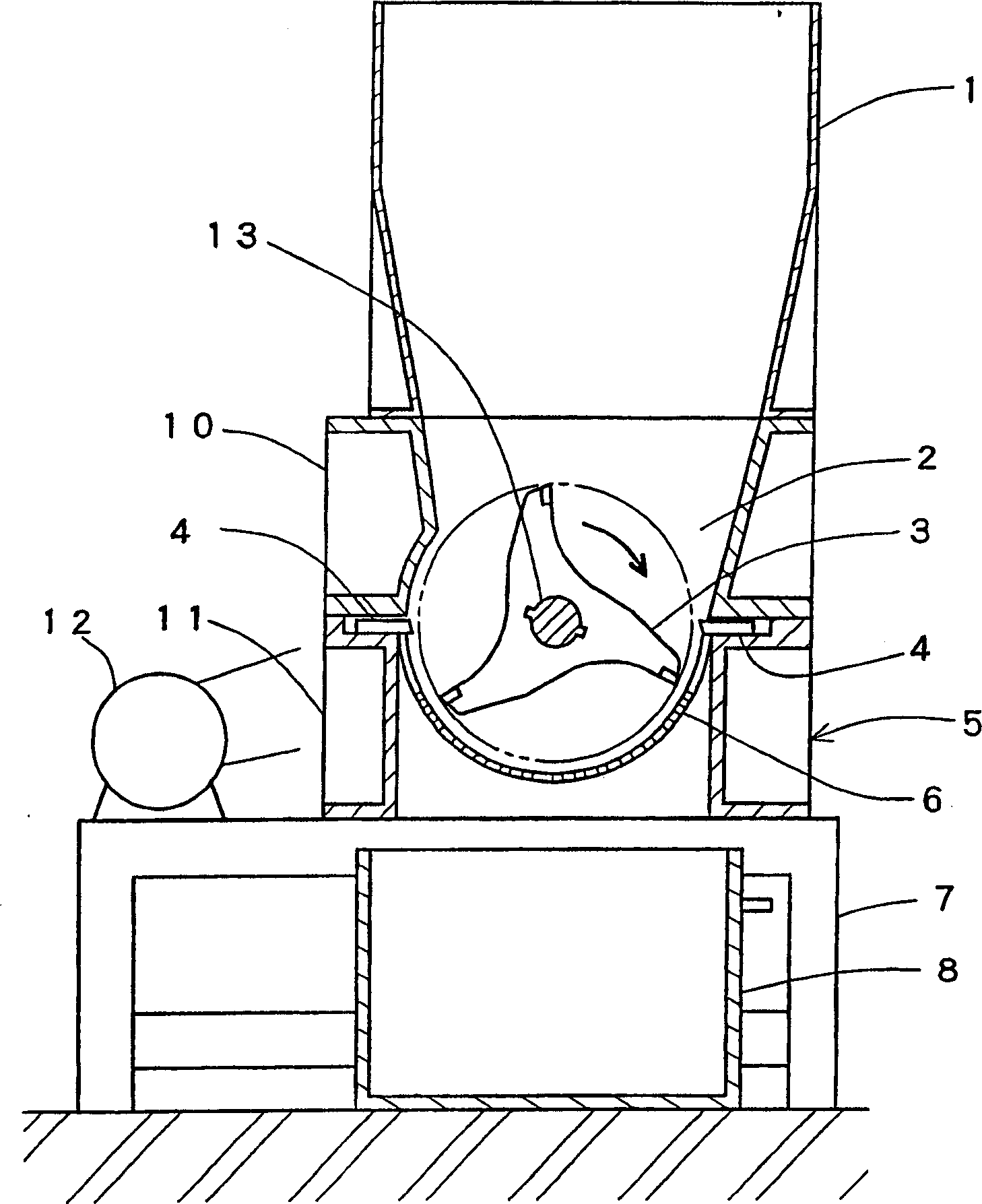

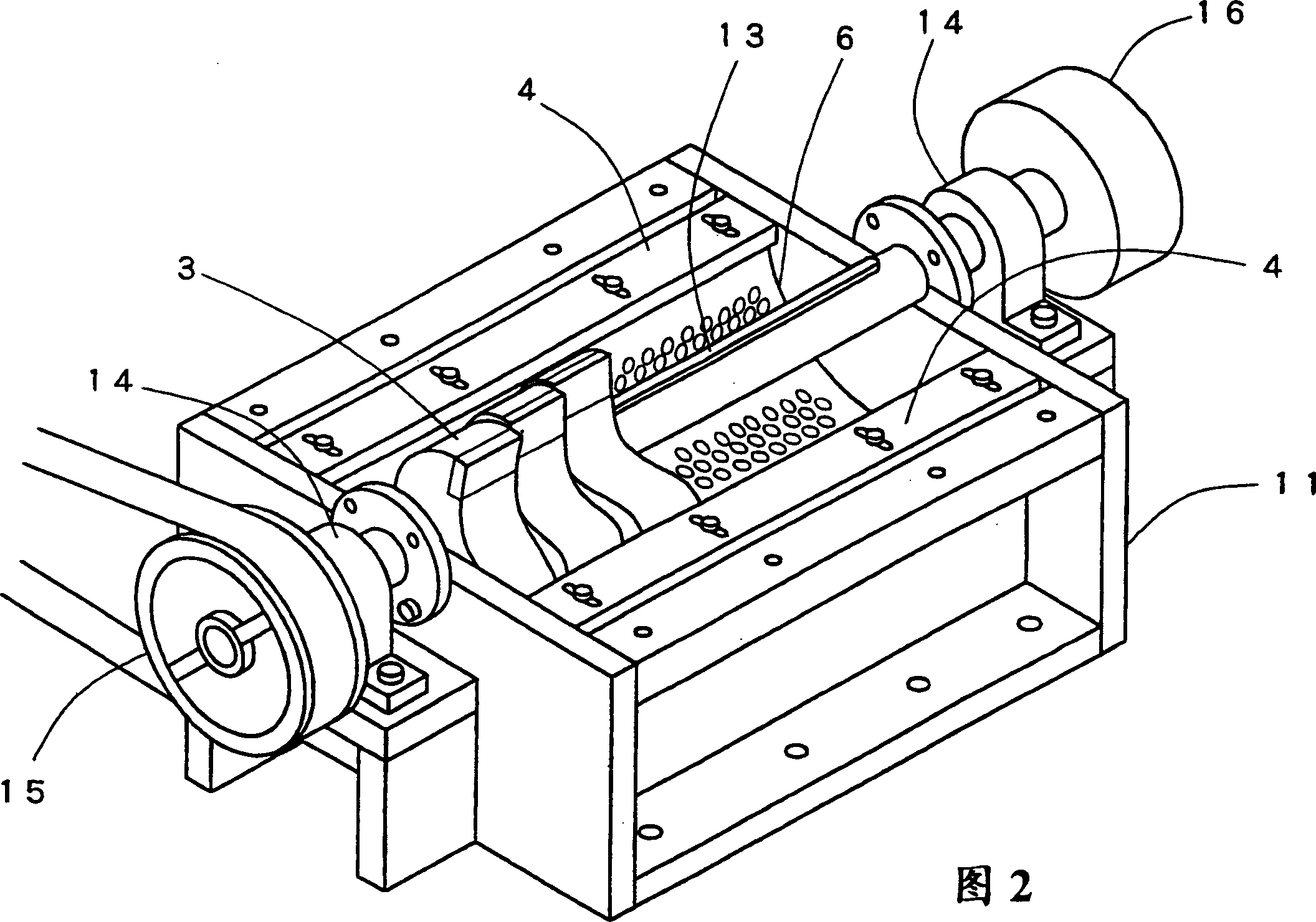

[0032] The crushing device for waste tires according to the present invention will now be specifically described with reference to the accompanying drawings.

[0033] figure 1 1 is a sectional view of the pulverizing device, and FIG. 2 is a perspective view of the main parts of the pulverizing device. This crushing device is composed of a hopper 1 for throwing waste tire chips, a main body 5 with a rotary knife 3 for stirring and crushing the tire chips in a box 2 communicated with the outlet of the hopper, and a base 7 for placing them. .

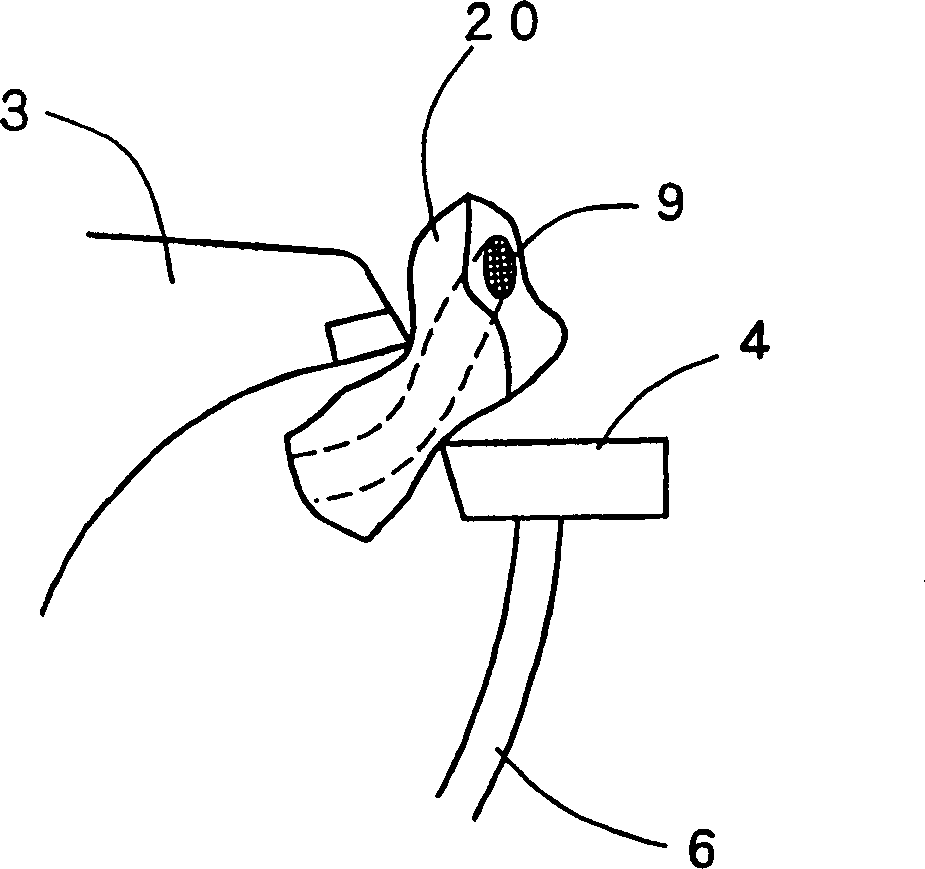

[0034] The rotary cutter 3 is a tool in which a plurality of superhard cutting bits are brazed at three positions at the vertices of a substantially triangular thick plate-shaped tool holder, through a main shaft 13 with pins embedded therein, and adjacent blades The state of slightly shifted phase is fixed and constituted. The reason why the rotating knife is separated in this way is to distribute the resistance applied to the blade. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com