Method for continuously preparing 1,5-naphthalene diisocyanate

A technology of carbonate and diaminonaphthalene, which is applied in the field of continuous preparation of 1,5-naphthalene diisocyanate, can solve the problems of small production capacity of a single reactor, unstable product quality, and low utilization rate of equipment, and achieve improved production operations The environment, production capacity is easy to enlarge, and the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

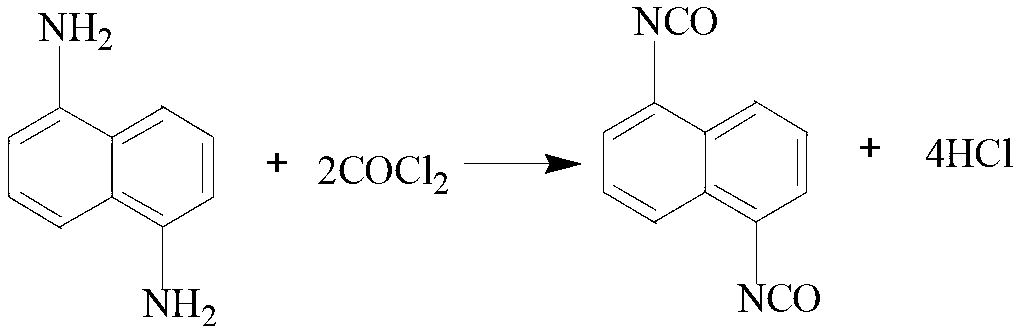

Image

Examples

Embodiment 1

[0022] The chlorobenzene solution of 1,5-diaminonaphthalene with a concentration of 3g / 100mL and the chlorobenzene solution of 20g / 100mL bis(trichloromethyl)carbonate, according to the concentration of bis(trichloromethyl)carbonate and 1,5 - The molar ratio of diaminonaphthalene is 1.5:1. After mixing in a Venturi mixer, it enters a tubular reactor for 0.1 minutes. After the reaction temperature rises to 70°C, it enters a series of 6-stage stirred tank reactors. Combined reactor reaction, the temperature of the first-stage stirred tank reactor is controlled at 70 °C, the temperature of the next-stage stirred tank reactor is increased by 10 °C, and the temperature of the last-stage stirred tank reactor is controlled at 130 °C ℃ reaction, the total residence time of the reactor is controlled to be 6 hours, after the material is completely reacted, it is filtered, and the filtrate is concentrated and crystallized to obtain 99.1% of 1,5-naphthalene diisocyanate; the yield of 1,5-na...

Embodiment 2

[0024] Dimethyl carbonate solution of 1,5-diaminonaphthalene with a concentration of 10g / 100mL and dimethyl carbonate solution of bis(trichloromethyl)carbonate at a concentration of 5g / 100mL, according to bis(trichloromethyl)carbonate The molar ratio with 1,5-diaminonaphthalene is 2:1. After mixing at the inlet of the pipeline pump, it enters a tubular reactor for reaction for 5 minutes. After the reaction temperature rises to 90°C, it enters a stirred tank type reactor consisting of 3 stages in series. For reactor reaction, the temperature of the first-stage stirred tank reactor is controlled at 90°C, the temperature of the second-stage stirred tank reactor is controlled at 105°C, and the temperature of the third-stage stirred tank reactor is controlled at 130°C. The total residence time of the reactor is controlled to be 8 hours. After the material is completely reacted, it is filtered, and the filtrate is concentrated and crystallized to obtain 98.1% of 1,5-naphthalene diiso...

Embodiment 3

[0026] The chlorobenzene solution of 1,5-diaminonaphthalene with a concentration of 6g / 100mL and the chlorobenzene solution of 20g / 100mL bis(trichloromethyl)carbonate, according to the concentration of bis(trichloromethyl)carbonate and 1,5 - The molar ratio of diaminonaphthalene is 1.5:1. After mixing in a static mixer, it enters a tubular reactor for 1.5 minutes. After the reaction temperature rises to 70°C, it enters a combination of 6-stage stirred tank reactors in series. Reactor reaction, the temperature of the first stirred tank reactor is controlled at 70°C, the temperature of the next stirred tank reactor is increased by 10°C, and the temperature of the last stirred tank reactor is controlled at 130°C For the reaction, the total residence time of the reactor is controlled to be 5 hours. After the material is completely reacted, it is filtered, and the filtrate is concentrated and crystallized to obtain 99.3% of 1,5-naphthalene diisocyanate, and the yield of 1,5-naphthal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com