Suspended steel tube externally sprayed plastic powder recovery integrated spraying production line

A hanging, production line technology, applied in spray booths, spray devices, etc., can solve problems such as damage to workers and the environment, toxic fumes, excessive fumes, etc., to achieve a clean and tidy environment, save raw materials, and improve the production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot sequentially limit the protection scope of the present invention.

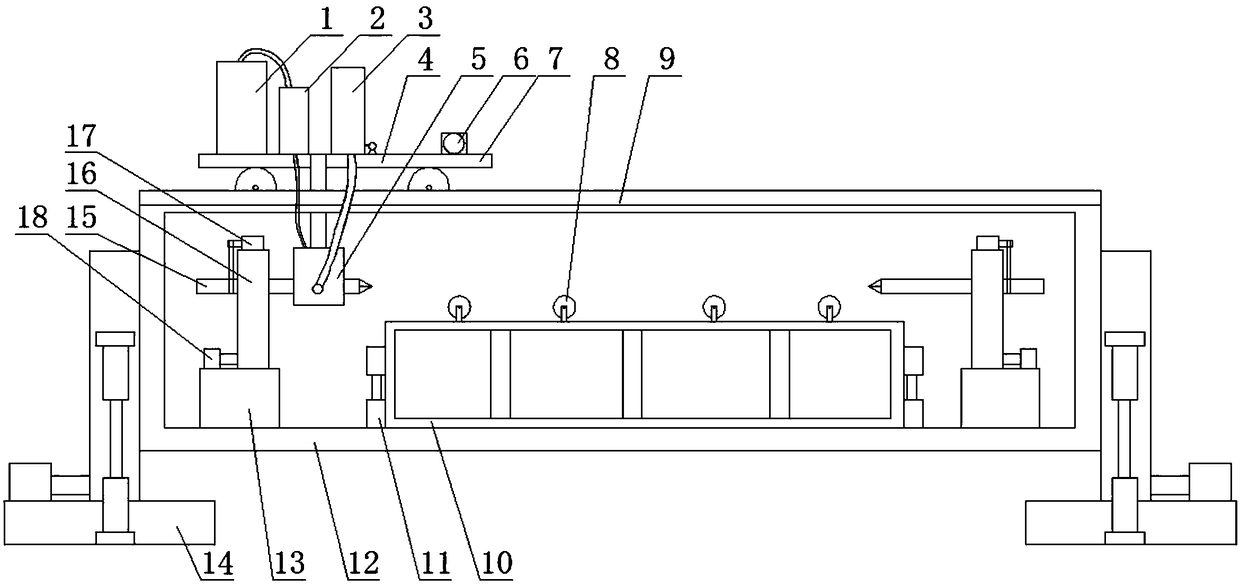

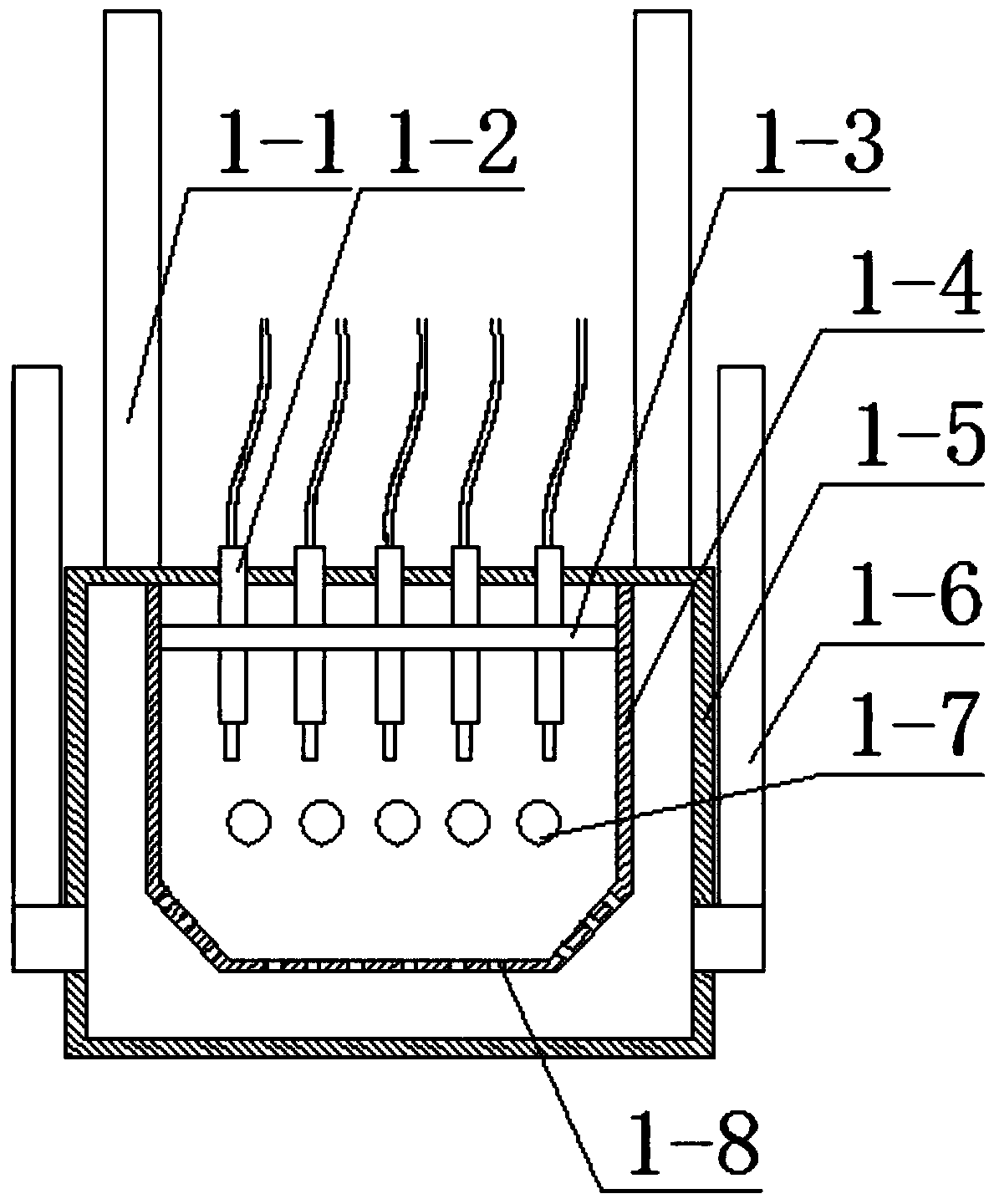

[0021] A suspended steel pipe external plastic coating powder recovery integrated spraying production line, including a base 14, a frame 12, a powder coating mobile box 5, a powder coating mobile box moving device, a steel pipe conduction frame and a steel pipe support frame. The steel pipe coming out of the preheating furnace moves to the steel pipe support frame, which supports the steel pipe from both ends and rotates at the same time. The powder coating moving box moving device passes the powder coating moving box through the outer surface of the steel pipe to spray the outer surface of the steel pipe. The specific structure is as follows:

[0022] The frame is installed on the base,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com