Preparation method of medium element water-soluble fertilizer liquid product containing calcium nitrate

A medium element and liquid product technology, which is applied in the field of preparation of medium element water-soluble fertilizer liquid products containing calcium nitrate, can solve problems affecting crops' absorption of calcium, lack of targeted supplementation of medium elements and trace elements, Unbalanced nutrient supply and other problems to achieve the effect of improving the production and operating environment, alleviating scaling problems, and eliminating NOx exhaust gas pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

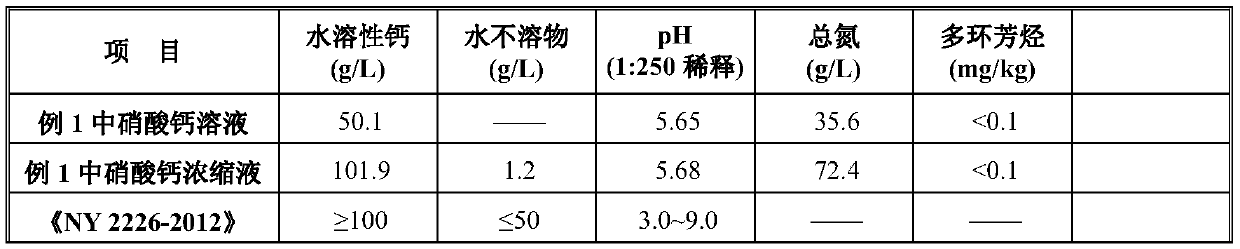

Embodiment 1

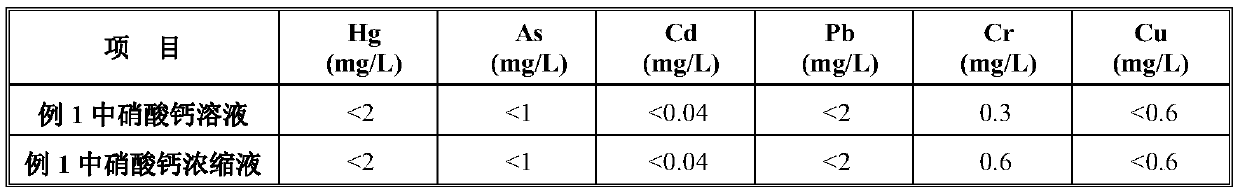

[0022] First, take a 3-liter three-neck flask, add 200 ml of water as a base, and insert the pH meter below the liquid level; then, use a 1-liter measuring cylinder to hold 1.0 liter each of tin stripping waste nitric acid a and 25% milk of lime, and pass through two A peristaltic pump and a hose connect the tin stripping waste nitric acid a and milk of lime to the flask respectively. Turn on the stirring, then turn on the peristaltic pump, inject tin stripping waste nitric acid a and milk of lime into clear water at the same time for neutralization and precipitation reaction; fix the flow rate of tin stripping waste nitric acid a to 25 ml / min, adjust the flow rate of milk of lime to ensure the reaction solution The pH value is between 5 and 7. When 1 liter of tin stripping waste nitric acid a has been added, stop adding milk of lime, but continue to stir.

[0023] Then, get 20ml of the reaction slurry obtained through the above-mentioned treatment, filter with filter paper, ...

Embodiment 2

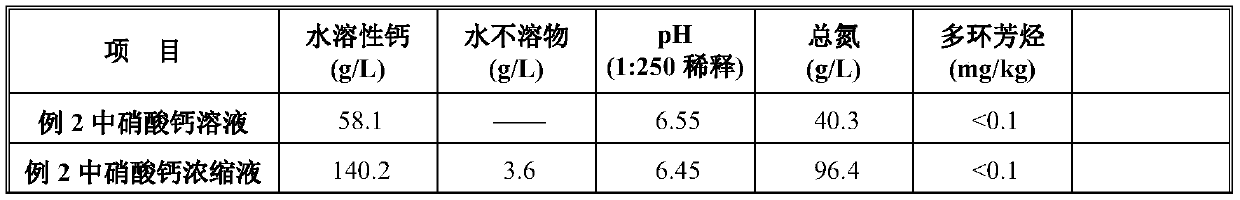

[0030] First, tap water 0.5m 3 Added to a volume of 5m 3 Reactor I, open the industrial online pH meter and stirring paddle respectively, and then start the waste tin stripping nitric acid b and 25% milk of lime feed pump, inject the waste tin stripping nitric acid b and milk of lime into the reactor I at the same time for neutralization Precipitation reaction; the flow rate of fixed tin stripping waste nitric acid b is 1m 3 / hour, adjust the lime milk flow rate to ensure that the pH value of the reaction solution is between 5 and 7; when 2m 3After the feeding of tin stripping waste nitric acid b is completed, close the tin stripping waste nitric acid and lime milk feed pump, but continue to stir.

[0031] Then, get reaction slurry 20ml, filter with filter paper, add 0.1ml heavy metal trapping agent with dropper in filtrate, be 20% sodium dimethyl dithiocarbamate solution DTC-20 in the present embodiment, have black precipitation to generate then filter mud and filtrate ar...

Embodiment 3

[0038] First, take a 3-liter three-necked flask, add 200 ml of clear water as a base, and insert the pH meter below the liquid surface; then, use a 1-liter measuring cylinder to hold 1.0 liters of copper-removing waste nitric acid c and 25% milk of lime respectively, and pass through two A peristaltic pump and a hose respectively connect waste nitric acid c and milk of lime to the flask. Turn on the stirring, then turn on the peristaltic pump, inject copper stripping waste nitric acid c and milk of lime into clear water simultaneously and carry out neutralization and precipitation reaction; fix the flow rate of copper stripping waste nitric acid c at 25 ml / min, adjust the lime milk flow rate to ensure the reaction solution The pH value is between 5 and 7. When 1 liter of copper-removing waste nitric acid A has been added, stop adding milk of lime, but continue to stir.

[0039] Then, get reaction slurry 20ml, filter with filter paper, add 0.1ml heavy metal trapping agent in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com