Movable slag hot-stew dust removal device and method

A dust removal device and a mobile technology, applied in the field of mobile steel slag hot and stuffy dust removal devices, can solve the problems of insignificant dust removal effect, high processing cost, low dust removal power, etc. Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

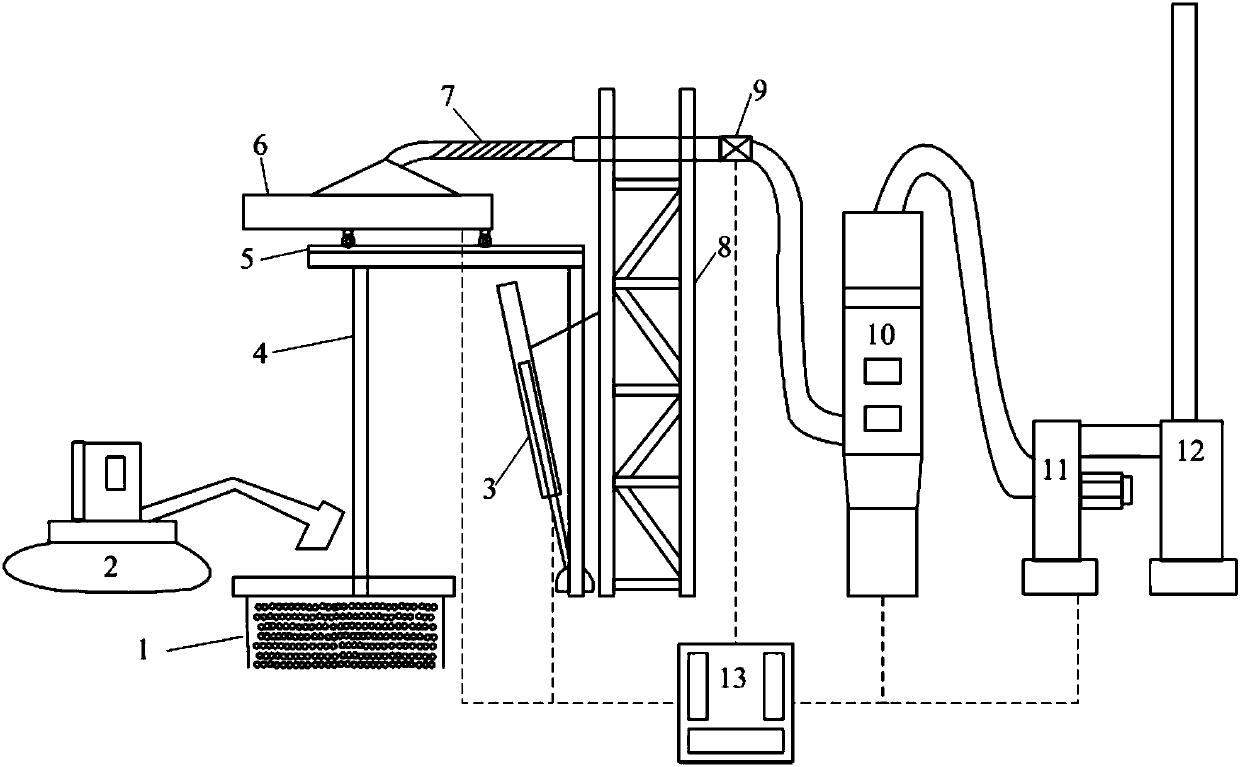

[0027] Such as figure 1 As shown, a mobile steel slag hot stuffiness dust removal device includes: hot stuffing pool 1, slag raking machine 2, rotating cover 3, dust removal cover bracket 4, moving track 5, moving cover car 6, telescopic pipe 7, and pipe support 8. Solenoid valve 9, wet cyclone 10, fan 11, chimney 12, PLC control system 13; slag raking machine 2 performs slagging or slagging operation on the side of hot pool 1; rotating cover 3 is in the process of hot stuffing Cover the hot stuffy pool 1, and rotate to the pipe support 8 during the dust removal process; the dust hood bracket 4 is used to support the mobile cover car 6 directly above the hot stuffy pool 1; the moving track 5 is above the dust hood bracket 4, moving The cover car 6 is above the moving track 5; the pipe bracket 8 is used to support the exhaust pipes such as the telescopic pipe 7; the hot and stuffy flue gas passes through the mobile cover car 6, the telescopic pipe 7, the solenoid valve 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com