Method for preparing electrodeposited cobalt under large flow

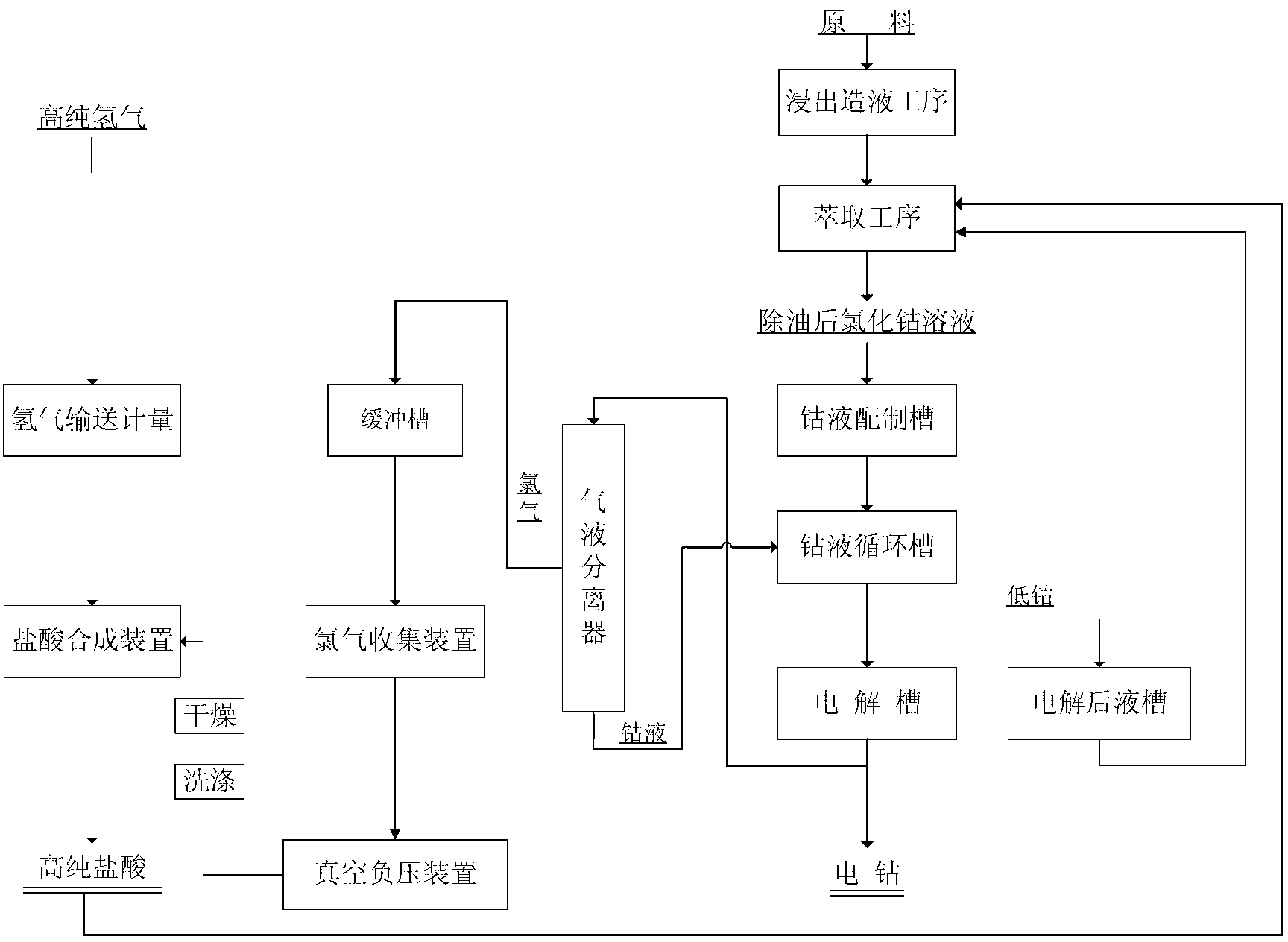

A high-flow, electrowinning technology, applied in the fields of instruments, optics, photographic technology, etc., can solve the problem that the purity of electrowinning cobalt or the recovery rate is difficult to meet the requirements, the secondary pollution of the liquid treatment process after the electrowinning, and the quality of the electrowinning cobalt product is difficult to guarantee. and other problems, to achieve the effect of improving the production and operating environment, benefiting physical and mental health, and shortening the electrolysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Cobalt chloride solution obtained by hydrometallurgy (Co 2+ :95g / l Cu 2+ :0.0051g / l Fe 2+ :2+ :2+ :2+ :2+ :2+ :0.0018g / l Al 2+ :2+ : 0.0020g / l Mn 2+ : 3 / h m 2 Pump the electrolysis solution into the electrolytic cell, and use a vacuum negative pressure device to maintain a negative pressure of 0.03~0.05MPa inside the system. When the negative pressure in the tank is stable, turn on the power supply and maintain 800A / m 2current density for electrowinning. In the process of electrowinning, the temperature is 30~50℃, and the cell voltage is 2.4~2.8V. During the electrolysis process, the chlorine gas generated by the anode and the liquid after the electrowinning enter the gas-liquid separator together, and the gas is separated through the gas-liquid separator. Liquid separation, the dechlorinated cobalt liquid is returned to the cobalt liquid circulation tank as the pre-electrodeposition liquid, and the obtained vacuum-removed chlorine gas is washed with pure water, d...

Embodiment 2

[0040] Cobalt chloride solution (Co 2+ :100g / l Cu 2+ :2+ :2+ :2+ :0.0008g / l Pb 2+ :2+ : 0.0059g / l Mg 2+ :0.0018g / l Ca 2+ : 0.0016g / l Mn 2+ : 0.00058g / l oil: 4.72 ph=2.3) as the pre-electrodeposition solution, electro-deposit in a closed electrolytic cell. Control flow rate 10~14m 3 / h m 2 Pump the electrolytic solution into the electrolytic cell, and use a vacuum negative pressure device to maintain a negative pressure of 0.06~0.08MPa inside the system and maintain a negative pressure of 800A / m 2 current density for electrowinning. In the process of electrowinning, the temperature is 30~50℃, and the cell voltage is 2.4~2.8V. During the electrolysis process, the chlorine gas generated by the anode and the liquid after the electrowinning enter the gas-liquid separator together, and the gas is separated through the gas-liquid separator. Liquid separation, the dechlorinated cobalt liquid is returned to the cobalt liquid circulation tank as the pre-electrodeposition liquid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com