Method for pre-de-magnesium enriched lithium from salt lake bittern with high-magnesium-lithium ratio with dry method de-magnesium

A high magnesium-lithium ratio, salt lake brine technology, applied in the direction of magnesium chloride, magnesium halide, alkali metal chloride, etc., can solve the problems of incomplete separation of magnesium, low energy consumption of precipitation method, high separation efficiency, etc., to improve roasting conditions and process Concise, streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

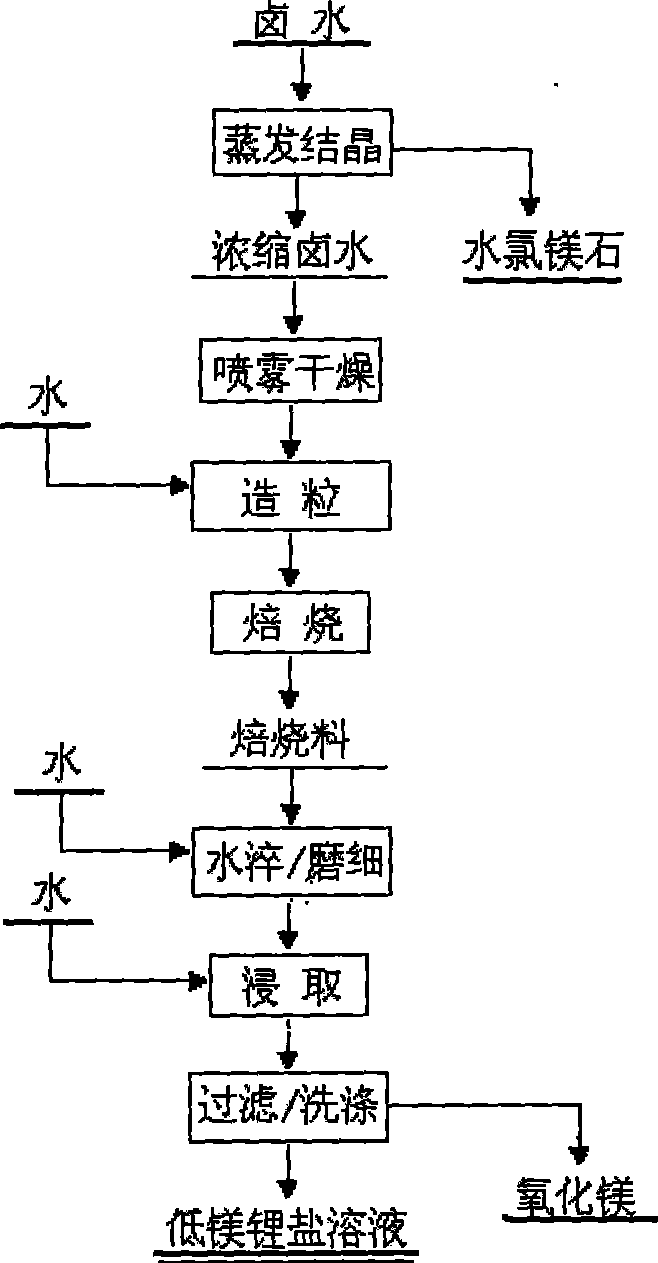

Method used

Image

Examples

Embodiment 1

[0039] A. Concentration of brine: Evaporate and dehydrate beach-dried salt lake brine with a mass ratio of magnesium to lithium of 21, and remove 10.4% of the total liquid volume; crystallize magnesium chloride hexahydrate, filter; after crystallization, the content of lithium and magnesium in the concentrated solution is: lithium 8.5g / L; Magnesium 99.3g / L.

[0040] B. Spray drying: The concentrated brine is spray-dried at 450-480°C, the water in the brine evaporates rapidly, chloride crystallizes, and dehydration and hydrolysis of magnesium chloride crystals occur simultaneously.

[0041] C. Granulation: Spray water on the dry powder according to 20-22% of the dry material to make 8-10mm granules; place it at room temperature for natural crystallization and strengthening.

[0042] D. Roasting: Put the crystallized pellets into the furnace for roasting, the roasting temperature is 760-780°C, and the roasting time is 60 minutes; the magnesium chloride is hydrolyzed at high tem...

Embodiment 2

[0046] A. Concentration of brine: Evaporate and dehydrate beach-dried salt lake brine with a mass ratio of magnesium to lithium of 21, and remove 11.3% of the total liquid volume; crystallize magnesium chloride hexahydrate, filter; after crystallization, the content of lithium and magnesium in the concentrated solution is: lithium 9.7g / L; Magnesium 99.6g / L.

[0047] B. Spray drying: The concentrated brine is spray-dried at 560-580°C, the water in the brine evaporates rapidly, the chloride crystallizes, and the dehydration and hydrolysis of magnesium chloride crystals occur simultaneously.

[0048] C. Granulation: according to the amount of dry material 14-16%, spray water on the dry powder to make 12-14mm granules; place it at room temperature for natural crystallization and strengthening.

[0049] D. Roasting: Put the crystallized pellets into the furnace for roasting, the roasting temperature is 680-700°C, and the roasting time is 100 minutes; the magnesium chloride is hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com