Winding machine base for winding of dry-type transformer high-voltage coil

A dry-type transformer and high-voltage coil technology, which is used in inductor/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve problems such as hidden safety hazards and troubles, and achieve the effects of improving safety, large area and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

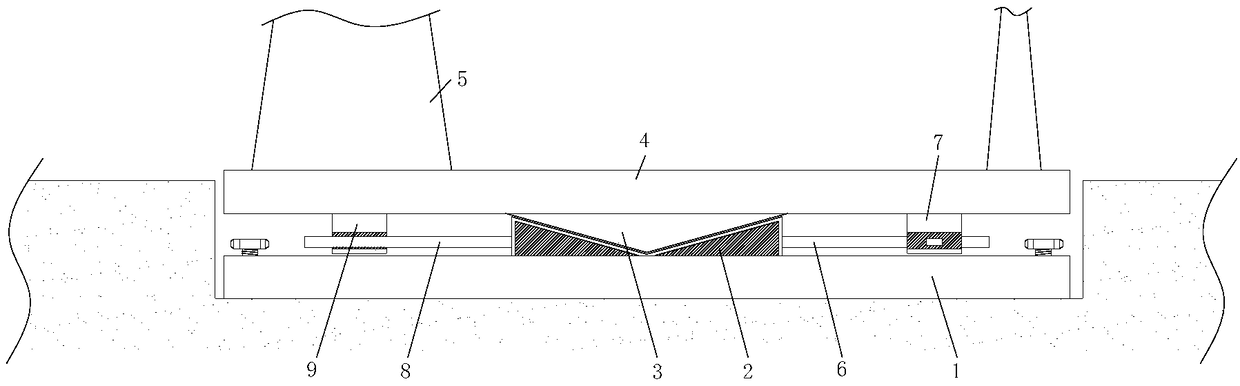

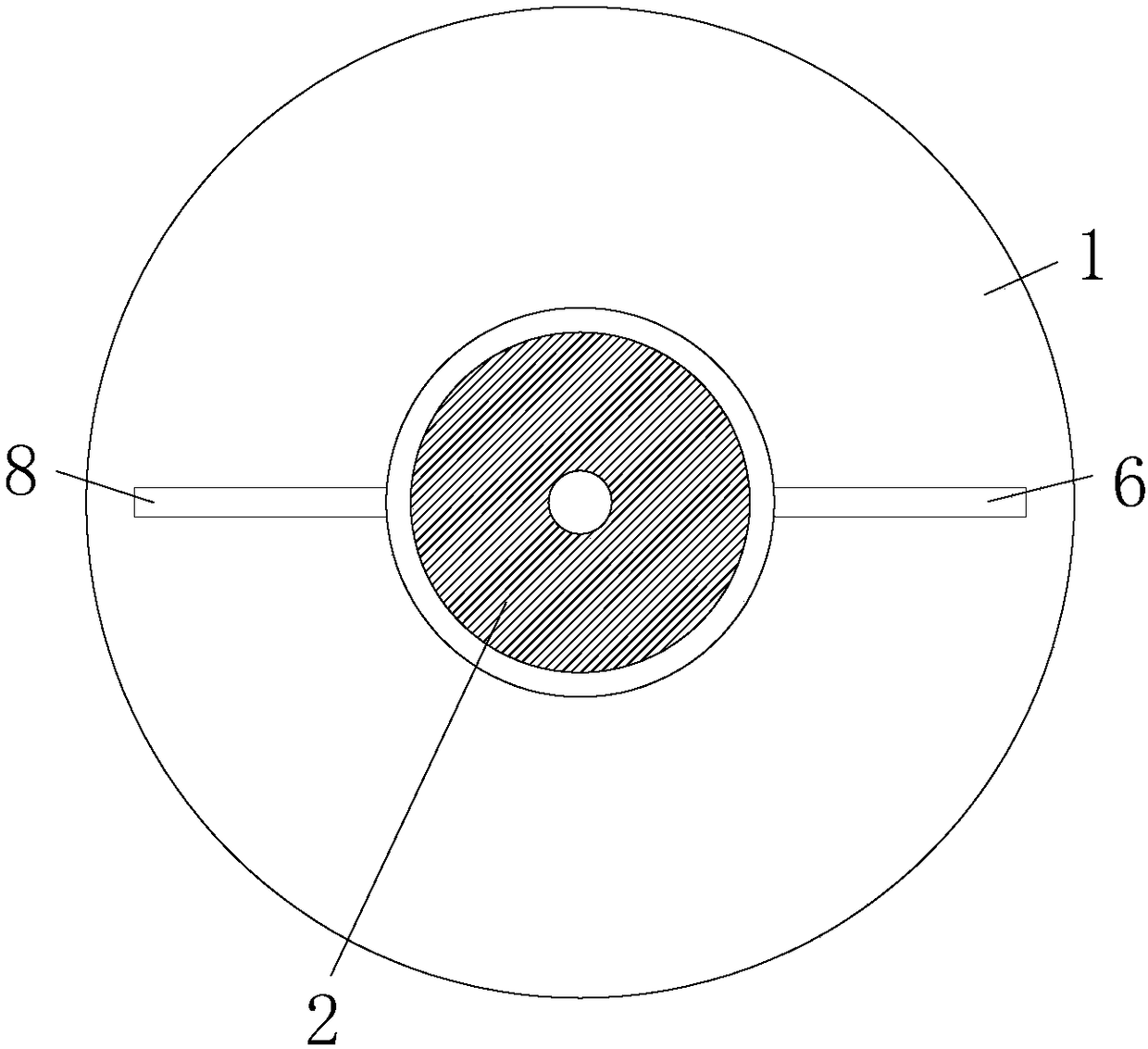

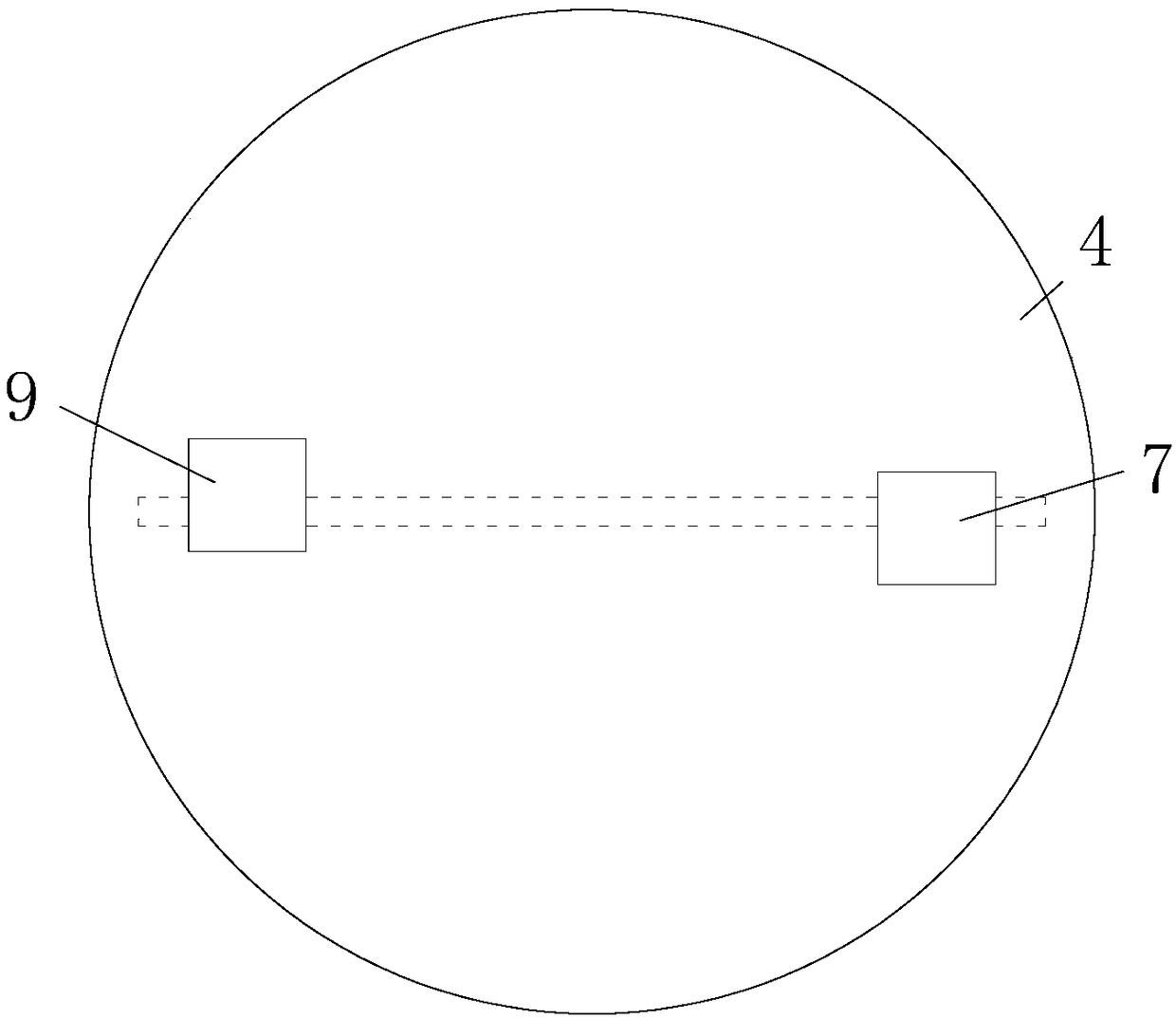

[0030] Such as Figure 1-9As shown, the present invention provides a technical solution: a winding machine base for high-voltage coil winding of a dry-type transformer, including a fixed circular plate 1, which is fixed in a groove opened on the ground, and the fixed circular plate The central position of 1 is vertically connected with a conical rotary positioning seat 2, the inner wall of the conical rotary positioning seat 2 is socketed with the outer surface of the conical positioning rotary block 3, and the top of the conical positioning rotary block 3 is connected to the bottom of the rotating circular plate 4 The center position of the rotating disc 4 is fixedly connected, the top of the rotating disc 4 is fixedly connected with the bottom of the winding machine body 5, and the conical rotating positioning seat 2 fixedly connected at the top of the fixed disc 1 and the cone at the bottom of the rotating disc 4 are fixedly connected. The conical positioning rotary block 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com