Hydraulic mandrel for grinding end surfaces of slender pipe fittings

A technology of end face grinding and slender tubes, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding workpiece planes, and can solve the problem of small contact surface between tooling and parts, unsuitability for mass production, and inconsistency in actual size and other problems, to achieve the effect of consistent processing standards, large clamping force, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

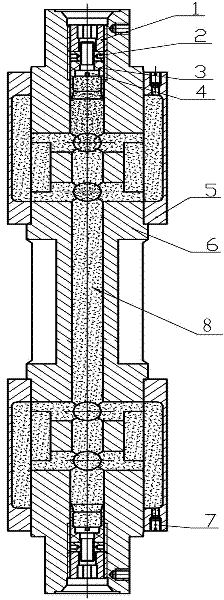

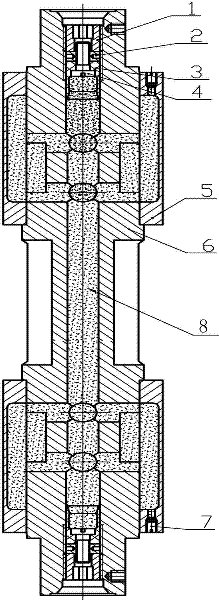

[0017] The structure of the present invention is shown in Figure 1, a hydraulic mandrel for end face grinding of a slender pipe, an elastic sleeve 5 is placed outside the mandrel 6, a semi-solid medium 8 is filled between the elastic sleeve 5 and the mandrel 6, and the elastic sleeve The outer end of 5 is provided with a screw plug 7, the plunger 3 is connected with the nut 2 through the screw 4, and cooperates with the mandrel 6 in a small gap, and the plunger 3 is also equipped with a screw plug 1. The plunger 3 is a thin-walled part made of non-metal wear-resistant material, which expands through extrusion to seal the semi-solid medium 8 in the mandrel 6 . The circle of the elastic sleeve 5 is coaxial with the center hole at the two ends of the mandrel 6 in a free state.

[0018] In the present invention, the semi-solid medium 8 can be selected from industrial butter, lubricating grease and the like.

[0019] The function of the screw plug 1 on the plunger 3 is to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com