Full-scale testing method for pressure bearing capacity and ductile-brittle transition behaviors of gas transmission steel pipe at low temperature

A technology of ductile-brittle transition and pressure-bearing capacity, applied in the field of structural integrity test of gas pipelines, it can solve problems such as accurate judgment, loss, and inability to quantitatively analyze components, and achieve the effect of maintaining constant temperature, easy operation, and large capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

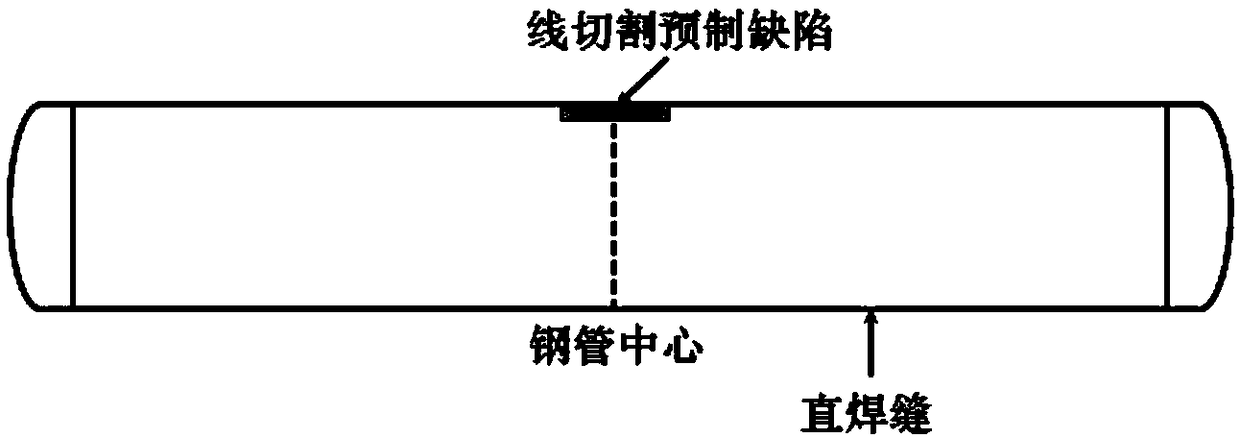

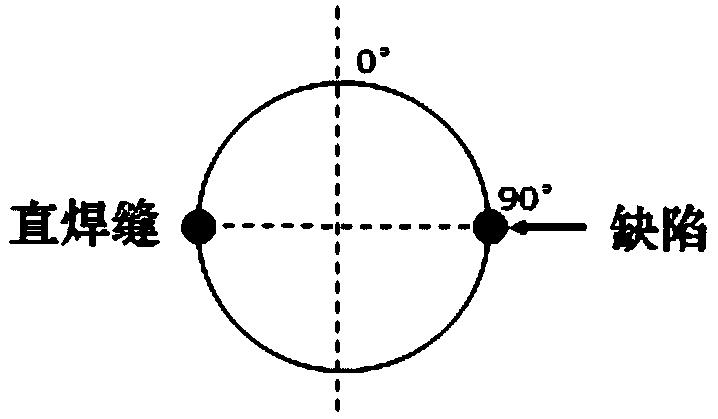

[0087] In October 2015, the Management Research Institute conducted three low-temperature blasting tests at the full-scale blasting test site in Hami. The steel grade of the test steel pipe is X80, the outer diameter of the steel pipe is 1422mm, the length is 12m, and the wall thickness is 21.4mm.

[0088] The failure pressure and ductile-brittle transition temperature of the steel pipe at a specific temperature were determined through the full-scale blasting test of a single pipe at a series of temperatures (-50°C, -40°C, -30°C, -20°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com