Bottle clamp mechanism

A bottle clamp and cylinder technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of low manufacturing precision, unsmooth movement, difficult adjustment of bottle clamp opening, etc., and achieve smooth surface, stable operation, easy disinfection and The effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

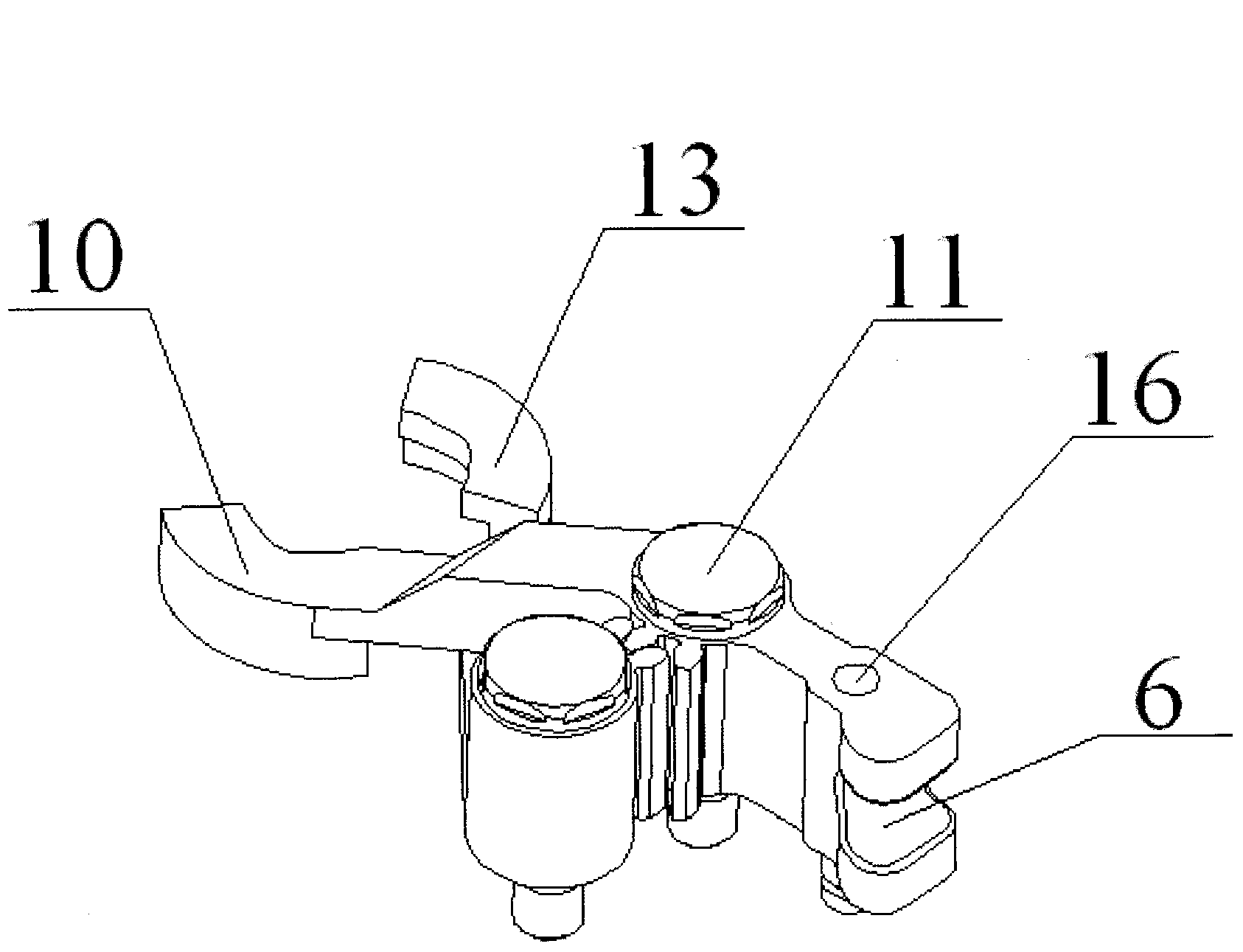

[0016] The present invention is a kind of bottle clip mechanism, such as figure 1 As shown, it is a schematic structural view of the bottle clamp. The bottle clamp rotating pin 11 is installed in the main bottle clamp 10 and the auxiliary bottle clamp 13 to form a bottle clamp. The main bottle clamp 10 and the auxiliary bottle clamp 13 are engaged with each other through their own teeth, and can rotate around the bottle clamp rotating pin 11 at the same time. The tail of the main bottle clamp 10 has a U-shaped groove 6 .

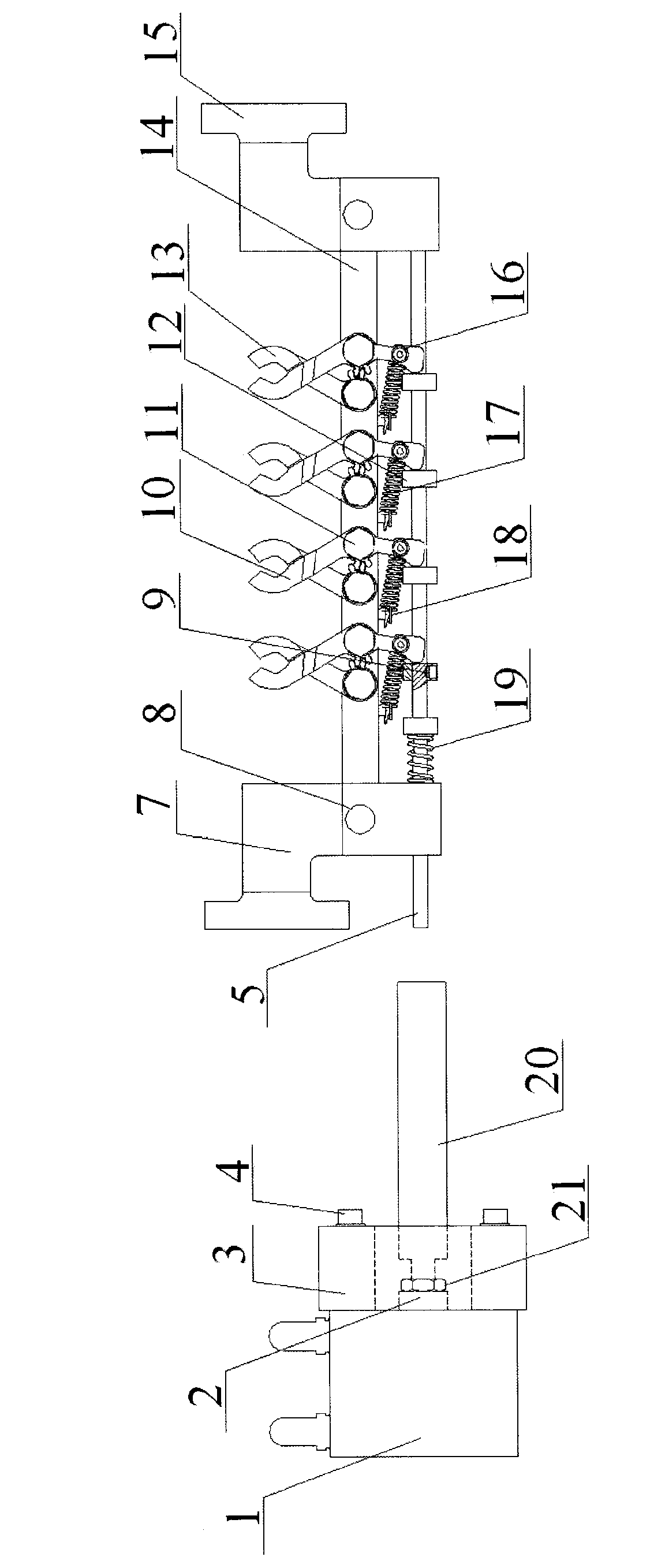

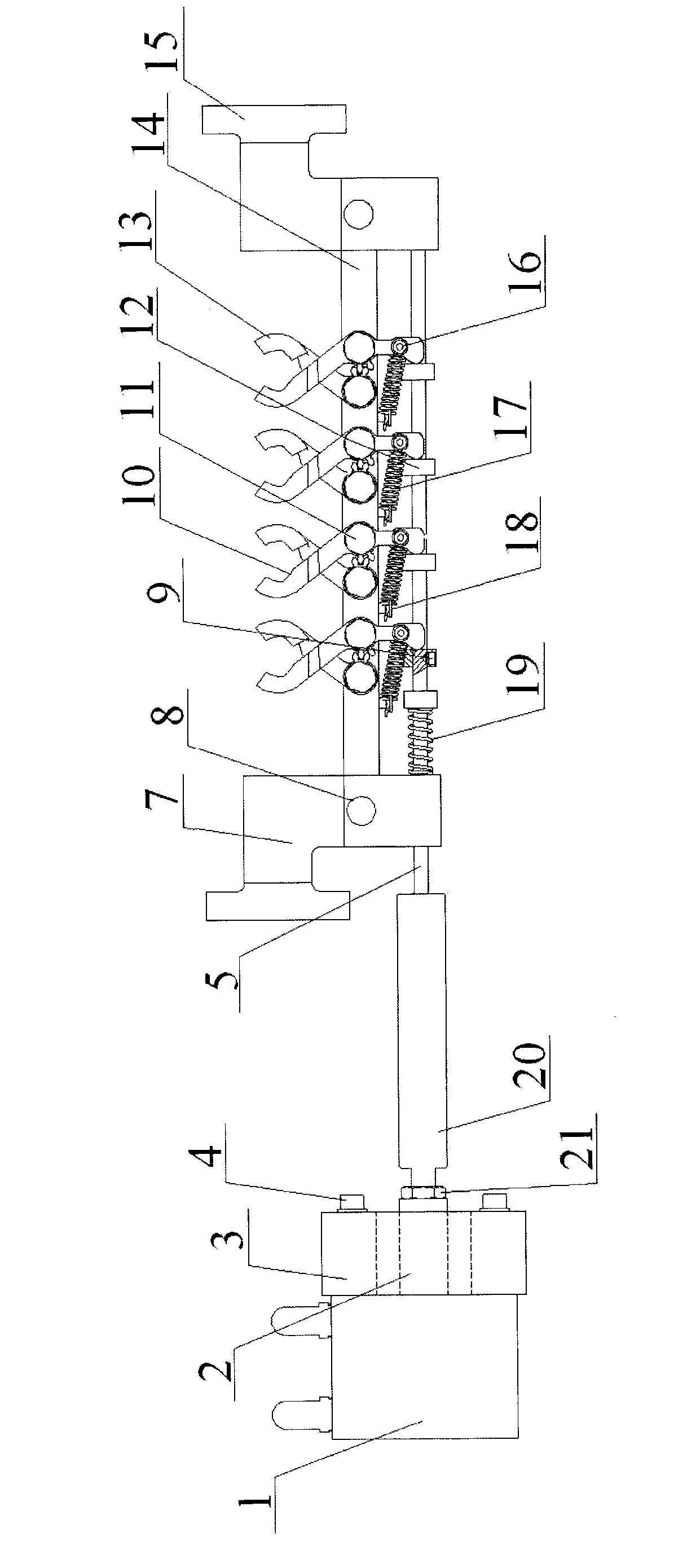

[0017] Such as Figure 2-Figure 4 As shown, the cylinder 1 is installed on the cylinder fixing seat 3 through the cylinder fixing bolt 4, and the cylinder fixing seat 3 is fixed. There is an internal thread hole on the cylinder piston rod 2 of the cylinder 1, and the internal thread hole is connected with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com