Microbubble workover fluid and preparation method thereof

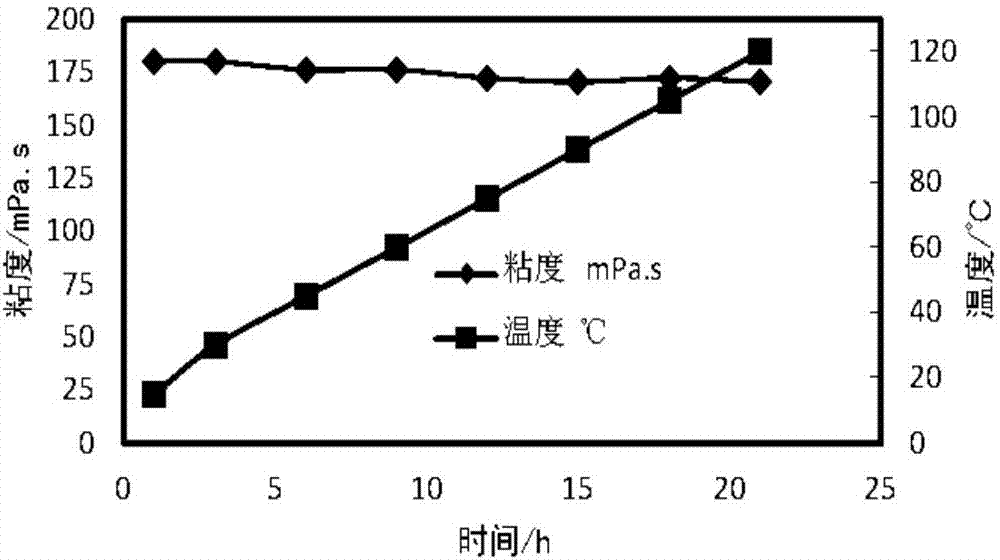

A workover fluid and micro-bubble technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor thermal stability of micro-bubbles, and achieve improved foam stability, foaming ability, and large molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

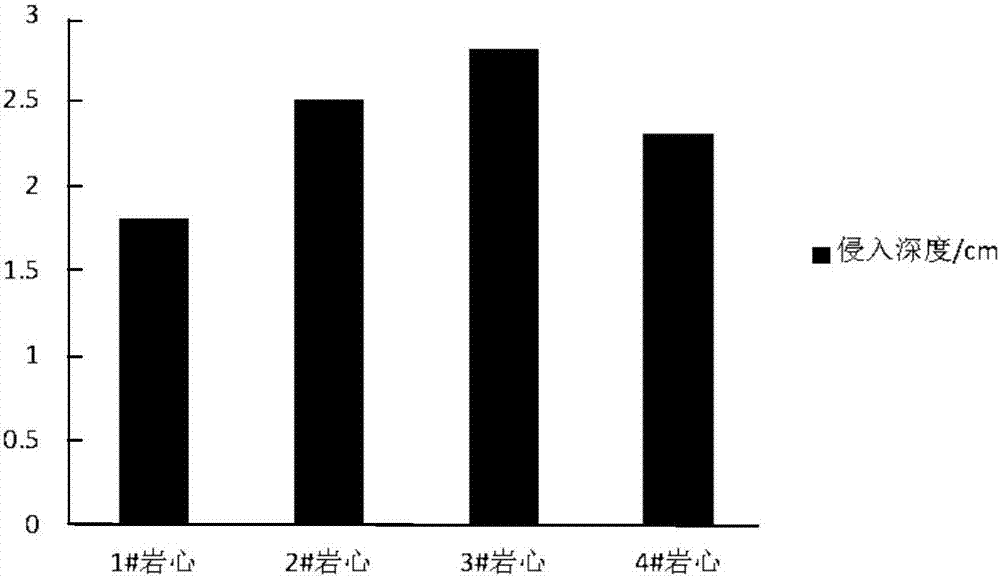

Method used

Image

Examples

Embodiment 1

[0029] Microbubble workover fluid in the present embodiment, by 200g clear water, 0.2g fatty alcohol polyoxyethylene ether AEO 18 , 0.4g Sapinberry extract, 1g xanthan gum, 0.3g thiourea.

[0030] The preparation method of the microbubble workover fluid in the present embodiment is:

[0031] 1) Accurately measure 200 ml of clear water with a graduated cylinder and place it in a 500 ml beaker. Slowly and evenly add 1 g of xanthan gum while stirring, then stir at high speed for 30 minutes at a stirring speed of 3000 r / min. During the stirring process, make xanthan gum Dissolve evenly, fully lift the viscosity, and obtain the mixed solution 1;

[0032] 2) Add 0.4g of Sapindus chinensis extract and 0.2g of fatty alcohol polyoxyethylene ether AEO to the mixed solution 1 obtained in step 1) while stirring 18 , stirred for 10 minutes, the stirring speed was 3000r / min, and mixed evenly to obtain the mixed solution 2;

[0033] 3) Add 0.3 g of thiourea to the mixed solution 2 obtaine...

Embodiment 2

[0035] The microbubble workover fluid in the present embodiment, by 200g clear water, 0.5g fatty alcohol polyoxyethylene ether AEO 18 , 1g Sapinberry extract, 2g xanthan gum, 0.6g thiourea.

[0036] The preparation method of the microbubble workover fluid in the present embodiment is:

[0037] 1) Accurately measure 200ml of water with a measuring cylinder and place it in a 500ml beaker, slowly and evenly add 2g of xanthan gum while stirring, then stir at high speed for 30min at a stirring speed of 3000r / min, during the stirring process, dissolve the xanthan gum Uniform, fully viscous, to obtain the mixed solution 1;

[0038] 2) Add 1g of Sapindus chinensis extract and 0.5g of fatty alcohol polyoxyethylene ether AEO to the mixed solution 1 obtained in step 1) while stirring 18 , stirred for 10 minutes, the stirring speed was 3000r / min, and mixed evenly to obtain the mixed solution 2;

[0039] 3) Add 0.6 g of thiourea to the mixed liquid 2 obtained in step 2) while stirring, ...

Embodiment 3

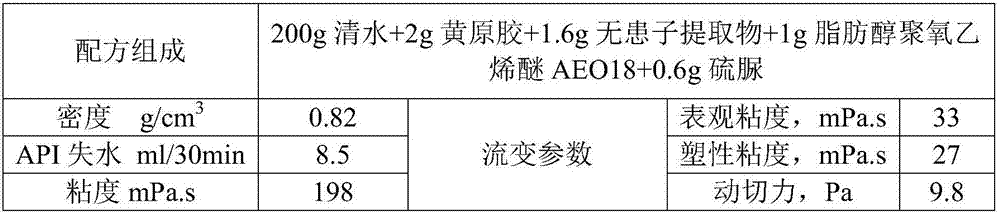

[0041] The microbubble workover fluid in the present embodiment, by 200g clear water, 1g fatty alcohol polyoxyethylene ether AEO 18 , 1.6g Sapinberry extract, 2g xanthan gum, 0.6g thiourea.

[0042] The preparation method of the microbubble workover fluid in the present embodiment is:

[0043]1) Accurately measure 200ml of water with a measuring cylinder and place it in a 500ml beaker, slowly and evenly add 2g of xanthan gum while stirring, then stir at high speed for 30min at a stirring speed of 3000r / min, during the stirring process, dissolve the xanthan gum Uniform, fully viscous, to obtain the mixed solution 1;

[0044] 2) Add 1.6g of Sapindus chinensis extract and 1g of fatty alcohol polyoxyethylene ether AEO to the mixed solution 1 obtained in step 1) while stirring 18 , stirred for 10 minutes, the stirring speed was 3000r / min, and mixed evenly to obtain the mixed solution 2;

[0045] 3) Add 0.6 g of thiourea to the mixed liquid 2 obtained in step 2) while stirring, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com