Filter sealing system

一种过滤器罩、密封件的技术,应用在空气过滤器进行保养领域,能够解决小制造公差、连接、增加成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

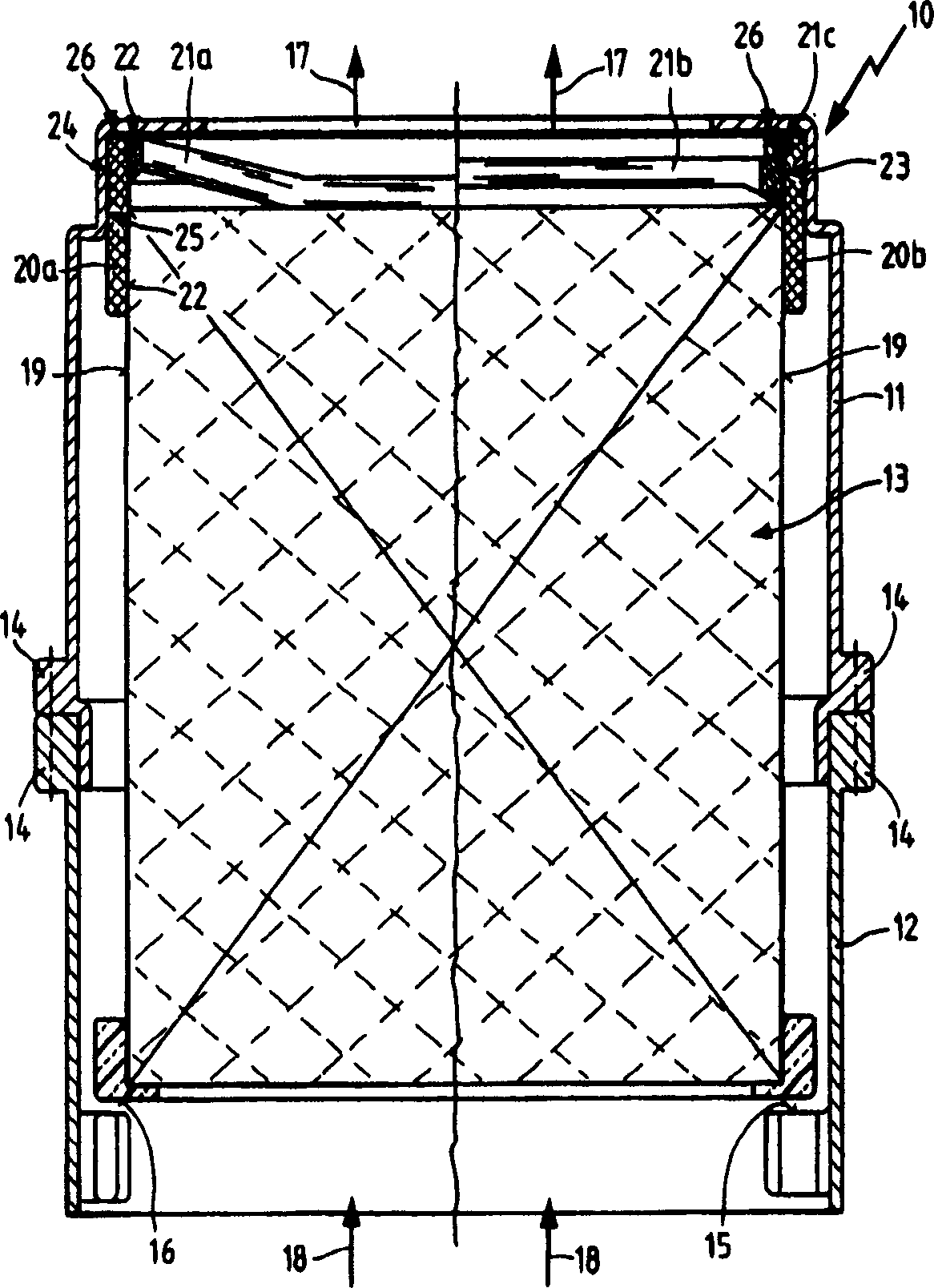

[0017]The single figure shows an air filter 10 having an upper filter housing part 11 and a lower filter housing part 12 with a filter element 13 arranged therein. The filter element 13 is an axially flow-through filter element with mutually closed axially extending channels. As filter medium, paper, synthetic material or a felt is preferably specified here. The upper and lower filter housing parts 11 , 12 are connected to each other by a connecting mechanism 14 . Here, for example, the connection mechanism may be a clip, a screw or other detachable connection methods known in the prior art. In the lower region of the lower filter housing part 12 , the filter housing forms an axial stop 15 which serves to axially support and fix the filter element 13 when the two filter housing parts 11 , 12 are assembled. Correspondingly, on the lower end face of the filter element 13 in the region of the axial stop 15 is formed a preferably circumferential stop damper 16 . The retaining d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com