Cracking prevention semi-hard cable

An anti-cracking and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as system paralysis, component damage, and cracking of tubular outer conductors, and achieve the effect of ensuring concentricity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

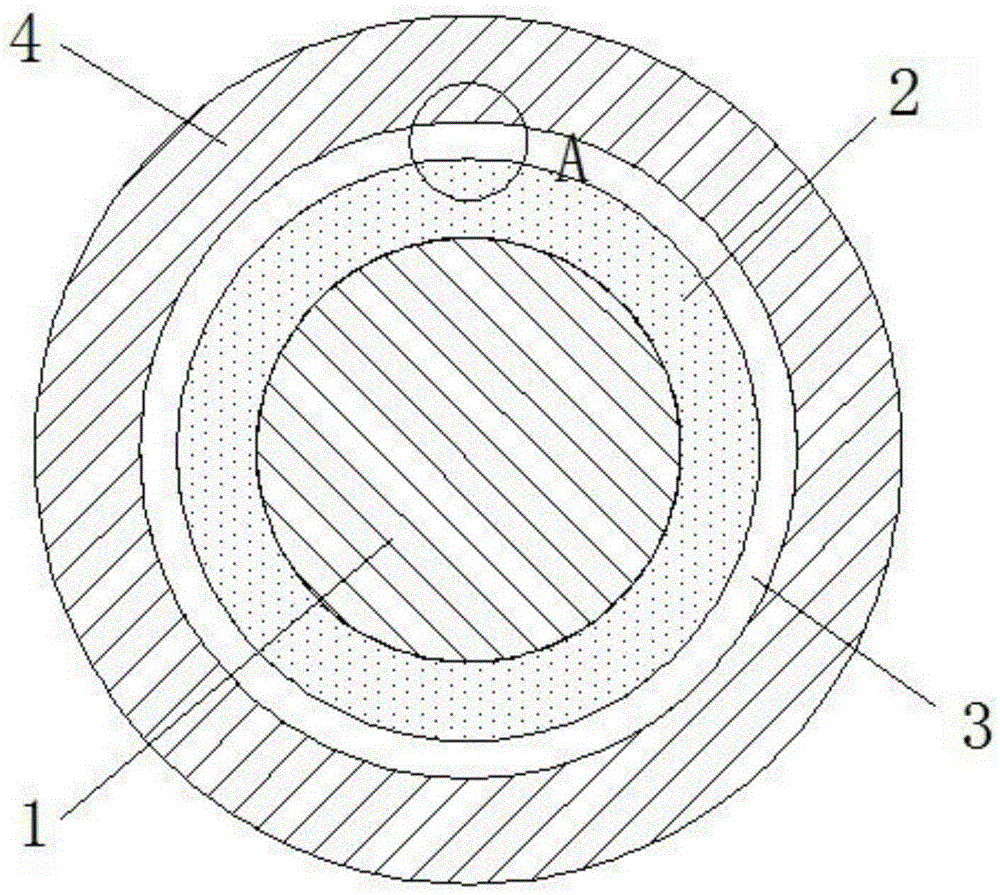

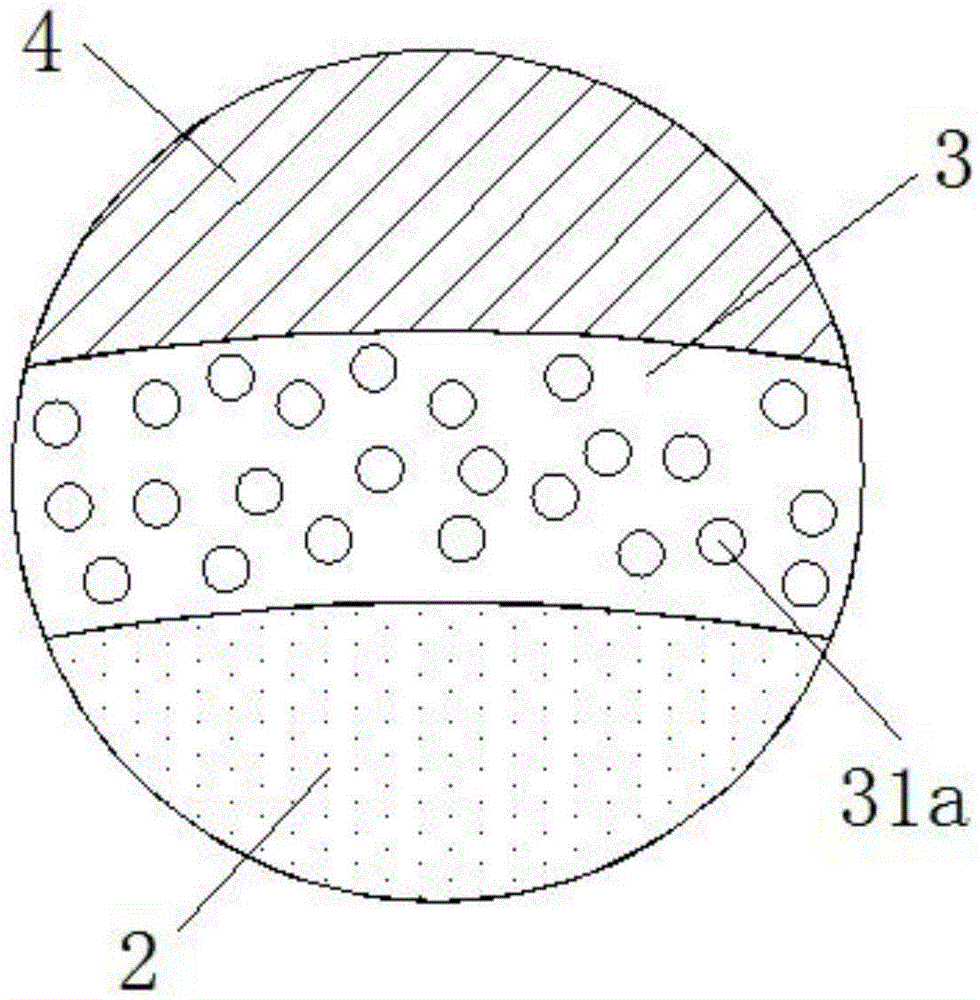

[0031] Such as figure 1 and figure 2 As shown, it includes an inner conductor 1, a dielectric layer 2 wrapped outside the inner conductor 1, and an outer conductor 4 wrapped outside the dielectric layer 2. A buffer layer 3 is also provided between the dielectric layer 2 and the outer conductor 4. The buffer layer 3 consists of It is made of continuous solid material with pores, specifically: the buffer layer 3 is a cylindrical structure with air bubbles 31a dispersed inside, and the thickness of the buffer layer 3 is 0.1-5mm. The dielectric layer 2 and the buffer layer 3 play the role of isolating the inner conductor 1 and the outer conductor 2, and can maintain a certain degree of concentricity between the two to avoid disturbance during power transmission. The dielectric layer 2 is attached to the inner conductor 1, and when the inner conductor 1 heats up, the dielectric layer 2 will expand; but because the buffer layer 3 contains air bubbles 31a, it is compressible, and i...

Embodiment approach 2

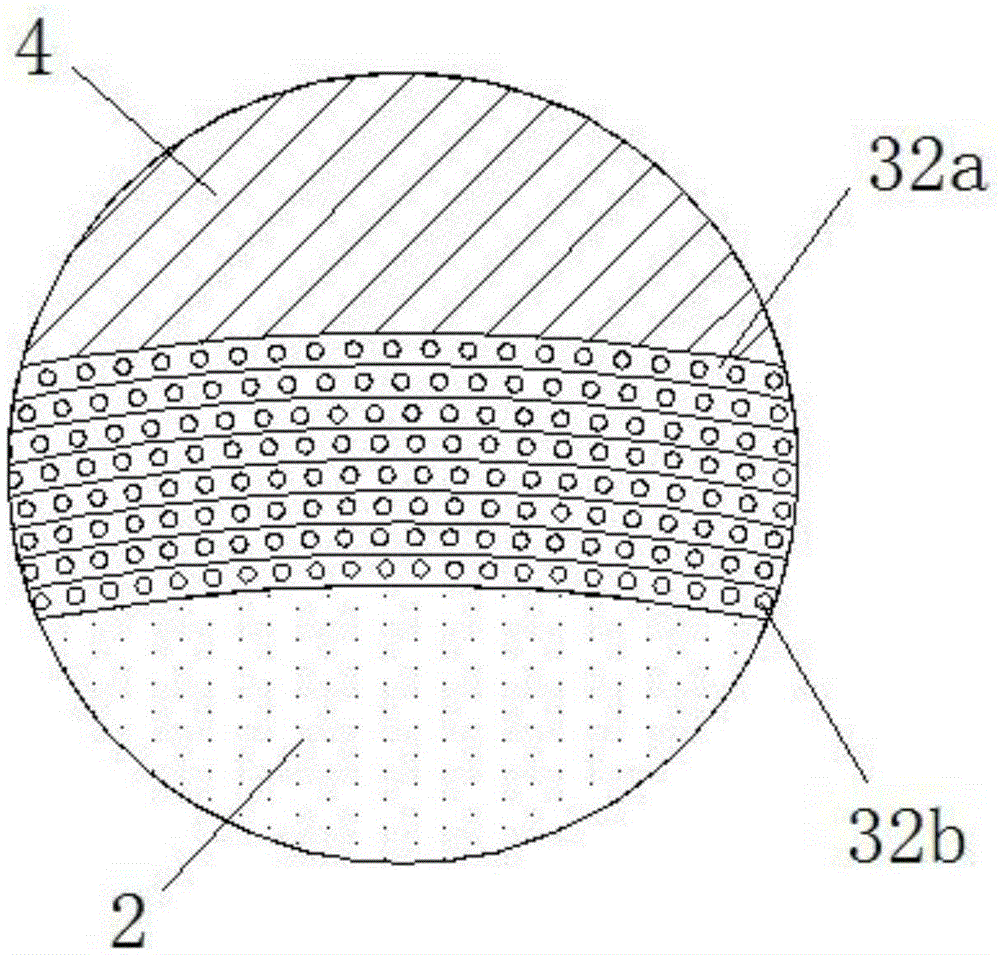

[0033] Such as figure 1 and image 3 As shown, the difference from Embodiment 1 is that the buffer layer 22 is wrapped by a film 32a with micropores 32b in a single layer or multiple layers, and the single layer thickness of the film 32a is 0.01-2mm, and the total wrapping thickness is 0.05-5mm. The package can be in various forms such as wrapping, longitudinal wrapping or extrusion wrapping. Since the film 32a itself has micropores 32b inside, it is compressible, so the buffer layer 3 formed by wrapping is also compressible. In addition, in the case of cable bending, the wrapping layers can slide against each other, and the material will not be fatigued by cable bending and is less likely to be damaged.

[0034] This film 32a can be the expanded microporous film produced by stretching the PTFE material, and the density of the film 32a is 0.5-1.9g / cm 3 . Within a certain stretching range, the film 32a can all play the role of preventing cracking of the outer conductor 4 ....

Embodiment approach 3

[0036] Such as figure 1 and Figure 4 As shown, the difference from Embodiment 1 is that the buffer layer 3 includes a ring portion 33a close to the outer conductor 4 and a number of protruding teeth 33b uniformly distributed on the inner wall of the ring portion 33a, and the protruding teeth 33b are held against the dielectric layer 2 of the outer surface. The ring portion 33a can conform to the inner wall structure of the outer conductor 4. When the dielectric layer 2 expands, the protruding teeth 33b will still bear against the outer surface of the dielectric layer 2 but elastically deform, so that the expansion of the dielectric layer 2 can be compensated. Prevent the outer conductor 4 from bursting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com