Graphite aluminum foil heat-conducting material

A technology of heat-conducting materials and graphite substrates, applied in the direction of cooling/ventilation/heating transformation, layered products, chemical instruments and methods, etc., can solve problems such as inconvenient operation and installation, heavy heat sink, poor heat dissipation effect, etc., to achieve heat dissipation Good effect, excellent resilience, light material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

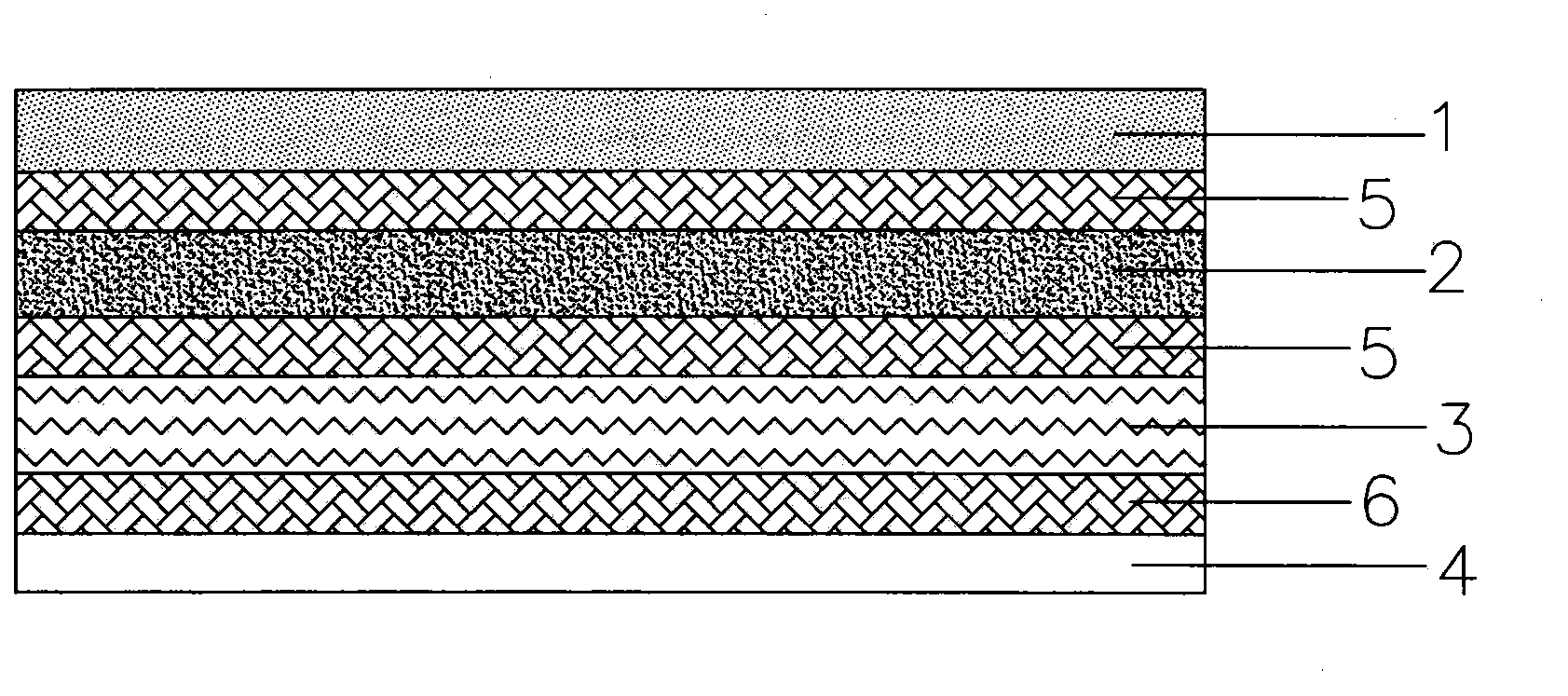

[0025] Such as figure 1 As shown, a graphite aluminum foil heat-conducting material is sequentially composed of a black matt base material layer 1, a graphite base material layer 2, an aluminum foil base material layer 3 and a PET release film 4; one surface of the black matt base material layer 1 One surface of the graphite substrate layer 2 is bonded with an acrylic adhesive layer 5, and the other surface of the graphite substrate layer 2 is also bonded with the one surface of the aluminum foil substrate layer 3 by an acrylic adhesive layer 5. The aluminum foil substrate The other surface of the layer 3 is bonded to the surface of the PET release film 4 by an acrylic insulating adhesive layer 6 .

[0026] Wherein, the thickness of the black matte substrate layer 1 is 0.005mm; the thickness of the acrylic adhesive layer 5 is 0.005mm; the thickness of the graphite substrate layer 2 is 0.03mm; the thickness of the aluminum foil substrate layer 3 is 0.007mm ; The thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com