Static pressure suspension piston type hydraulic breaking hammer

A hydraulic breaker and piston technology, applied in construction, earth mover/excavator, etc., can solve the problems of no support, reduce the mechanical strength of the piston, and inconvenient cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

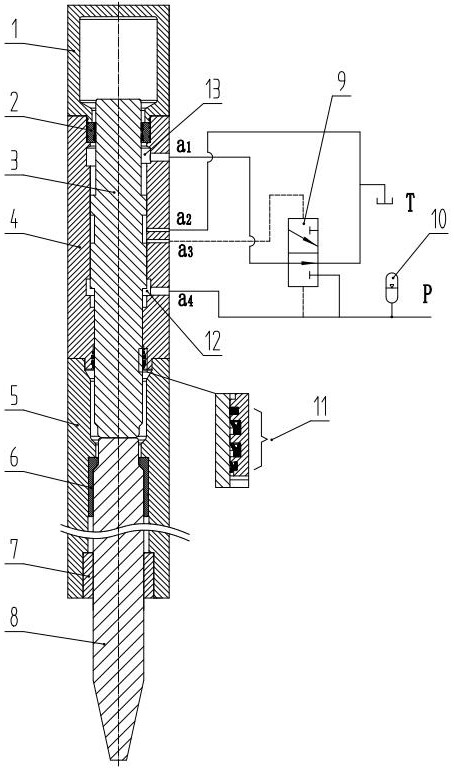

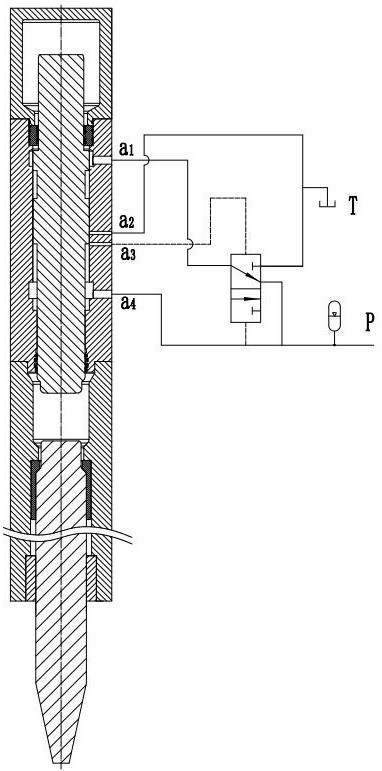

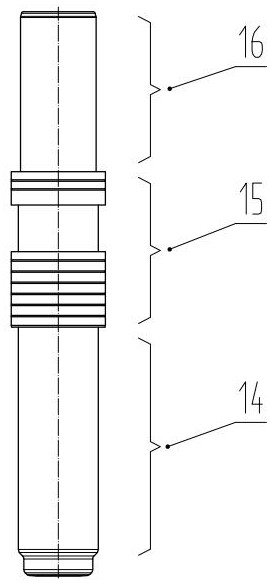

[0052] This embodiment mainly includes: a piston 3 and a cylinder 4 . The piston 3 reciprocates in the cylinder 4 . In the area where the cylinder block 4 and the head 14 of the piston 3 are matched (between the front chamber 12 and the main seal 11 ), two circles are provided with three static pressure suspension chambers 18 evenly distributed in each circle to support the piston 3 .

Embodiment 2

[0054] This embodiment mainly includes: a piston 3 and a cylinder 4 . The piston 3 reciprocates in the cylinder 4 . In the area where the cylinder 4 and the head 14 of the piston 3 are matched (between the front chamber 12 and the main seal 11 ), two circles with four static pressure suspension chambers 18 are evenly distributed in each circle to support the piston 3 .

Embodiment 3

[0056] This embodiment mainly includes: a piston 3 and a cylinder 4 . The piston 3 reciprocates in the cylinder 4 . In the area where the cylinder 4 and the head 14 of the piston 3 are matched (between the front chamber 12 and the main seal 11 ), three circles, each of which is evenly distributed with three hydrostatic suspension chambers 18 , are used to support the piston 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com