High pressure powder-spray nozzle for high pressure powder spray method

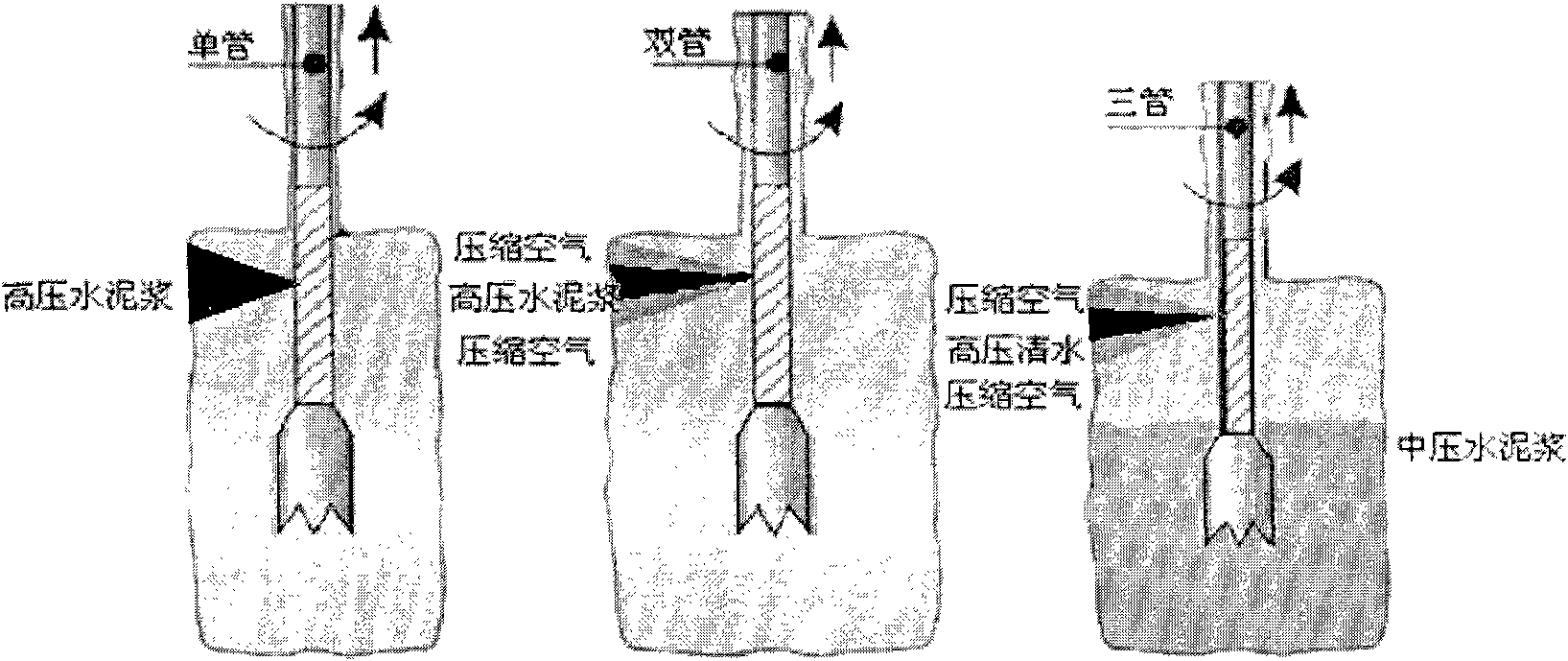

A high-pressure jet and powder technology, which is applied in the fields of soil protection, construction, and infrastructure engineering, can solve the problems of insufficient foundation reinforcement, affecting water-stopping effect, and low cement-soil strength, achieving good water-stopping effect, The effect of increasing the reinforcement range and reducing the water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

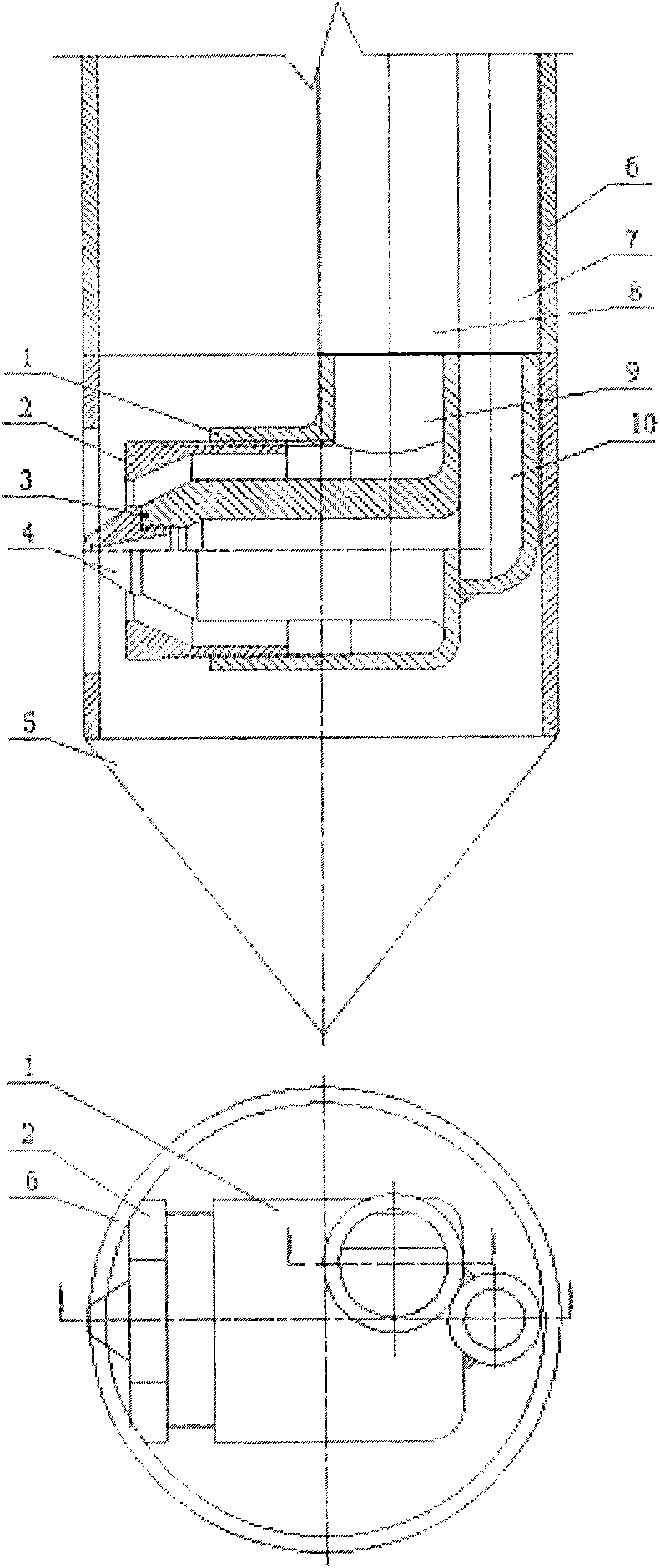

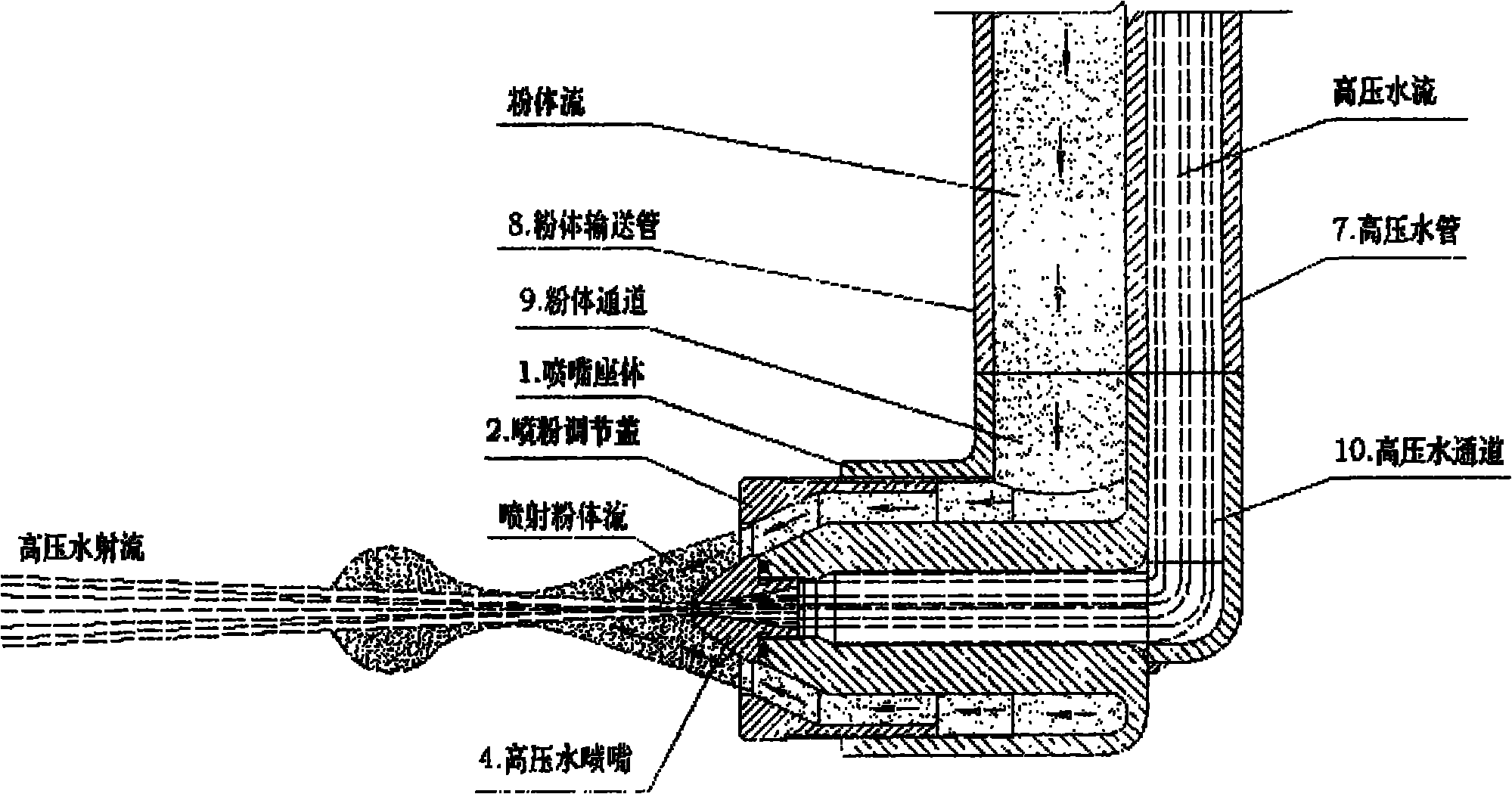

[0026] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the high-pressure jet powder nozzle of the present invention.

[0027] The high-pressure jet powder nozzle includes: nozzle base 1, powder spraying adjustment cover 2, sealing ring 3, high-pressure water nozzle 4, drill bit 5, drill pipe 6, high-pressure water pipe 7, powder conveying pipe 8, powder channel 9 and The high-pressure water channel 10 is characterized in that: the high-pressure jet powder nozzle is installed inside the drill bit 5, the drill bit 5 is connected to the drill pipe 6, and the high-pressure water nozzle 4 and the high-pressure water channel 10 of the nozzle base 1 are connected by threads , the powder spraying regulating cover 2 is threadedly connected with the powder channel 9 of the nozzle base 1, and is combined with the high-pressure water nozzle 4 to form an annular powder spraying nozzle, and the annular gap of the powder spraying nozzle is adjusted by rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com