Rock cross-cut coal uncovering method with horizontal jet grouting piles for reinforcement

A technology of horizontal rotary jetting piles and coal excavation by stone gates, which is applied in earth-moving drilling, drilling with liquid/gas jet, ground mining, etc., can solve the problems of inability to achieve reinforcement, limited diffusion radius of cement slurry, etc., and achieves wide practicability, The effect of improving the reinforcement strength and expanding the reinforcement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the patent of the present invention will be further described below in conjunction with the accompanying drawings:

[0019] The method for unearthing coal at the reinforced stone gate of the horizontal jet grouting pile of the present invention adopts equipment such as a drilling rig, a high-pressure horizontal jet grouting pile machine, and uses high-pressure water jets, compressed air, and cement slurry as the jet jetting materials. The specific steps are as follows:

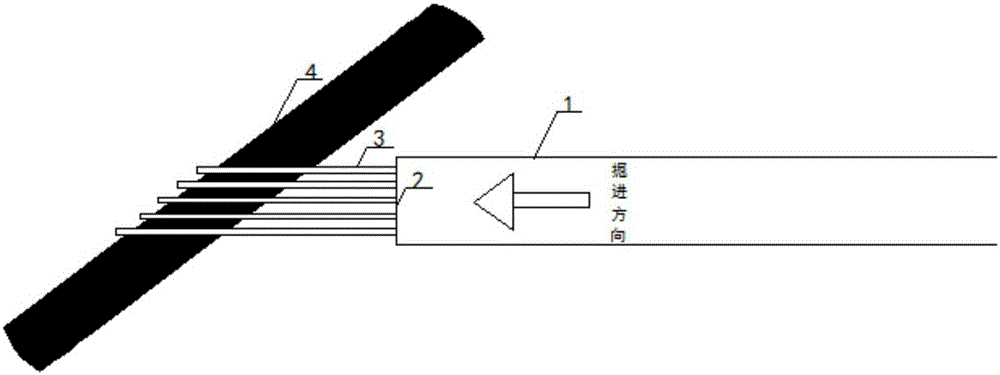

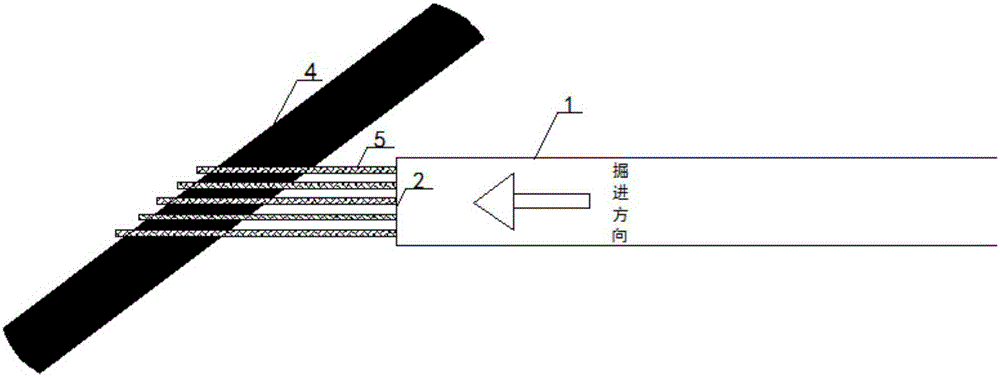

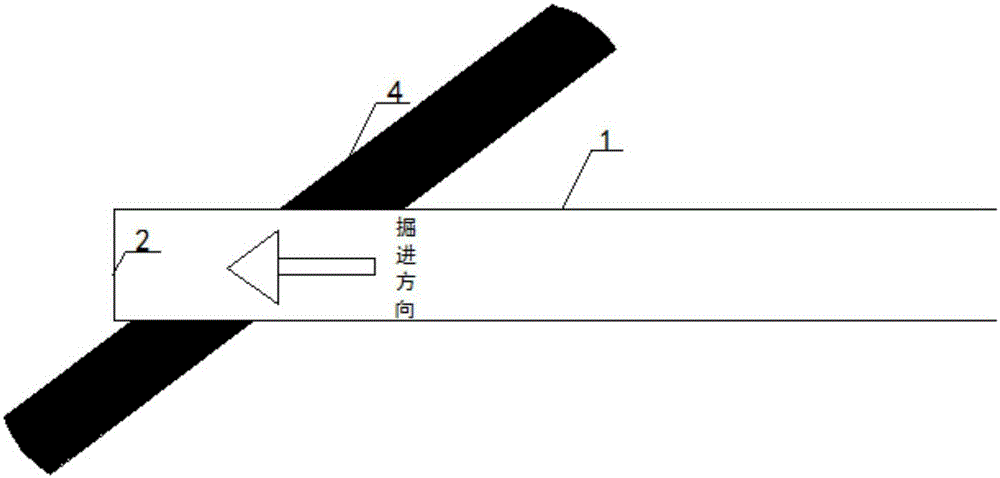

[0020] Excavate along the coal uncovering working face 2 in front of the tunneling roadway 1. Before the minimum normal distance between the coal uncovering working face 2 and the uncovered coal seam 4 is less than 7 meters, use the hanging wire and level to debug and install the hole opener, and move towards the coal seam. Construction of multiple pre-opening holes, the number of multiple pre-opening holes constructed in the direction of the coal seam is 4, and the depth of the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com