Natural gas hydrate reservoir reinforcing method

A hydrate and natural gas technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as limited reinforcement range, hydrate decomposition, low permeability of muddy silt reservoirs, etc. Achieve the effects of improving particle size distribution and soil composition ratio, promoting the improvement of seepage capacity, and expanding the scope of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

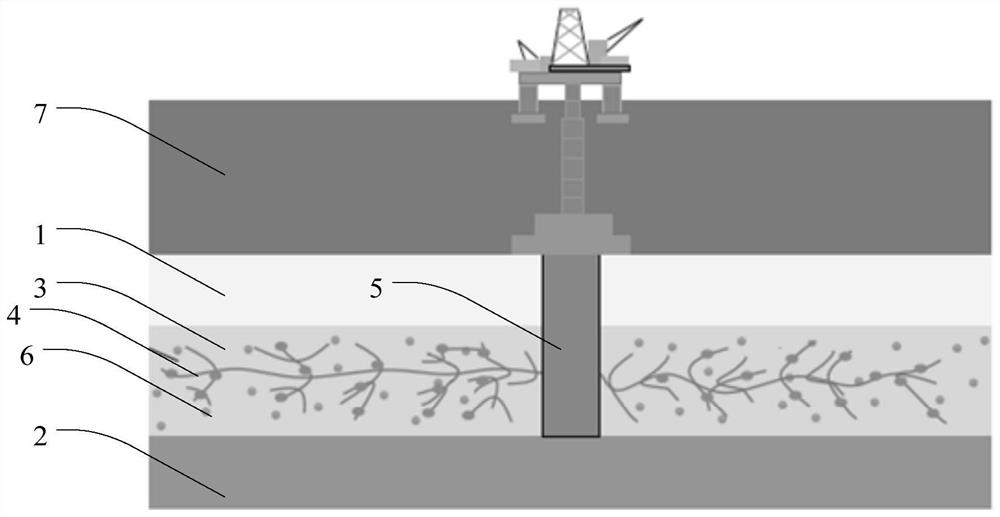

[0037] refer to figure 1 , the natural gas hydrate reservoir comprises an upper overburden 1 and a lower overburden 2, and between the upper overburden 1 and the lower overburden 2 is a hydrate zone 3 where gas hydrates are stored, and the hydrate zone 3 There are seepage channels 4. In this embodiment, the upper covering layer 1 is located at a sea depth of 1200m, the thickness of the upper covering layer 1 is 400m, the thickness of the hydrate zone 3 is 270m, and the seabed temperature is about 10°C , the seabed pressure is about 10 MPa, and there are seepage channels 4 in the hydrate zone 3, but it is not limited to this embodiment.

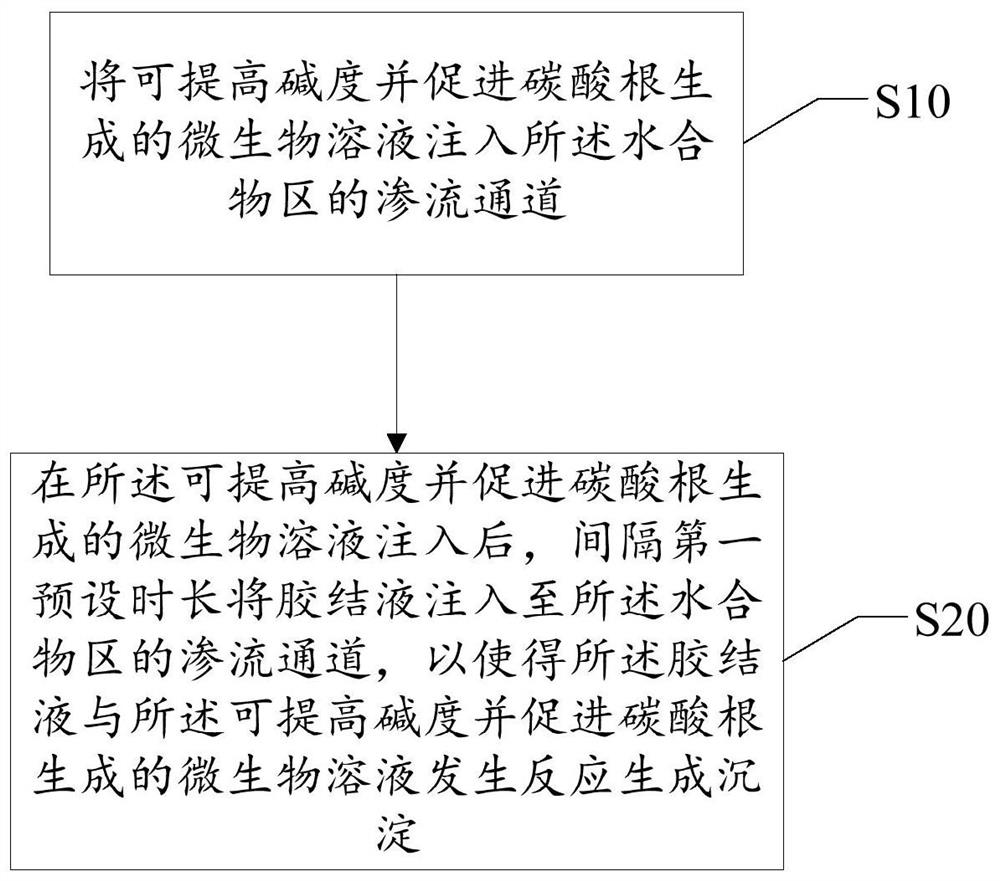

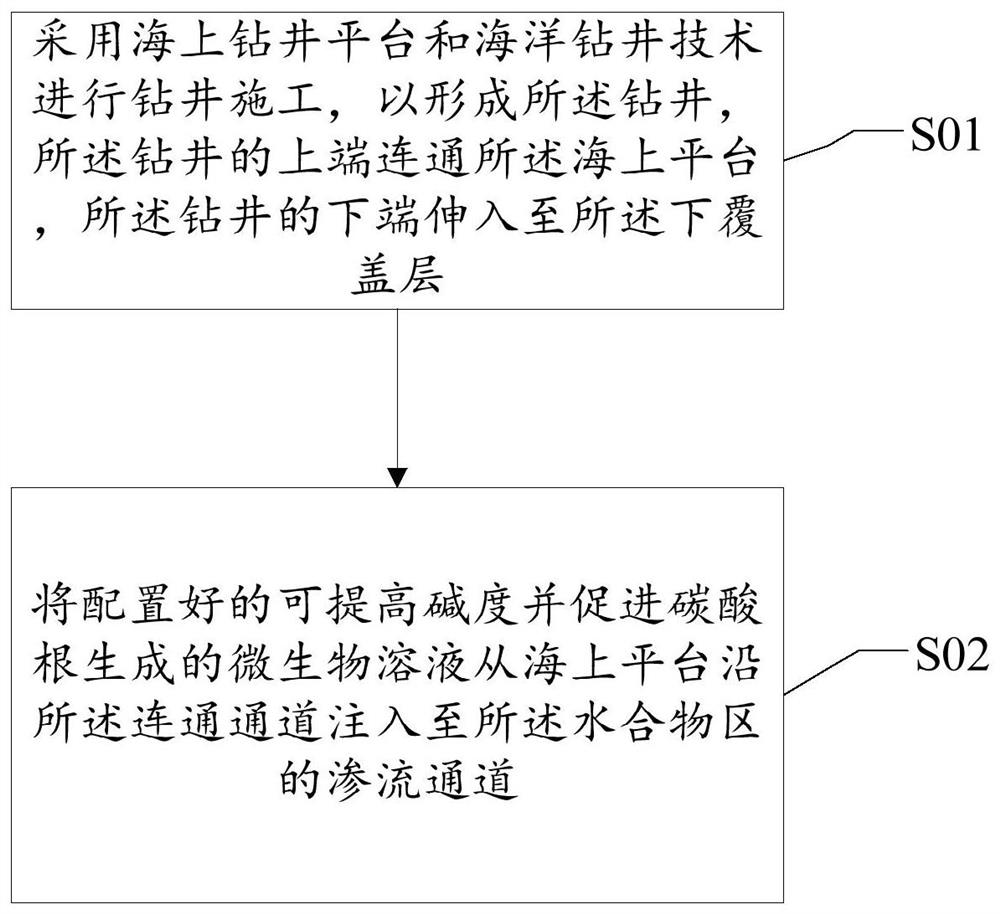

[0038] The embodiment of the present invention provides a natural gas hydrate reservoir strengthening method, referring to figure 2 , figure 2 It is a schematic flowchart of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com