Method for consolidating tilting combination structure

A combined structure, inclined technology, applied in the direction of building construction, building maintenance, construction, etc., can solve the problems of poor reinforcement structure strength, inconvenient construction, improper force, etc., to achieve convenient construction, reasonable structure, and reasonable structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings and embodiments of the specification.

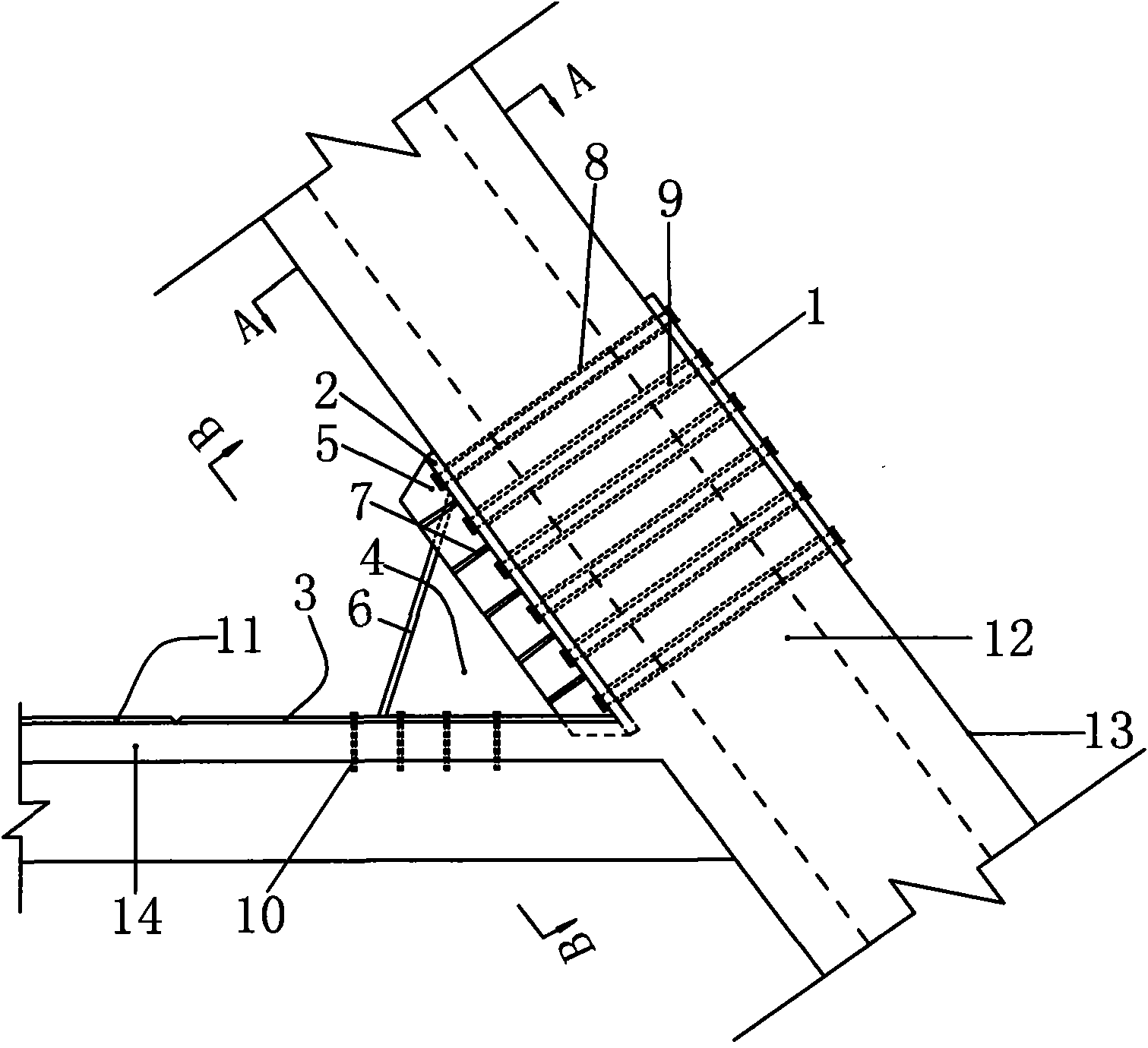

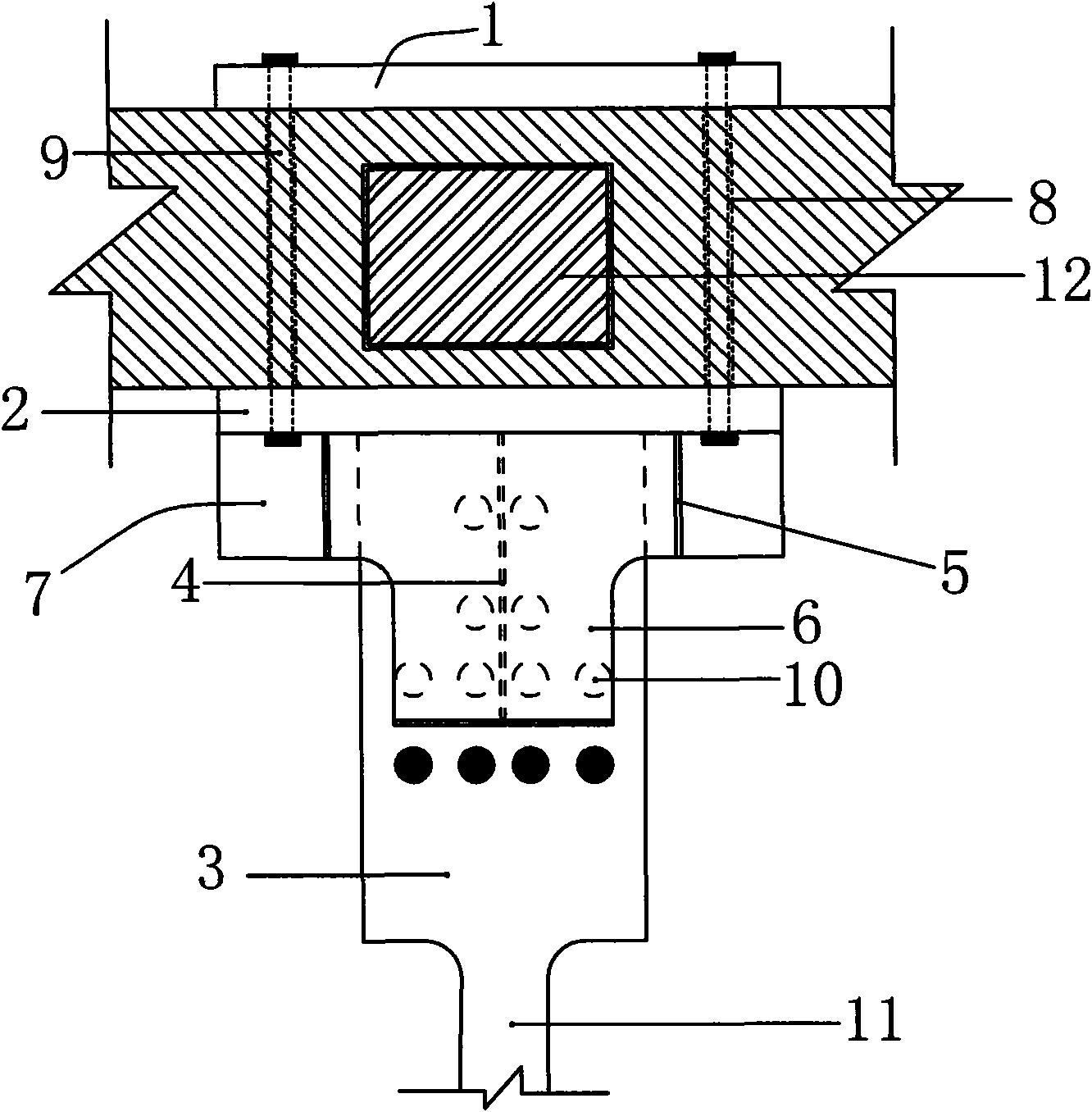

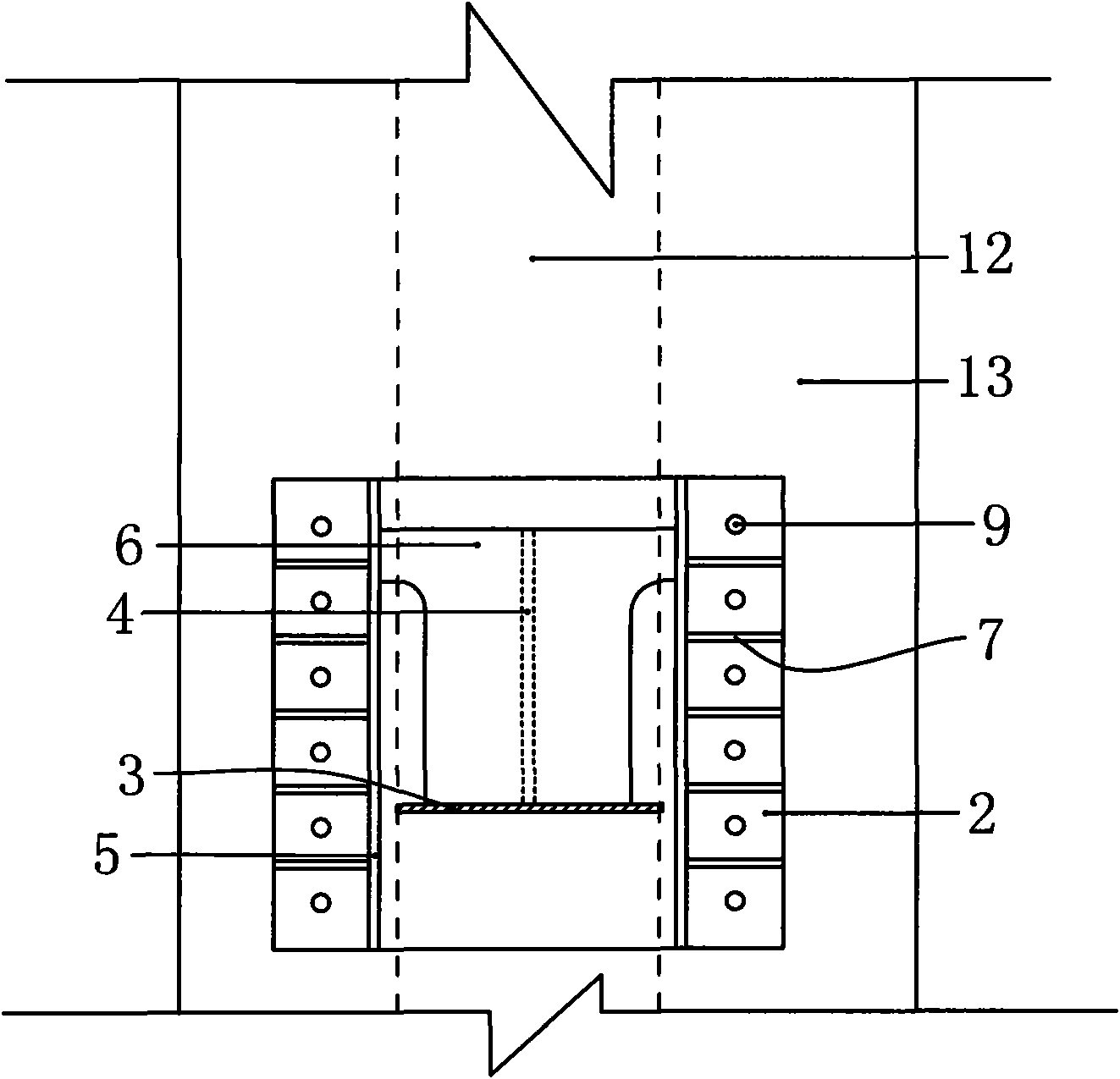

[0020] refer to figure 1 , figure 2 and image 3 ; The reinforcement method of this inclined composite structure is as follows:

[0021] In this example, at the beginning, the position of laying tie steel strip 11 is reserved on the surface of the concrete building to be reinforced, and then the third steel plate 3 is fixed on the concrete to be reinforced by twelve chemical anchor bolts 10 at both ends of the reserved position. The surface of the building 14 and extends to the edge of one side of the inclined steel concrete member 13;

[0022] Then before the first and second steel plates (1, 2) are fixed, two rectangular first stiffened steel plates 5 and ten square second stiffened steel plates 7 are welded on the second steel plate 2, wherein the rectangular first stiffened steel plates 5 are parallel And be welded on the both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com