Vibration eliminating structure for concrete sleeper

A vibration-absorbing structure, concrete technology, applied in the direction of tracks, fixed rails, roads, etc., can solve the problem of difficulty in accurately fixing sleepers and shock-absorbing pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the concrete vibration-absorbing structure according to the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

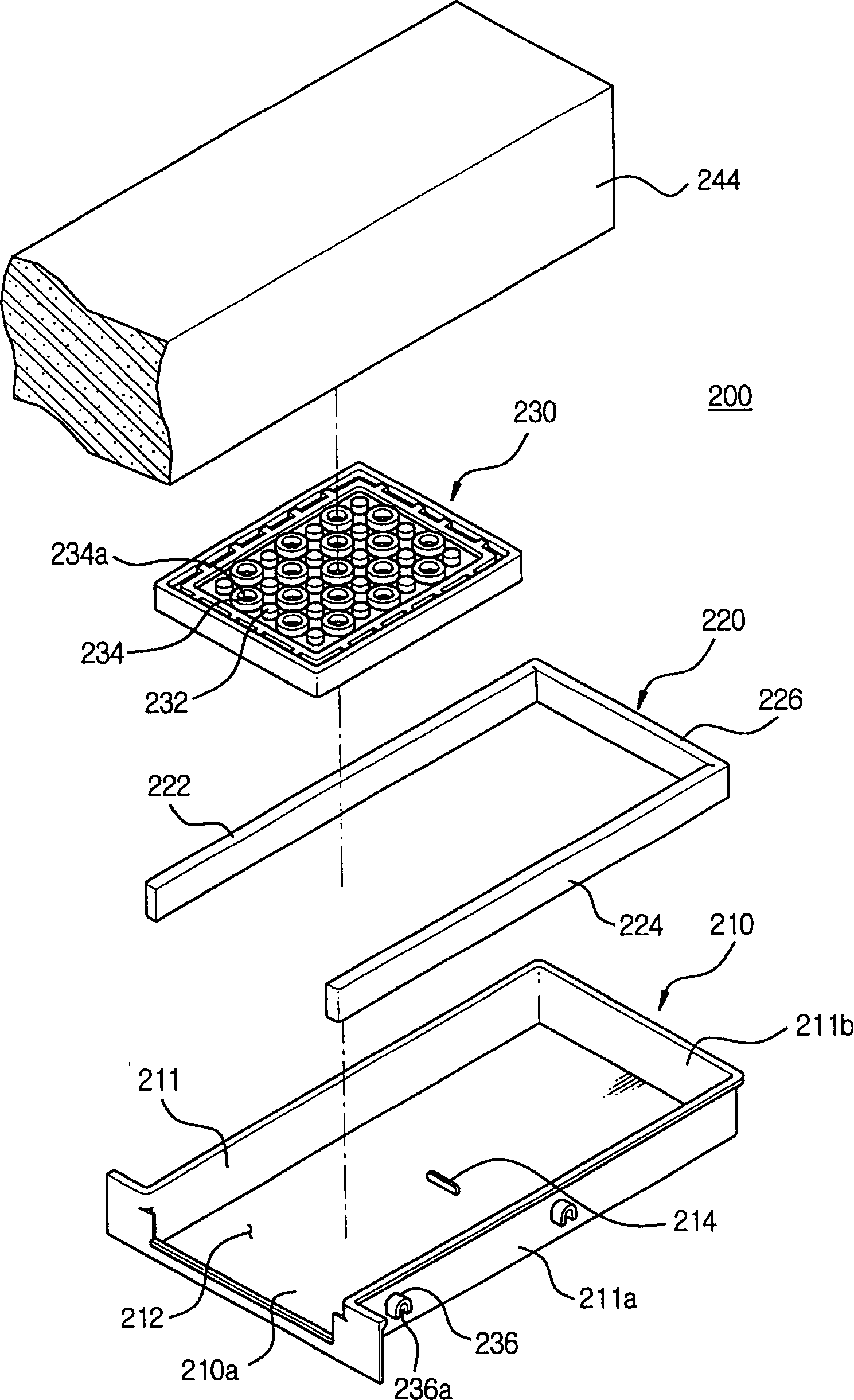

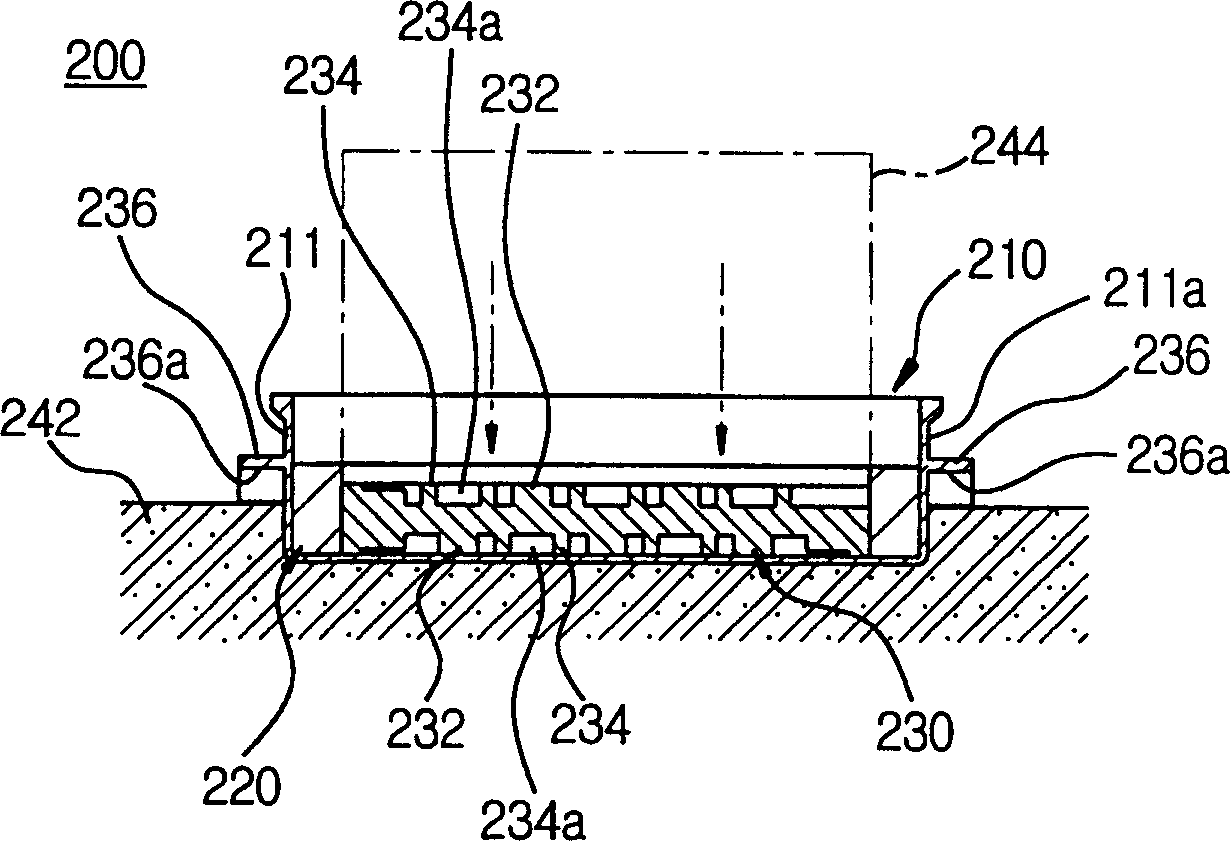

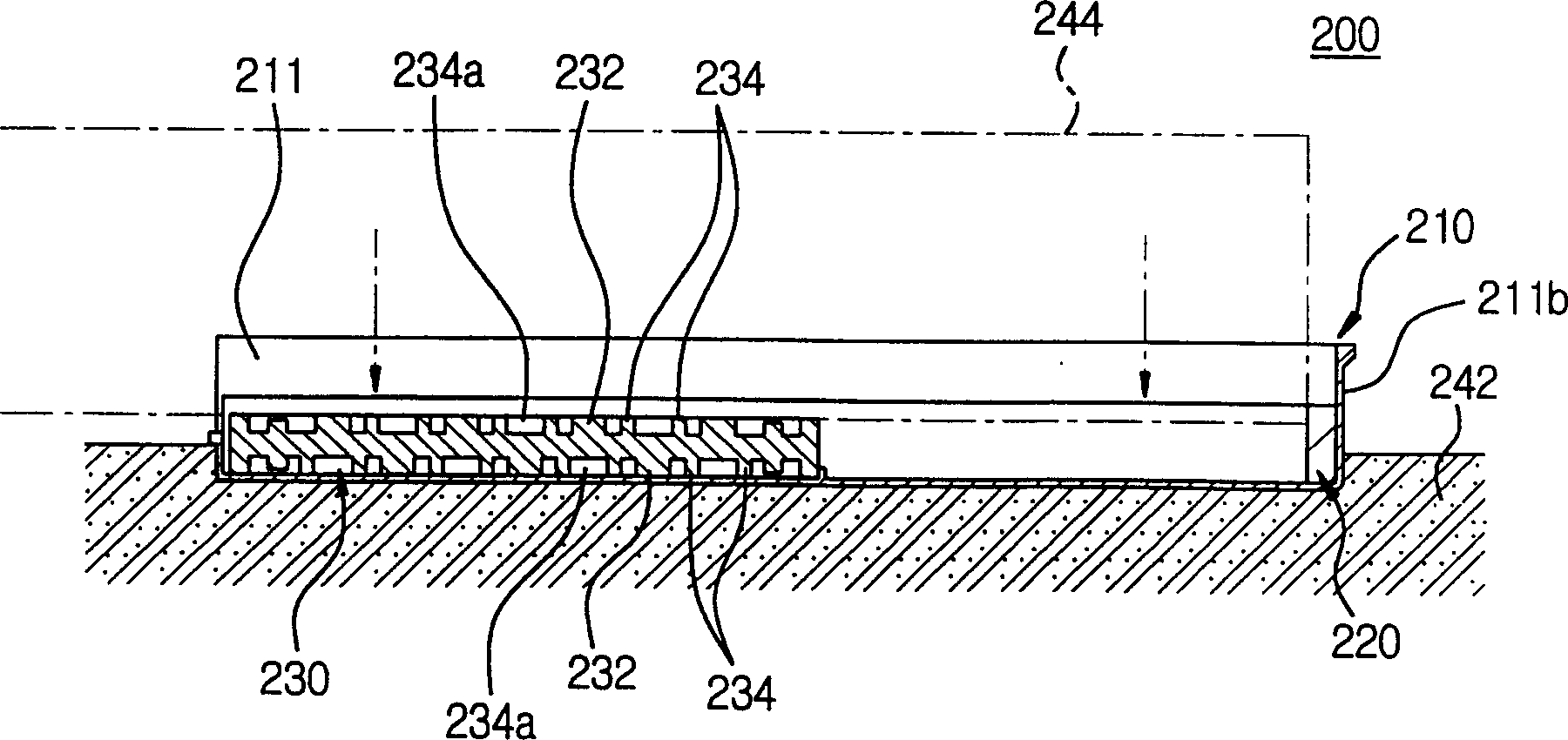

[0025] see figure 1 Referring to FIG. 4 , the vibration-absorbing structure 200 is placed on the roadbed 242 . The roadbed 242 is mainly made of concrete material. The vibration damping structure 200 has a structure body 210 . The structure body 210 includes a substrate 210a, a first sidewall 211, a second sidewall 211a and a third sidewall 211b. The first side wall 211 and the second side wall 211a are substantially parallel to each other. The third side wall 211a is connected to ends of the first side wall 211 and the second side wall 211a. A seating space 212 is enclosed between the first side wall 211 , the second side wall 211 a and the third side wall 211 b. A positioning protrusion 214 is formed at the central portion of the bottom of the structure body 210 . The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com