Safe guide wheel ring bushing device of enameling machine

A technology of guide wheel and lacquer machine, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, electrical components, etc. It can solve problems such as slippage, wire jumping, and unfavorable enameled wire production, so as to prevent metal wires from falling and prolong their use. Longevity and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

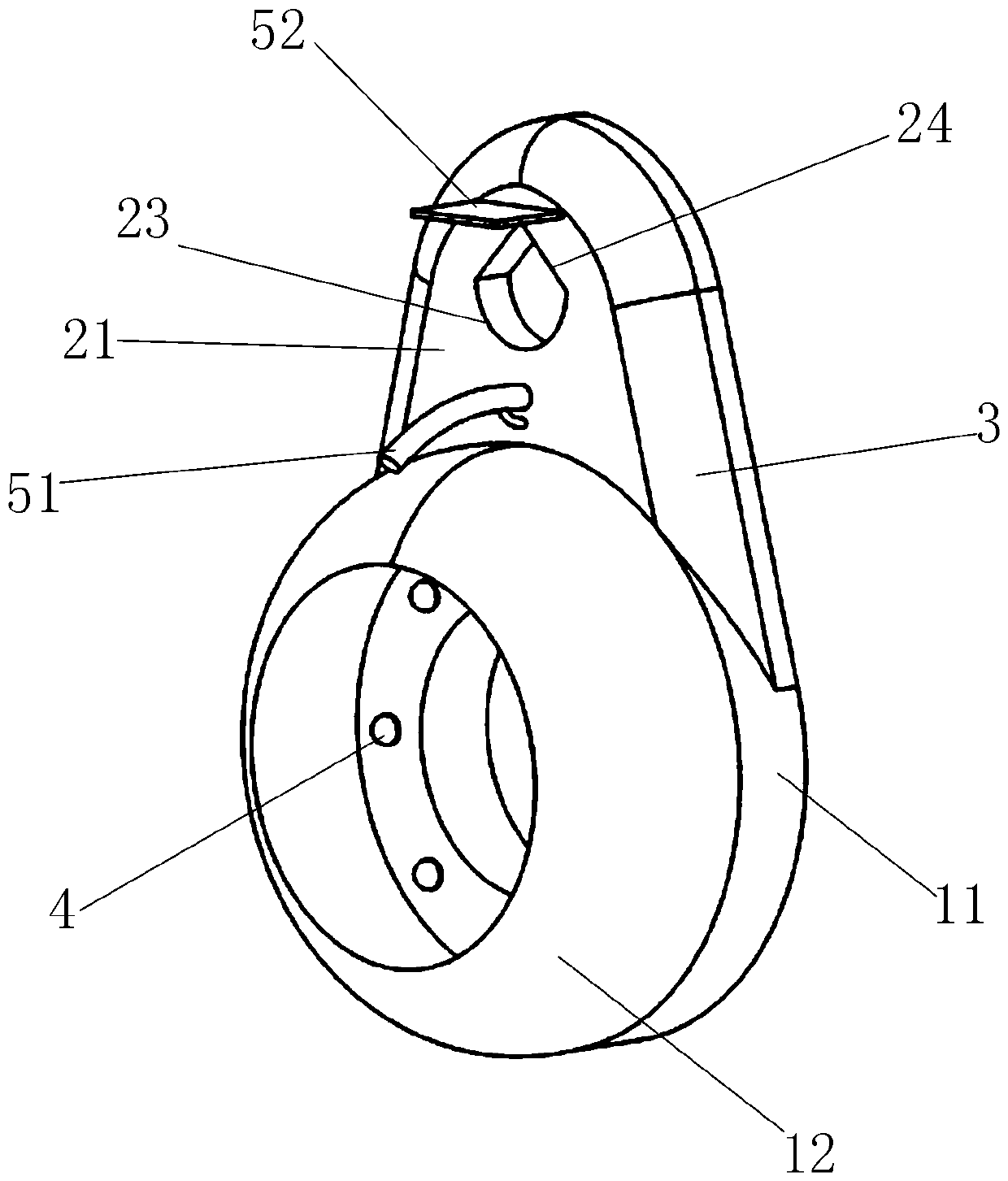

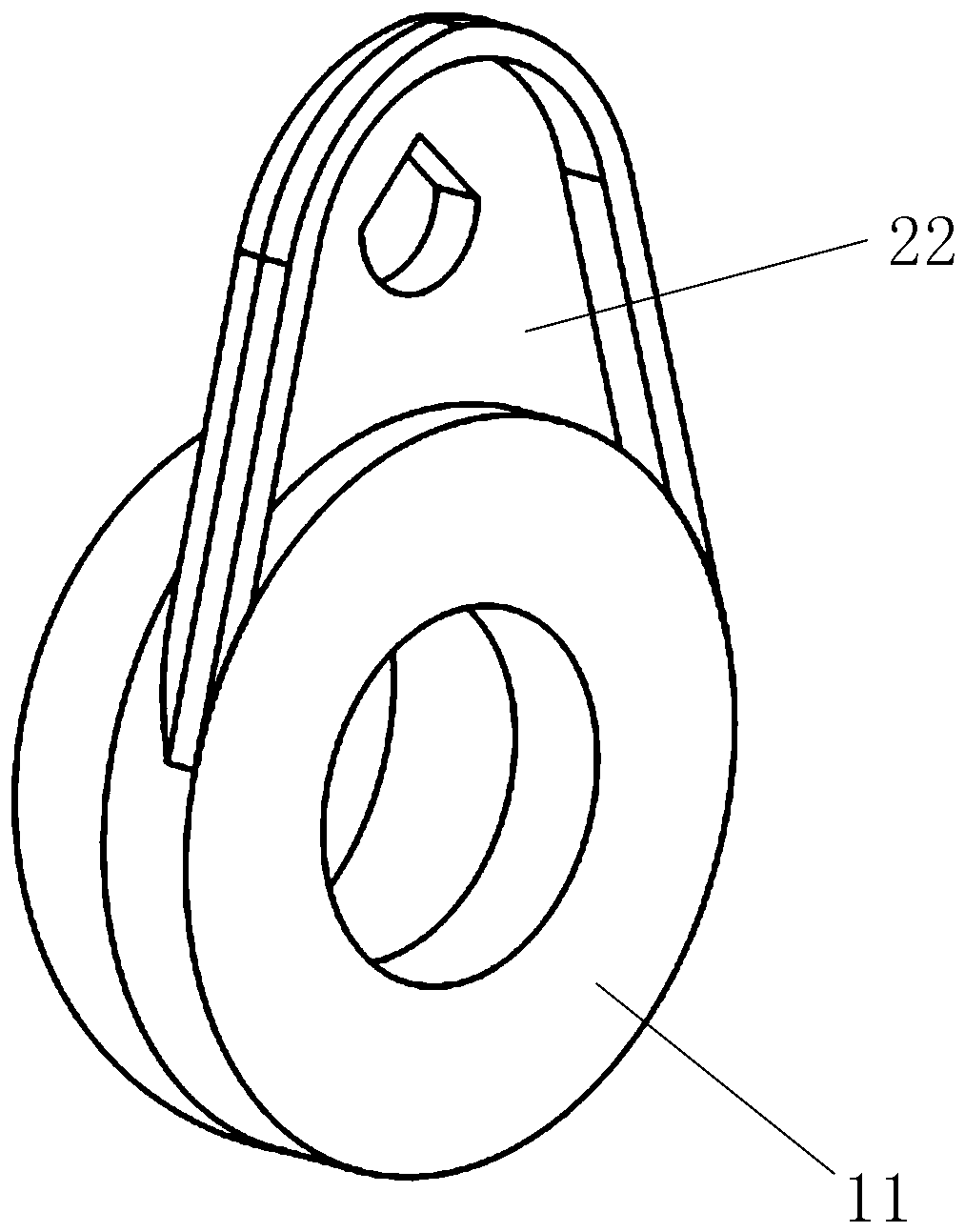

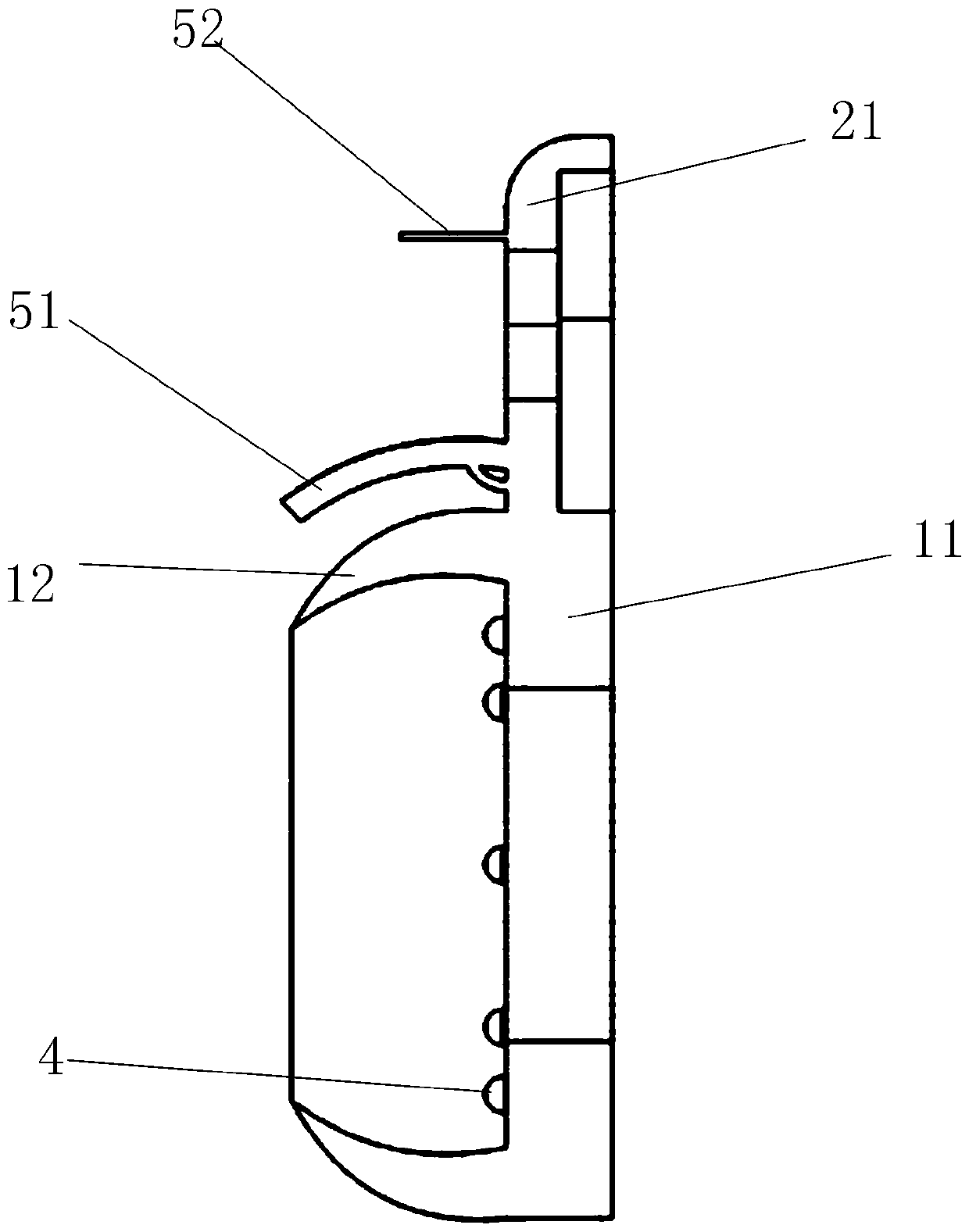

[0032] Example 1, such as figure 1 Shown is the oblique front view of the guide wheel ring device, a safe guide wheel ring device for coating machine, which includes a wheel wrapping part for wrapping on the metal wheel and a hand grip for force picking part 21, the wheel part includes an outer wrapping part 11 and an inner wrapping part 12, the outer wrapping part 11 is a disc-shaped panel, and the inner wrapping part 12 extends from the surface edge of the outer wrapping part 11 to the direction away from the outer wrapping part 11, and gradually moves toward the outer wrapping part The central axis direction of 11 is an arc-shaped panel close to each other. The handle 21 is a panel that is gradually narrowed from bottom to top from the side of the upper half of the outsourcing portion 11. The handle 21 includes an arc top, which is a hand The end of the holding part 21 away from the side of the outer wrapping part 11 is an arc-shaped convex surface extending toward the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com