Processing technology of protective plate of PCB (Printed Circuit Board) testing device

A technology of processing technology and testing device, which is applied in the field of PCB testing device guard plate processing technology, can solve the problems of test device failure, large gap between the pinhole of the guard plate and the needle bar of the test needle, loss of elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

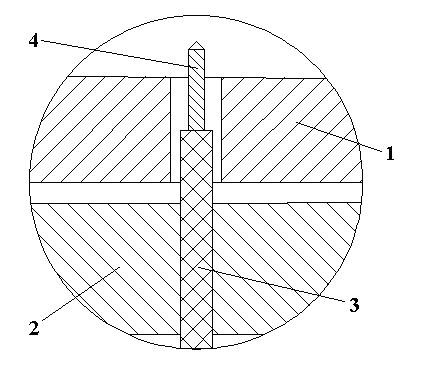

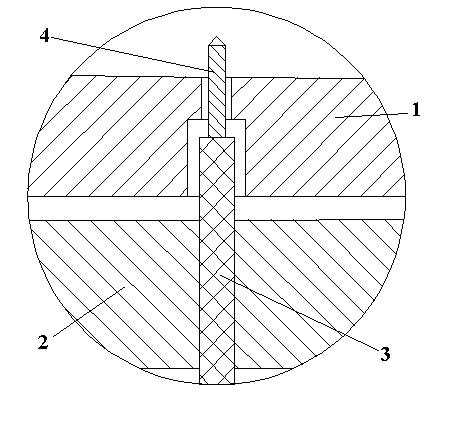

[0013] refer to figure 2 , image 3 with Figure 4 , a PCB testing device guard plate processing technology, its steps are as follows:

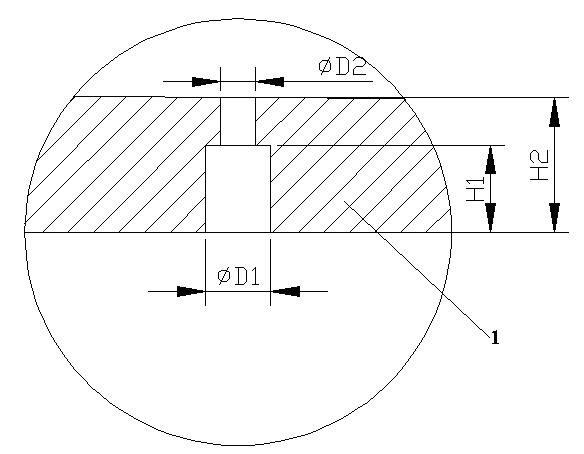

[0014] a. Open a blind hole with a diameter of D1 and a depth of H1 on the surface of the guard plate 1 facing the side of the needle planting plate 2 and corresponding to the position of the test needle 4, and D1>d1, h1

[0015] b. On the corresponding position on the reverse side of the guard plate 1 processed by the blind hole, a through hole with a diameter of D2 and a depth directly reaching the blind hole is opened, and D1>D2>d2, wherein, d2 is the maximum diameter of the needle bar 4 of the test needle, and the specific size of D2 dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com