Parameter calibration method for cameras of vehicle-mounted all-round view system

A parameter calibration and camera technology, which is applied in image data processing, image analysis, instruments, etc., can solve problems affecting the stitching accuracy of surround-view images, and achieve the effects of improving accuracy and computing efficiency, clear imaging, and image stitching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings.

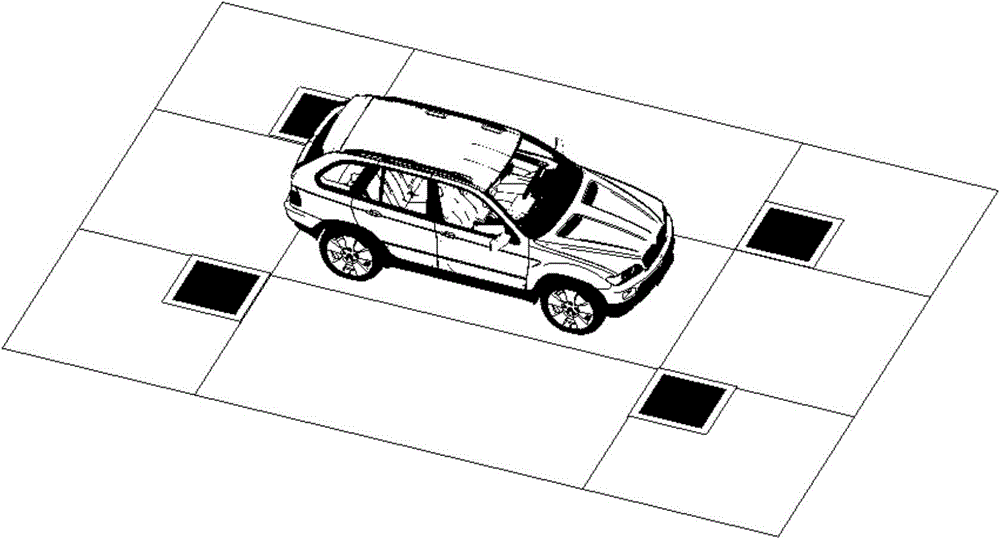

[0036] Such as figure 1 As shown, the traditional vehicle surround view system calibration adopts a two-dimensional calibration method, laying a flat calibration cloth on the ground. Since the vehicle-mounted surround view system uses a wide-angle camera of about 170 degrees, the imaging distortion of the fisheye lens is serious, so this method makes the size of the image of the calibration cloth in the camera very small and the edges are blurred.

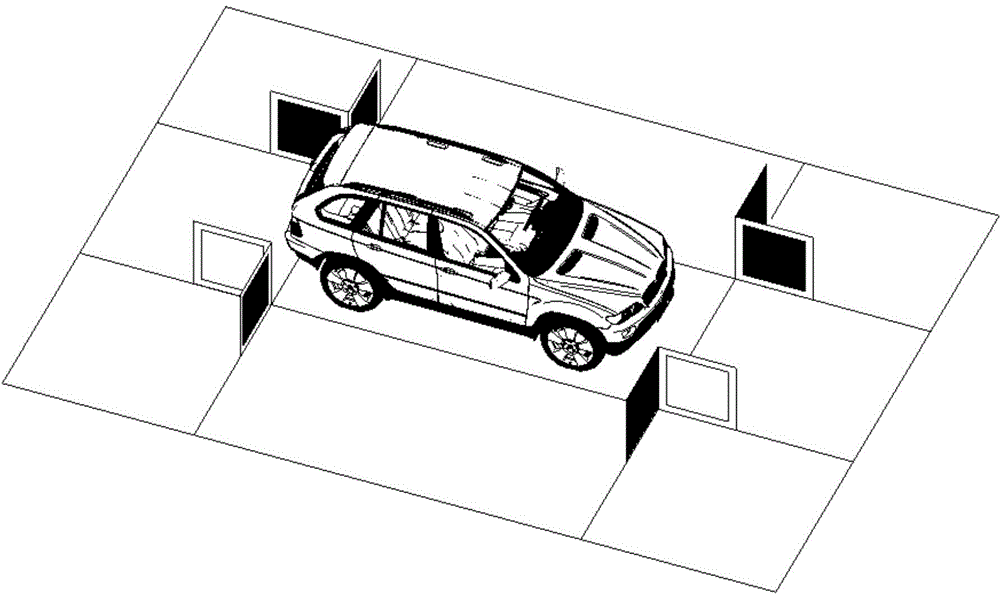

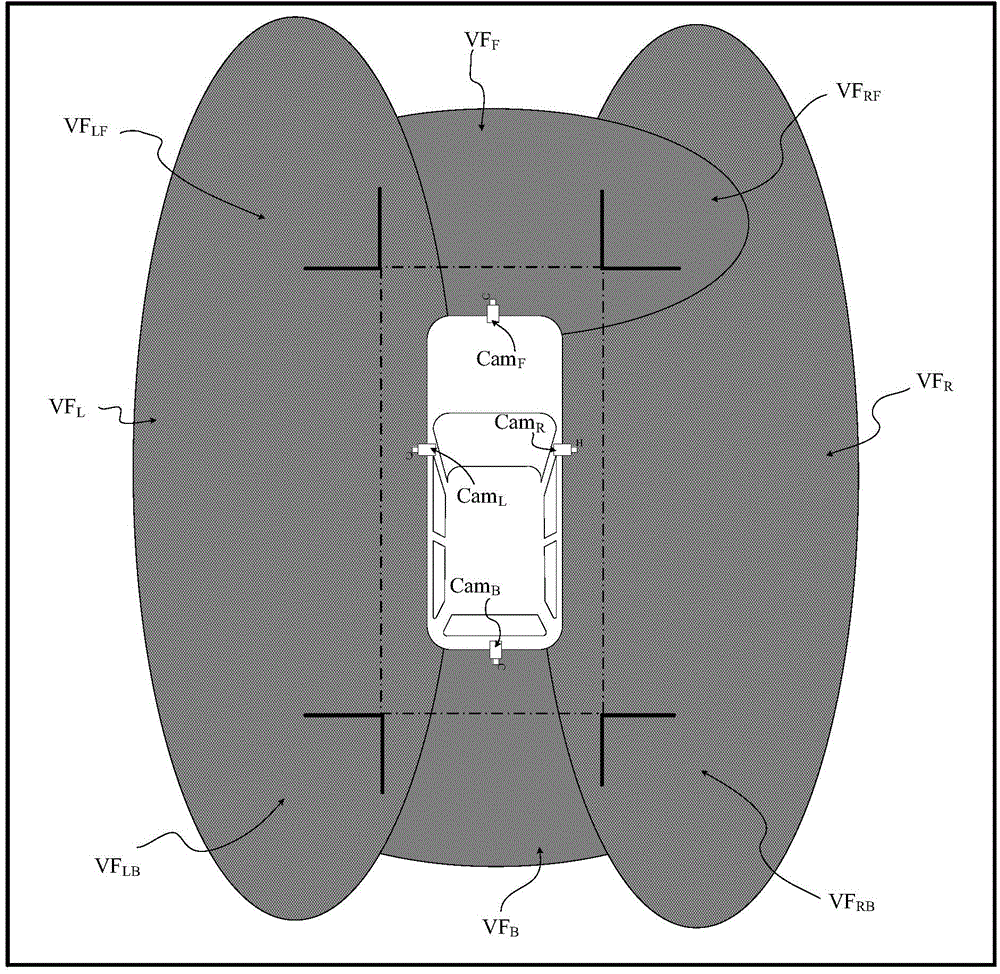

[0037] The calibration markers provided by the present invention are placed perpendicular to the ground. In this embodiment, calibration plates with red and blue color blocks are used, with clear edges, and other common calibration plates on the market can also be used. Intersecting the calibration cloth placed flat on the ground in the past, the feature points on the calibration plate perpendicular to the ground are locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com