Elastic milling and polishing tool for free-form surface machining and manufacturing method of elastic milling and polishing tool

A surface processing and elastic technology, applied in the field of fixed abrasive milling and polishing tools, can solve the problems of poor stability, environmental pollution, environmental impact of waste abrasives, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

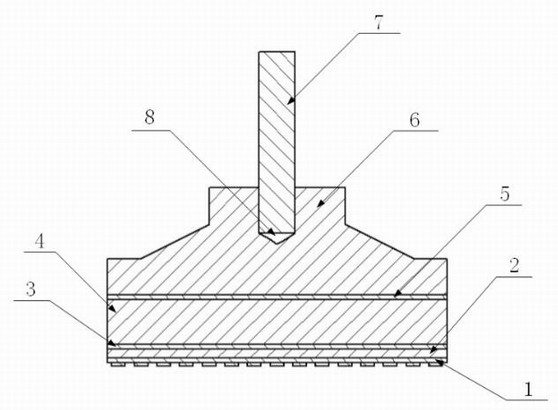

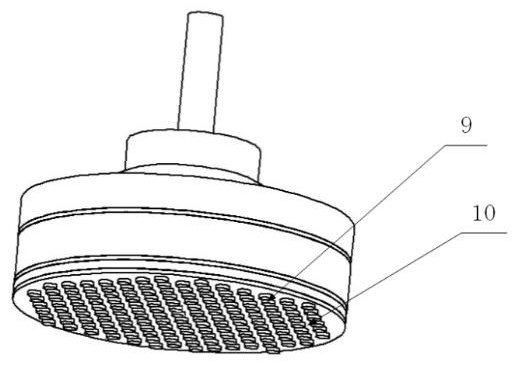

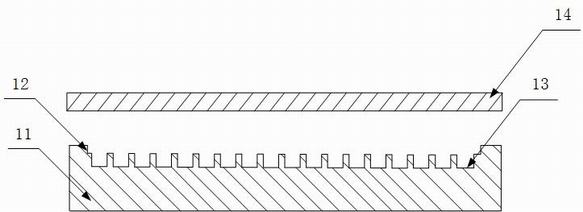

[0050]According to the processing requirements of the TC4 titanium alloy workpiece with free-form surface characteristics, select diamond with a particle size of 20-30 microns and mix the other raw materials of the abrasive layer uniformly in proportion, add heat curing agent and accelerator, stir again, and then apply evenly Into the flat mold sprayed with release agent in advance; cover the 0.8mm thick non-woven fabric base layer on the flat mold, cover the mold; heat and press to solidify and form, you can get the abrasive layer and cloth base for the elastic milling and polishing tool Consolidated abrasive pad composed of layers.

[0051]Bond the prepared consolidated abrasive pad with nylon buttons to a 2mm thick sphere with a radius of 100mm on the polyurethane elastic layer, bond the elastic layer to the rigid substrate with crystal glue, and perform milling and polishing on the ABB robot platform TC4 titanium alloy free-form surface workpiece test, milling and polishing pressur...

example 2

[0054]According to the milling and polishing requirements of the fused silica glass workpiece with free-form surface characteristics, select diamond with a particle size of 10-14 microns and other raw materials of the abrasive layer after uniformly mixing in proportion, adding heat curing agent and accelerator, stirring again, and then uniform Apply the ground to a flat mold sprayed with release agent in advance; cover the 0.5mm non-woven fabric base layer on the flat mold and cover the mold; heat and press to solidify to form the abrasive layer and cloth base for the elastic milling and polishing tool Consolidated abrasive pad composed of layers.

[0055]Bond the prepared consolidated abrasive pad to a 2mm thick flat polyurethane elastic layer with resin glue, and bond the elastic layer to the rigid substrate with AB epoxy glue, and mill on a five-axis machining center Test of polishing fused quartz workpiece, milling and polishing pressure is 0.018MPa, electric spindle speed is 650rp...

example 3

[0058]According to the processing requirements of fused silica workpieces with free-form surface characteristics, select diamonds with a particle size of 5-7 microns and other raw materials of the abrasive layer and mix them uniformly in proportion, add the thermosetting agent and accelerator, stir again, and then evenly apply to In the plane mold sprayed with the release agent in advance; cover the 1mm thick non-woven fabric base layer on the plane mold, cover the mold; heat and press to solidify and form, you can get the abrasive layer and cloth base layer for the elastic milling tool Consolidated abrasive pad.

[0059]Bond the prepared consolidated abrasive pad with resin glue to the polyurethane elastic layer of 2mm thick ball with a radius of 80mm, and bond the elastic layer to the rigid substrate with AB epoxy resin glue, and process the five-axis linkage The milling and polishing fused quartz workpiece test was performed on the center. The milling and polishing pressure was 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com