Machining device for large-caliber optic free curved surface

A surface processing, large-diameter technology, applied in optical surface grinders, automatic grinding control devices, metal processing equipment, etc., can solve the problems of low processing efficiency, poor load capacity, slow dynamic response speed, etc., to overcome the processing stiffness. Insufficiency, improvement of the limited processing range, and the effect of increasing the machinable angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

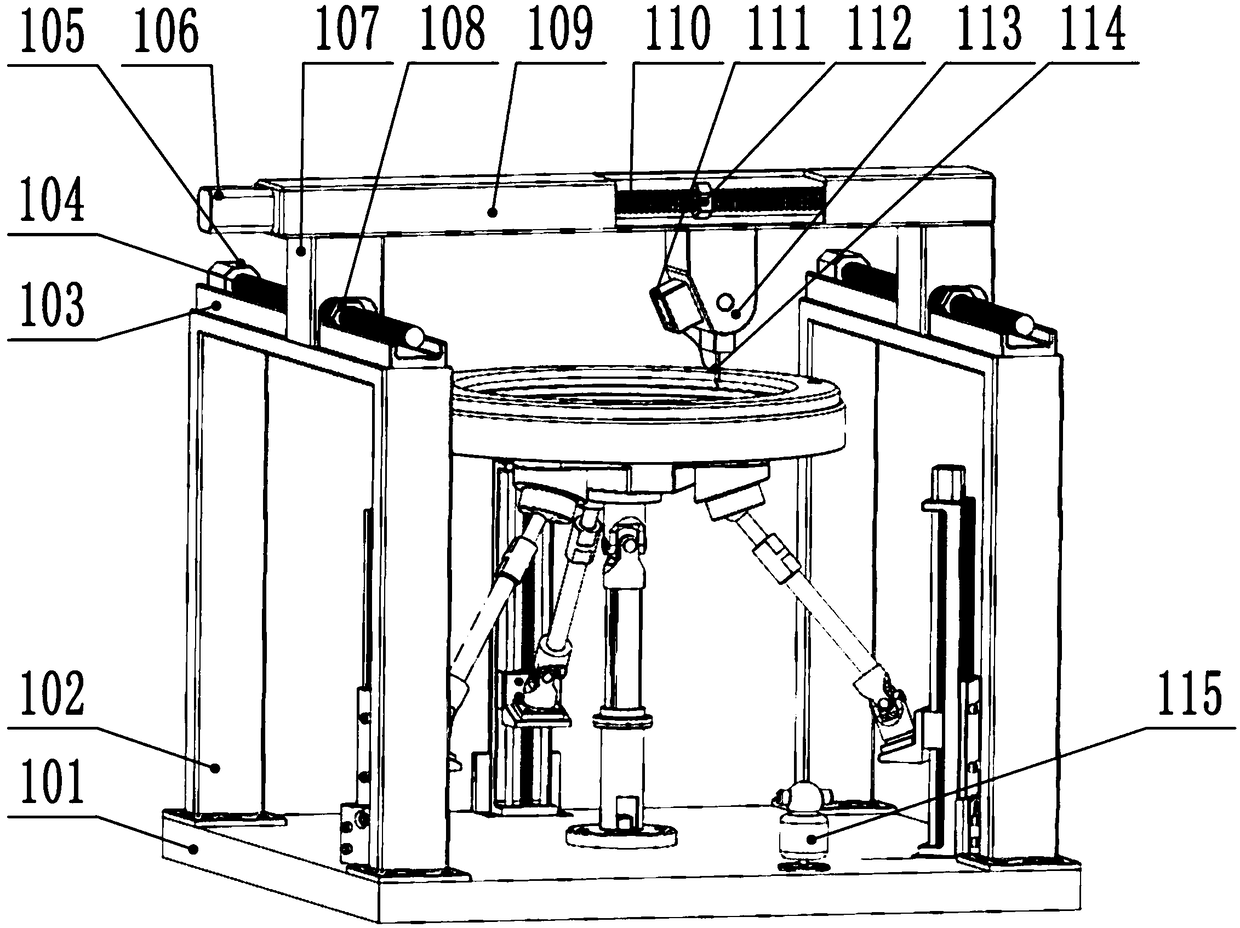

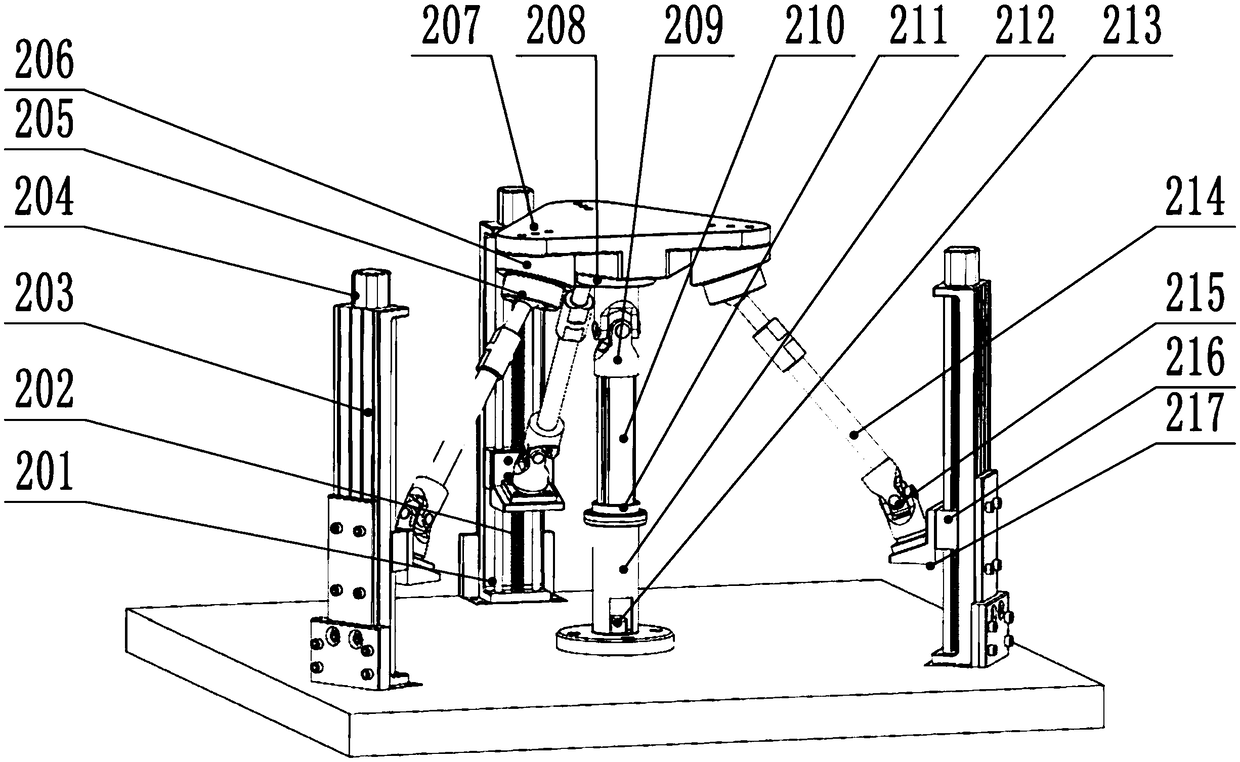

[0021] Such as figure 1 and figure 2As shown, a large-diameter optical free-form surface processing device includes a processing unit, an optical free-form surface support unit, and an optical free-form surface clamping unit; the processing unit is installed on the upper end of the processing support seat, and the processing support seat includes a base 101 and is fixed on the base The support frame 102 at both ends of 101; the processing unit includes a processing tool 114 and a driving mechanism that provides a processing path for the processing tool 114. The driving mechanism includes an X-direction driving mechanism and a Y-direction driving mechanism, and the Y-direction driving mechanism is two groups of parallel arrangements. Lead screw nut drive mechanism, including Y direction lead screw support seat 103 fixed on two supporting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com