Patents

Literature

44results about How to "Consistent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

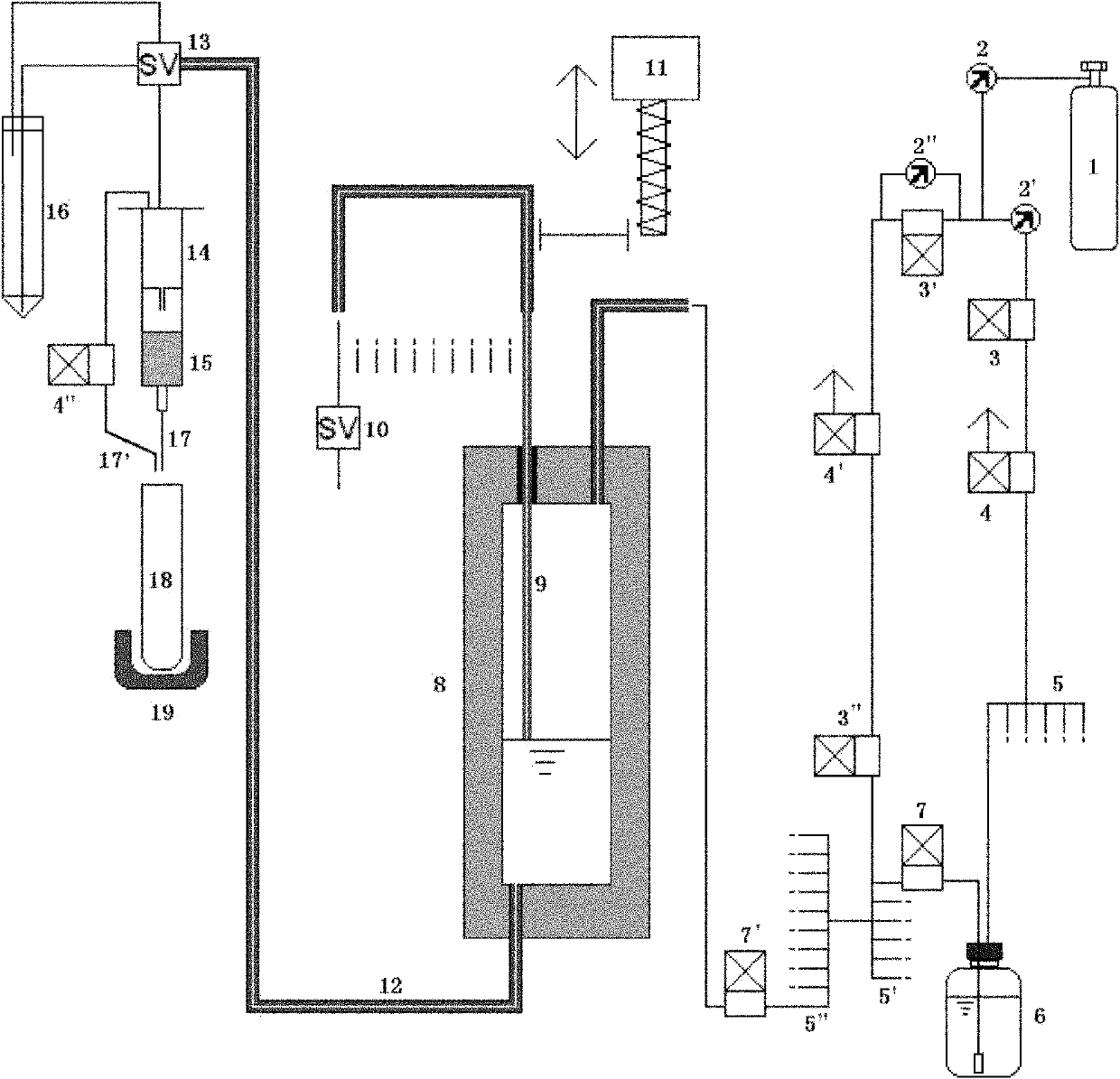

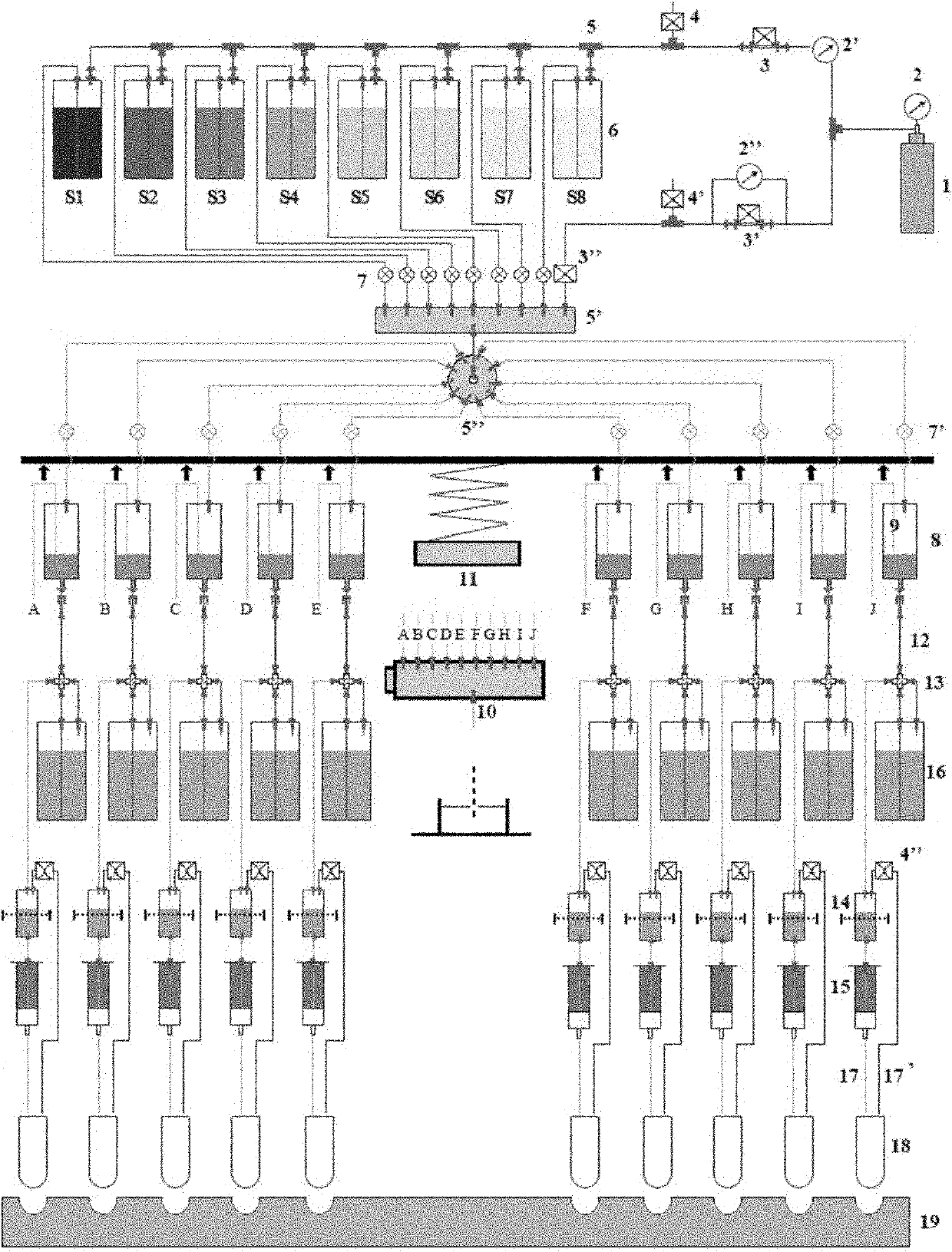

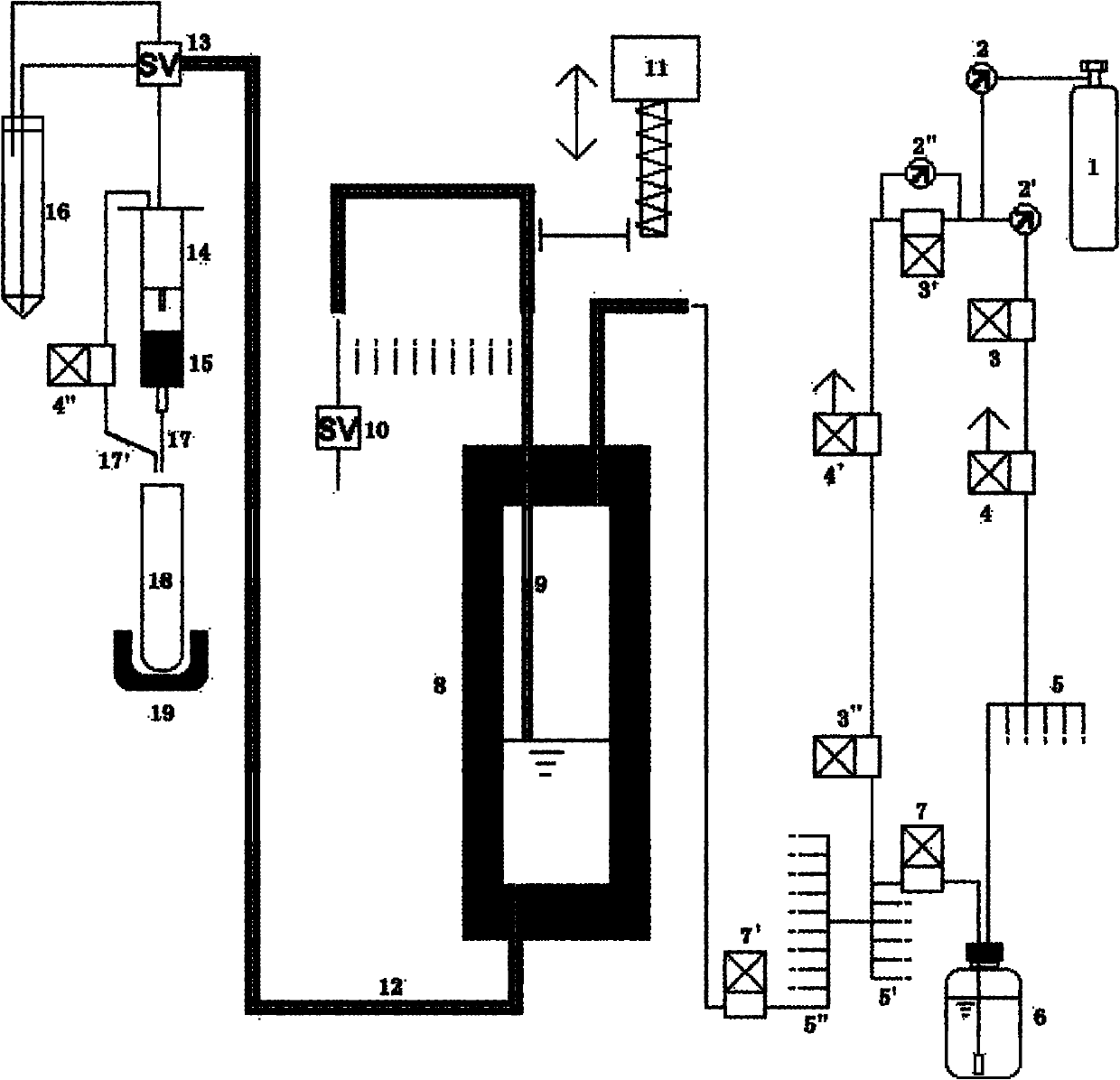

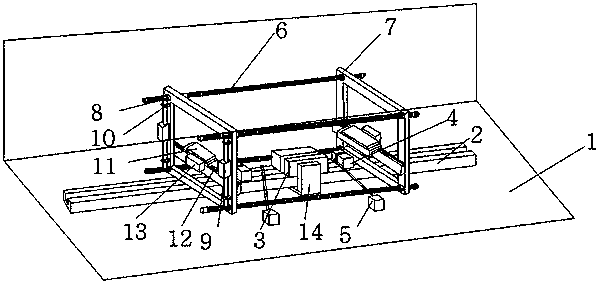

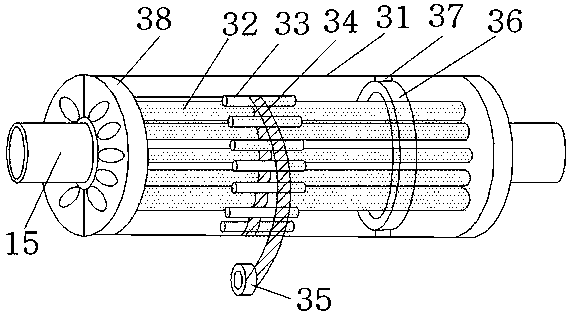

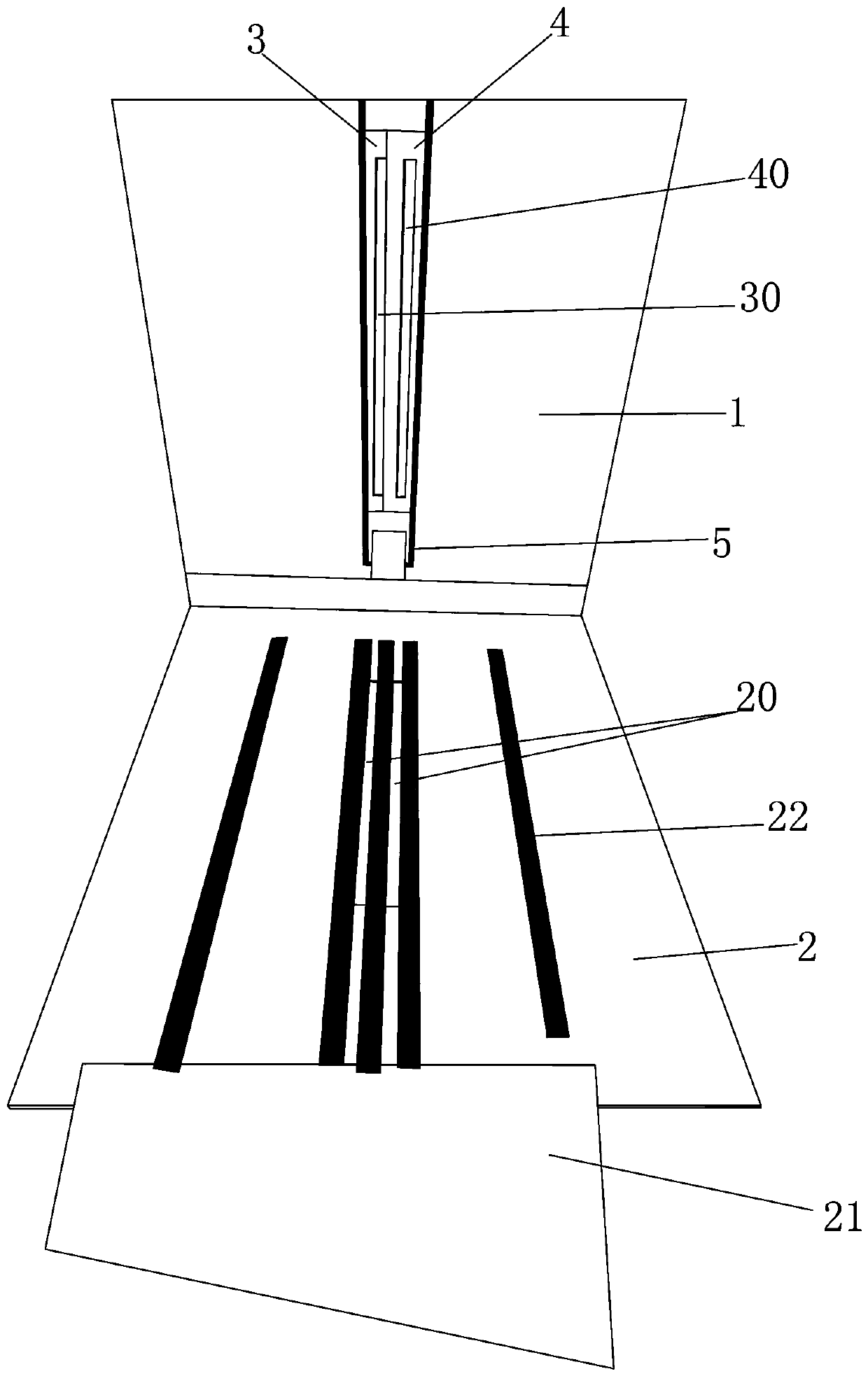

Multichannel parallel automatic solid phase extraction device

ActiveCN102166433AAutomate processingEasy to handlePreparing sample for investigationSolid sorbent liquid separationEngineeringSolvent

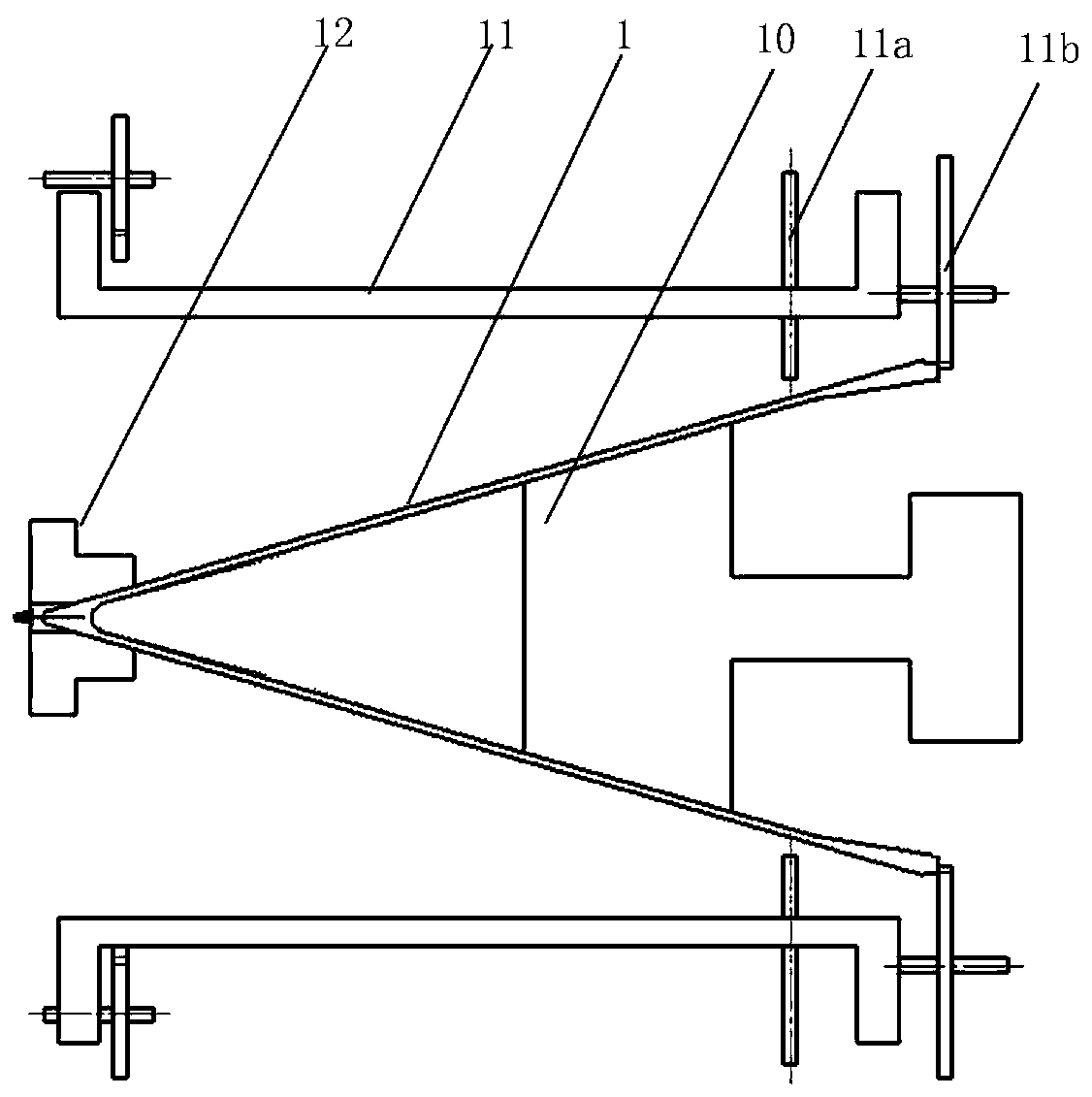

The invention discloses a multichannel parallel automatic solid phase extraction device, which comprises a steel bottle, a solvent supply device, a quantifying pool, a multichannel changeover valve, a closed and pressure-tight sample bottle, a buffer pool, a solid phase extraction part, and a collection bottle, wherein the solvent supply device is connected with a bus of a third distributor and the steel bottle; the inlet of the quantifying pool is connected to a branch of the third distributor, and the quantifying pool is used for automatically determining the volume of the required solvent;the multichannel changeover valve is provided with a sample adding position and a solvent adding position, and is connected with an outlet of the quantifying pool through a first flow limiting pipe; the inlet and the outlet of the sample bottle are connected with the multichannel changeover valve; the buffer pool is connected with the multichannel changeover valve and is used for keeping a solid phase extraction medium moist; the solid phase extraction part is provided with the solid phase extraction medium and is connected with the buffer pool through a thin pipeline, and a second flow limiting pipe is connected behind the solid phase extraction part; and the collection bottle is positioned below the second flow limiting pipe. The multichannel parallel automatic solid phase extraction device can be used for performing solid phase extraction and eluant concentration on a plurality of samples at the same time, the channels cannot influence one another, so an efficient, automatic and consistent sample processing process is realized.

Owner:BEIJING LABTECH

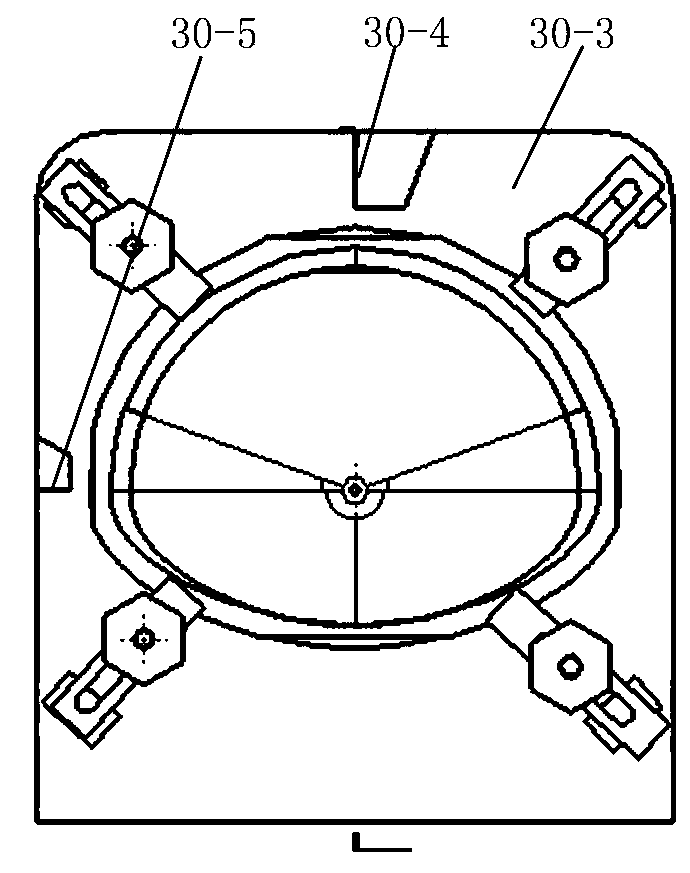

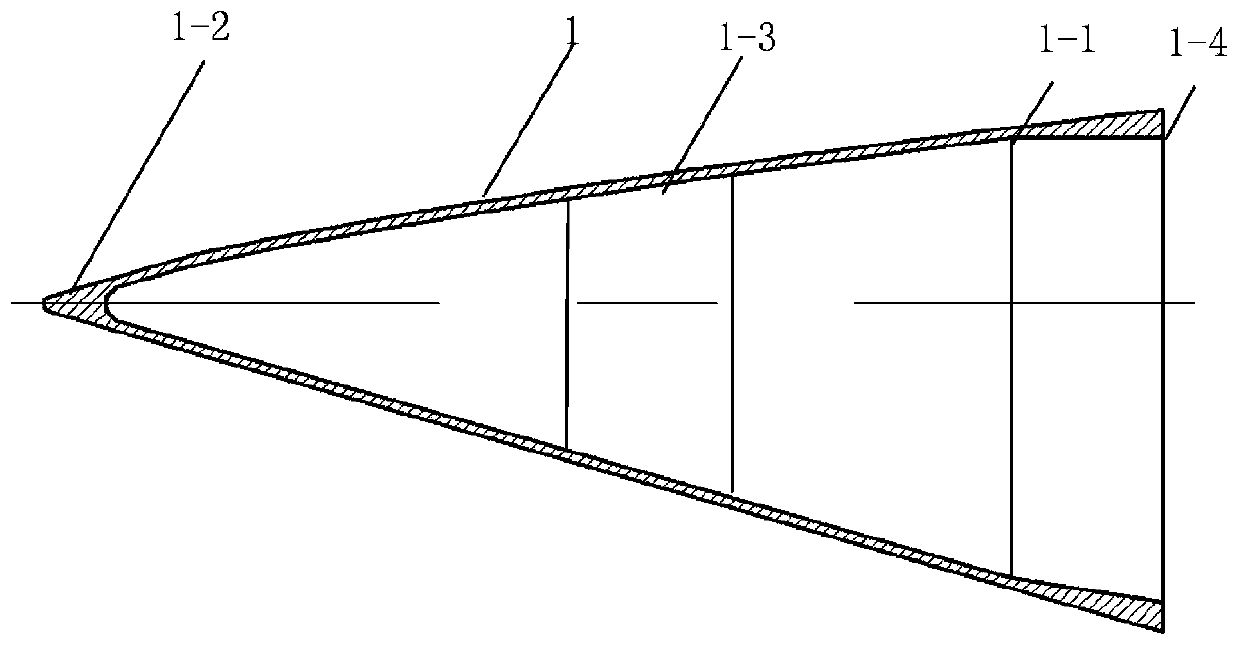

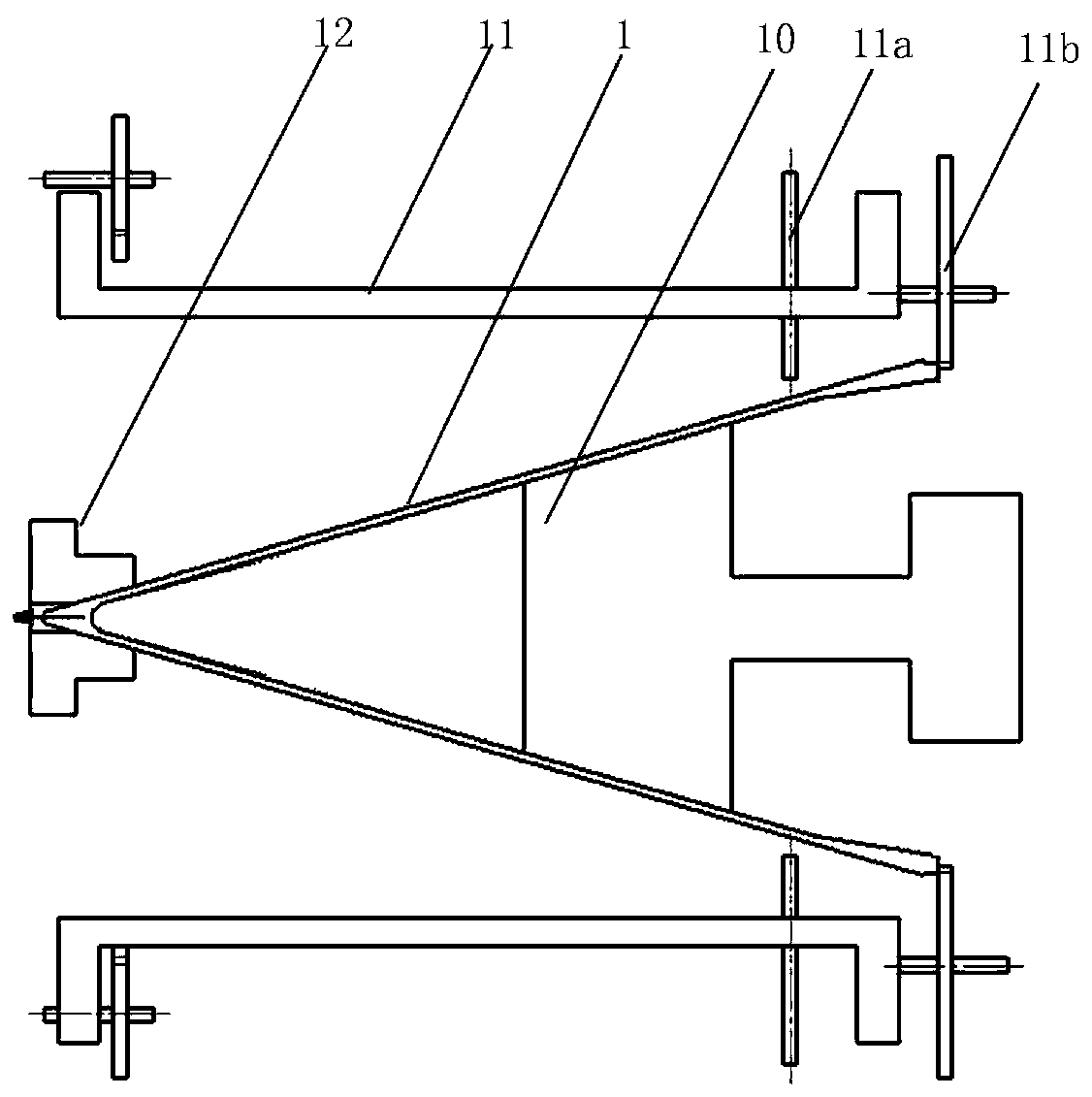

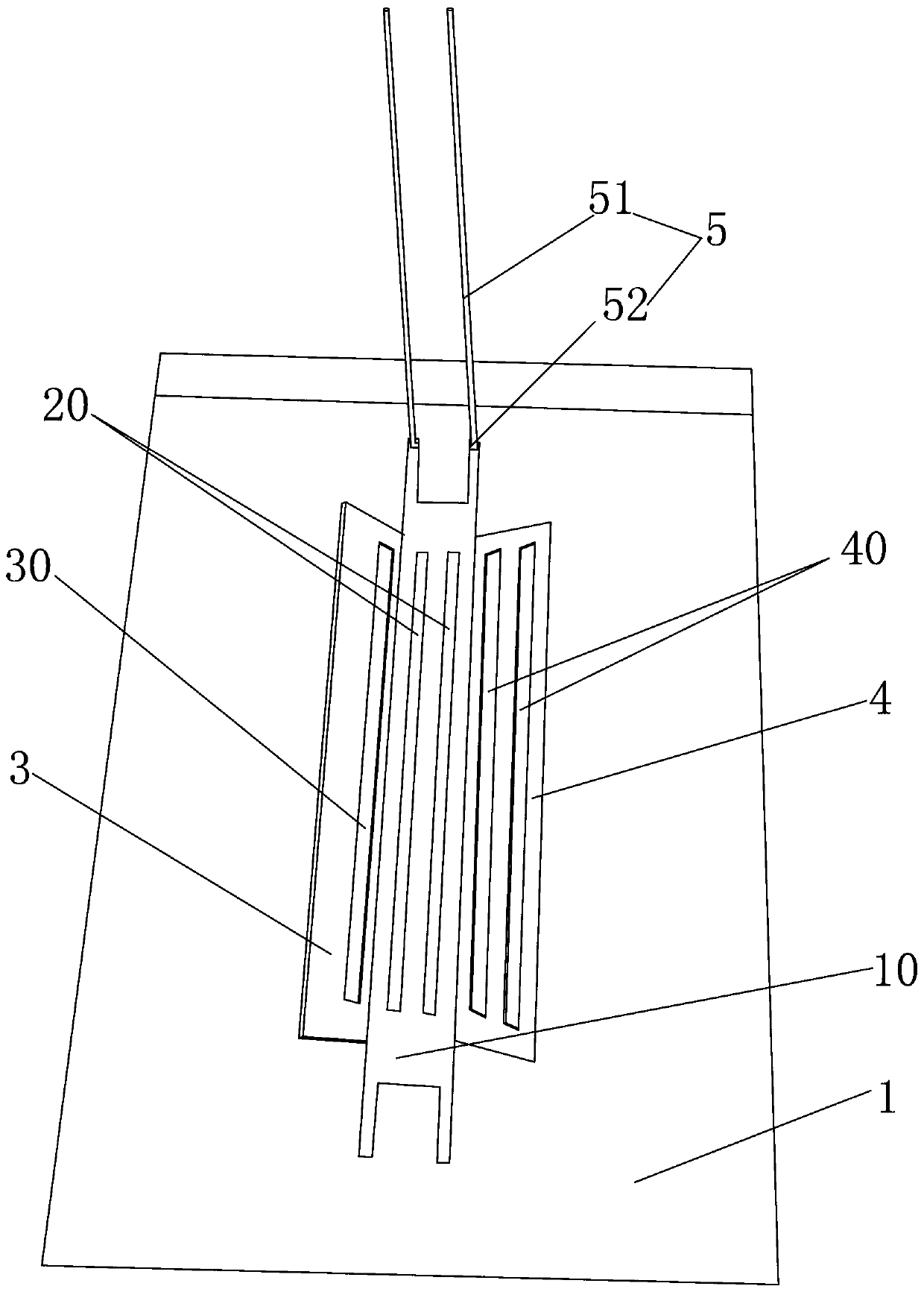

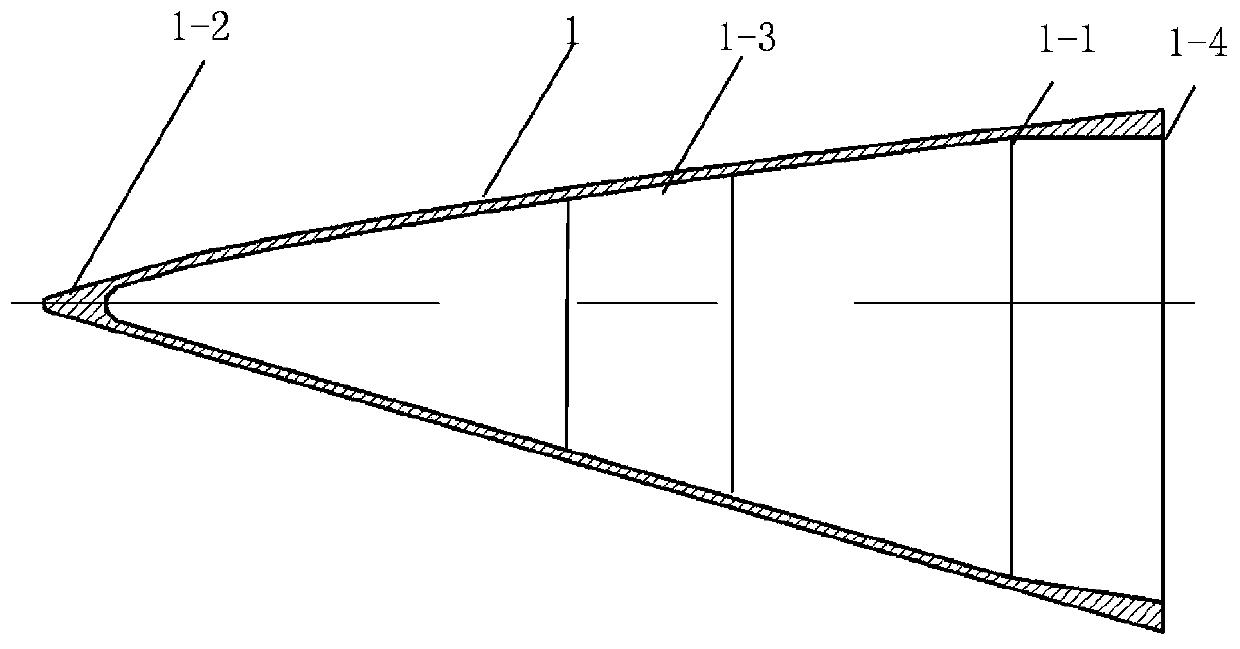

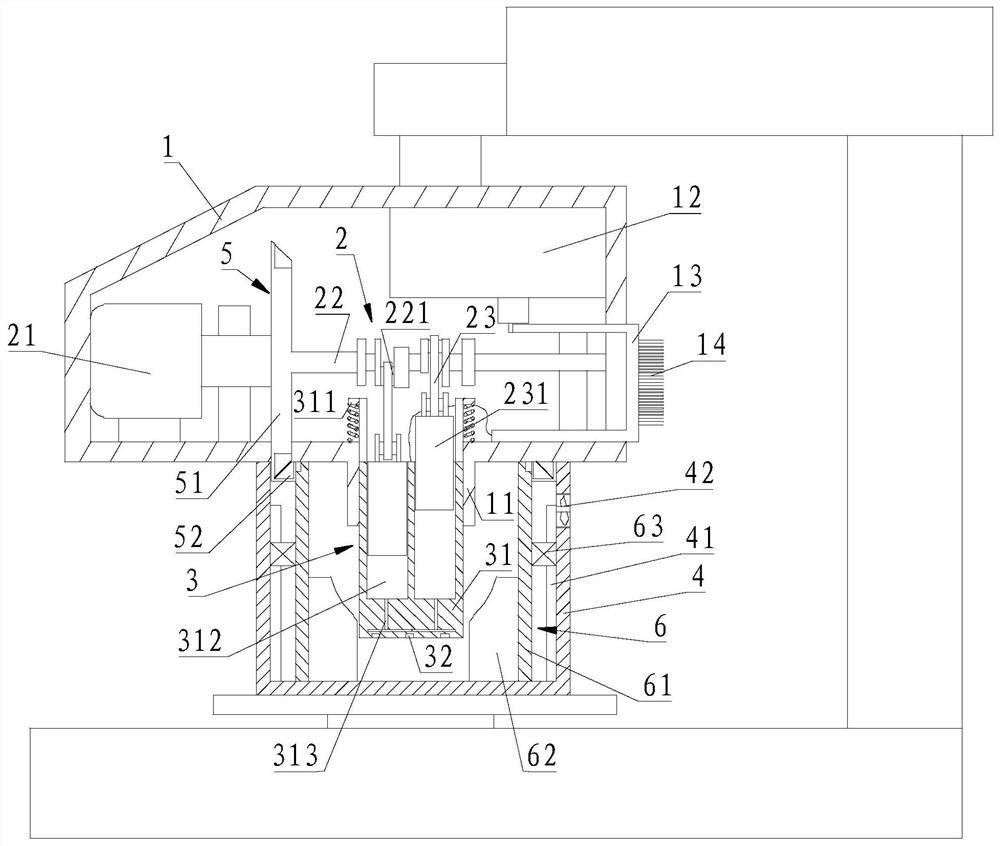

Special-shaped ceramic antenna cover machining device and method

ActiveCN109702605AUnified processing standardsControl machining accuracyRadiating element housingsWorking accessoriesMechanical engineeringEngineering

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

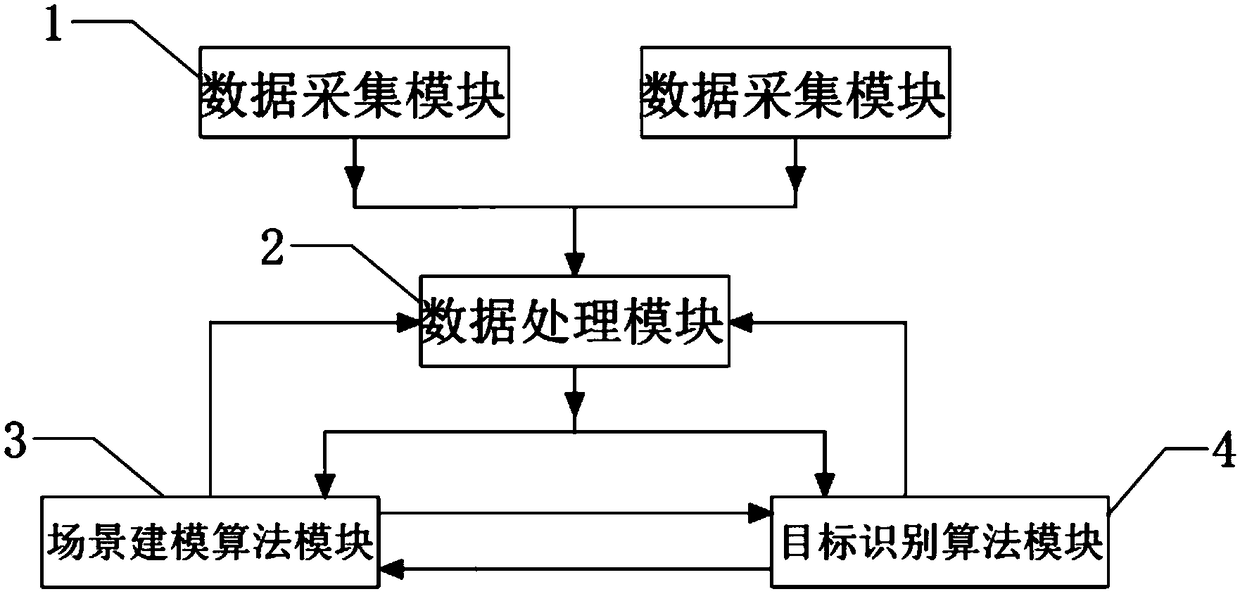

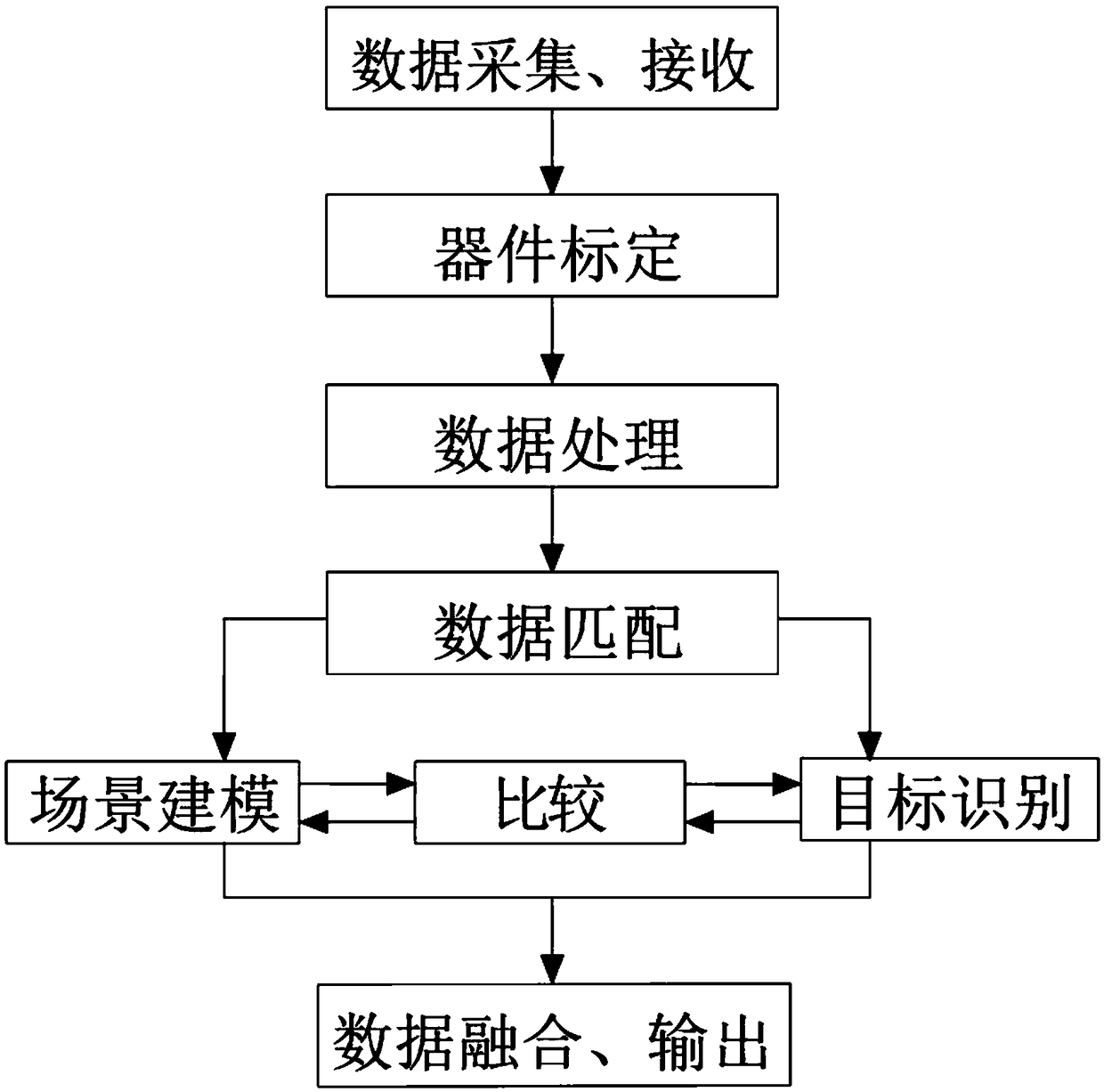

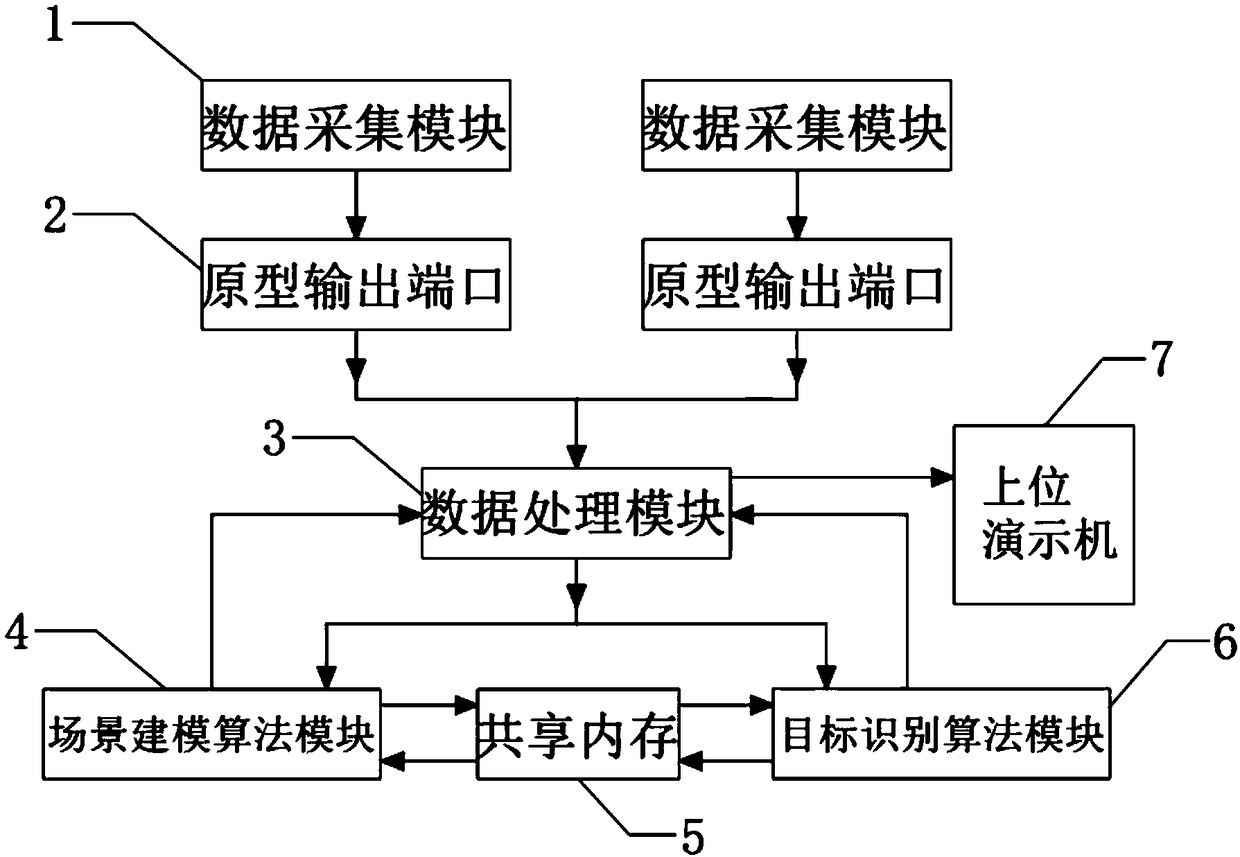

target recognition and scene modeling system based on RGBD

PendingCN109344813AProcessing speedImprove accuracyScene recognitionInternal combustion piston enginesData setGoal recognition

The invention discloses a target recognition and scene modeling system based on RGBD, which relates to the technical field of target recognition. The system includes data acquisition module, data processing module, scene modeling algorithm module, target recognition algorithm module, data acquisition module is used to collect RGBD images; The data processing module is used for storing the local data set, controlling the work of each functional module, and processing the data transmitted from each functional module. The scene modeling algorithm module is used for scene modeling; A target recognition algorithm module is use for target recognition; Data exchange between scene modeling algorithm module and target recognition algorithm module, and work according to each other 's data. Through the simultaneous target recognition and scene modeling, the data obtained from the target recognition module and scene modeling module are exchanged, evaluated and fused to form a processing mechanism.The system solves the problem of slow processing speed in the traditional system, and improves the accuracy of target recognition.

Owner:BENEWAKE BEIJING TECH CO LTD

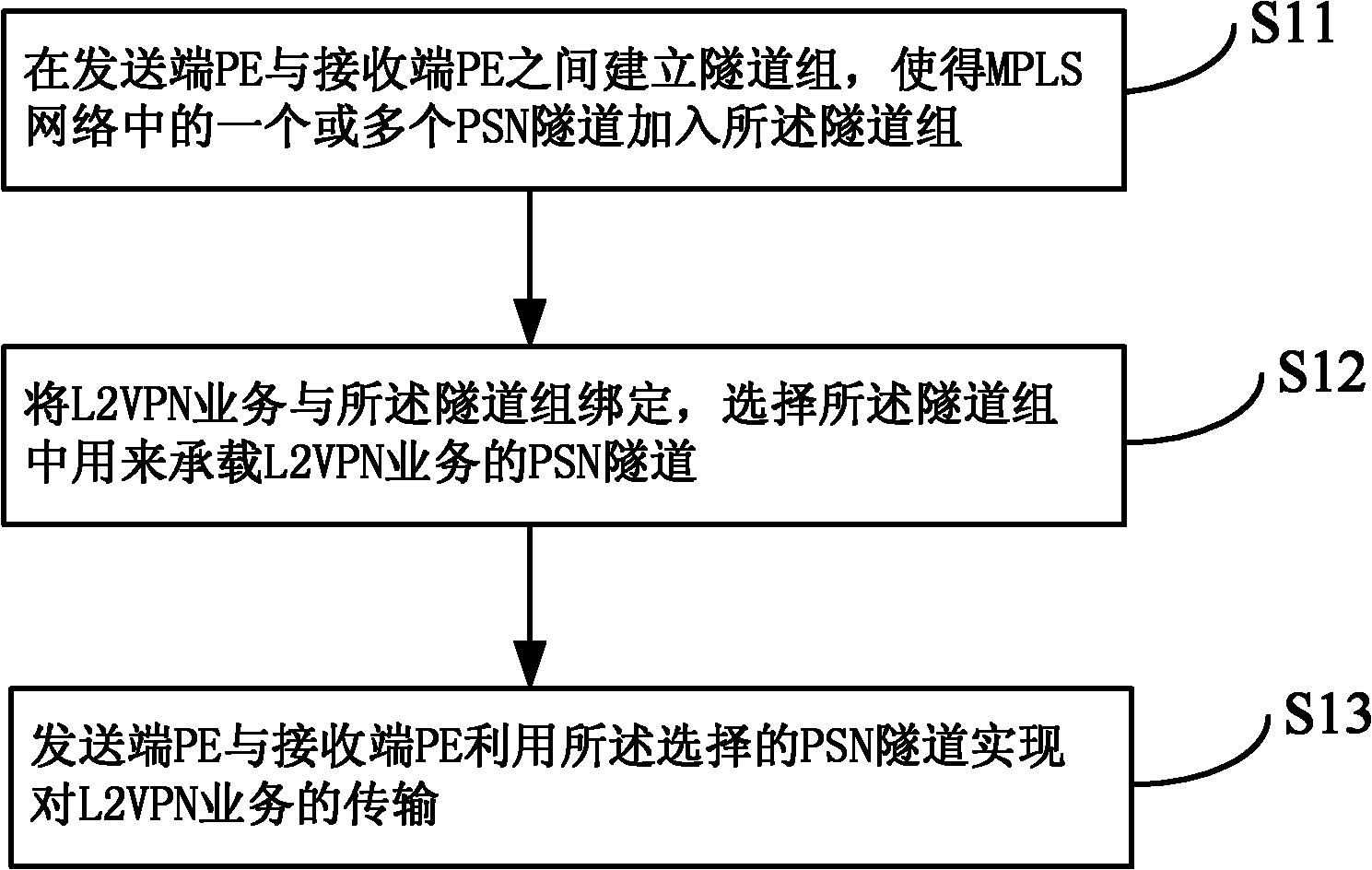

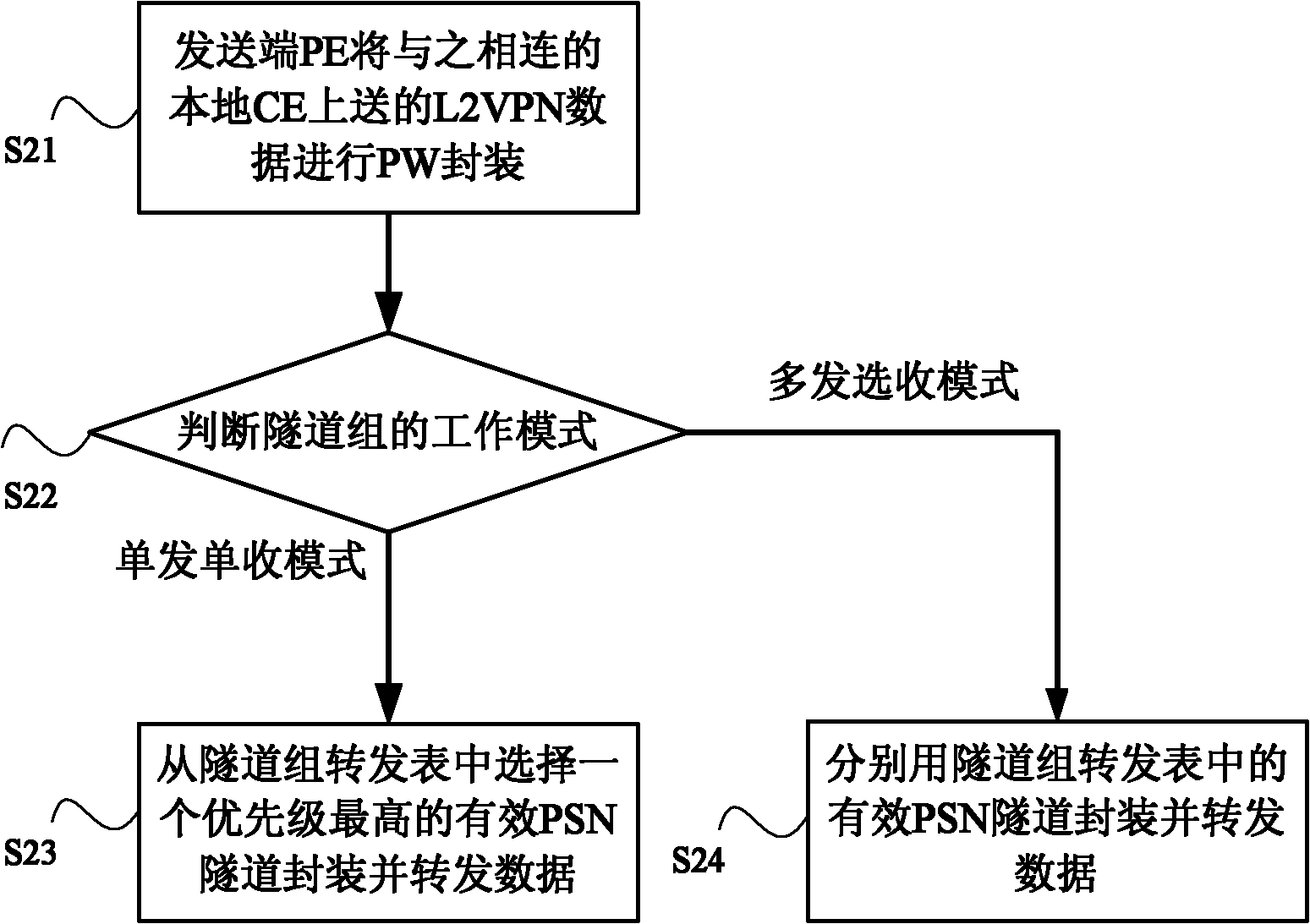

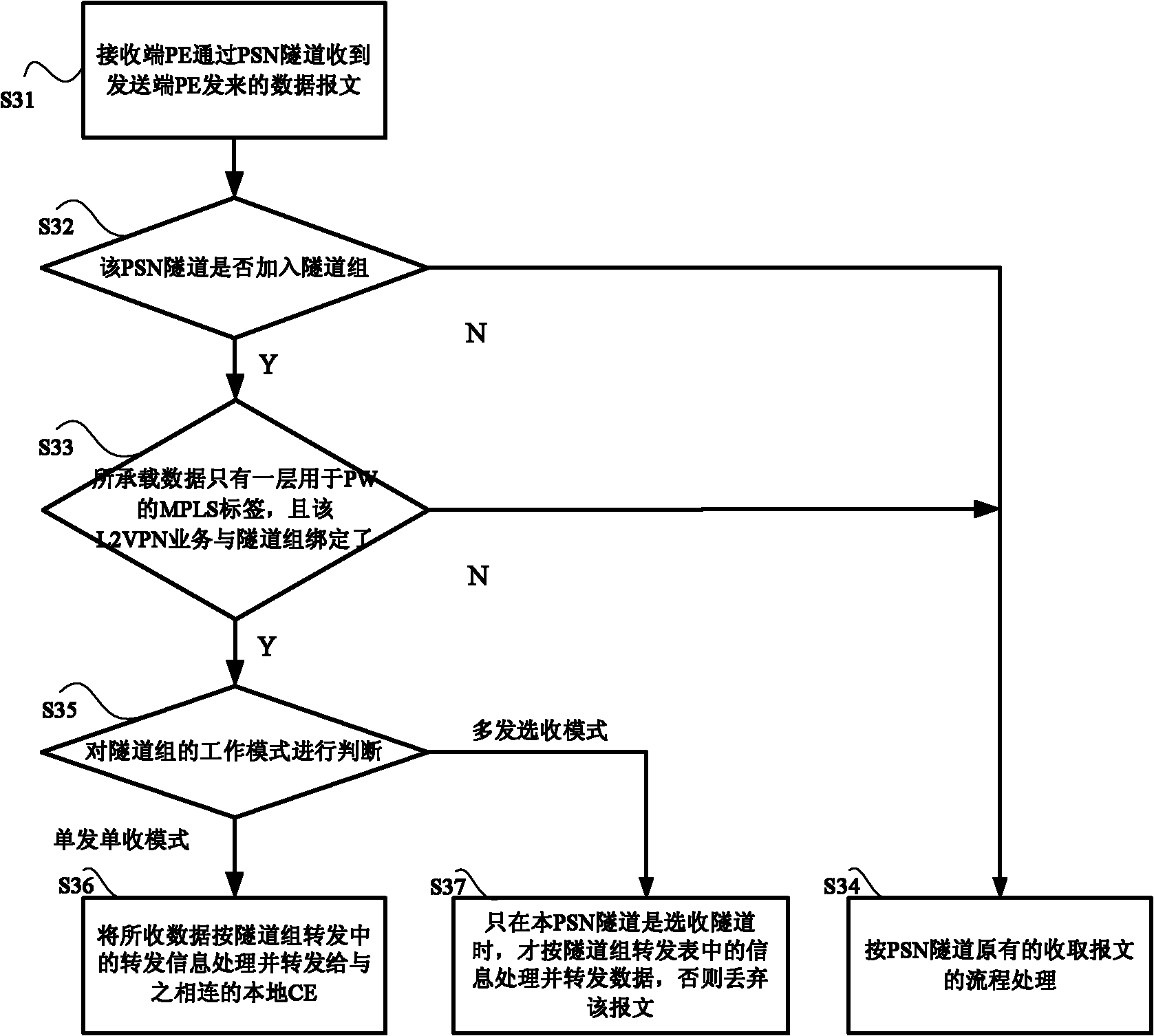

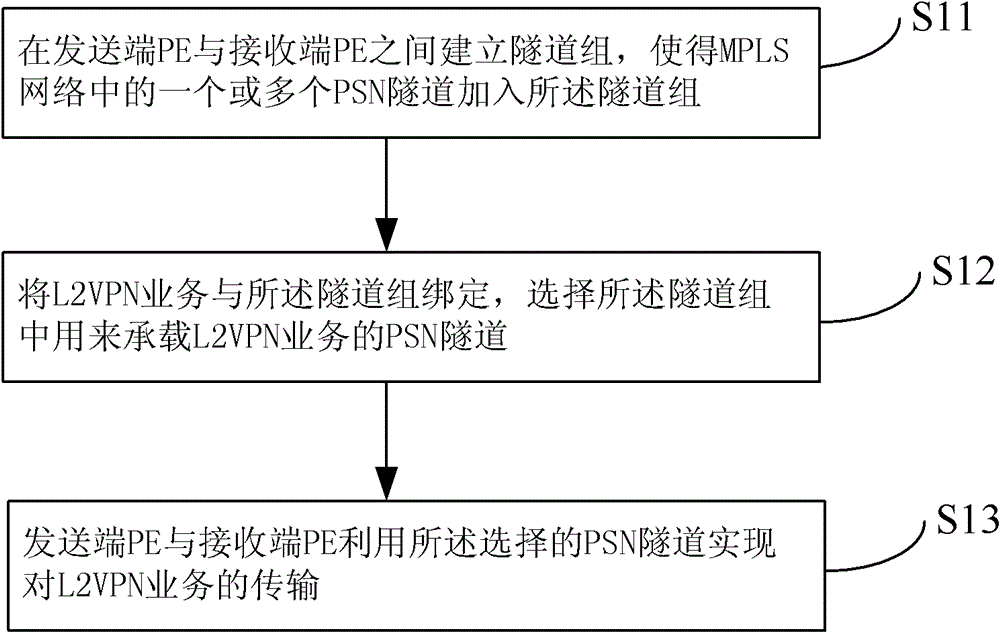

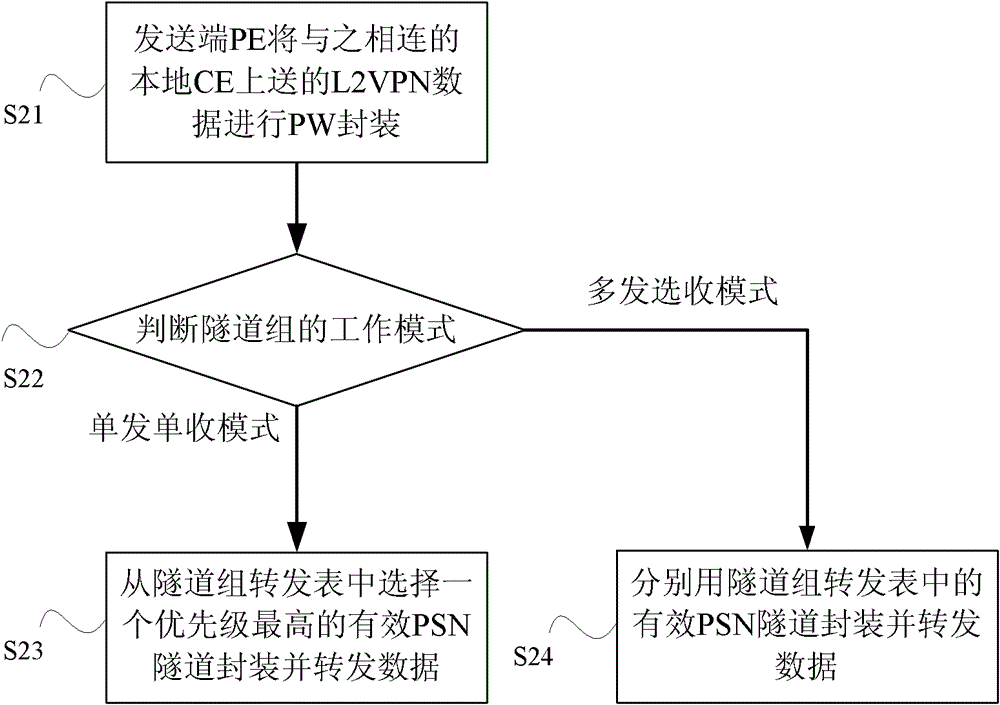

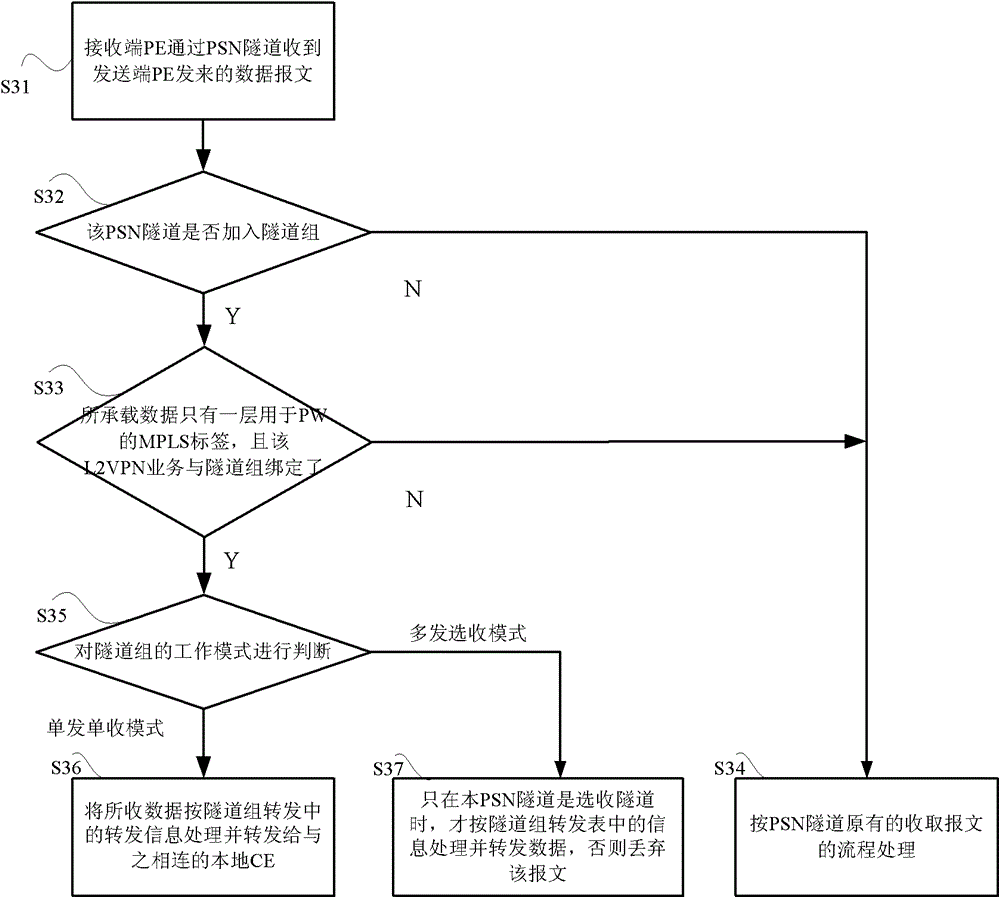

Method and device for transmitting L2VPN service by using tunnel group in MPLS network

InactiveCN102065020AImprove scalabilitySimple configurationNetworks interconnectionExtensibilityPrivate network

The invention relates to a method and a device for transmitting a layer 2 virtual private network (L2VPN) service by using a tunnel group in a multi-protocol label switching (MPLS) network. The method comprises the following steps of: establishing the tunnel group between a transmitting end provider edge device (PE) and a receiving end PE, so that one or more packet switching network (PSN) tunnels in the MPLS network join in the tunnel group; binding the L2VPN service with the tunnel group, and selecting a PSN tunnel for bearing the L2VPN service in the tunnel group; and transmitting the L2VPN service by using the transmitting end PE and the receiving end PE through the selected PSN tunnel. The protection of pseudo wires (PWs) can be neglected in the L2VPN service, and the tunnel group can protect the PWs. The tunnel group technology has high extensibility, can support the conventional MPLS tunnel technology, and also can conveniently support MPLS tunnel technology which possibly occurs in the future. The tunnel group is easy to configure, and the configuration of the tunnel group can be dynamically modified in the state that the L2VPN service is not interrupted.

Owner:ZTE CORP

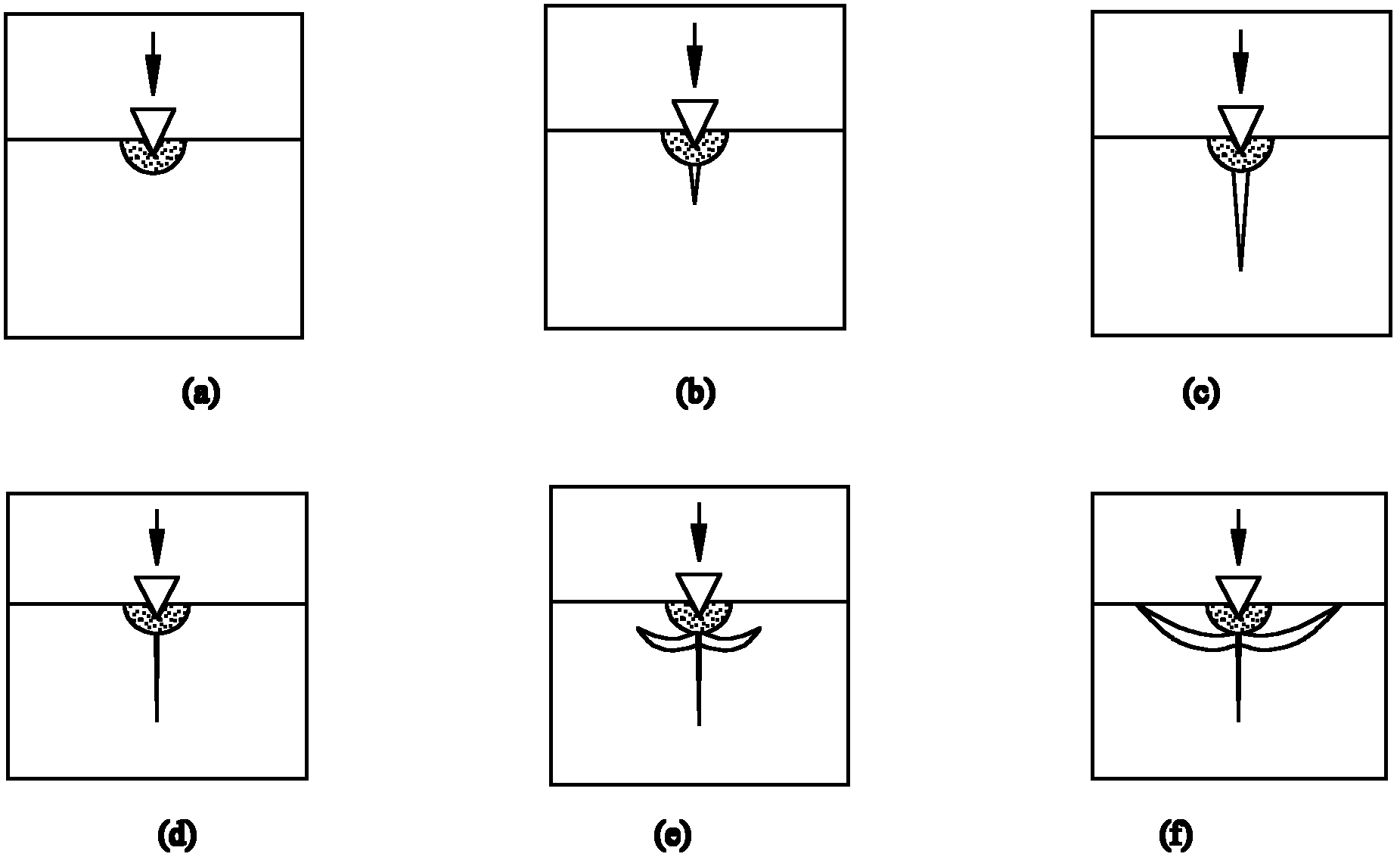

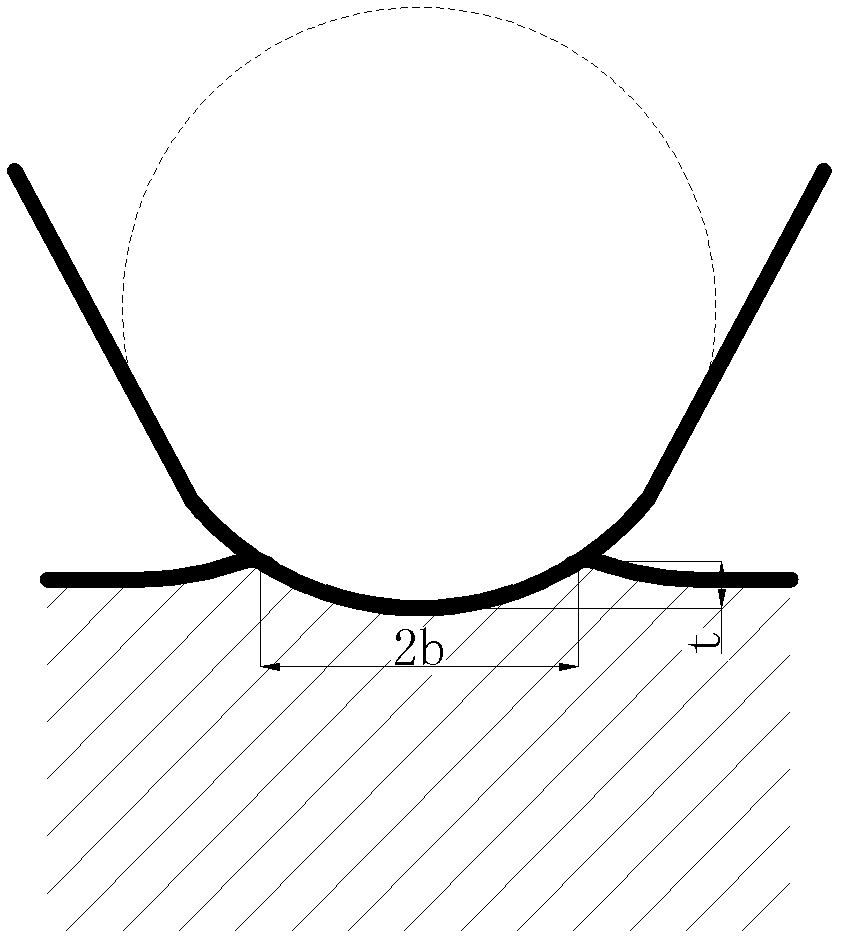

Method for detecting critical cutting depth of hard and brittle ceramic material

ActiveCN102564336AConsistent processingThe analysis result is accurateUsing optical meansWhite lightMaterials science

The invention relates to a method for detecting the critical cutting depth of a hard and brittle ceramic material. The method comprises the following steps of: (1), firstly, sticking a thin gasket on a basal disc, taking a polished hard and brittle ceramic material slice with an ultra-smooth surface and without scratches as a work-piece slice, and putting the work-piece slice on the thin gasket to be stuck, so that the work-piece slice forms a tiny slope; (2), enabling the particle size number, processing load, processing rotation speed and processing liquid of a grinding disc to be the same to those under experimental processing conditions, wherein abrasive particles form micro cutting marks from shallow to deep on the surface of the work-piece slice during processing; and (3), tracking and observing the cutting marks of the abrasive particles in a processing transition area by adopting a white light interferometer, finding out the cutting marks, with obvious plastic and brittle conversion characteristics, of the abrasive particles, finding out a first fragmental crack, and carrying out two-dimensional outline analysis on the first fragmental crack, wherein the cutting mark depth of the fragmental crack is defined as the critical cutting depth of the hard and brittle ceramic material. The method disclosed by the invention has the advantages of high detection precision and good reliability.

Owner:ZHEJIANG UNIV OF TECH

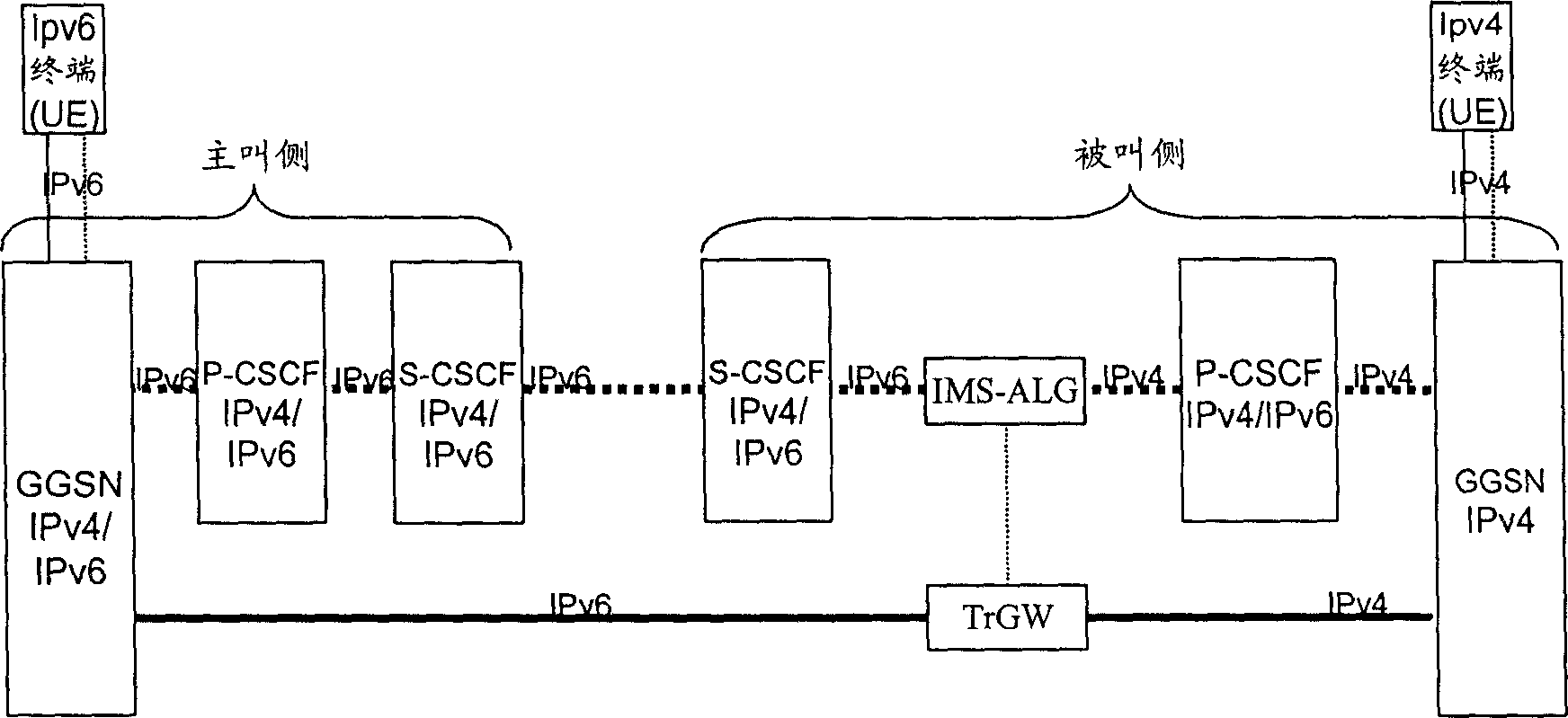

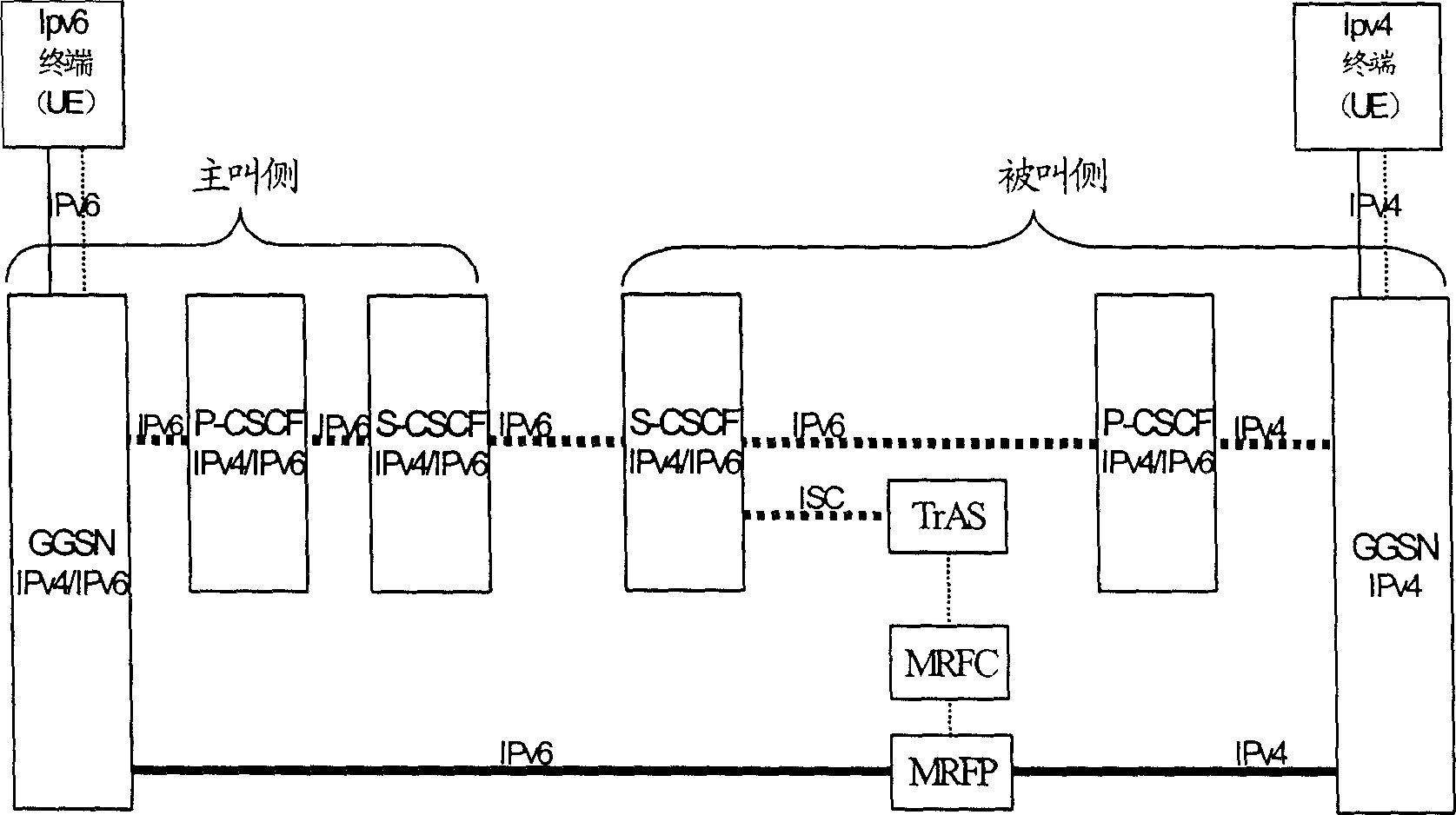

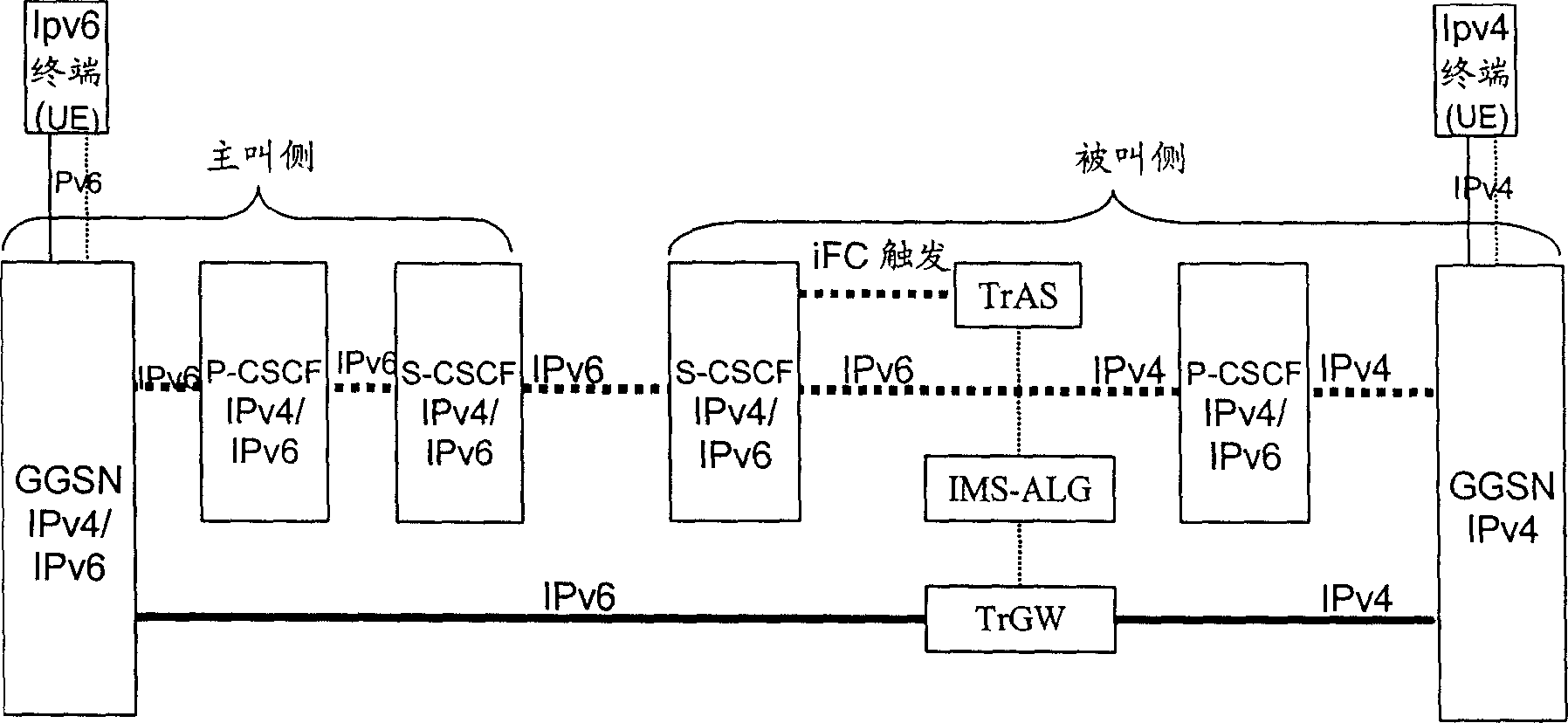

Method of communicating between different protocal of terminal user interface of IP multimedia subsystem

This invention discloses a method for mutual communicating between the terminal user surfaces of Ipv4 and Ipv6 of IMS including: 1, a calling terminal starts up a session request to a called terminal based SIP, 2, a service call session control function unit of the called terminal receives said session request and transfers it a transformation control unit, 3, the transformation control unit controls the transformation to finish the conversion of the address edition of the calling terminal and the called terminal IP. In this invention, an applied server logic entity is taken as a conversion unit and a signed data trigger mode is applied to enable the flows of IP edition conversion and that of code ¿Cdecode transformation completely the same.

Owner:HUAWEI TECH CO LTD

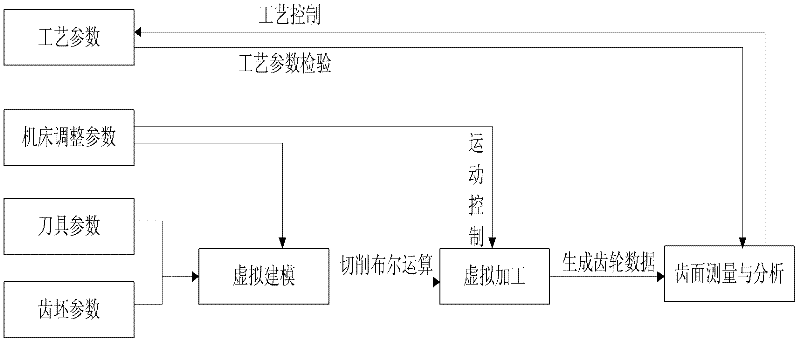

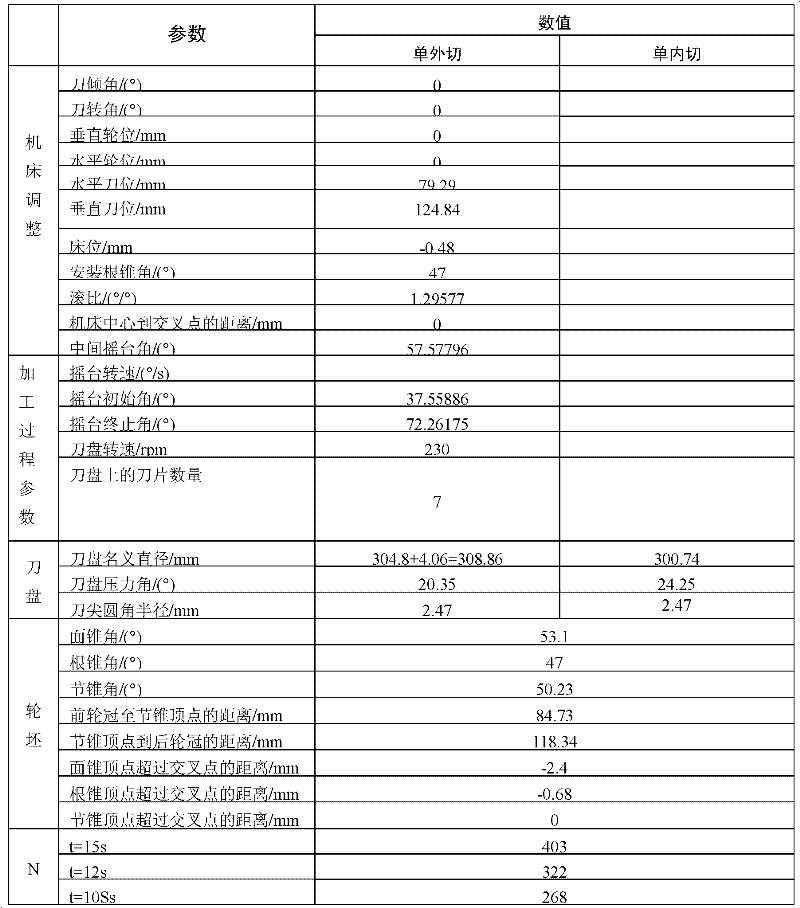

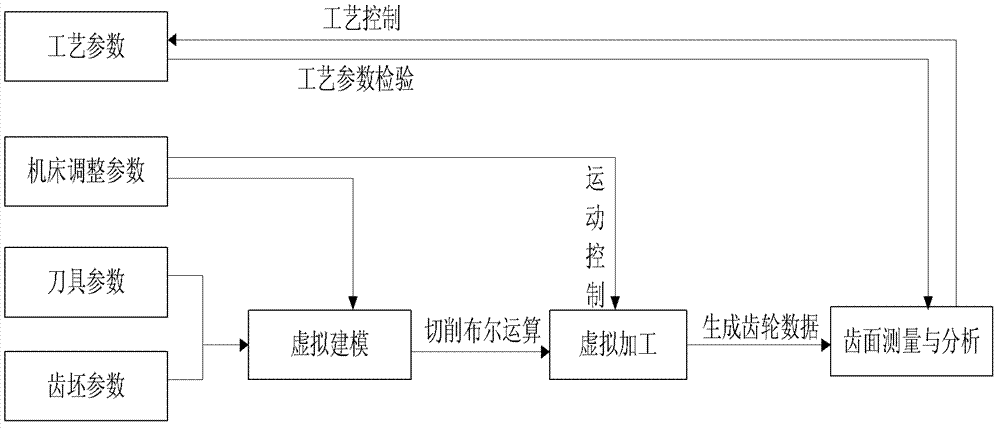

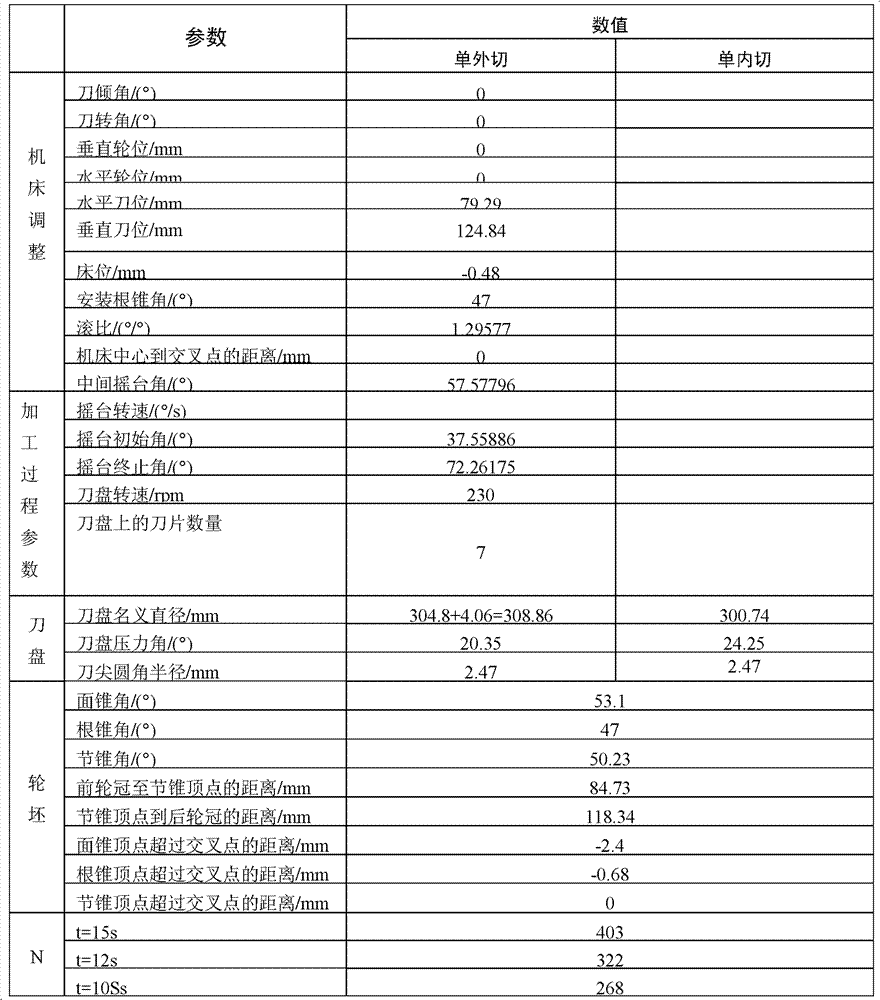

Method for controlling cutting quantity of spiral bevel gear

A method for controlling the cutting quantity of a spiral bevel gear solves the problem of adjusting processing technology parameters such as rotating speed of a cutter, number of blades on the cutter, processing time, and the like according to the cutting quantity and the precision of a tooth surface. The method comprises a cutting simulation method in the hobbing process of the spiral bevel gear and processing parameter methods for controlling a chipping simulation method and the cutting process. On the basis of a hobbing simulation method, the processing technology parameters, tool adjusting parameters, tool adjusting parameters and cutter and tooth billet parameters are adopted for conducting virtual three-dimensional entity molding, simulating the high-speed cutting process of the gear, and providing the method for controlling the cutting quantity. The method is applied in practical processing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for the treatment of turquoise by using aluminum phosphate salts

The invention relates to a method for the filling treatment of turquoise by using aluminum phosphate salts. A method for the treatment of turquoise by using aluminum phosphate salts is characterized in that the method comprises the following steps of: 1) pretreatment: wall rock and dirty surface are worn off on the surface of the turquoise with loose texture and are then put in a constant-temperature drying box for being dried for 3-4 hours at 80-110 DEG C after being cleaned, so as to obtain the pretreated turquoise; 2) preparation of an adhesive: KH2PO4, NaH2PO4 and MgO are respectively ground to 200 meshes and are then selected based on the proportion of Al(H2PO4)3 solution KH2PO4:NaH2PO4:MgO = 800mL:2-10g:1-20:1-20g to be mixed and stirred evenly, thus resulting in the adhesive; 3) the pretreated turquoise is vacuumized and then soaked in the adhesive for 1-30 days at 15-30 DEG C under normal pressure of 40Mpa; the turquoise is taken out and put into the constant-temperature drying box for heating and curing, upon the ending of the heating, the turquoise is naturally cooled to room temperature and is subsequently polished to a finished product. The method has simple process, low cost and good simulation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

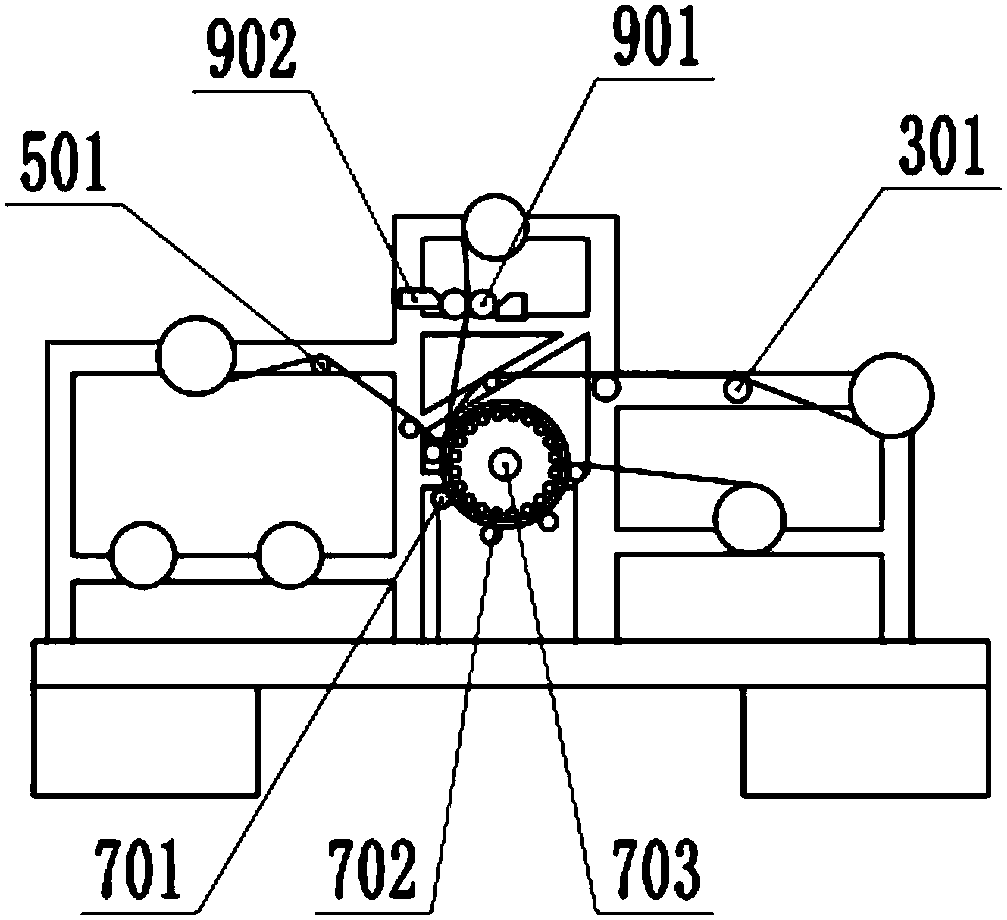

Three-layer glue coating compound machine for cloth and use method thereof

InactiveCN108045067AReduce stepsSave electricityLaminationLamination apparatusPulp and paper industryPulley

The invention discloses a three-layer glue coating compound machine for cloth. A bracket is arranged on a base and includes a first bracket body, a second bracket body and a third bracket body which are connected with one another in sequence; a first cloth discharging roller is arranged on the first bracket body, a cloth collecting roller is arranged at the lower end of the first cloth dischargingroller, a second cloth discharging roller is arranged at the upper end of the second bracket body, and a glue coating device is arranged at the lower end of the second cloth discharging roller; a compound roller is arranged at the lower end of the glue coating device, a third cloth discharging roller is arranged on the third bracket body, and the glue coating device comprises glue coating rollersand glue boxes; one glue box and one glue coating roller are fixedly arranged beside a vertical rod of the second bracket body, the lower end of the other glue box is provided with a fixing pin, thetwo ends of the other glue coating roller are provided with connecting rotation shafts connected with sliding wheels, and wheel grooves are formed in the upper end of a transverse rod of the second bracket body and matched with the sliding wheels. A bracing plate is arranged on one side of a cross beam of the second bracket body and provided with a fixing hole, and the fixing hole is matched withthe fixing pin.

Owner:阮甜

Novel method for manufacturing microprism type light reflecting material mold

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

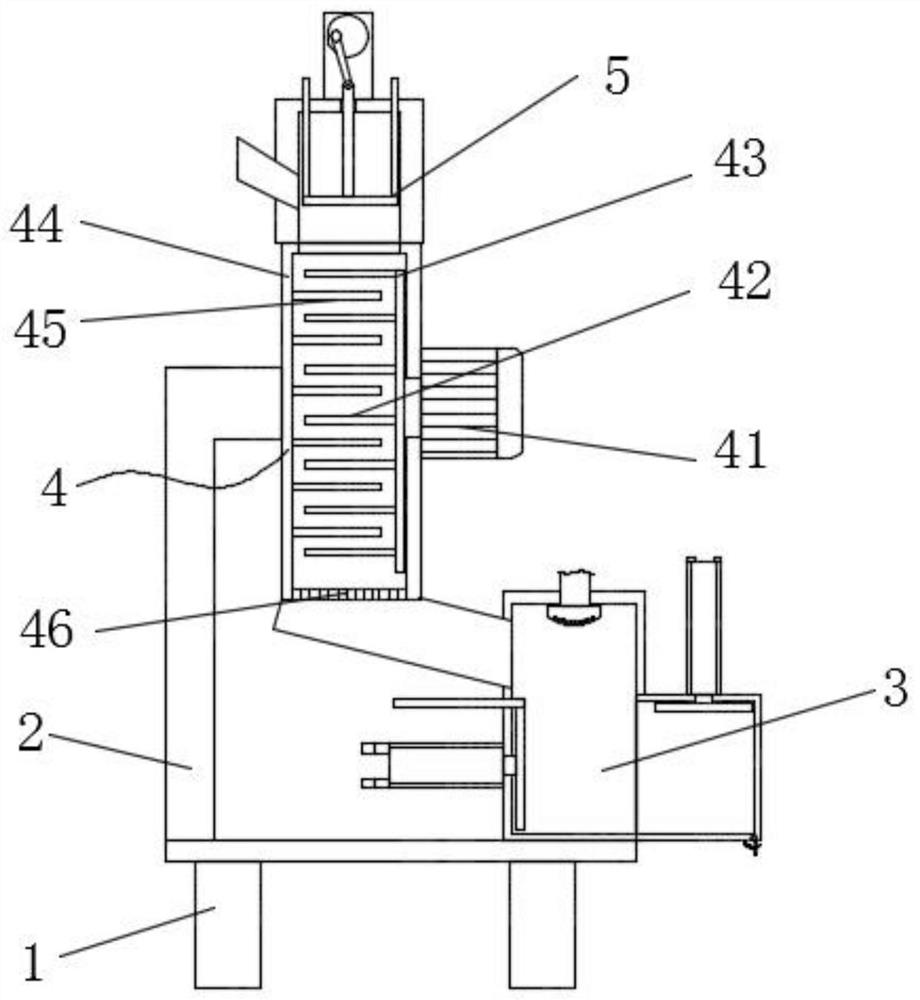

Crop waste smashing and compressing device

The invention relates to the technical field of agricultural waste treatment equipment and provides a crop waste smashing and compressing device. The crop waste smashing and compressing device comprises a supporting frame, a fixed beam, a compression forming structure, a smashing structure and a pushing structure. The fixed beam is fixed to the top side of the supporting frame, the compression forming structure is mounted on the top side of the supporting frame, the smashing structure is fixed to the top end of the fixed beam, and the pushing structure is mounted on the top side of the smashing structure. By arrangement of the pushing structure, a pushing plate is driven to reciprocate vertically to push materials under the action of a pushing motor, and accordingly waste splattering in material smashing can be avoided, and safety of feeding personnel can be guaranteed; by the smashing structure, various waste materials can be subjected to uniform smashing treatment, so that granular uniformity and convenience in subsequent treatment are realized; by synergistic operation of an extruding air cylinder and a pushing air cylinder, smashed waste can be extruded into a uniform shape prior to being discharged, and uniformity in processing and convenience in waste subsequent treatment are realized.

Owner:西安科技成果转化工程有限公司

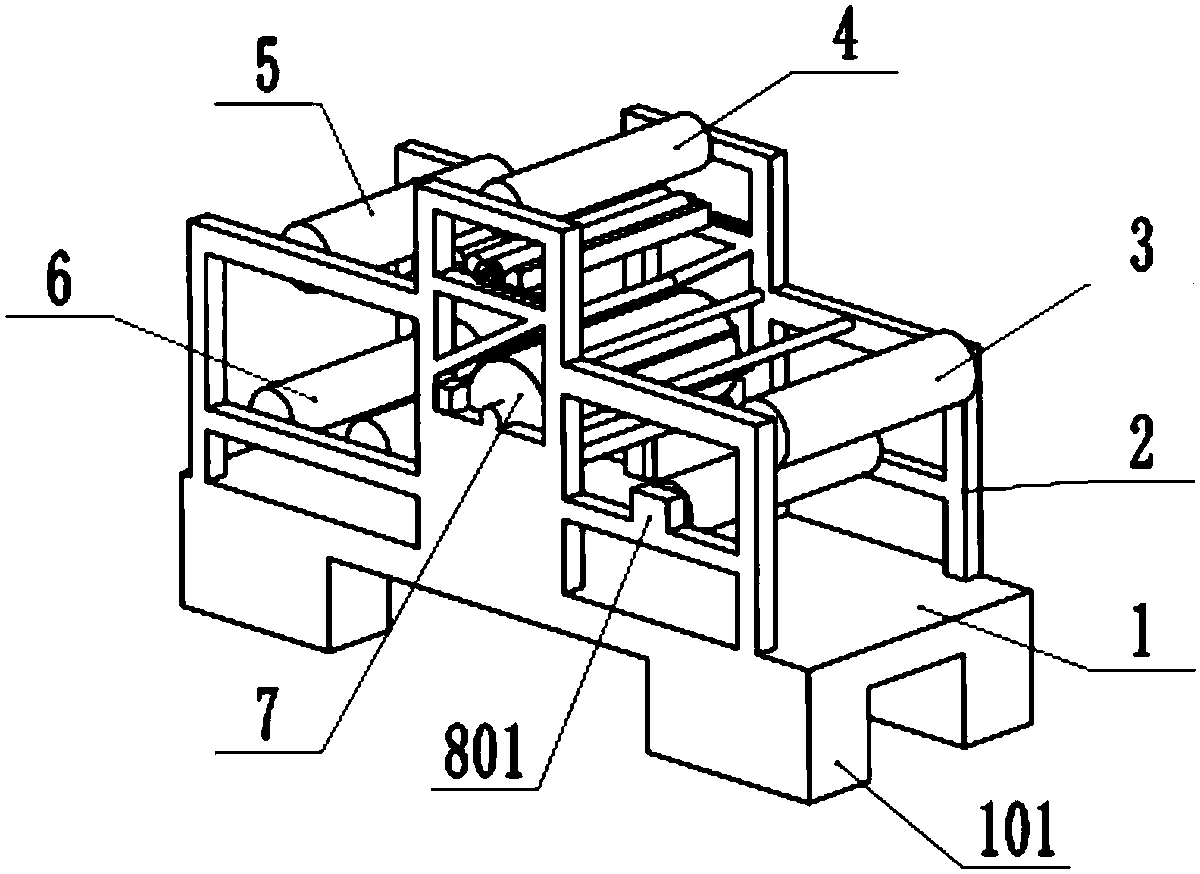

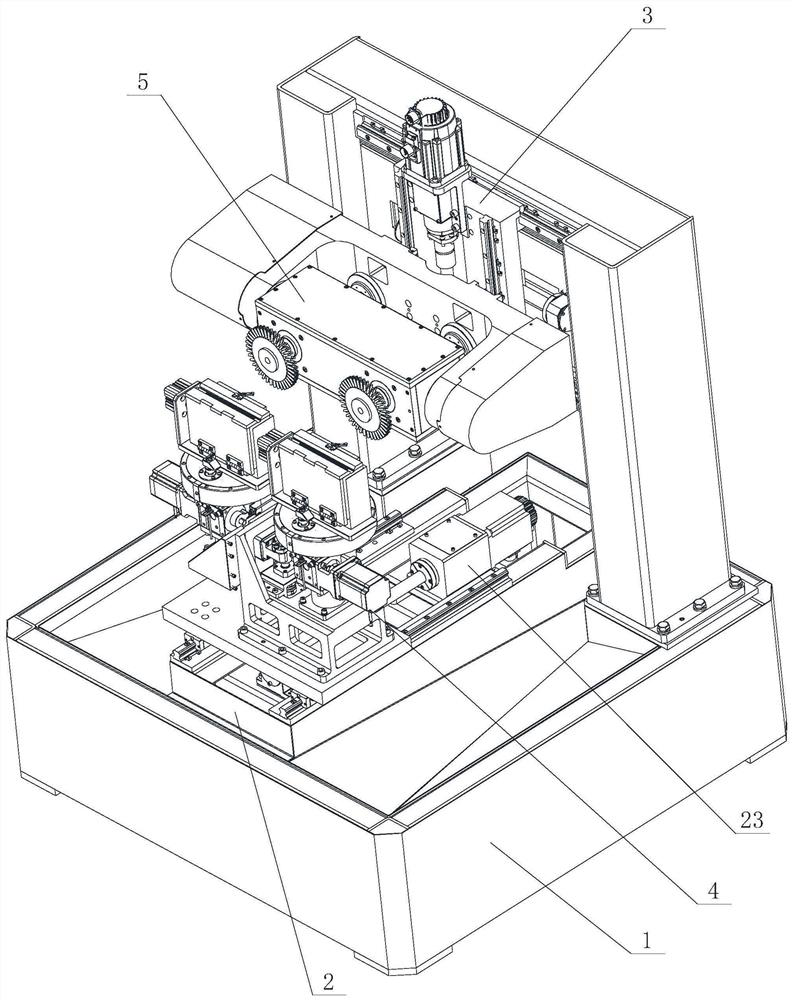

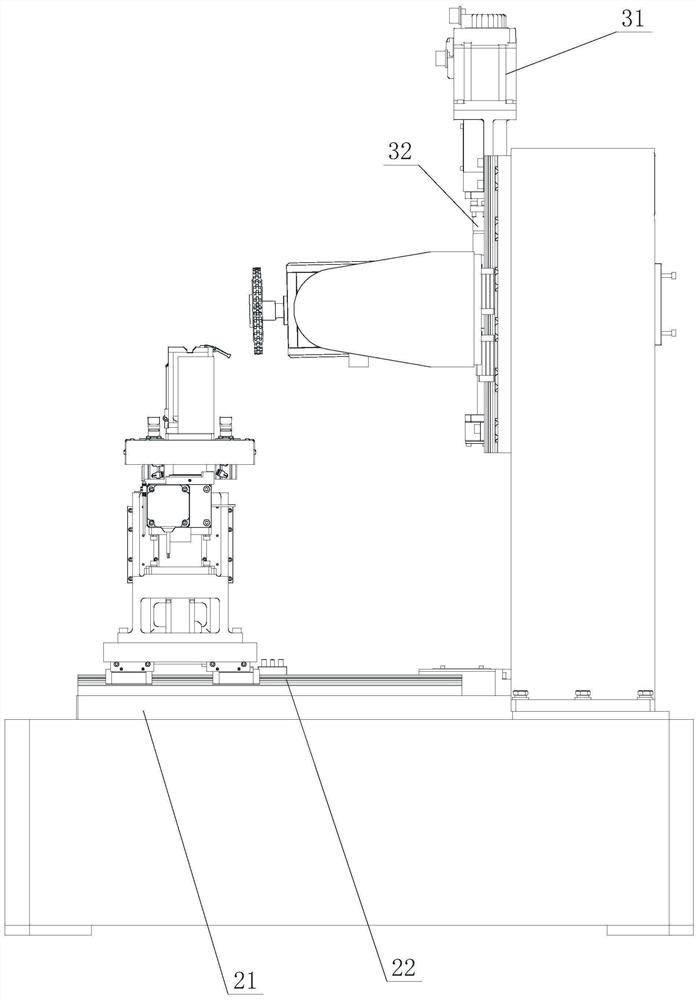

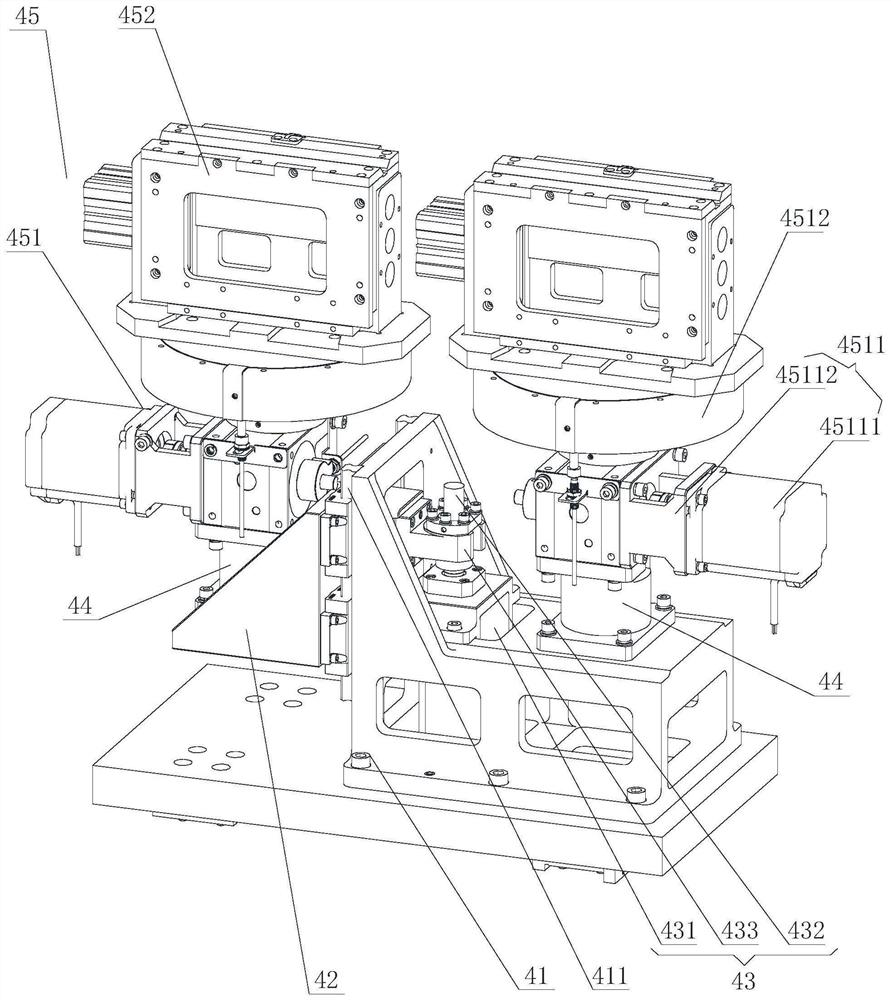

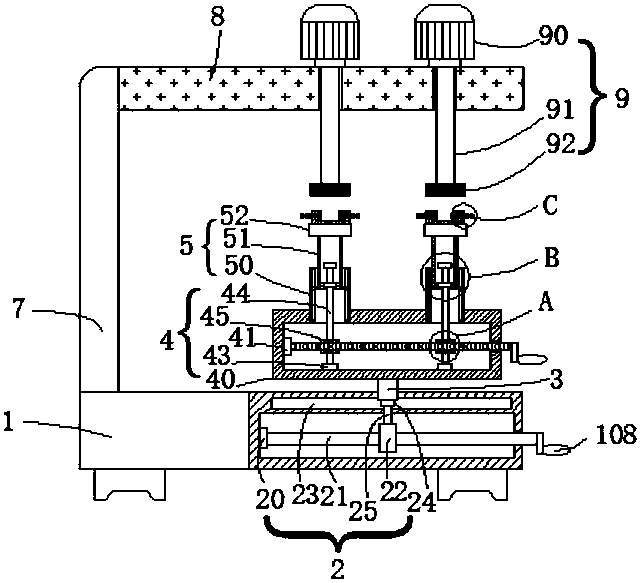

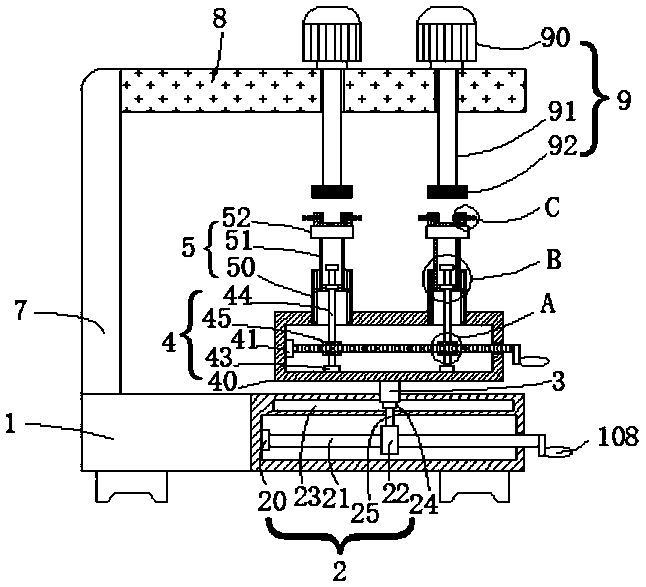

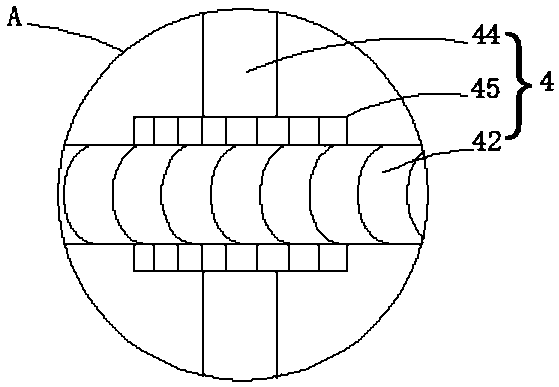

Double-station polishing machine

PendingCN112045547AConsistent forcePolishing power balanceGrinding carriagesPolishing machinesPolishingEngineering

The invention discloses a double-station polishing machine. The double-station polishing machine comprises a rack, a transverse movement driving set, a lifting driving set, a double-station pressure balance device and a polishing set, wherein the double-station pressure balance device comprises a fixing machine base, a lifting machine base, a balance lifting mechanism, a pair of pressure sensors and a pair of clamping tools, wherein the balance lifting mechanism is installed on the fixing machine base, the lifting machine base is installed on the balance lifting mechanism, the pair of pressuresensors are installed on the fixing machine base and the lifting machine base correspondingly, the pair of clamping tools are installed on the pair of pressure sensors respectively, the pair of pressure sensors and the lifting mechanism are connected through signals, the transverse movement driving set is installed on the rack, the fixing machine base is connected with the transverse movement driving set, the lifting driving set is installed on the rack, and the polishing set is connected with the lifting driving set. The double-station polishing machine has the advantages that the structureis simple and reliable, double-station polishing force balance can be achieved, and the product quality can be improved.

Owner:湖南宇环精密制造有限公司

Spherical tube machine tool and machining method thereof

PendingCN110405476AUniform forceImprove machining accuracyOther manufacturing equipments/toolsDouble-ended synchronizationEngineering

The invention provides a refrigerator freshness preservation device and a method thereof. The device comprises a machine frame, a guide rail arranged on the machine frame, and a double-ended synchronization die in sliding connection with the guide rail. The guide rail is in sliding connection with a fixture and two forming blocks furthermore. The fixture is used for clamping a workpiece. The forming blocks are located at the two ends of the workpiece, and are used for carrying out machining to form the external shapes of the two ends of the workpiece. Forming grooves which are matched with thetwo ends, formed after machining, of the workpiece in shape are formed in the forming blocks. With the refrigerator freshness preservation device and the method thereof, the workpiece which is a hollow metal tube is machined into a spherical tube, a traditional machining mode is effectively broken, the machining efficiency and the machining accuracy of the spherical tube are effectively improved,the workpiece is detected and corrected during machining, the ends of the workpiece are thickened evenly, the workpiece is improved in structural strength, and the machining quality of the sphericaltube is effectively improved; and the refrigerator freshness preservation device and the method thereof can be used for machining a metal tube into an integrally formed metal bottle or an article withother structure, and therefore being broad in application.

Owner:远军热能动力科技有限公司

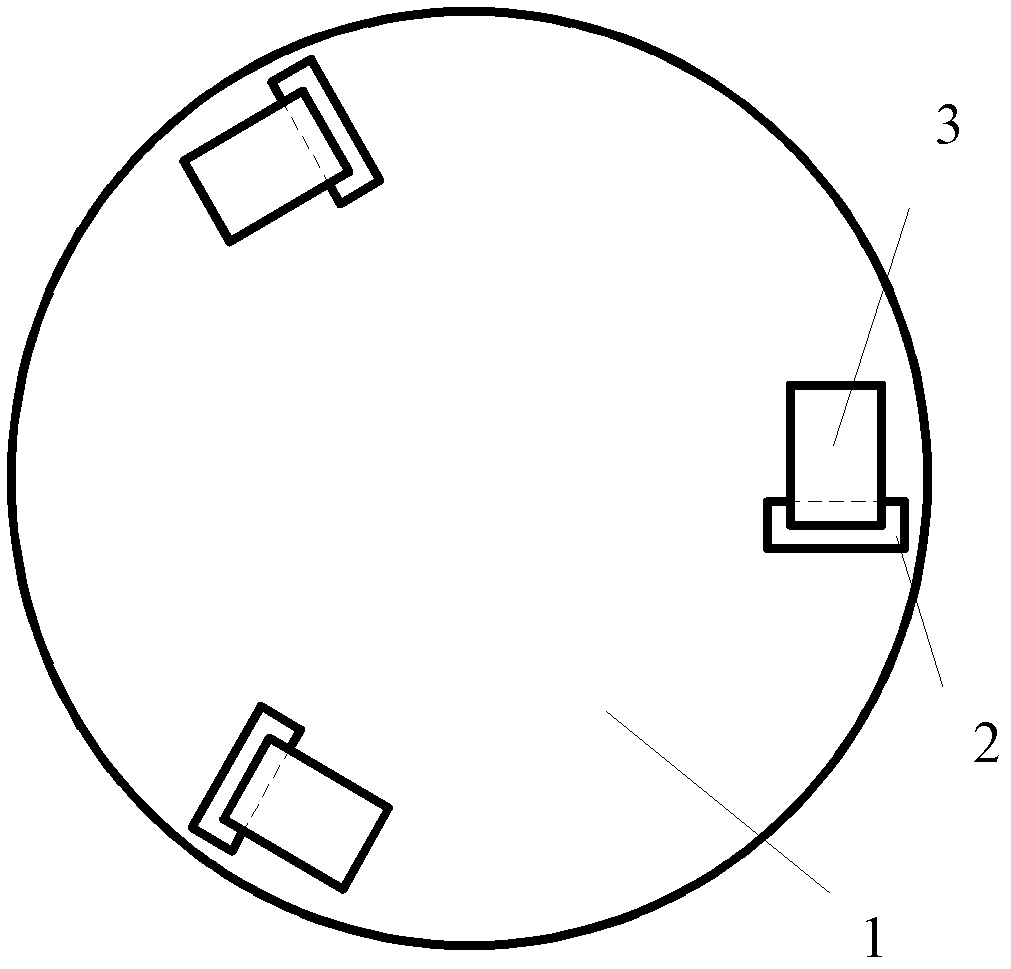

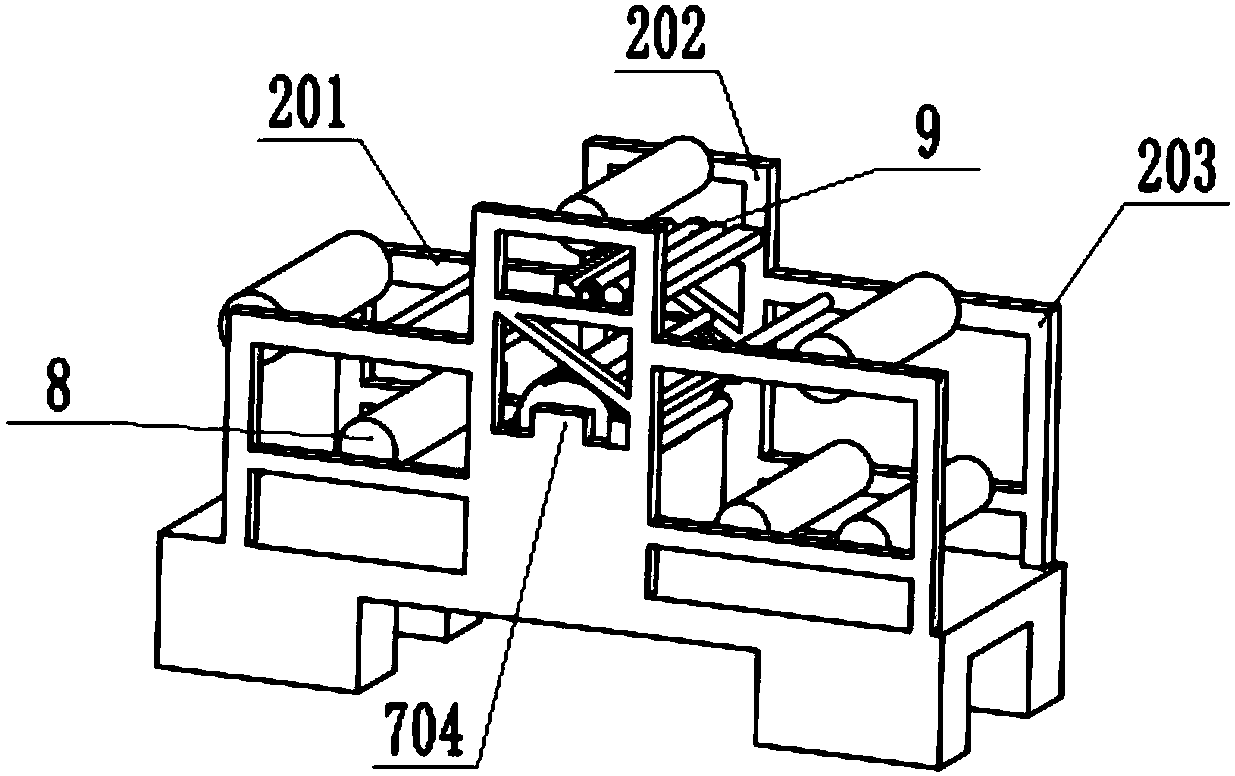

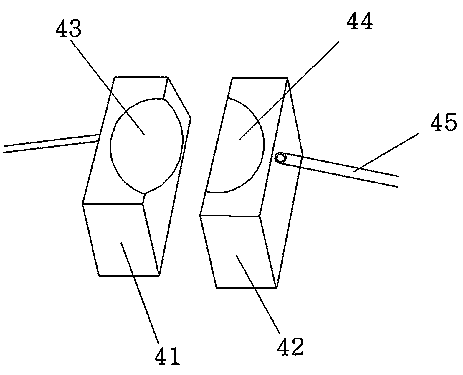

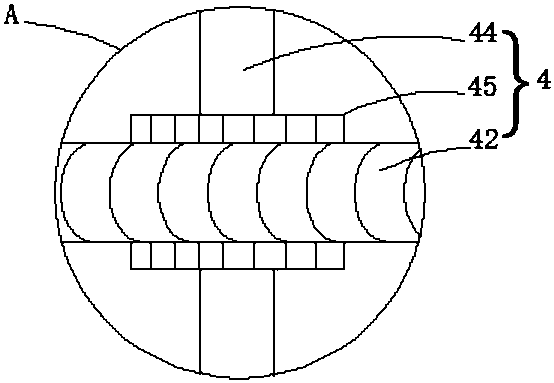

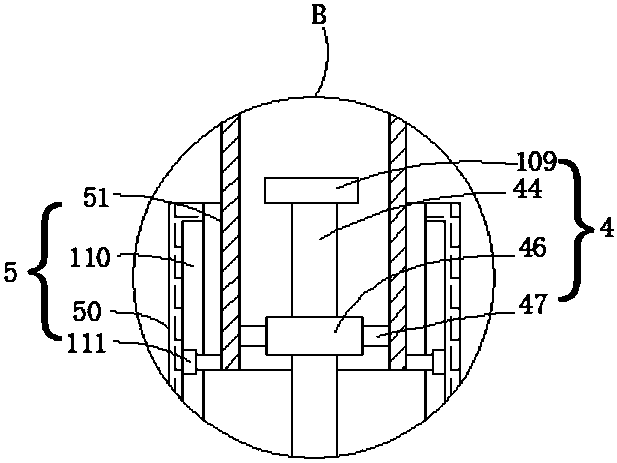

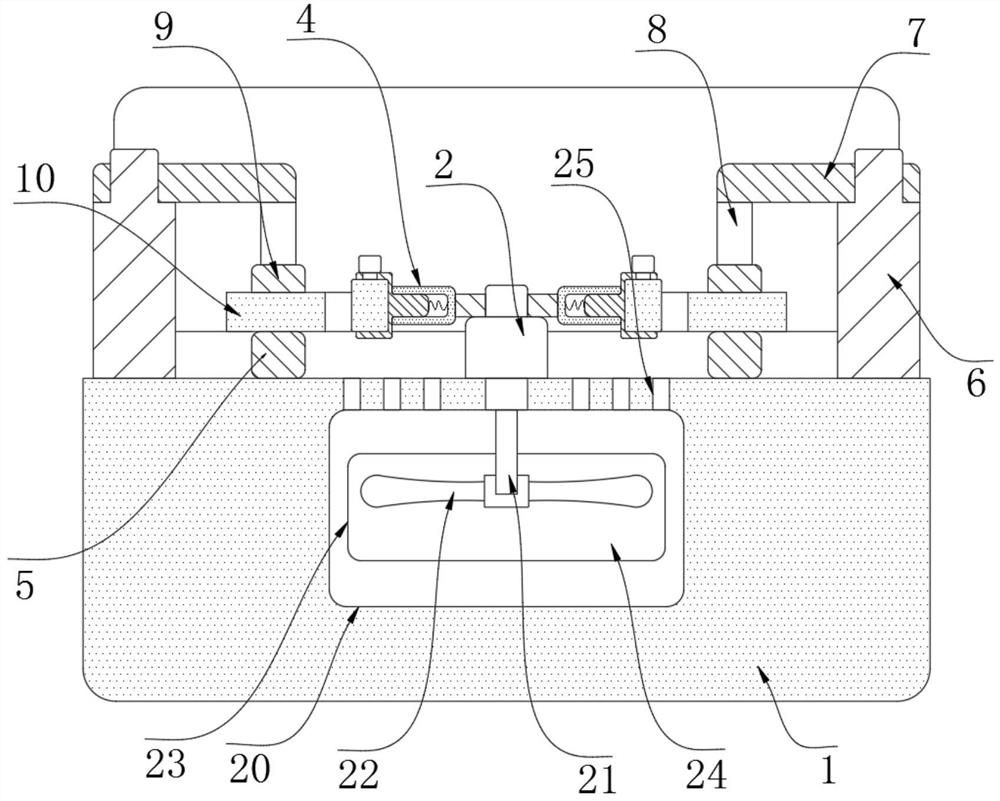

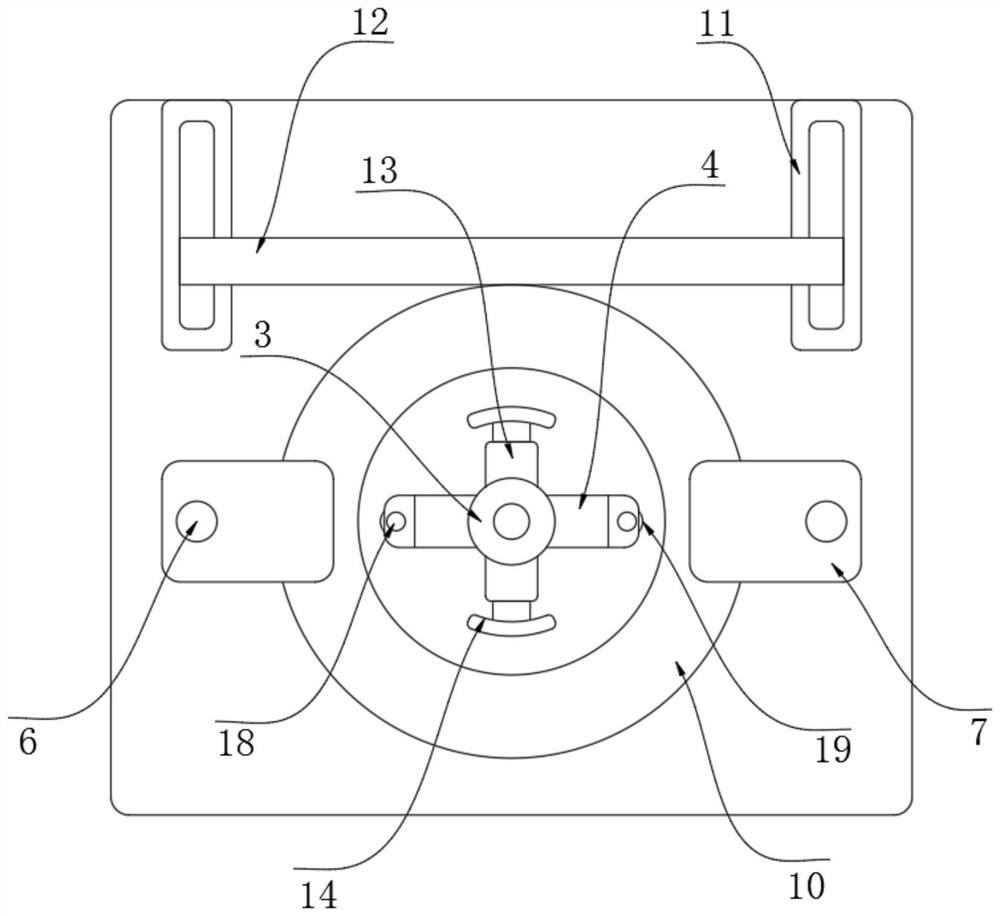

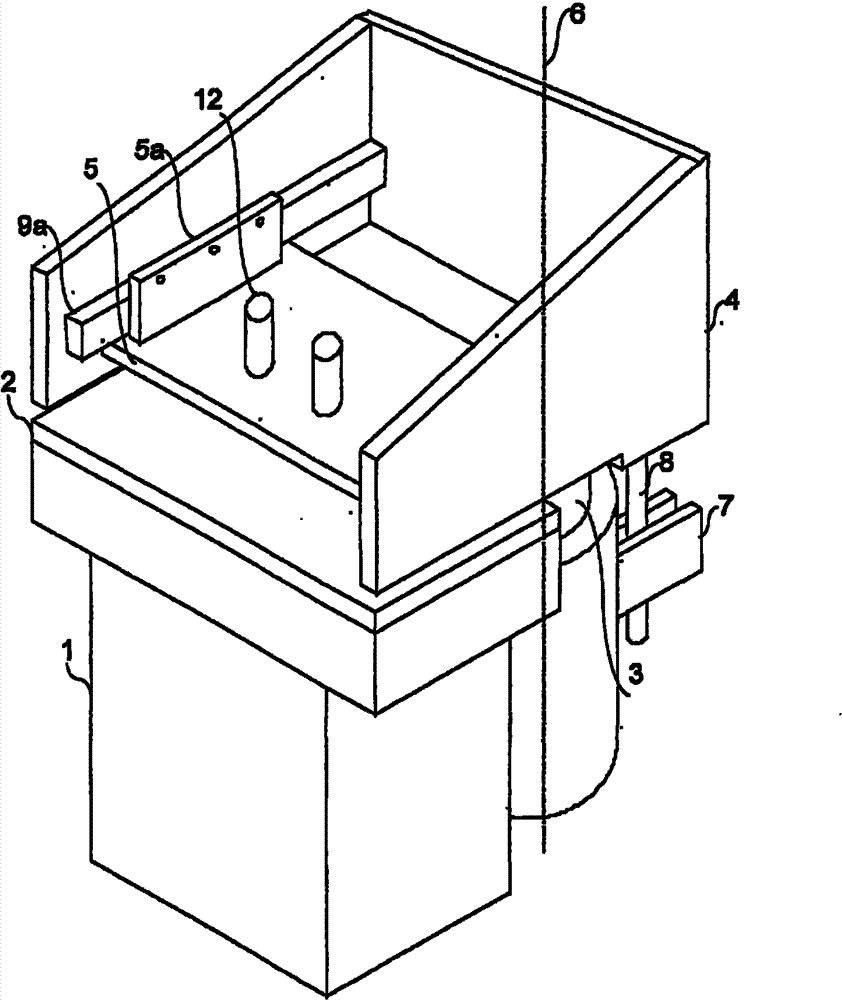

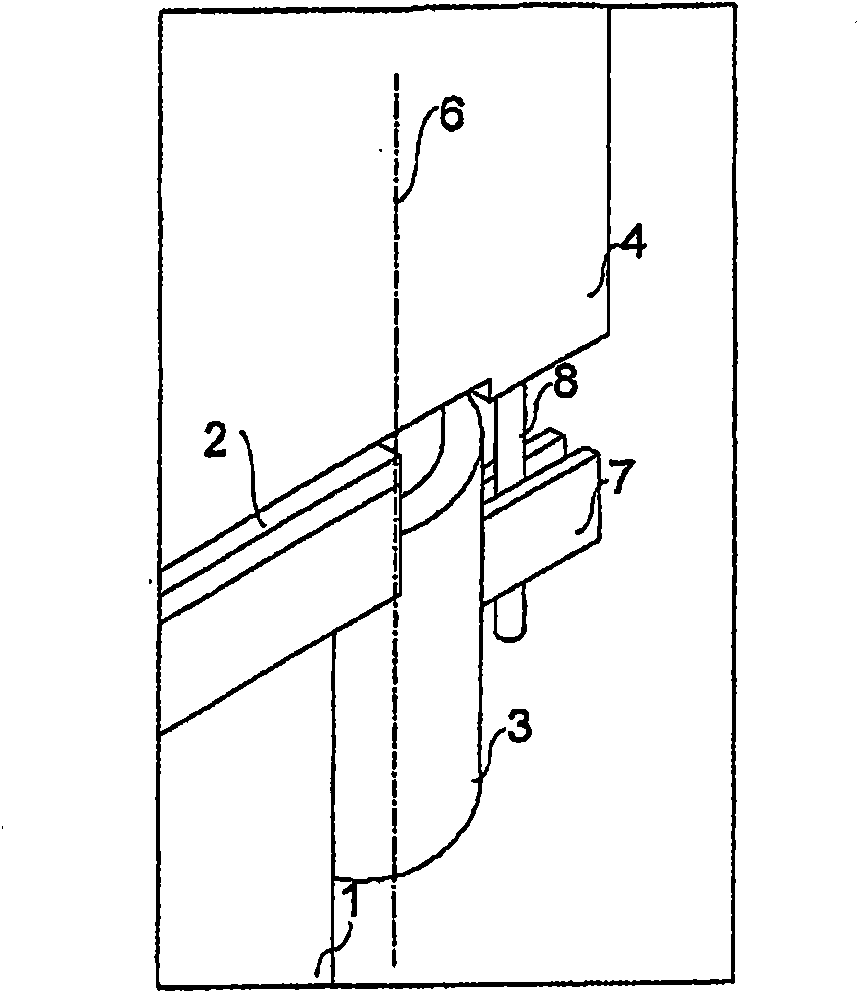

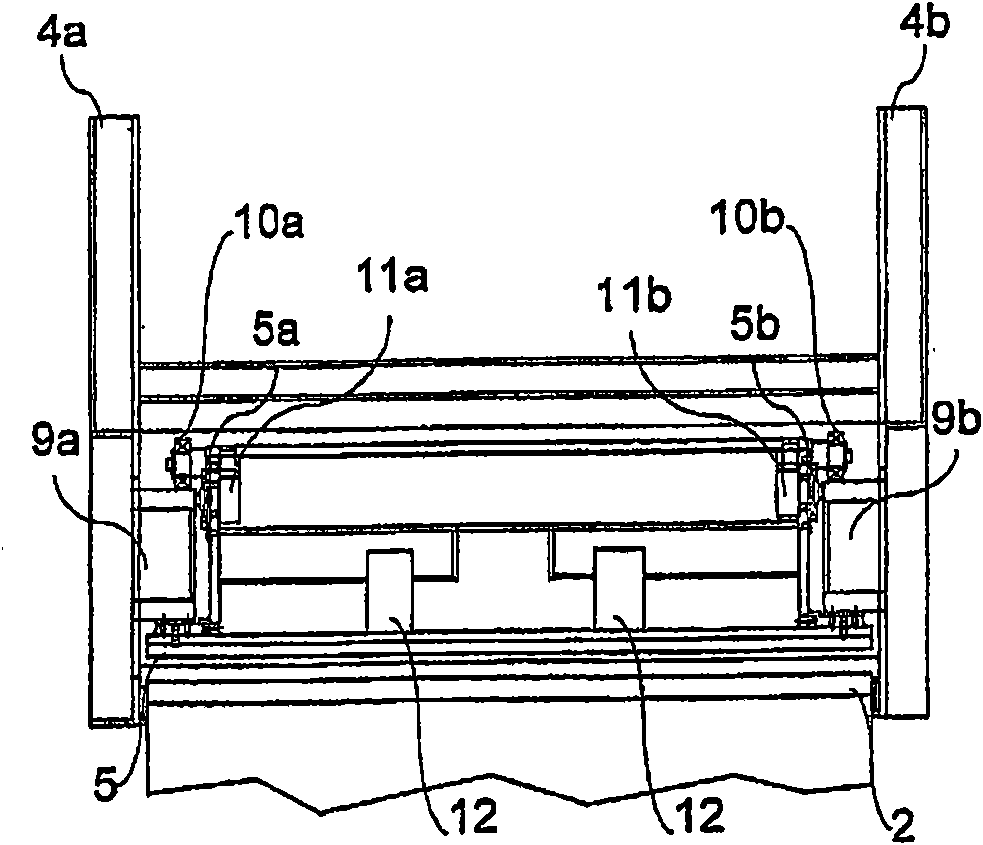

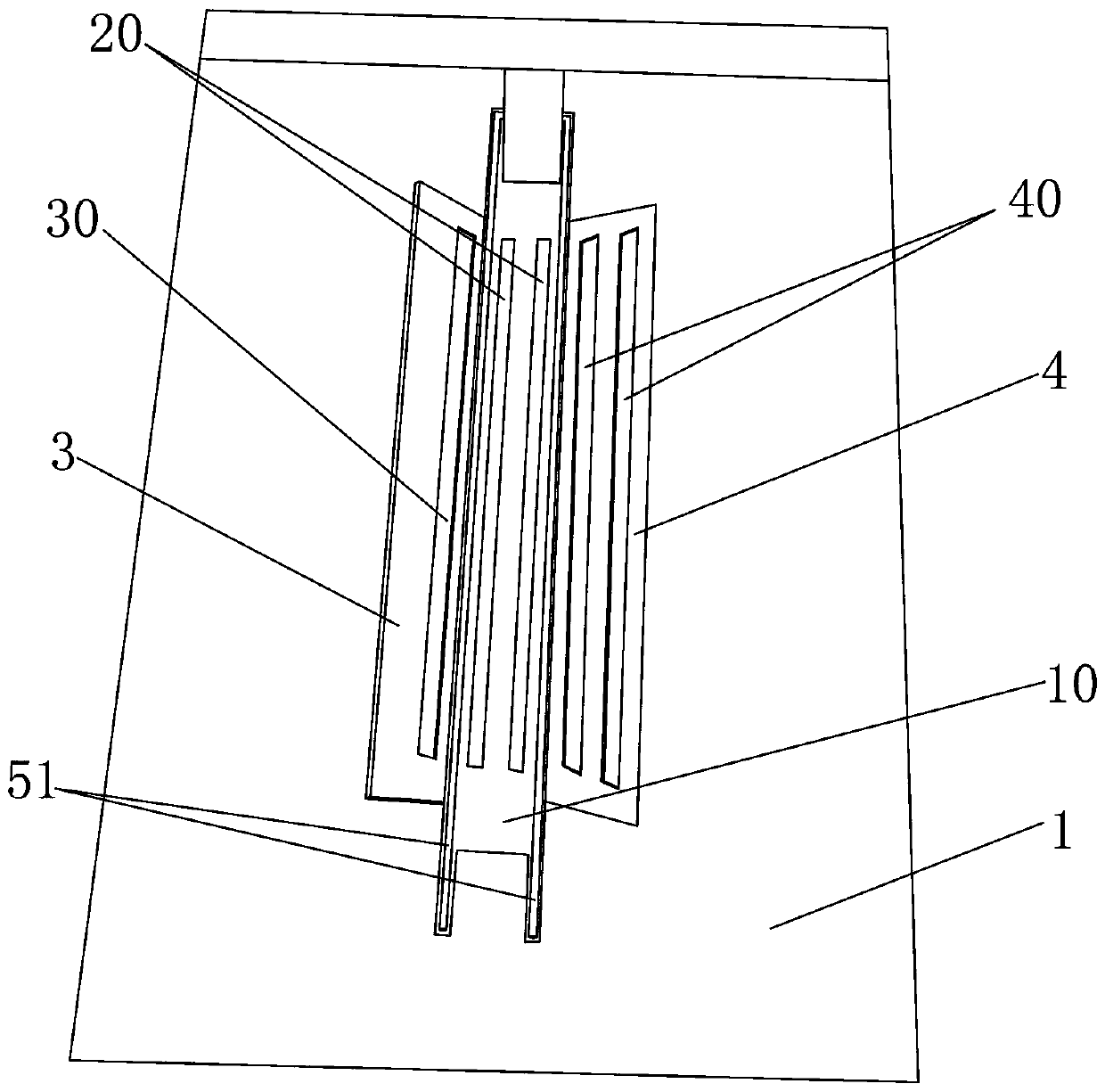

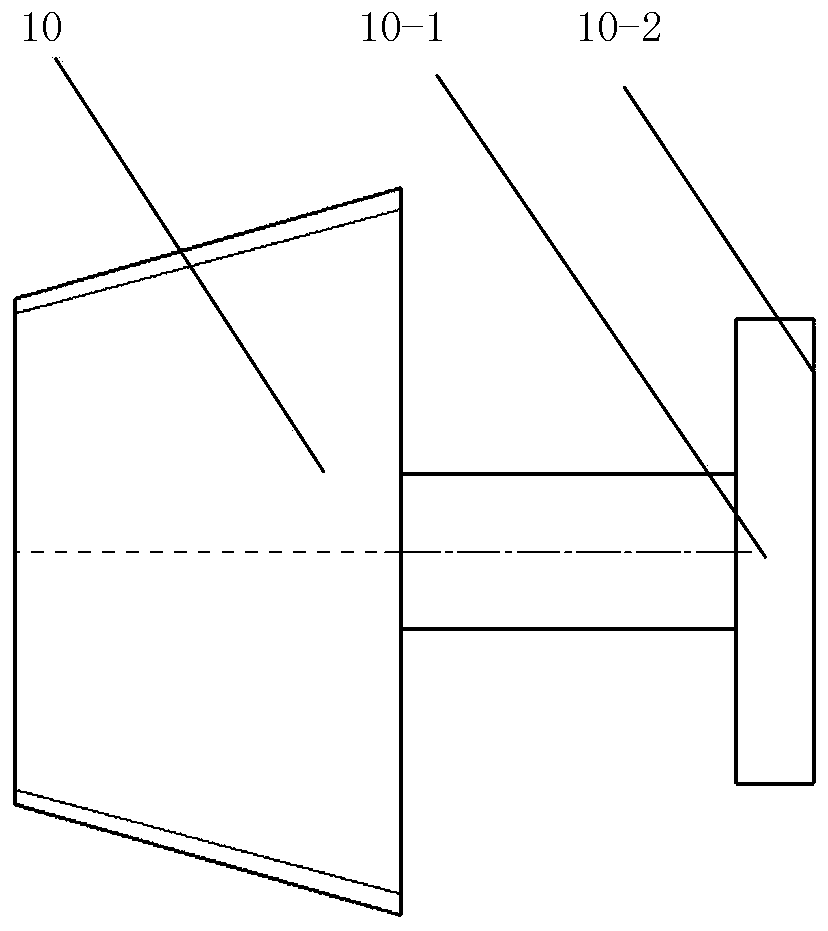

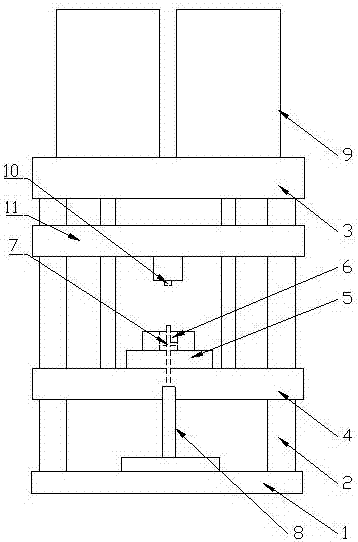

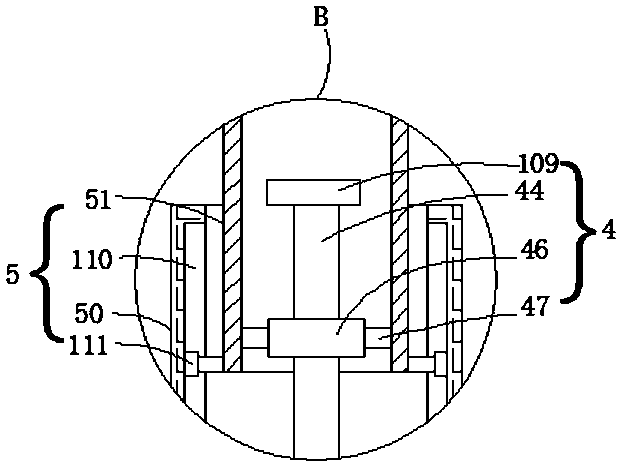

Novel fine grinding polishing assisting tool for wedge-shaped lens paired machining

ActiveCN108274341AConsistent processingReduce processing timeOptical surface grinding machinesGrinding drivesMechanical engineeringWedge shape

The invention discloses a novel fine grinding polishing assisting tool for wedge-shaped lens paired machining. The novel fine grinding polishing assisting tool comprises a base. A sliding mechanism isarranged in the base. The upper surface of the sliding mechanism is in sliding connection with a connecting block. An adjusting mechanism is fixedly connected to the upper surface of the connecting block. Two telescopic mechanisms are vertically arranged on the upper surface of the adjusting mechanism and communicate with the adjusting mechanism. A clamping mechanism is arranged at the upper endof each of the two telescopic mechanisms. A support column is further vertically arranged on the upper surface of the base, and a support is transversely fixed to the upper end of the support column and provided with two grinding mechanisms, wherein the two grinding mechanisms are located above the two clamping mechanisms correspondingly. The novel fine grinding polishing assisting tool can grindtwo wedge-shaped lenses at the same time, the machining efficiency is improved, sliding and telescopic movements of the two wedge-shaped lenses can be consistent, and it is guaranteed that wedge-shaped angles of the two wedge-shaped lenses can be completely matched.

Owner:温岭市奇锋工具有限公司

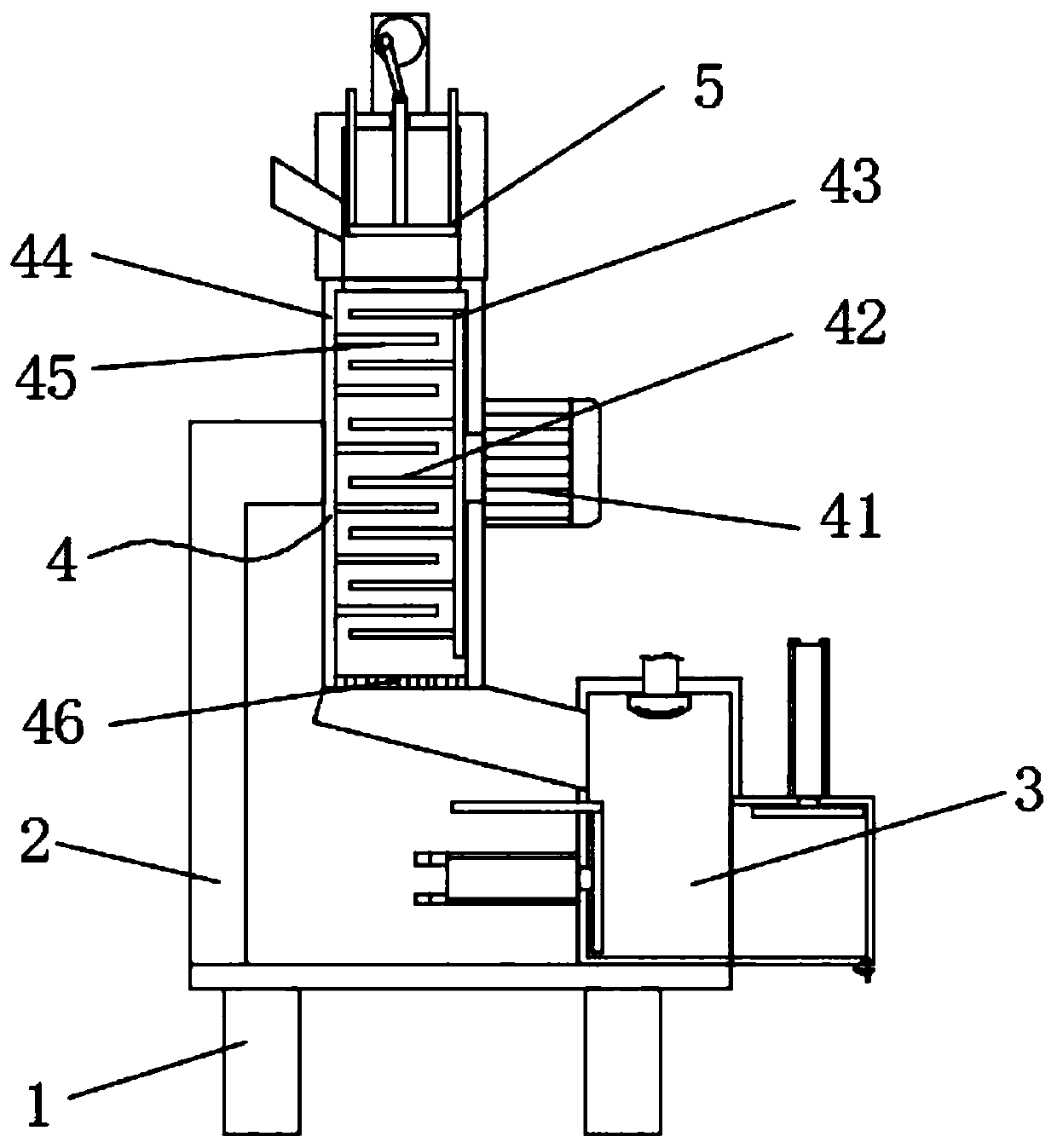

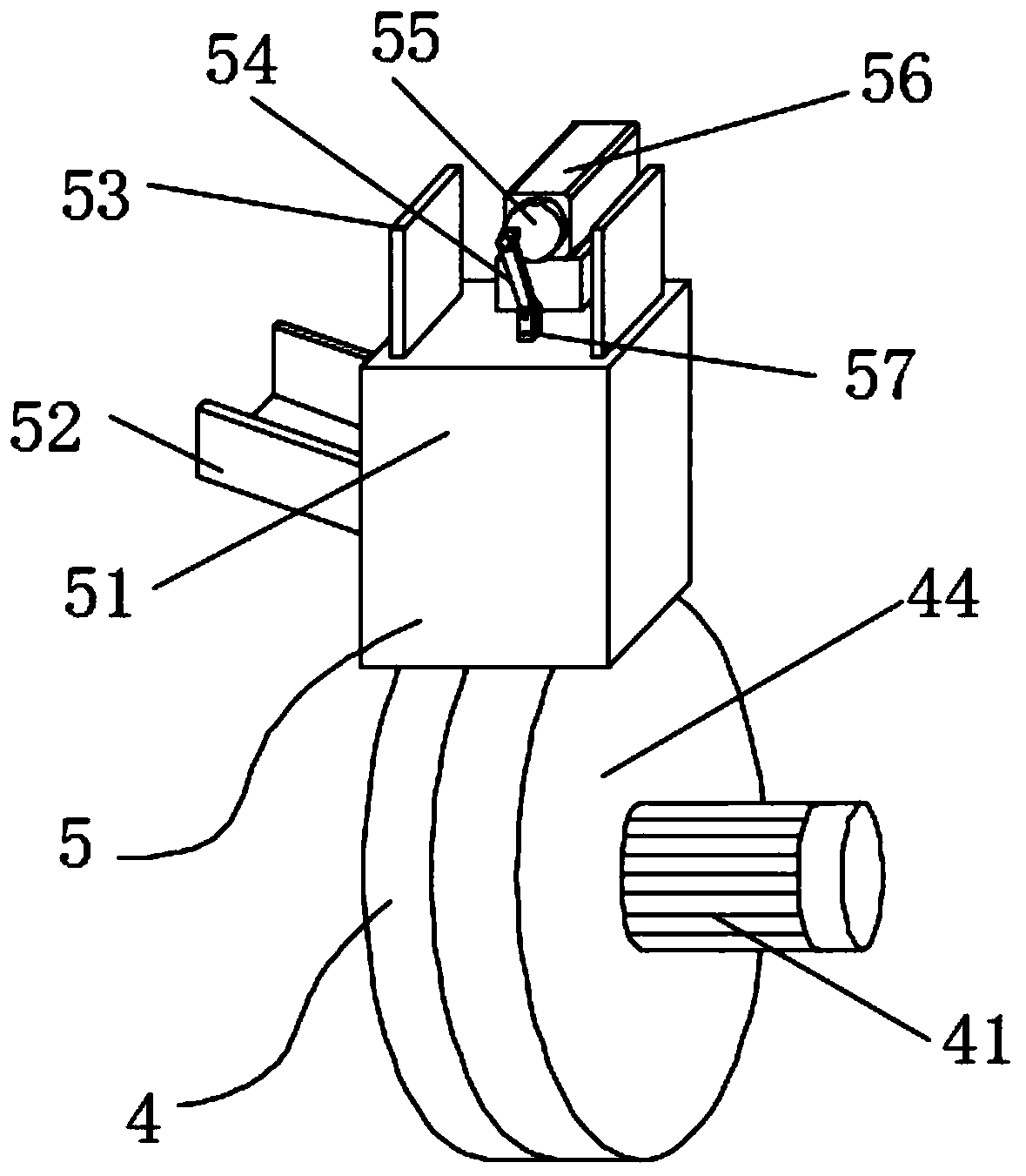

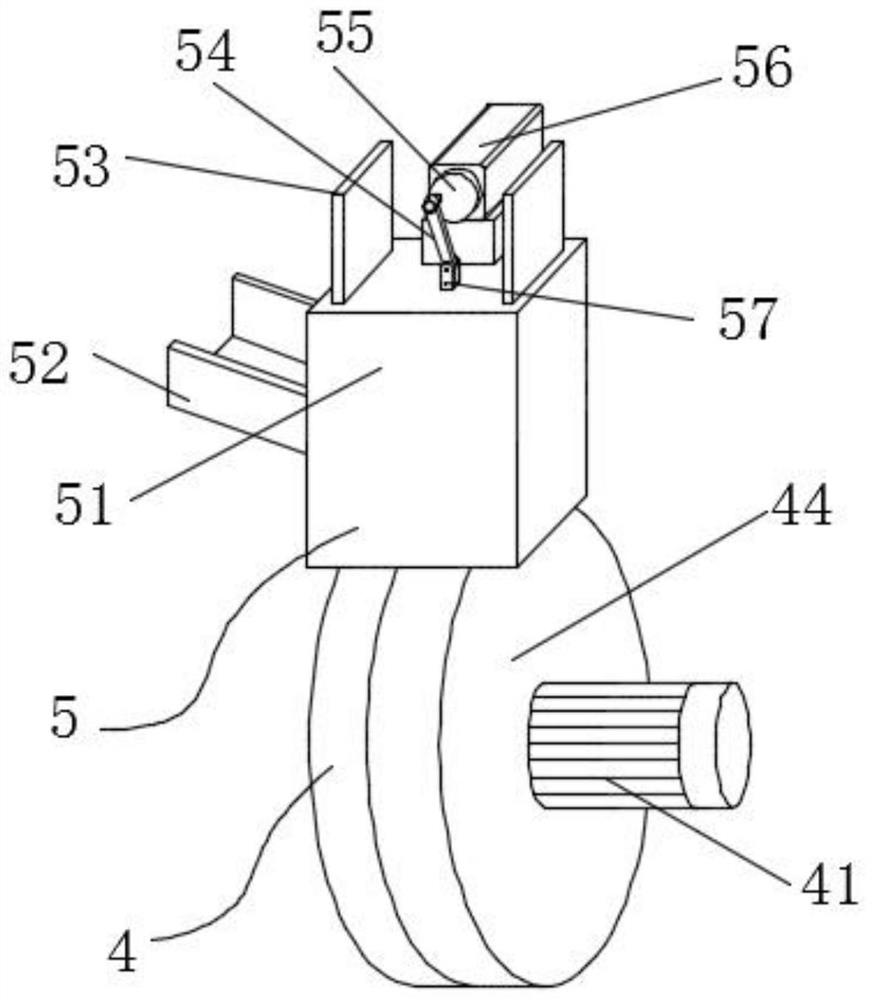

A special sander for ring parts

ActiveCN111604767BConsistent processingEasy to processDispersed particle filtrationGrinding drivesSanderFixed frame

The invention discloses a special sander for ring parts, which includes a processing table, a main motor is fixed on the upper end of the processing table, a driving disc is fixed on the output shaft of the upper end of the main motor, and two Two telescopic discs and two telescopic cylinders, the inside of the two telescopic discs are equipped with internal processing mechanism, the ends of the two telescopic cylinders away from the driving disc are fixed with laminating plates, and the upper end of the processing table is fixed with a ring The supporting platform and two symmetrically arranged fixed frames, the upper ends of the two fixed frames are rotatably connected with rotating plates. The advantages are: the main motor drives the telescopic disc to rotate, so that the sanding column rotates around the inner wall of the plate, and the sanding motor drives the sanding column to rotate, so that the sanding column itself rotates to complete the processing, and the sanding column rotates around the inner circle of the plate to make the plate The processing degree of each position of the inner ring is consistent, so that the processing effect of the inner ring of the plate is better, and the occurrence of uneven processing is avoided.

Owner:宁波索思机械设计有限公司

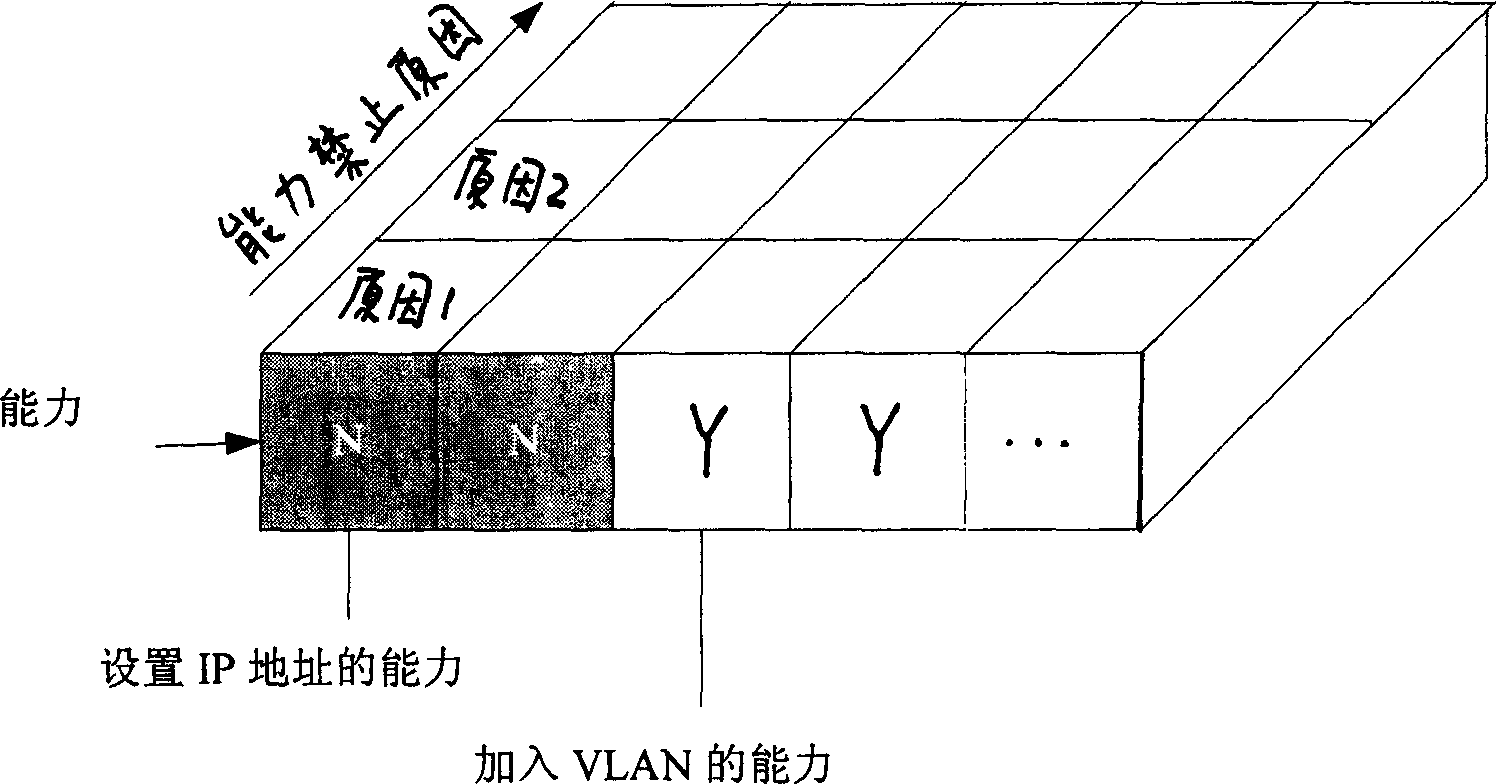

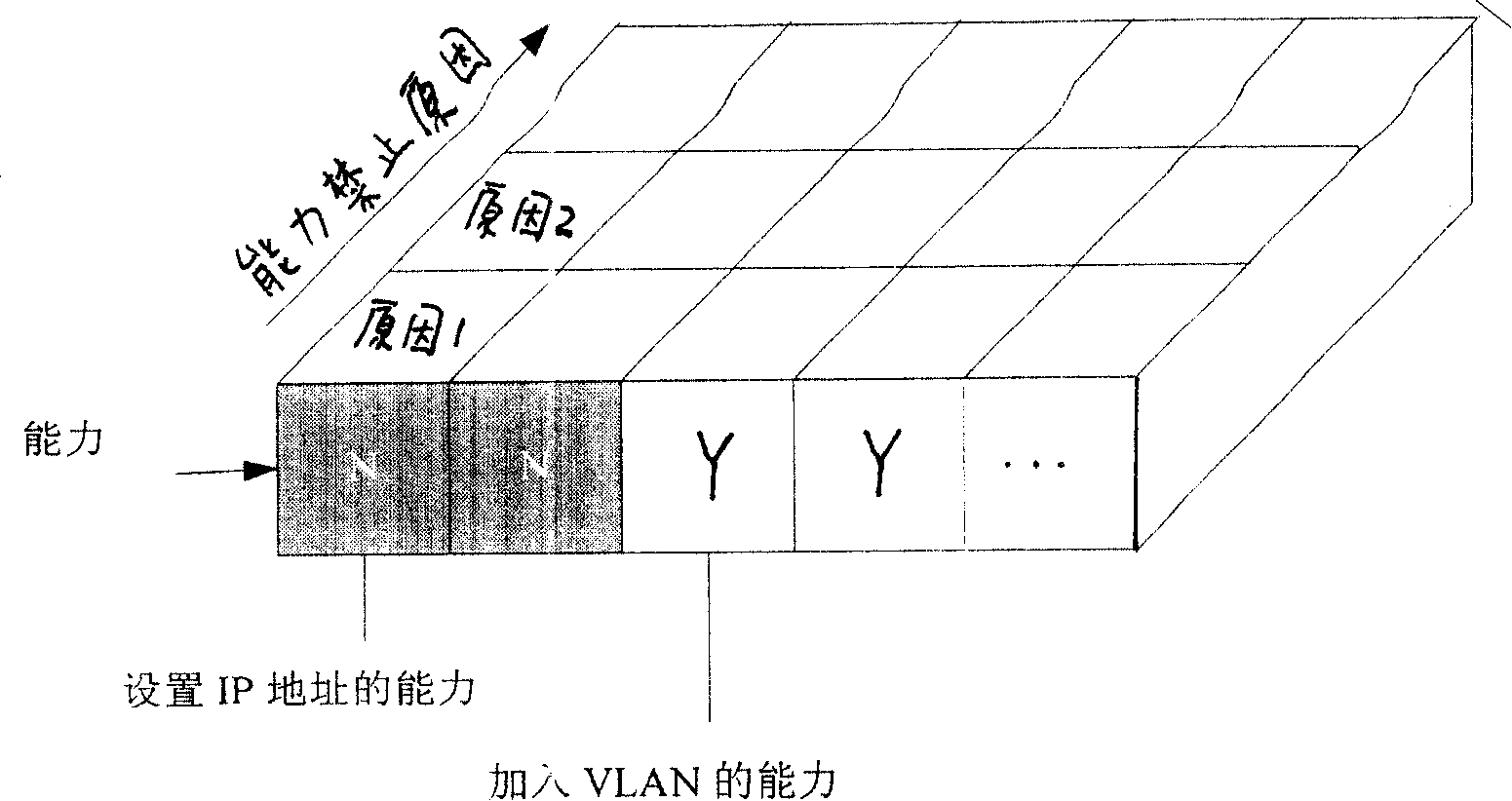

Method for inspecting network interface behavior under multiple network interface environment

The invention discloses a checking method for network interface behavior in multiple network interface environment. It includes: 1) creates memory area of network interface behavior information in data base, the network interface access pointer points to the first address of the memory; the network interface behavior information includes behavior items and the sign if the behavior items can be enabled, if it can not be enabled, it also includes the reason that the item can not be enabled; 2) when executing network interface behavior, it executes and checks the enable sign, if yes, it enables the behavior item of the network interface; if can not, it provides the reason. The method is simple, and the concept is clear.

Owner:BEIJING HUAWEI DIGITAL TECH

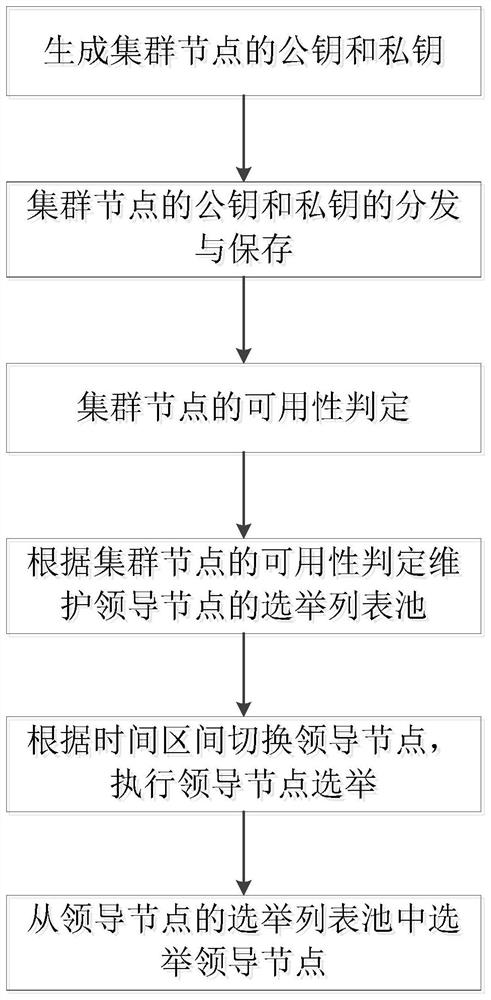

A performance maintenance method, system and storage medium of an alliance chain

ActiveCN111107103BImprove stable operation efficiencyConsistent processingSecuring communicationComputer networkEngineering

The invention discloses a performance maintenance method, system and storage medium of a consortium chain. The method includes: distributing public keys and private keys to all nodes in the consortium chain, and the public keys of each node are stored on all nodes of the consortium chain , the private keys of each node are respectively stored on the corresponding nodes; based on the public key and private key, check the availability of all nodes to obtain an availability list; according to the availability list, check the availability of each node in the consortium chain Rationality verification; update the availability list according to the result of the rationality verification, and determine the election list pool; elect a leader node from the election list pool; control the operation of the alliance chain through the leader node. The invention can maintain performance in an unstable network, improve the operating efficiency of the cluster, and can be widely applied in the field of block chain technology.

Owner:南京可信区块链与算法经济研究院有限公司

Method for controlling cutting quantity of spiral bevel gear

A method for controlling the cutting quantity of a spiral bevel gear solves the problem of adjusting processing technology parameters such as rotating speed of a cutter, number of blades on the cutter, processing time, and the like according to the cutting quantity and the precision of a tooth surface. The method comprises a cutting simulation method in the hobbing process of the spiral bevel gear and processing parameter methods for controlling a chipping simulation method and the cutting process. On the basis of a hobbing simulation method, the processing technology parameters, tool adjusting parameters, tool adjusting parameters and cutter and tooth billet parameters are adopted for conducting virtual three-dimensional entity molding, simulating the high-speed cutting process of the gear, and providing the method for controlling the cutting quantity. The method is applied in practical processing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Clicking press

InactiveCN101668868BQuality improvementProcessing size is largeLeather clicking/perforating/clickingMetal working apparatusEngineeringVertical axis

Owner:ARES ITALA

A inner bag double eyebrow forming mold and its application method

ActiveCN105908390BSewing skills do not require excessive requirementsSimple structureWork-feeding meansEngineeringDouble eyebrow

Owner:FUJIAN SEVEN FASHION TECH CO LTD

An initial alignment device, processing device and processing method for a special-shaped ceramic radome

ActiveCN109702605BUnified processing standardsReduce machining accuracyRadiating element housingsWorking accessoriesStructural engineeringRadome

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

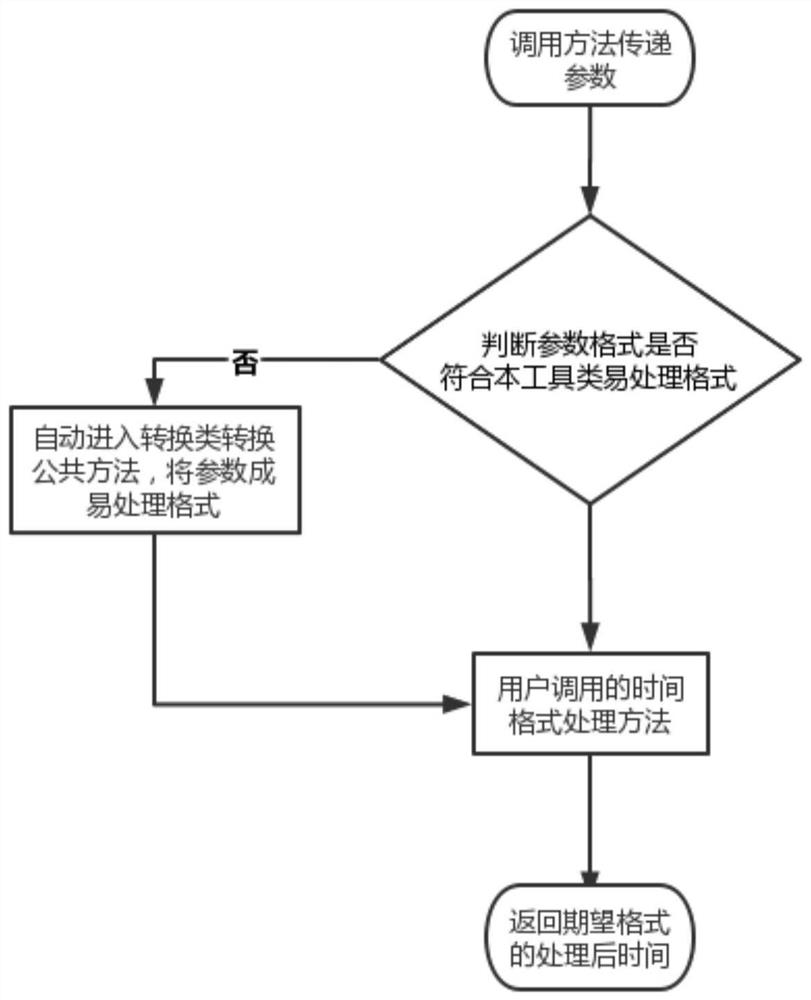

Time format conversion method based on Java

PendingCN114756230AHigh precisionReduce duplicationResource allocationSoftware engineeringInformation repositoryTime information

The invention provides a Java-based time format conversion method. The Java-based time format conversion method comprises the following steps: S1, acquiring a time parameter needing to be processed; s2, judging whether the format of the time parameter accords with an easy-to-process format of a time format conversion tool class or not; s3, if yes, calling a non-public conversion method of the time format conversion tool class for processing; if not, easy-to-process format conversion is carried out through a common conversion method of the time format conversion tool class, and then the non-common conversion method is called for processing; and S4, outputting the processed time of the expected format. According to the method, after the incoming information is compared with the pre-established information base, the key time information is extracted, and different time formats in various development environments are processed into target formats, so that the method can adapt to different development environments, the information extraction precision is improved, and the versatility of the tool class is enhanced.

Owner:WUHAN HONGXIN TECH SERVICE CO LTD

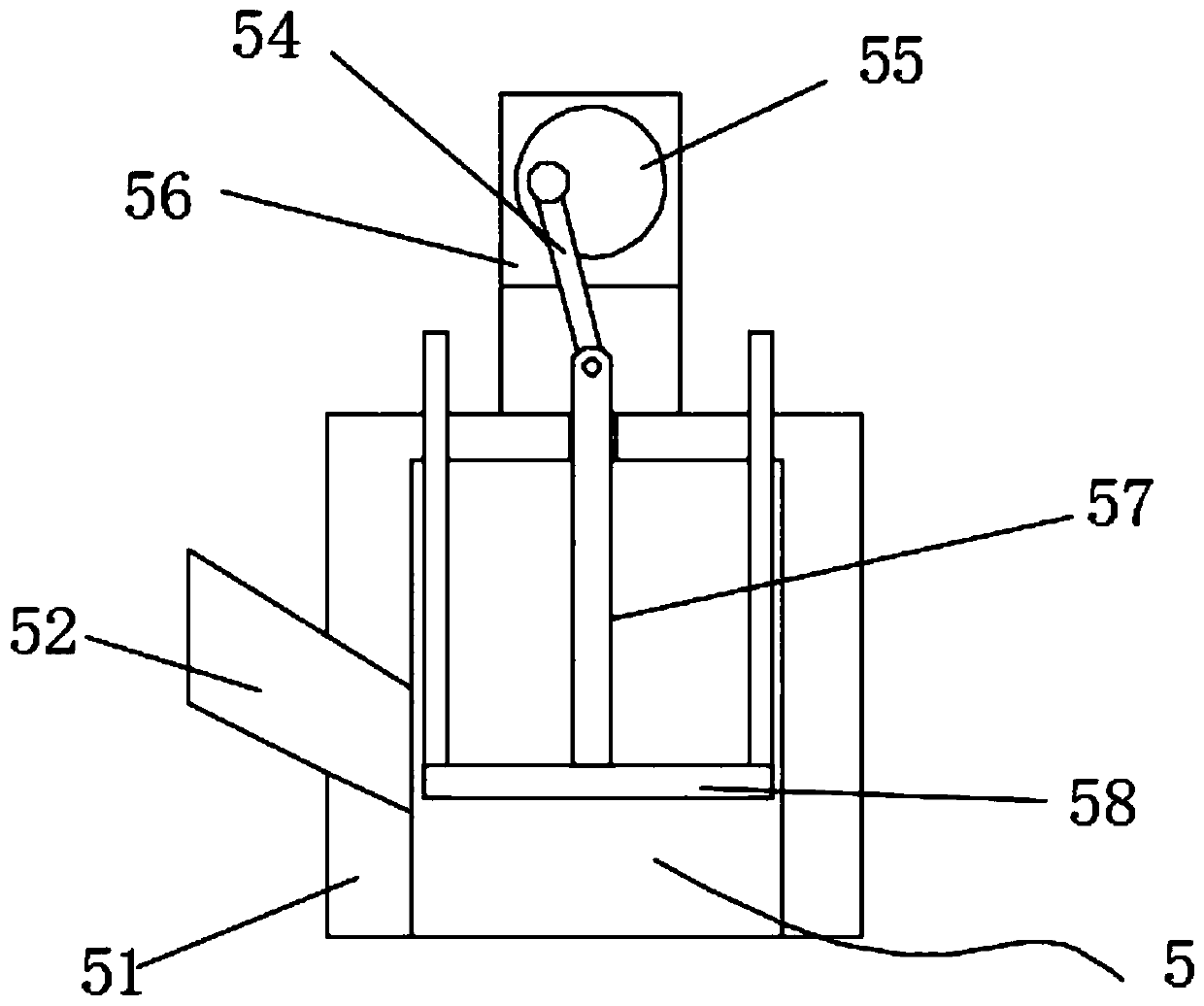

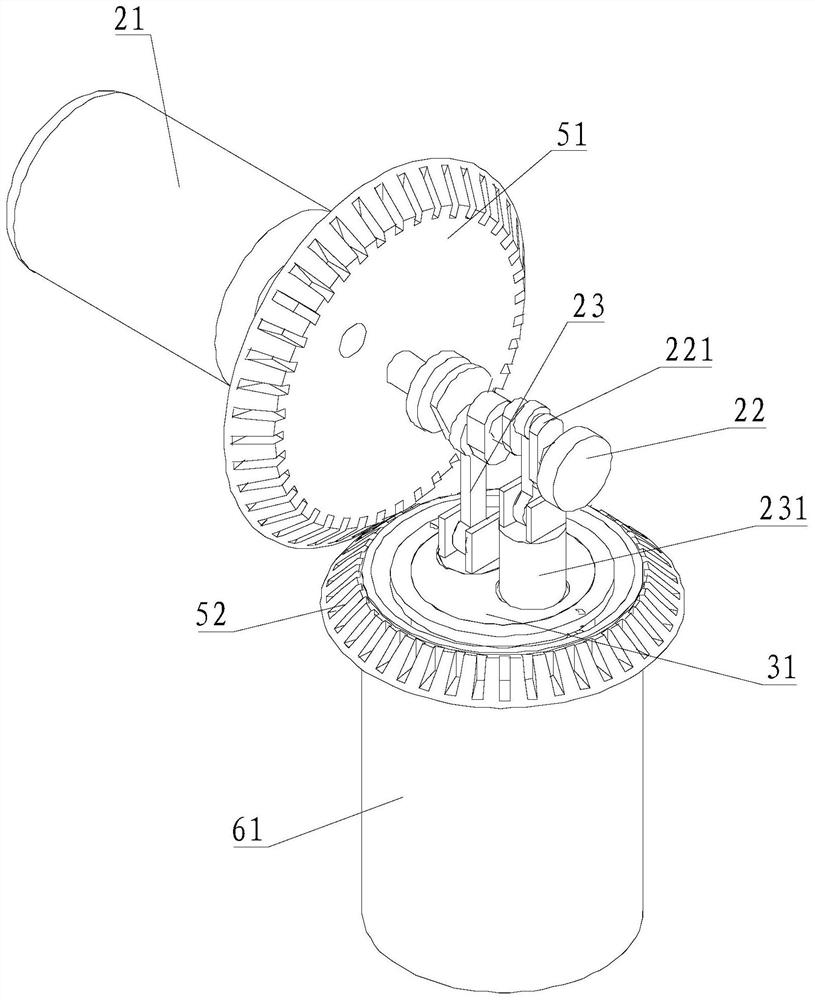

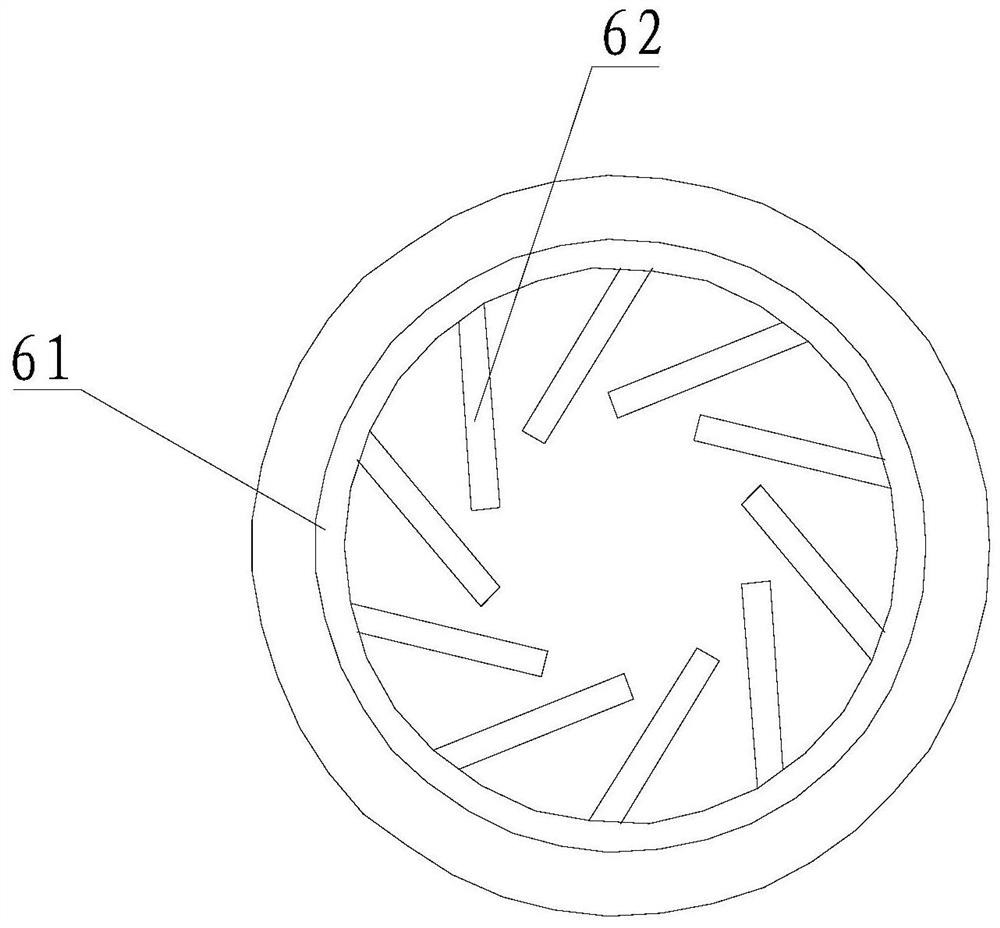

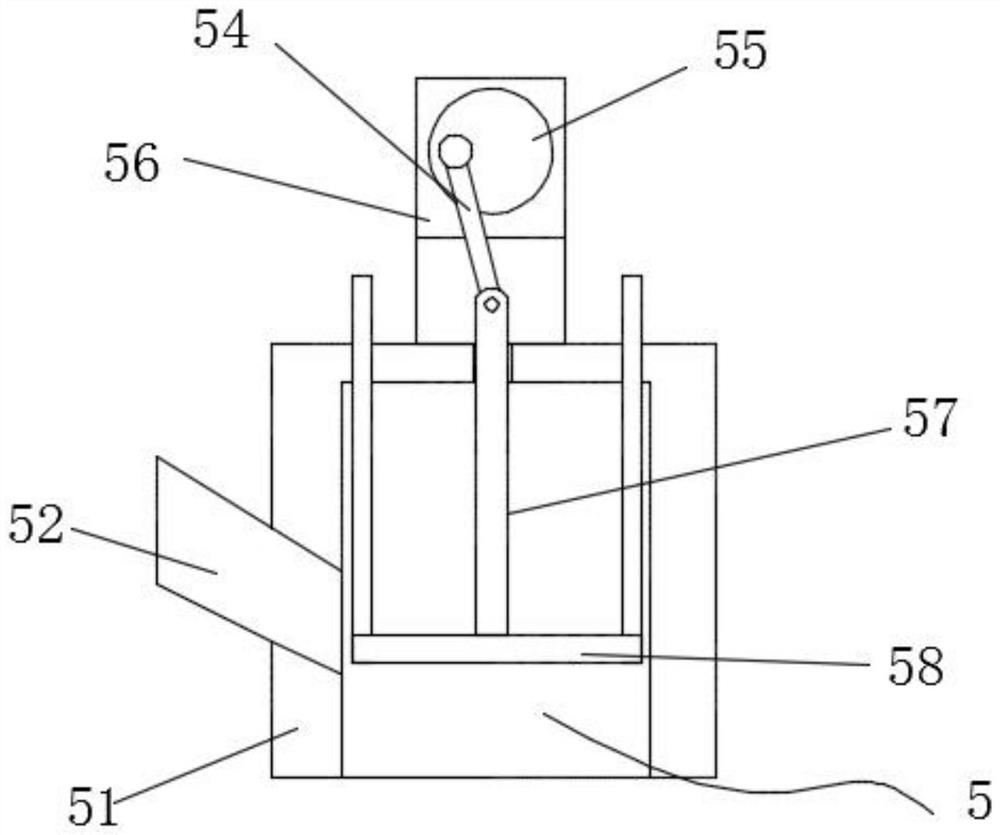

A processing device imitating hand-made meatballs

ActiveCN112841263BImprove hammering efficiencyElasticBeating-based meat tenderisingCrankElectric machinery

The invention relates to the technical field of food manufacturing machinery, in particular to a hand-made meatball processing device, which includes an upper casing, a driving assembly, a beating assembly and a container; the driving assembly is arranged inside the upper casing, and the driving assembly includes a driving motor, a crankshaft and The connecting rod and the driving motor are fixedly connected inside the upper housing, and the power output shaft of the driving motor is fixedly connected with one end of the crankshaft, and the crankshaft is provided with at least two crank throws in opposite directions. The beneficial effect of the present invention is that: the hammer body is connected with the upper casing through the spring, so that the hammer body can imitate the "hand-raising" action of manual hammering when hammering to the bottom end, ensuring that the processed meatballs are more accurate. It is elastic; the hammer body is driven down by at least two sliders. Different sliders have different positions inside the hammer body, which can imitate the regional change of hammering force during manual hammering, and then make the hammered meat pulp The processing degree is more consistent everywhere, avoiding large differences in the taste of meatballs in the same batch.

Owner:福建天清冷链物流有限公司

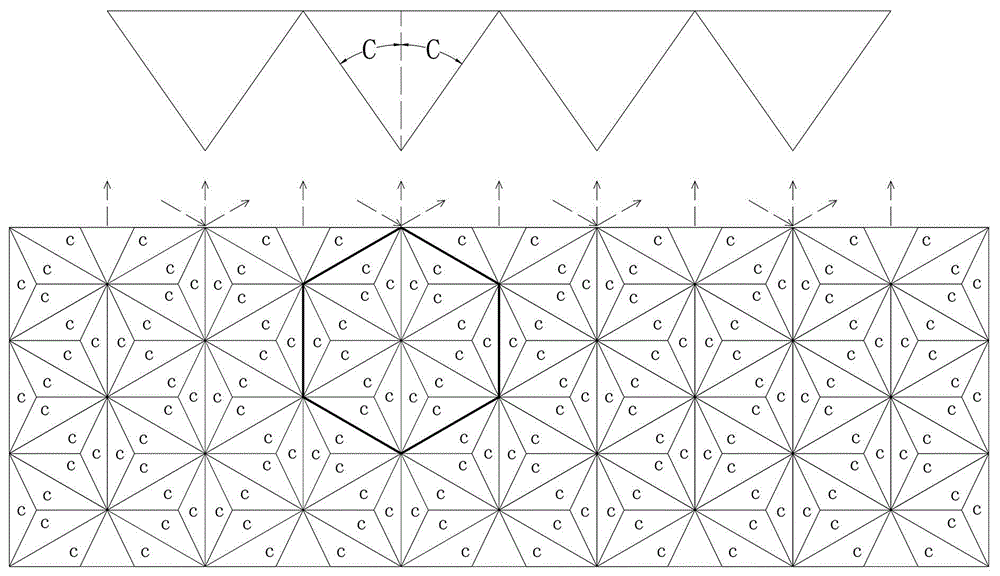

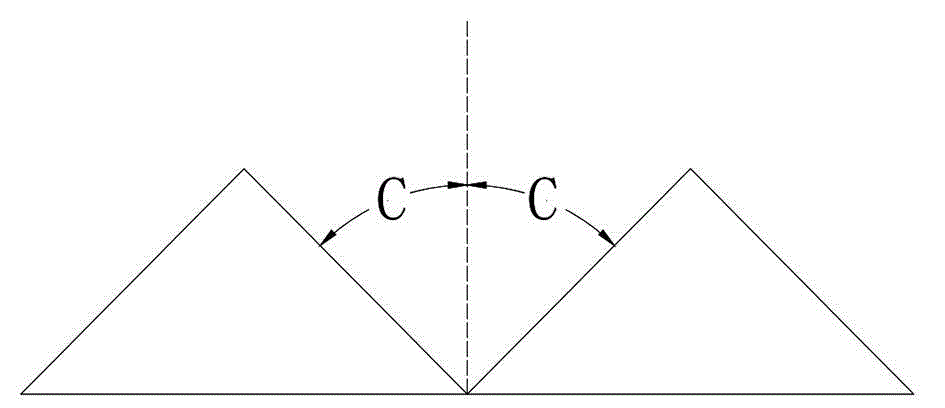

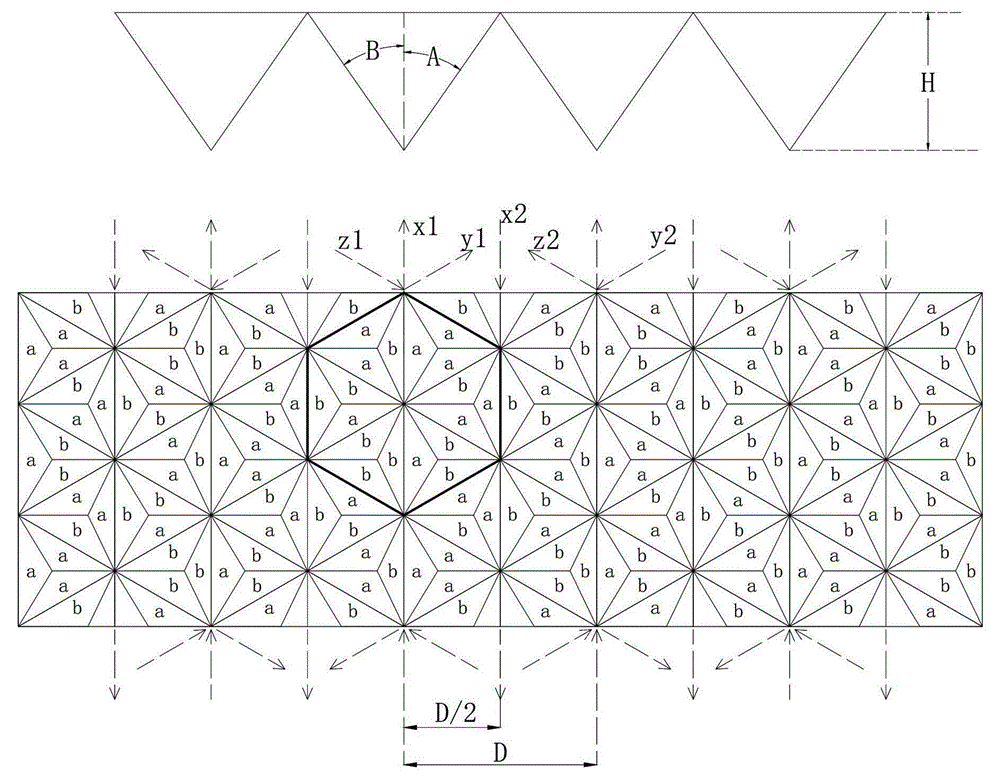

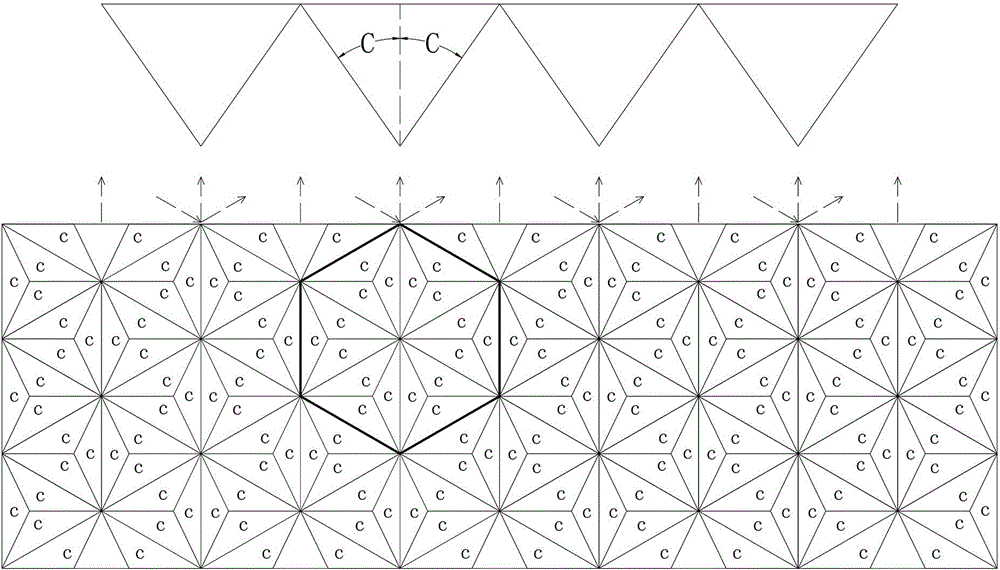

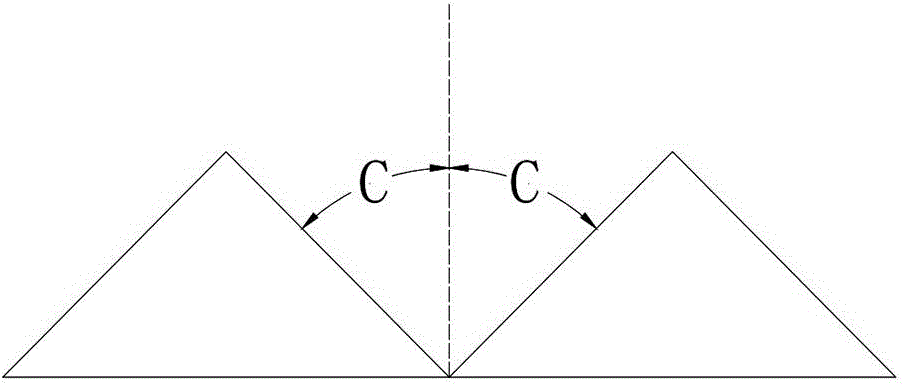

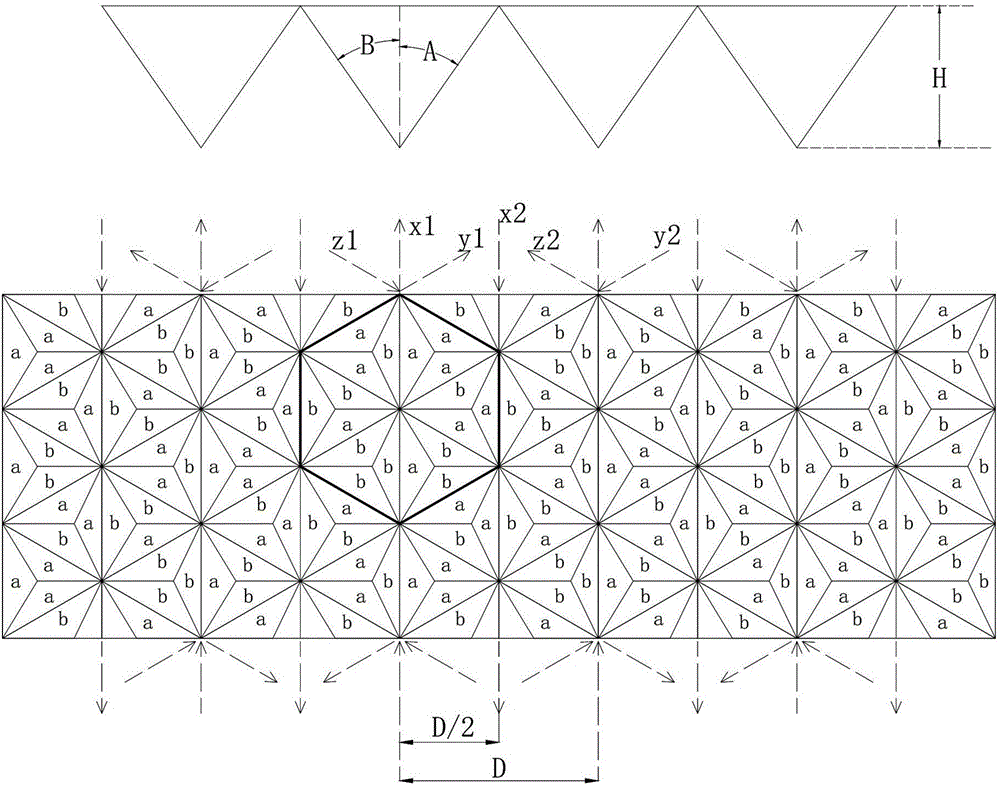

A new method of making a microprism type reflective material mold

The invention relates to a manufacturing method of a novel microprism type reflective material mold. The microprism mold obtained by the existing method only has a microprism reflective unit of one structure, and the reflected light intensity of the reflective material thus formed is difficult to meet the requirements of recognition in a wide range of irradiation and observation angles. The present invention mainly includes the following steps: using a cutting tool to cut the substrate in three directions, the distance D between cutting lines in the three cutting directions is 300 μm to 500 μm, and the cutting tool has two cutting angles A and B with different angles, The cutter is offset by a distance D / 2, and the substrate is cut in a direction opposite to the three cutting directions, and a microprism type reflective material mold is formed after cutting. The microprism type reflective material mold obtained by the present invention has excellent "wide-angle property" and "directivity" is not obvious, and can well meet the recognition requirements within a wide range of illumination angle and observation angle.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

Method and device for transmitting L2VPN service by using tunnel group in MPLS network

InactiveCN102065020BImprove scalabilitySimple configurationData switching networksExtensibilityPrivate network

The invention relates to a method and a device for transmitting a layer 2 virtual private network (L2VPN) service by using a tunnel group in a multi-protocol label switching (MPLS) network. The method comprises the following steps of: establishing the tunnel group between a transmitting end provider edge device (PE) and a receiving end PE, so that one or more packet switching network (PSN) tunnels in the MPLS network join in the tunnel group; binding the L2VPN service with the tunnel group, and selecting a PSN tunnel for bearing the L2VPN service in the tunnel group; and transmitting the L2VPN service by using the transmitting end PE and the receiving end PE through the selected PSN tunnel. The protection of pseudo wires (PWs) can be neglected in the L2VPN service, and the tunnel group can protect the PWs. The tunnel group technology has high extensibility, can support the conventional MPLS tunnel technology, and also can conveniently support MPLS tunnel technology which possibly occurs in the future. The tunnel group is easy to configure, and the configuration of the tunnel group can be dynamically modified in the state that the L2VPN service is not interrupted.

Owner:ZTE CORP

Belt pulley outer wall deburring device

The invention relates to a belt pulley outer wall deburring device. The belt pulley outer wall deburring device comprises a machining support, a belt pulley fixing unit, a compression unit and a driving unit. The belt pulley fixing unit comprises a belt pulley fixing platform; the two ends of the belt pulley fixing platform are mounted on stand columns in a sleeving manner correspondingly; a beltpulley fixing seat is mounted in the center of the belt pulley fixing platform; a groove allowing a belt pulley to be embedded therein is formed in the upper end of the belt pulley fixing seat; and the inner wall of the groove is provided with a tooth-shaped structure corresponding to the outer wall of the belt pulley. The compression unit comprises a compression block, wherein the compression block is mounted at the lower end of a cross beam. The driving unit comprises a pair of driving cylinders which are mounted at the upper end of the cross beam. The belt pulley outer wall deburring devicehas the beneficial effects that burrs on the outer wall can be well removed only through one time of machining; great convenience is achieved; machining consistency is guaranteed; in addition, manualwork is reduced; and work efficiency is improved.

Owner:南通冠达粉末冶金有限公司

Method for the treatment of turquoise by using aluminum phosphate salts

The invention relates to a method for the filling treatment of turquoise by using aluminum phosphate salts. A method for the treatment of turquoise by using aluminum phosphate salts is characterized in that the method comprises the following steps of: 1) pretreatment: wall rock and dirty surface are worn off on the surface of the turquoise with loose texture and are then put in a constant-temperature drying box for being dried for 3-4 hours at 80-110 DEG C after being cleaned, so as to obtain the pretreated turquoise; 2) preparation of an adhesive: KH2PO4, NaH2PO4 and MgO are respectively ground to 200 meshes and are then selected based on the proportion of Al(H2PO4)3 solution KH2PO4:NaH2PO4:MgO = 800mL:2-10g:1-20:1-20g to be mixed and stirred evenly, thus resulting in the adhesive; 3) the pretreated turquoise is vacuumized and then soaked in the adhesive for 1-30 days at 15-30 DEG C under normal pressure of 40Mpa; the turquoise is taken out and put into the constant-temperature drying box for heating and curing, upon the ending of the heating, the turquoise is naturally cooled to room temperature and is subsequently polished to a finished product. The method has simple process, low cost and good simulation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A crop waste crushing and compressing device

Owner:西安科技成果转化工程有限公司

A fine grinding and polishing auxiliary tool for paired processing of wedge-shaped mirrors

ActiveCN108274341BConsistent processingReduce processing timeOptical surface grinding machinesGrinding drivesMechanical engineeringWedge shape

The invention discloses a novel fine grinding polishing assisting tool for wedge-shaped lens paired machining. The novel fine grinding polishing assisting tool comprises a base. A sliding mechanism isarranged in the base. The upper surface of the sliding mechanism is in sliding connection with a connecting block. An adjusting mechanism is fixedly connected to the upper surface of the connecting block. Two telescopic mechanisms are vertically arranged on the upper surface of the adjusting mechanism and communicate with the adjusting mechanism. A clamping mechanism is arranged at the upper endof each of the two telescopic mechanisms. A support column is further vertically arranged on the upper surface of the base, and a support is transversely fixed to the upper end of the support column and provided with two grinding mechanisms, wherein the two grinding mechanisms are located above the two clamping mechanisms correspondingly. The novel fine grinding polishing assisting tool can grindtwo wedge-shaped lenses at the same time, the machining efficiency is improved, sliding and telescopic movements of the two wedge-shaped lenses can be consistent, and it is guaranteed that wedge-shaped angles of the two wedge-shaped lenses can be completely matched.

Owner:温岭市奇锋工具有限公司

Method for inspecting network interface behavior under multiple network interface environment

The invention discloses a checking method for network interface behavior in multiple network interface environment. It includes: 1) creates memory area of network interface behavior information in data base, the network interface access pointer points to the first address of the memory; the network interface behavior information includes behavior items and the sign if the behavior items can be enabled, if it can not be enabled, it also includes the reason that the item can not be enabled; 2) when executing network interface behavior, it executes and checks the enable sign, if yes, it enables the behavior item of the network interface; if can not, it provides the reason. The method is simple, and the concept is clear.

Owner:BEIJING HUAWEI DIGITAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com