A inner bag double eyebrow forming mold and its application method

A technology for forming molds and double eyebrows is applied in the field of forming molds for inner bags and double eyebrows, which can solve the problems of easy dislocation, incompatibility, and high labor costs, and achieve the effects of prolonging service life, facilitating mass production, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

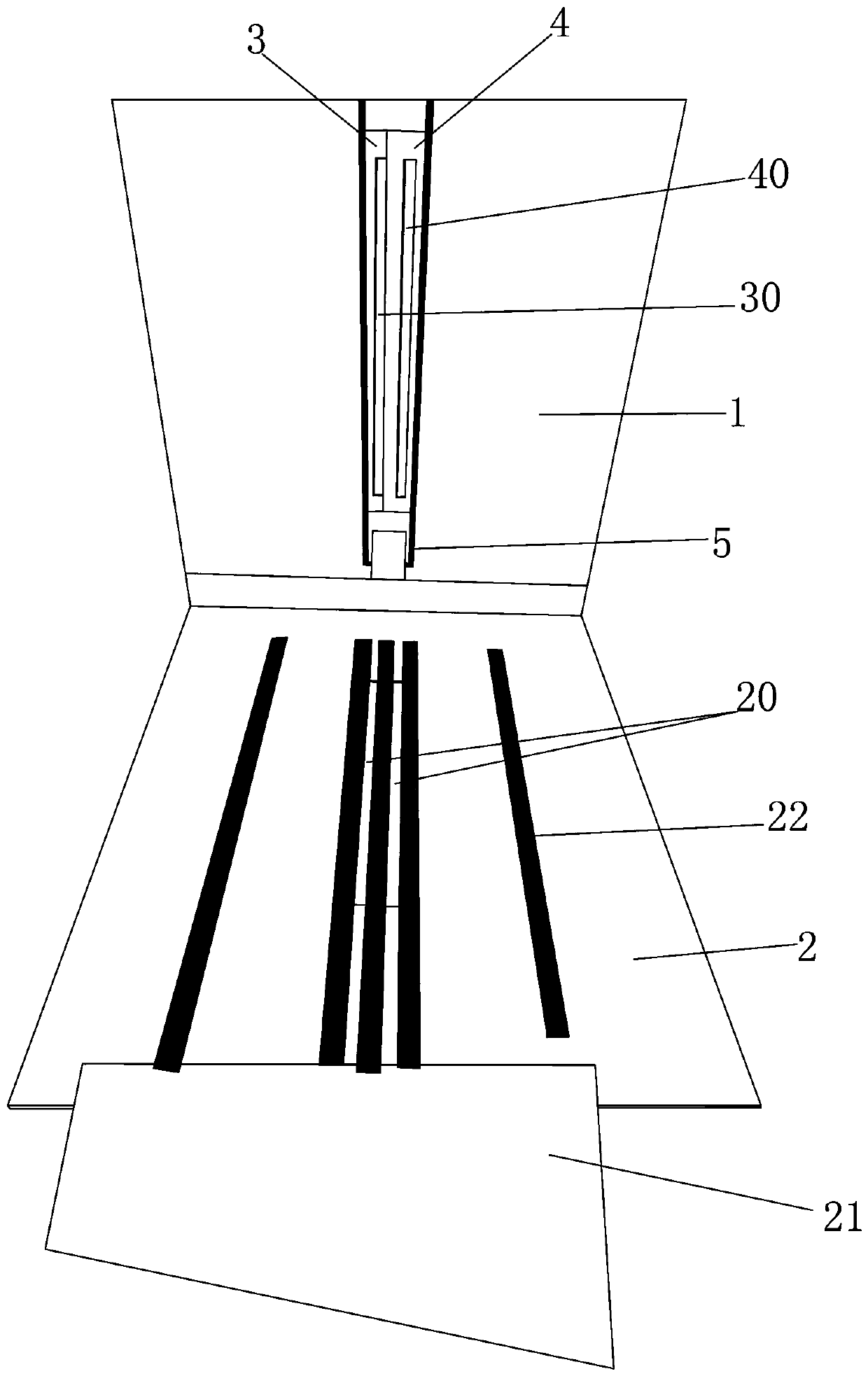

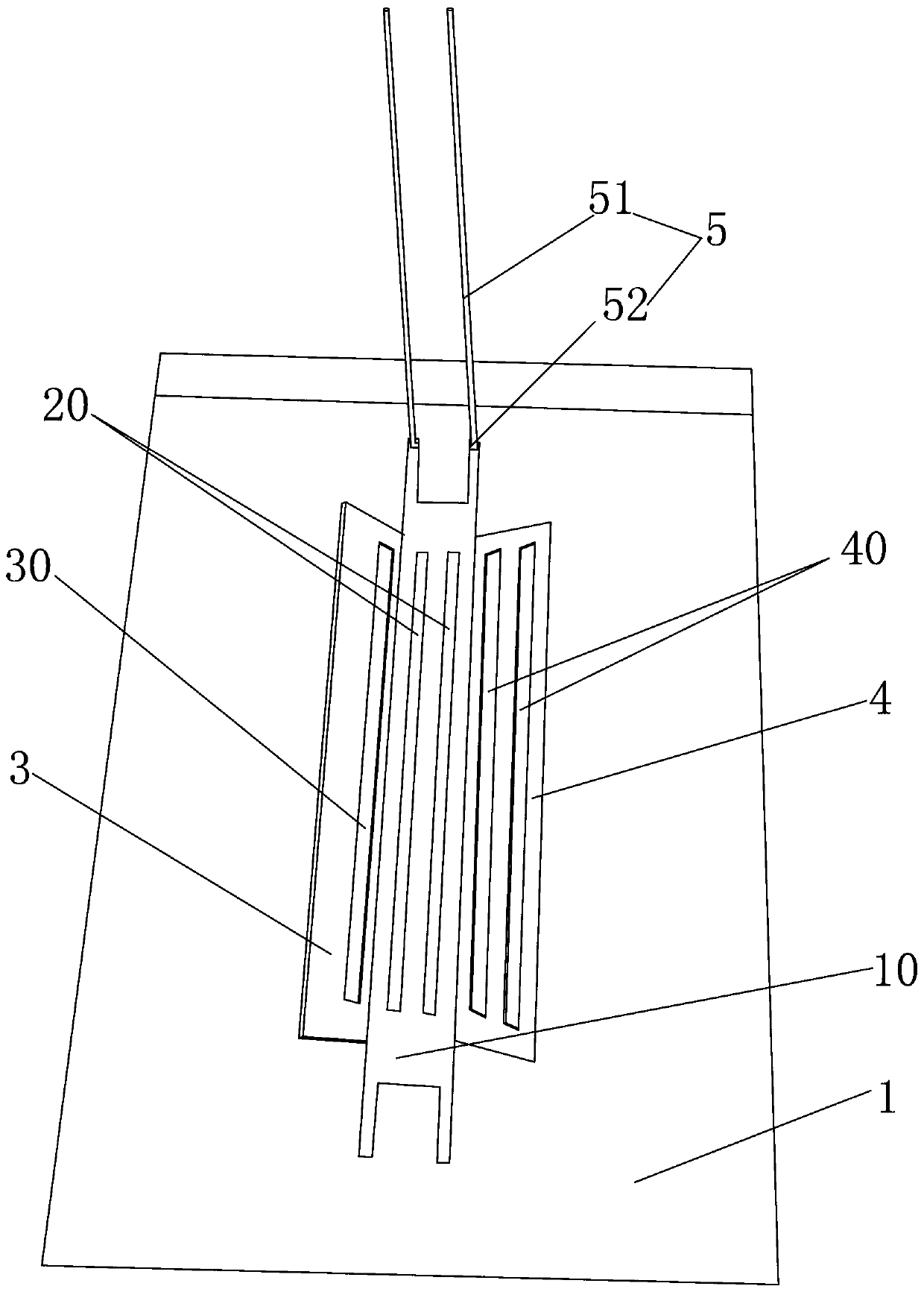

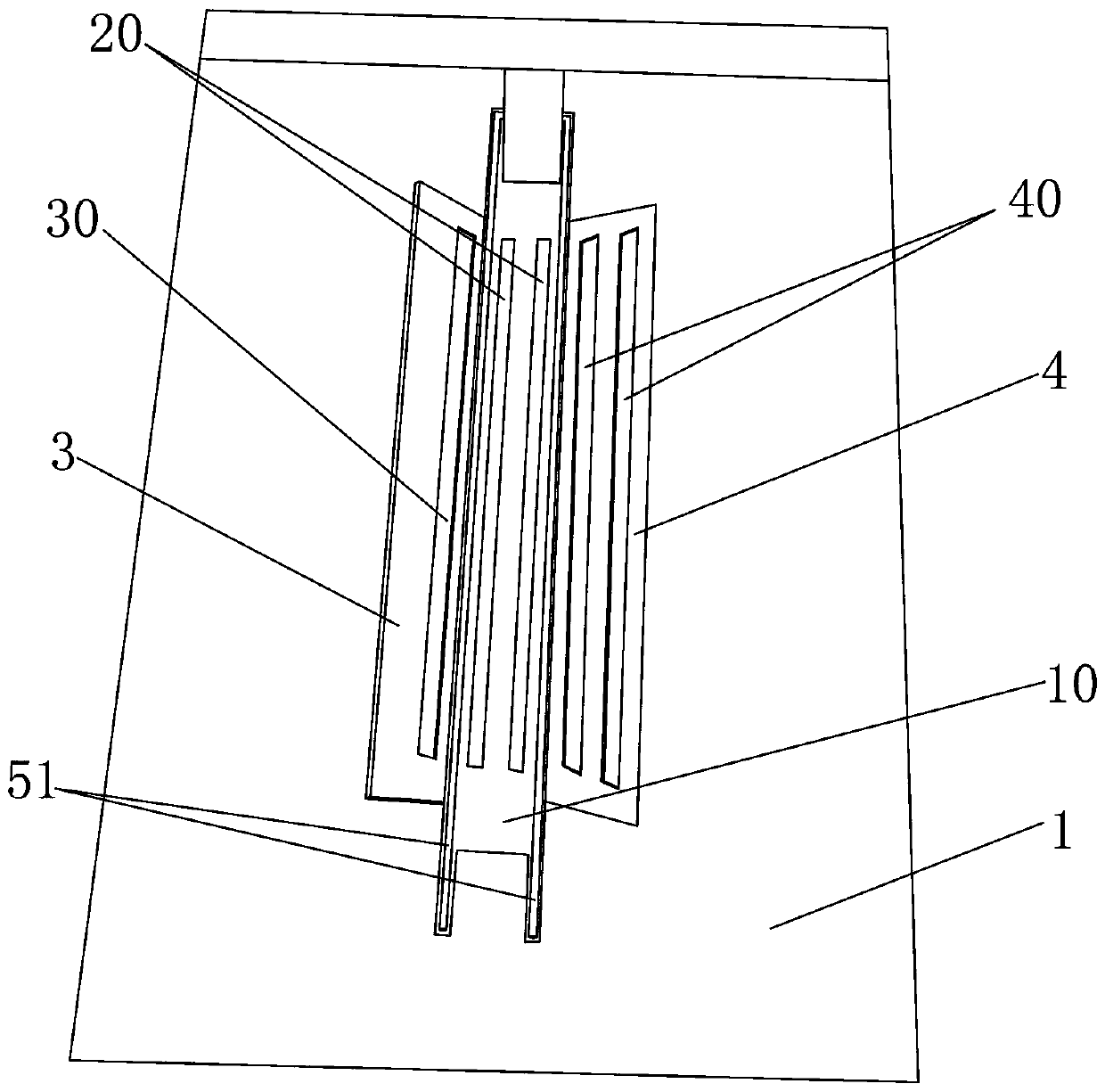

[0034] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS, the inner bag and double eyebrow molding mold of the present invention mainly includes the following components: upper template 1, lower template 2, left mold 3, right mold 4, movable rod 5, anti-skid strip 22 and molding Reference part 21;

[0035] In actual production and assembly, firstly, a accommodating groove 10 and two sewing grooves 20 are opened in the upper and lower templates 1, 2 respectively. The overall length and width of the accommodating groove 10 is greater than the two sewing grooves 20; then, the left and right molds 3, 4 The guide grooves 30 and 40 are respectively opened, and the guide grooves 30 and 40 respectively correspond to the sewing groove 20; secondly, the movable rod 5 is produced, and the movable rod 5 includes a forming part 51 and a connecting part 52, and the forming part 51 and the connecting part 52 are adopted Columnar steel strip production (the steel strip is used to ensure the hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com