Special-shaped ceramic antenna cover machining device and method

A ceramic antenna and radome technology, applied in stone processing equipment, stone processing tools, metal processing equipment and other directions, can solve the problems of insufficient introduction, difficult to learn and reference, etc., to achieve convenient operation, ensure the uniformity of wall thickness, The effect of controlling the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Equipment requirements: processing tools such as elongated high-rigidity tool holders, diamond grinding wheels, and three-axis horizontal CNC milling equipment. The tools and equipment are well-known technologies in the field.

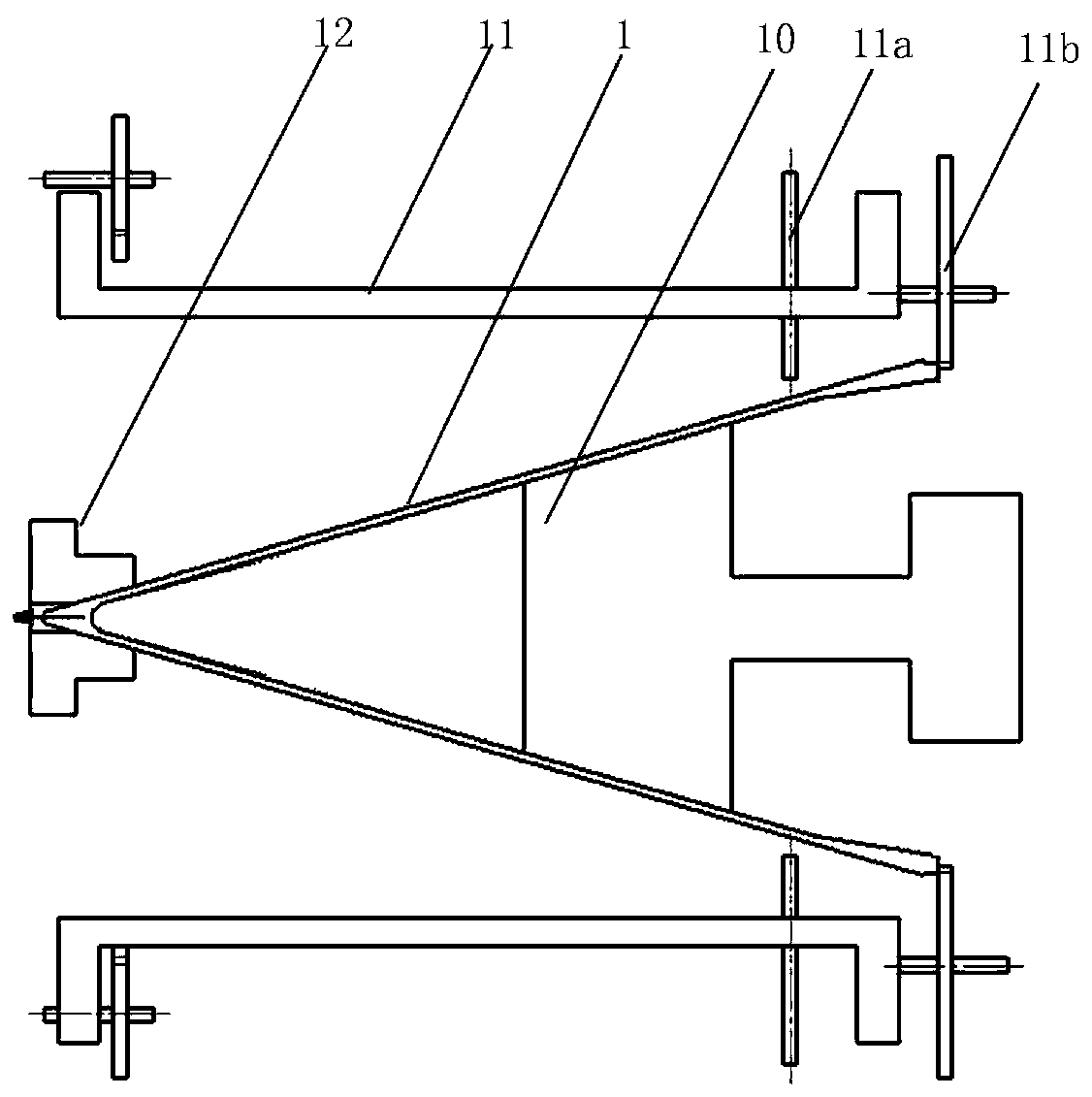

[0095] A special-shaped ceramic radome processing device and method, such as figure 1 As shown in ~6, it is realized through the following steps: including the following steps:

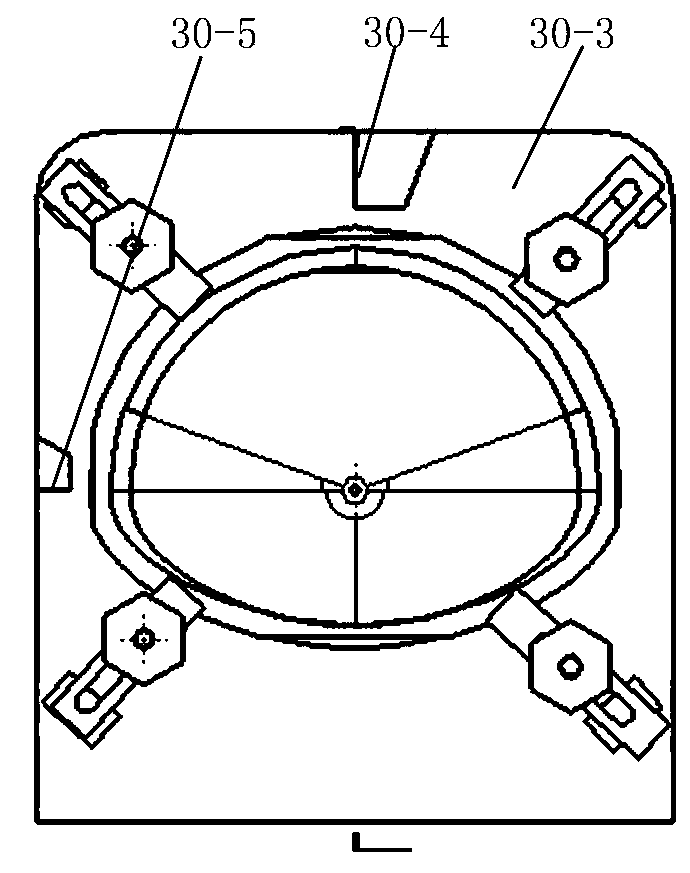

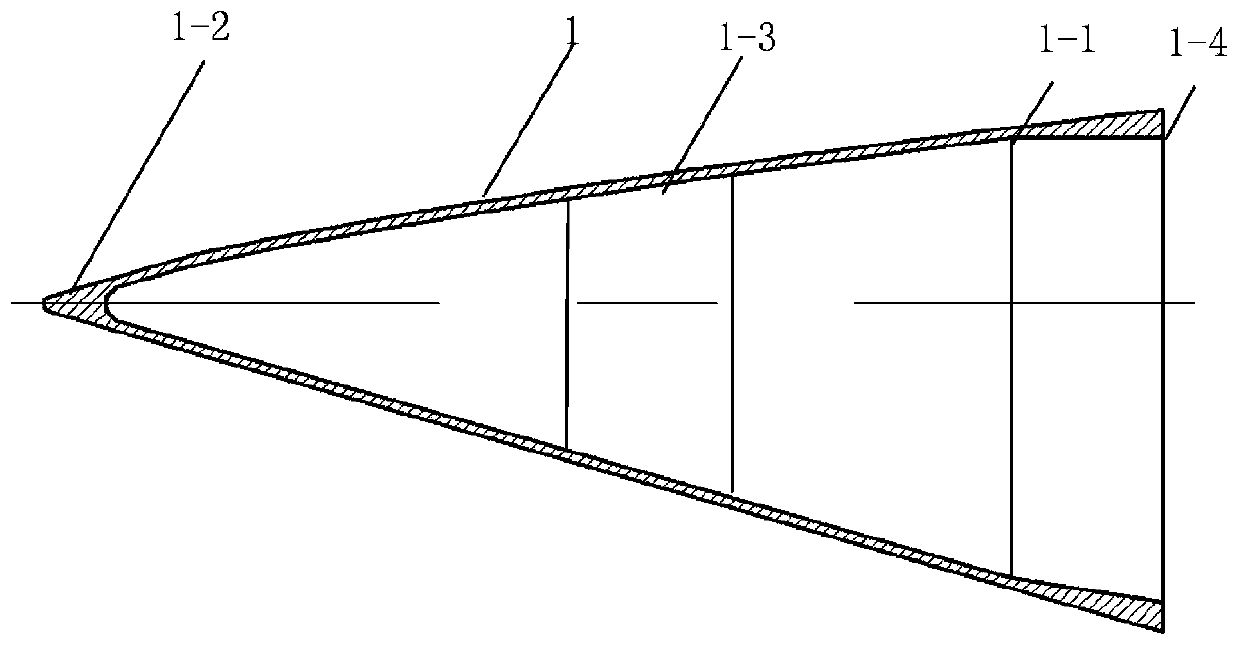

[0096] Step 1, such as figure 1 As shown, determine the inflection point position 1-1 of the primary cone and secondary cone on the inner surface of the radome blank 1 to be processed, and mark it with a pencil; Surface 1-2 is hand-polished evenly, and it can be seamlessly matched with the nose cone fixing ring 12; the inner surface of the radome blank 1 and the matching section 1-3 of the aligning ring 10 are hand-polished with aluminum oxide sandpaper until it is aligned Ring 10 is inserted in the radome until there is no shaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com